#chemtexspecialitylimited

Text

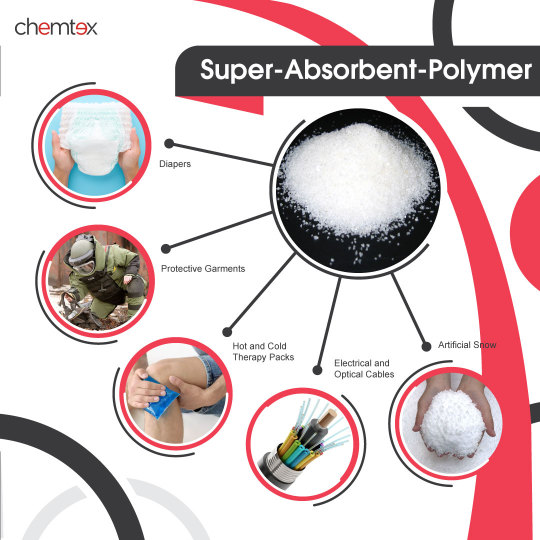

Super Absorbent Polymer Polyacrylate based | Chemtex Speciality Limited

Sodium Polyacrylate is a widely accepted super absorbent polymer, that finds extensive usage in various applications like ice gel packs, protective garments, baby diapers, etc., owing to its high water absorption capacity of about 300 – 400 times of its own weight.

Visit-

https://www.chemtexltd.com/products-and-solutions/performance-chemicals/general-chemicals/sodium-polyacrylate/

#polymers#polymer#polyacrylamide#absorbent#watergel#chemistry#polymerclay#manufacturing#chemicals#superabsorbentpolymer#waterabsorbent#sap#chemtexspecialitylimited

2 notes

·

View notes

Text

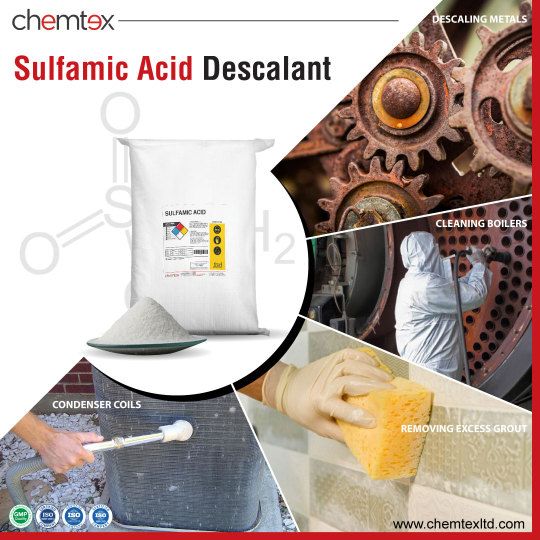

Sulfamic Acid is a Cleaning Agent Used in Various Industries

Chemtex Speciality Limited is one of India’s leading manufacturers of sulfamic acid GP grade. The GP grade of sulfamic acid is used for removing scales obtained from water in heating and cooling systems such as boilers, heat exchangers, condensers, jackets, and coils. Chemtex also manufactures industrial-grade sulfamic acid, with aided inhibitors.

#sulfamicacid#scaleremover#descaler#chemical#cleaning#rustremoval#chemicals#chemtex#chemtexltd#chemtexspecialitylimited#manufactuer

0 notes

Text

The Role and Importance of Demulsifiers in Oil and Gas Industry

Demulsifier helps to extract oil and purify water, which is especially important in crude oil production and wastewater treatment. It is a substance that separates an emulsion into components and destabilizes water-in-oil emulsions. In Crude production, Water-in-oil emulsions are typically produced, owing to the presence of emulsifying agents such as surfactants, slits, fine solids, drilling mud, clay, water, and other impurities. These impurities are undesirable need to be removed which would otherwise shackle the quality of the crude.

How does It work?

Demulsifier consists of two liquids that are not mixed with each other and tiny droplets of one liquid are evenly distributed throughout the volume of the other. This kind of liquid is called dispersion medium, and the droplets are called dispersed phase. During the demulsification process, a demulsifier accumulates on the surface of the droplets and groups them together.

The process of separating an emulsion into its constituent oil and water phases requires the disruption or destabilization of the protective film that surrounds water droplets. To break these oil–water emulsions, and ensure transfer of high-quality crude to the refinery, a demulsifier is used. The hydrophobic nature of this molecule bonds with the hydrocarbon, attacks the droplet interface, disperses or congeals into larger droplets, causing a change in density which separates the emulsion.

Demulsifiers are essential for the oil and gas industry for various reasons:

Enriched Separation: These are designed to destabilize and enhance the separation of oil and water, making it more efficient and cost-effective.

Increased Productivity: Demulsifier helps to boost production rates, by accelerating separation process.

Cost Effective: Efficient demulsifier reduces the need for expensive equipment and energy-intensive processes.

The role of Demulsifiers cannot be underestimated in improving the efficiency of crude. This chemical plays a crucial role in breaking down emulsions, ensuring that the valuable crude oil is separated from water effectively. Sustainable and efficient oil and petroleum production processes will be achieved as demulsifiers will continue to be developed and refined.

Demulsifiers come in various formulations, each tailored to specific emulsion challenges and environmental conditions.

As the industry evolves, demulsifiers will continue to be refined and developed, contributing to more efficient and sustainable oil and gas production processes.

Chemtex manufactures a specialized series of highly concentrated demulsifiers meticulously designed to yield top-tier hydrocarbon streams. These demulsifiers swiftly penetrate the emulsion layer, efficiently extracting maximum oil while minimizing waste and reducing energy consumption. This results in the production of high-quality hydrocarbons.

Application Areas

Downhole, Production Line, Storage Tank, Slop and Tramp Treatment, Refinery

Key Features and Benefits

Shows excellent performance at lower temperatures

Can be used to treat high gravity crude, enhance the interface, clean up, and improve water clarity.

They act as polishers, brighteners, and finishing compounds

They can increase the speed of water flow

Water-soluble Demulsifiers: These are designed for water-in-oil emulsions, where water droplets are dispersed in the oil phase.

Oil-soluble Demulsifiers: These are used for oil-in-water emulsions, where oil droplets are dispersed in the water phase.

For more information, visit us: https://www.chemtexltd.com/products-and-solutions/energy-chemicals/upstream-chemicals/oil-soluble-demulsifier/

0 notes

Text

What Is Coolant Additives and How Does it work? | Chemtex Speciality Limited

Pioneering excellence in coolant additive manufacturing, with Chemtex Specialty's advanced coolant additives – where innovation meets cooling system's demands for a smoother, cooler, and hassle-free journey!

#coolant#coolantadditives#coolingsystem#enginecoolant#radiator additives#antifreeze#heattransfer#corrosioninhibitor#coolantforcar#coolantprice#vehicels#chemicals#chemtex#chemtexspecialitylimited#chemtexltd

0 notes

Text

Role of Polyelectrolytes in Wastewater Treatment

Effluent Treatment or Industrial wastewater treatment consists of mechanisms and processes which are used to treat water that have been contaminated by anthropogenic, industrial or commercial activities prior to its release into the environment. Industrial wastewater serves as one of the important pollution sources that add up in polluting the water environment. The sewage sludge produced is subjected to sludge treatment. Many problems are associated with wastewater collection and treatment such as foaming, solid accumulation, high BOD, sludge de-watering, heavy metals and offensive odour. But such treatments are no more complicated processes, since there are chemicals that are applicable for the treatment. These chemicals follow various treatment mechanisms in various different standards, which include from chemically treating raw wastewater before discharging it into the environment, to recovering valuable resources from sludge treatment and wastewater.

Conventional treatment consists of a combination of physical, chemical, and biological processes for removal of suspended solids, organic & inorganic contaminants, germs and microbes from wastewater. When using total wastewater treatment solutions, these chemicals remove and eliminate harmful pathogens, expel hazardous chemicals, detergents and toxins, reduce odour and improve water colour, and separate and extract valuable substances and clean water from the wastewater.

Polyelectrolytes are regarded as polymer chains with an electrolyte group on every repeat unit. When dissolved in a polar solvent, these polymers are charged due to dissociation of small counter ions that leave behind a charged micro ion. These are formulated in a way so as to be used as coagulants and flocculants as well as a sludge dewatering agent in the waste water treatment plants. Flocculants are chemicals responsible for bringing about secondary settling and sludge dewatering. They carry active groups with a charge which helps in counterbalancing the charge of the particles. Coagulants are referred to as chemicals that are used to help in the removal of colour and turbidity present in untreated, raw water and are used for their attributes like quick flocculation, precise pH value, etc.

Based on electrolyte group present in the chain, polyelectrolytes are categorized into anionic, cationic and non – ionic species. Cationic polyelectrolytes have positively charged group for use in coagulation of negatively charged flocs through electrostatic interactions. They are useful in various process of effluent r wastewater treatment, depending upon their molecular weight and charge density. Anionic polyelectrolytes have negatively charged group on each repeating unit, acrylamide-based polymers being the most available type. They are widely useful as flocculants, rheology modifiers, and adhesives and immensely used in municipal wastewater and effluent treatment. Anionic flocculants are also used in enhanced oil recovery, decolouring, paper making, mineral processing, etc. Non – Ionic Polyelectrolytes are organic high molecular weight polymers, used in flocculating colloidal suspensions, water clarification, sludge dewatering, etc.

In general, aqueous solutions having pH value more than 4 have negative charged suspended particles whereas having pH less than 4 contains positively charged suspensions. This might help in analysing the type of polyelectrolyte to be used in the treatment.

Chemtex Speciality Limited is a well-known manufacturer and supplier of liquid and powder polyelectrolytes. For more information on our range of products, visit https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/wastewater-treatment/s

0 notes

Text

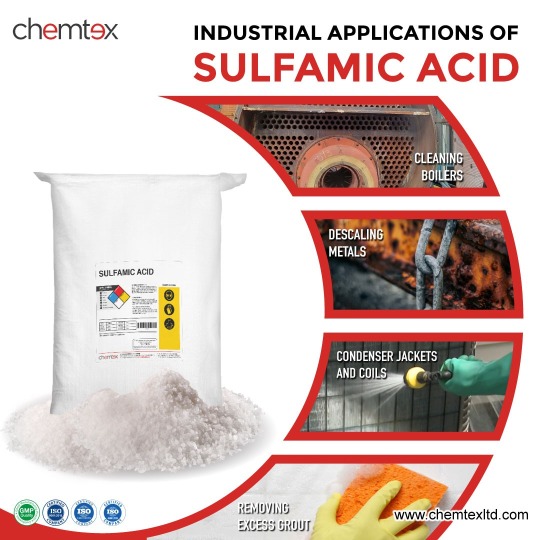

What makes Sulfamic Acid an effective descaling agent in industrial applications?

Heavy engineering industries like Iron & Steel, Alloy Manufacturing, Thermal Power, etc face one common issue i.e., formation of scales and deposits over metal surfaces in their boilers, condensers and heat exchangers. These industries undergo descaling process using acids. Why? Because, acids are cheap and easily available. And the most common acids available this process are Hydrochloric Acid, Nitric Acid and Sulfuric Acid. But these acids are highly corrosive and causes adverse effect on metal surfaces.

Sulfamic Acid, also known as amido sulfuric acid (H3NSO3), commercially available in white crystalline solids, is produced from urea and fuming sulphuric acid and finds extensive application in industrial maintenance and cleaning solutions and can be thought of as a replacement to the use of commonly used cheap acids for enhanced efficacy and results. Let us understand some of the unique properties.

Highly Acidic: Highly effective at dissolving and removing mineral deposits, scales, and rust from various surfaces, especially metal and ceramic surfaces, particularly useful for equipment and pipelines that come into contact with hard water or other scaling minerals.

Less Corrosiveness: Unlike some other strong acids, such as hydrochloric acid or sulfuric acid, sulfamic acid is relatively less corrosive to metals. It can efficiently remove scale without causing significant damage to the underlying metal surface.

High Temperature Stability: It can be used effectively at high temperatures where industrial settings often operate at elevated temperatures.

Metal Compatibility: Compatible with a wide range of materials, including metals, ceramics, glass, and plastics. This versatility allows it to be used on different surfaces without causing damage to the materials being cleaned.

Inhibitor Addition: In some formulations, it can be combined with inhibitors that further enhance its descaling performance by providing protection to metal surfaces against corrosion.

Due to these favourable characteristics, it is commonly used in industries such as water treatment, cooling tower maintenance, metal cleaning, chemical manufacturing, and many other industrial processes where scale and mineral deposits can cause operational inefficiencies and equipment damage. However, as with any chemical substance, proper safety measures and handling procedures should be followed when using sulfamic acid in industrial applications.

How Sulfamic Acid works as a descaling agent?

It works by eliminating calcium and magnesium ions from water through its acidic nature. When it comes in contact with water, it releases hydrogen ions that reacts with mineral deposits such as limescale, calcium sulphate, and rust, dissolving and breaking down the molecular bond that holds these deposits together.

Common application areas

A crucial ingredient for various household cleaning products, as it provides an excellent alternative to harmful chemicals.

Metal surface treatment by removing rust, scale, and other contaminants from metal surfaces.

It prevents mineral build-up on heat exchanger surfaces, ensuring efficient heat transfer and minimizing energy consumption.

In the world of chemical manufacturing, Chemtex Specialty Limited boasts a rich legacy of expertise in the chemical industry. With decades of experience, we share a strong market presence as a manufacturer of Sulfamic Acid GP Grade, commonly used for removing scales obtained from water in heating and cooling systems such as boilers, heat exchangers, condensers, jackets, and coils.

For more information, visit https://www.chemtexltd.com/products-and-solutions/performance-chemicals/general-chemicals/sulfamic-acid/

1 note

·

View note

Text

Chemicals used In Boiler, Cooling Tower, RO Plant & ETP

Boilers, Cooling Towers, Reverse Osmosis Plants, and Effluent Treatment plants are essential for various industries to optimize the essential system. These systems require chemicals to enhance operational efficiency, optimize membrane life expectancy and reduce maintenance costs.

This blog helps you to understand the key chemicals for each system and their significance in maintaining their performance.

Chemicals for Boiler

Boilers generate steam to generate power for industries. The capacity of boiler that are installed depends upon the type of industries. The main issue with them is that they are prone to scaling, corrosion, fouling, and many more that can lead to reducing the capacity of steam production, reason being the quality of water used. To avoid such adverse instances, chemical treatment of water is required.

Oxygen Scavengers: These chemicals help to remove dissolved oxygen from the boiler water, preventing corrosion and reducing the alkalinity of the feed water.

Antiscalants: To inhibit formation of scales due to the precipitation of minerals, which would otherwise impact the heat transfer efficiency.

pH Boosters - These chemicals are used to control and impart optimum pH levels of boiler water to minimize scaling and corrosion.

Chemicals for Cooling Tower

The continuous circulation of water in cooling towers lead to various issues, such as slime formation, algal bloom, corrosion, scale deposition, and others which can be addressed by following chemicals.

Biocides: These chemicals prevent biofilm formation by controlling the growth of harmful bacteria, algae, and fungi.

Scale and Corrosion Inhibitors - These formulation helps to prevent the formation of scale and corrosion system, ensure heat transfer efficiency, extends equipment life, and minimizes maintenance cost.

Dispersants – These chemicals prevent the accumulation of suspended particles and sludge formation, improving overall system performance.

Chemicals for RO Plant

RO membrane filtration system is the most widely used potable water treatment process for the removal of impurities such as salts, minerals, and other contaminants. RO membranes are designed with a dense, thin, and semi-permeable layer that allows water molecules to pass through while rejecting dissolved solids and other contaminants. But continuous subjection of contaminated water in membranes results in membrane fouling, scaling, and other complexities, calling for chemical treatment.

RO Antiscalants, available in high/low/neutral pH formulations to prevent the formation of scales such as carbonates/sulfates/silicates of Ca/Mg/Ba/Sr over membrane surfaces

RO Membrane Cleaners, to remove dirt, dust, iron deposits, and silicates from membrane surfaces

Biocide, to remove biofilms, slimes, algae, and foul smell.

Chemicals for ETP

Effluent Treatment Plants are utilized to treat wastewater generated by industrial processes.

Coagulants and Flocculants – These chemicals are crucial in the removal of suspended solids and contaminants from wastewater by promoting their aggregation for easier separation.

pH Adjusting Agents – pH adjustment is crucial for the efficiency of various treatment processes. These chemicals are used to adjust the pH of the feedwater to meet the requirement.

Chemtex Speciality Limited plays a vital role in this industry by giving efforts in research and development which leads to an excellent formulation for the water treatment industry. It is one of India’s leading chemical manufacturers offering a wide range of water treatment chemicals with varied applications

Visit Us: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/

0 notes

Text

Chemicals used In Boiler, Cooling Tower, RO Plant & ETP

Boilers, Cooling Towers, Reverse Osmosis Plants, and Effluent Treatment plants are essential for various industries to optimize the essential system. These systems require chemicals to enhance operational efficiency, optimize membrane life expectancy and reduce maintenance costs.

This blog helps you to understand the key chemicals for each system and their significance in maintaining their performance.

Chemicals for Boiler

Boilers generate steam to generate power for industries. The capacity of boiler that are installed depends upon the type of industries. The main issue with them is that they are prone to scaling, corrosion, fouling, and many more that can lead to reducing the capacity of steam production, reason being the quality of water used. To avoid such adverse instances, chemical treatment of water is required.

Oxygen Scavengers: These chemicals help to remove dissolved oxygen from the boiler water, preventing corrosion and reducing the alkalinity of the feed water.

Antiscalants: To inhibit formation of scales due to the precipitation of minerals, which would otherwise impact the heat transfer efficiency.

pH Boosters - These chemicals are used to control and impart optimum pH levels of boiler water to minimize scaling and corrosion.

Chemicals for Cooling Tower

The continuous circulation of water in cooling towers lead to various issues, such as slime formation, algal bloom, corrosion, scale deposition, and others which can be addressed by following chemicals.

Biocides: These chemicals prevent biofilm formation by controlling the growth of harmful bacteria, algae, and fungi.

Scale and Corrosion Inhibitors - These formulation helps to prevent the formation of scale and corrosion system, ensure heat transfer efficiency, extends equipment life, and minimizes maintenance cost.

Dispersants – These chemicals prevent the accumulation of suspended particles and sludge formation, improving overall system performance.

Chemicals for RO Plant

RO membrane filtration system is the most widely used potable water treatment process for the removal of impurities such as salts, minerals, and other contaminants. RO membranes are designed with a dense, thin, and semi-permeable layer that allows water molecules to pass through while rejecting dissolved solids and other contaminants. But continuous subjection of contaminated water in membranes results in membrane fouling, scaling, and other complexities, calling for chemical treatment.

RO Antiscalants, available in high/low/neutral pH formulations to prevent the formation of scales such as carbonates/sulfates/silicates of Ca/Mg/Ba/Sr over membrane surfaces

RO Membrane Cleaners, to remove dirt, dust, iron deposits, and silicates from membrane surfaces

Biocide, to remove biofilms, slimes, algae, and foul smell.

Chemicals for ETP

Effluent Treatment Plants are utilized to treat wastewater generated by industrial processes.

Coagulants and Flocculants – These chemicals are crucial in the removal of suspended solids and contaminants from wastewater by promoting their aggregation for easier separation.

pH Adjusting Agents – pH adjustment is crucial for the efficiency of various treatment processes. These chemicals are used to adjust the pH of the feedwater to meet the requirement.

Chemtex Speciality Limited plays a vital role in this industry by giving efforts in research and development which leads to an excellent formulation for the water treatment industry. It is one of India’s leading chemical manufacturers offering a wide range of water treatment chemicals with varied applications Visit Us: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/

0 notes

Text

Speciality Chemicals Manufacturer in India | Chemtex Speciality Limited

Chemtex Speciality Limited enjoys a considerable market share in speciality chemicals catering to Agriculture, Water Treatment, Cleaners, Disinfectants, Housekeeping, Laundry, Heat Transfer fluid, Glycol & Coolant, AC Chemicals, Oil and Gas and many other Industry specific verticals.

#chemical manufacturing#chemicalindustry#industrialchemicals#manufacturingchemical#chemicalsynthesis#specialtychemicals#petrochemical#agrochemicals#chemicalplant#hazardouschemicals#chemicalsupplier#chemtex#chemtexltd#chemtexspecialitylimited

1 note

·

View note

Text

Use of Acrylic Polymer and Polyacrylate as Antiscalant & Antifoulant

Scaling and fouling provide substantial difficulties in a variety of industrial processes and water treatment applications. Scaling, in general, means accumulation and precipitation of mineral deposits whereas fouling refers to organic or inorganic substance accumulation. Normally these are countered by the use of an organic acid and a dispersant, which are significantly corrosive and may degrade the metal surface. What if said, the same result or in fact a better result can be expected, if polymerized formulations are used. Yes. There are polymerized acids and phosphonates like Polyacrylic Acid (PAA), Polymaleic Acid (PMA), Polyphosphates, Polyphosphonates, PAPEMP, etc., which inhibits formation of carbonates, sulphates & silicates of Calcium, Barium, Magnesium, Strontium, over the surface, manifesting optimum efficacy in scale prevention and antifouling. These polymers functions by binding to the crystal surfaces of scale-forming minerals, preventing their growth and deposition. Moreover, these polymers also exhibit strong sequestration properties, keeping scale forming compounds away due to their ability to inhibit crystallization and precipitation of scale-forming minerals.

Polymer chemistry is the future for utility and industrial applications for its diverse applications such as Material Science Advancements, Sustainable Solutions, Energy Storage, Biomedical Applications, Electronics and Chemical Additive Manufacturing.

Acrylic Polymers as a versatile antiscalant and antifoulant manages to gain popularity from various industries. Why? Because the ability of the acrylic polymer to prevent scale formation by securing and distributing metal ions in solution is one of its primary benefits. Acrylic polymer aids in preserving the effectiveness and integrity of industrial equipment by avoiding the precipitation and deposition of minerals on surfaces. Additionally, acrylic polymer has potent antifouling qualities since it repels organic compounds. Its hydrophobic characteristic prevents fouling agents like algae, bacteria, and biofilms from adhering to and growing on it. With regard to applications in cooling towers, reverse osmosis systems, desalination plants, and other industrial processes where fouling is a concern, acrylic polymer is the best choice due to this property. The distinct structure of polyacrylate molecules enables them to sequester and disperse metal ions in water. Thus, the ions are kept apart and unable to combine to create the insoluble compounds that cause scale deposition. Some primary functions of Polymeric antiscalants and Polyacrylates are

High impact resistance

Transparency and Clarity

Weatherability

Chemical Resistance

Ease of processing

Wide color range and versatility

Easy maintenance and cleaning

Scale divergence

Threshold inhibition

Easy handling

Chemtex’s polyacrylate based antiscalant and antifoulants have remarkable scale inhibition properties. Their special compositions effectively scatter and stop the growth of chemicals that cause scale, protecting equipment surfaces from buildup and reducing downtime. The improved stability, solubility, and compatibility of these solutions make them appropriate for a variety of water treatment applications. These formulations are meticulously developed to provide superior scale inhibition and fouling resistance. Their products, fortified with advanced technology, effectively disperse and sequester metal ions, ensuring optimal performance of industrial equipment. Chemtex's expertise in polymer chemistry enables them to tailor solutions to specific water conditions and industry requirements, enhancing system efficiency and longevity.

For more information visit: https://www.chemtexltd.com/products-and-solutions/performance-chemicals/phosphonates-polymers/polymers/

0 notes

Text

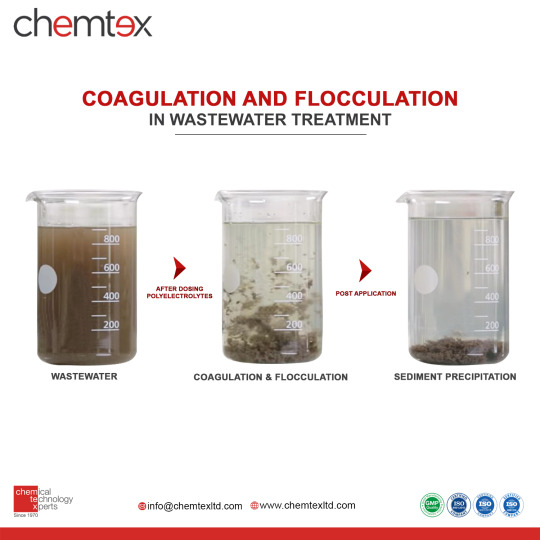

Coagulation and Flocculation in Wastewater Treatment

Industrial wastewater contains higher levels of suspended solids and organic materials. These suspended solids are stabilized by negative electric charges, causing them to repel each other. Rather than settling, these particles are kept in suspension by repulsion. In such cases, chemical treatment is required to neutralize the charges on colloidal particles, as the solids cannot be separated easily with conventional filtration or settling methods. On chemical dosing, mainly polyelectrolytes, there undergo two very basic working mechanisms i.e., coagulation and flocculation.

Coagulationis the neutralization of charges on suspended particles, leading to their destabilization and subsequent aggregation. Flocculation helps to fill the gaps between the destabilized particles, allowing them to make larger, denser flocs, which can be easily separated from the treated water through sedimentation. The efficiency of this process depends upon the coagulant type, dosage, pH value, temperature, nature, the concentration of organic matter, and distribution of colloidal particles in suspensions. The benefits of coagulation and flocculation are numerous. They effectively remove suspended solids, organic matter, inorganic compounds, and microorganisms from wastewater and minimize the impact on the environment.

Some of the major impacts, these processes have on water treatment.

Removal of suspended solids – The primary purpose is to remove suspended solids, resulting the clear effluent.

Contaminants removal - The coagulants bind with these contaminants, allowing them to be captured and removed during subsequent treatment steps.

Enhanced Treatment Efficiency –This indispensable Process enhances the overall efficiency of wastewater treatment by reducing the load on downstream processes.

Phosphorus Removal - It is a critical environmental concern, and is efficiently addressed through the process.

pH Adjustment – It is necessary for water treatment to optimize the performance of coagulant and flocculant polyelectrolytes

Wastewater treatment deals with the processes required to decrease contaminant levels present in the water before its disposal in the environment, depending upon the source of water and geographical conditions. We are witnessing a lot of implementations of physicochemical processes which handle wastewater starting from simple removal of suspended matter to cleaning of RO membrane systems. The process may range from simple sedimentation and decantation to the use of UV technology, depending upon the type of level of contamination. The treated wastewater can be used for agriculture, soil conditioning, energy generation, etc.

Chemtex Speciality Limited is a manufacturer of polyelectrolytes whose work depends upon coagulation and flocculation. Chemtex is at the forefront of wastewater treatment practices due to its expertise, innovative solutions, and commitment to sustainability. With Chemtex's help, wastewater treatment plants can optimize their processes, achieve regulatory compliance, and contribute to cleaner, healthier environments. The chemicals address common challenges found in wastewater treatment plants and provide solutions to treat sludge before release. The formulations meet all the standard requirements and also help in the removal and elimination of harmful pathogens, and bacteria, taking out hazardous chemicals, detergents, and toxins from the wastewater. By employing appropriate coagulants and facilitating floc formation, these steps contribute to the overall efficiency and effectiveness of treatment plants.

What do we offer?

Organic Polyelectrolytes – We provide a diverse range of organic coagulants for wastewater treatment. These formulations remove impurities, enhance floc formation, and improve sedimentation. With their expertise, Chemtex delivers sustainable and effective solutions for wastewater treatment challenges.

Inorganic Polyelectrolytes – We are a leading provider of innovative solutions for wastewater treatment. These formulations are specifically formulated to provide effective removal of suspended particles and impurities, improving the overall efficiency of the treatment process.

For more information, please visit our website: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/wastewater-treatment/

0 notes

Text

Coagulation and Flocculation in Wastewater Treatment -Chemtex Speciality Limited

Coagulation and Flocculation are essential duos for treating water. These are the preliminary steps to separate the portion of the suspended solids from the wastewater treatment.

It is considered one of the best chemical processes to treat wastewater with polyelectrolytes.

#WaterTreatment#CoagulationAndFlocculation#CleanWater#EnvironmentalProtection#EnvironmentalSustainability#StayHydrated#chemtex#chemtexspecialitylimited#chemtexltd

0 notes

Text

Boost Up Solar Panel Efficiency with Chemtex’s Solar Panel Cleaning Chemical

The market size of solar panels installation for institutions and industries are growing at a rapid rate, seeking to reduce their carbon footprint and lower energy costs. As this number will increase, the demand for solar panel cleaning and maintenance would also upsurge. Why? During the course of time, solar panels accumulate dirt, dust, bird droppings, twigs, stains and grime, which obstructs sunlight contact, resulting in decreasing of efficiency and power output. Owing to which, regular cleaning becomes essential to maximize the energy output.

Why is solar panel cleaning essential?

To maximize power output and efficiency: Dirty panels reduce efficiency by at least 30% which decreases energy yield and increases financial burden. Regular cleaning helps maintain the maximum efficiency of solar panels.

Prolong Lifespan: Overtime accumulation of debris build-up leads to hotspots and increased heat, causing potential damage to the panels. Cleaning prevents such issues and ensures their longevity.

Water, alone might be able to remove loose deposits but will lag behind when it would come to tough stains and marks. Only solution to this would be using specialized solutions. The main purpose of using these would be to improve the overall performance and efficiency of solar panels. When solar panels are covered with dirt or debris, they receive less sunlight, resulting in reduced energy production. Cleaning solution would help to remove these obstructions, allowing maximum sunlight absorption and increasing the energy output of the panels. These are easy to apply and can be used in conjunction with soft brushes or sponges to gently scrub away the dirt without causing any damage. Regular cleaning using these solar panel cleaning chemicals helps to maintain the optimal performance of solar panels and increase their operational life. It is important to follow the manufacturer's instructions and guidelines when using these chemicals to ensure safe and effective cleaning.

Choose Right Solar Panel Cleaning Chemicals

Chemtex Speciality Limited manufactures advanced cleaning formulations that consists of powerful surfactants that easily disperse toughest of deposits, for solar panels. These chemicals are non-abrasive and non-scratching, and do not damage the delicate surface of solar panels. This gentle formulation helps maintain the integrity of the panels and prolong their lifespan. Chemtex understands the importance of sustainability and environmental responsibility. Their cleaning chemical is biodegradable, non-toxic, and free from harmful chemicals like phosphates, chlorine, and solvents. This eco-friendly approach ensures minimal impact on the environment and surrounding ecosystems. These cleaning chemical leaves no residue after application, ensuring a spotless and streak-free surface. This residue-free cleaning helps maximize the amount of sunlight absorbed by the solar cells, thereby optimizing energy production. Regular cleaning with Chemtex's solar panel cleaning chemical helps maintain the panels' efficiency, preventing potential energy loss. By maximizing energy output, users can experience increased savings on electricity bills, making the cleaning chemical a cost-effective investment.

Chemtex Speciality Limited is a speciality chemical manufacturer with a diverse range of chemicals catering to various industries, including solar energy. With extensive research and expertise, Chemtex has developed a high-quality solar panel cleaning chemical specifically formulated to meet the unique cleaning requirements of solar installations. For more information, visit https://www.chemtexltd.com/products-and-solutions/cleaning-and-disinfectant-chemicals/speciality-industrial-cleaning/pv-module-cleaner/

0 notes

Text

#descaler#cleaninghacks#foodgrade#products#descalingpowder#bolier#heating#service#hvac#boilerservice#condenser#cooling#chiller#freezer#chemtex#chemtexltd#chemtexspecialitylimited#chemicalindustry#chemical#chemical manufacturing

1 note

·

View note

Text

EDTA Manufacturer and Supplier - Chemtex Speciality Limited

What is EDTA?

EDTA or ethylenediaminetetraacetic acid is a weak acid used as a chelating agent. Ethylenediamine tetra acetic acid (EDTA) contains an amino carboxylic group with the formula C10H16N2O8. The chelating agent EDTA is a compound of massive use worldwide with household and industrial applications, being one of the anthropogenic compounds with the ability to sequester various polyvalent cations, used to minimize metal contaminants and facilitate enzymatic reactions that could be inhibited by heavy metal traces. EDTA is the most widely used chelating agent for the removal of toxic heavy metal ions in wastewater treatment.

How does EDTA Work?

EDTA is prepared from the compound Ethylenediamine and Monochloroacetic acid. EDTA grabs metallic cations such as lead or calcium from the process and forms a stable compound that is then excreted from the system. If the bond is weak, other chemicals can break this bond to form their own compounds. EDTA is the most widely used chelating agent for the removal of toxic heavy metal ions in wastewater treatment. EDTA can react with metallic cations, creating a stable rigid compound that can be easily excreted from the application system. The ability to form strong covalent bonds with metallic ions allows inorganic contaminants to react with these ions, forming their own compounds.

What is ethylenediaminetetraacetic acid used for?

Wastewater treatment: EDTA is the most widely used chelating agent for the removal of removing toxic heavy metal ions in wastewater treatment.

Textile industry: Prevents metal ion impurities from modifying the colours of dyed products.

Pulp & paper industry: It inhibits the ability of metal ions, especially Manganese from catalysing the disproportionation of hydrogen peroxide in chlorine-free bleaching.

Laundry: Reduces water hardness by dissolving scales of Ca2+, Mg2+, and cations, which are then less likely to interfere with soaps and detergents

‘Scrubbing’: Removes hydrogen sulphide from gas streams. This conversion is achieved by oxidizing the hydrogen sulphide to elemental sulphur, which is non-volatile.

Laboratory: Widely used for scavenging metal ions.

Cosmetics: Used in shampoos, cleaners, and other personal care products as a sequestering agent

Leading EDTA Manufacturers in India

Chemtex Speciality Limited is a pioneering speciality chemical manufacturer, The best EDTA manufacturers in India, We Tetrasodium EDTA (4Na), Disodium EDTA (2Na), EDTA Trisodium (3Na) and Pure Acid form.

Disodium EDTA (2Na) – Disodium salt of EDTA is used as sequestering / chelating agent, that helps in cleaning and descaling from metal surfaces. Also, it finds extensive usage in the removal of iron oxide/hydroxide and calcium carbonate, other organic substances and microbial slimes.

Trisodium EDTA (3Na) – It is used as a disinfectant, colour retention agent, anticoagulant for blood collection, preservative, antioxidant, a chelating agent in personal care products and flavouring agent for foods. It is used to minimize metal ion contaminants and to facilitate enzymatic reactions that could be inhibited by heavy metal traces.

Tetrasodium EDTA (4Na) – Tetrasodium EDTA is also used as a chelating agent, with the ability to sequester various polyvalent cations, that bind calcium, magnesium and other metal ions, minimizing metal ion contamination and facilitate enzymatic reactions that could be inhibited by heavy metal traces. EDTA Tetrasodium Salt also works as a slime dispersant and is even effective in reducing scale deposits and water hardness.

Key Features & Benefits

Optimum Chelating efficiency

Prevents metal contamination

Sequesters magnesium, calcium and other metal ions.

Cost-effective

Visit Us today https://www.chemtexltd.com/products-and-solutions/performance-chemicals/general-chemicals/edta/

0 notes

Text

Chemtex Speciality Limited offers a wide range of its speciality chemicals used in oilfields and refineries, serving all leading production units across the globe. Chemtex is affiliated with ISO 9001:2015, EMS 14001:2015, ISO 45001:2018 standards, GeM registered OEM and has GMP certified state of art production facility.

For more information, visit https://www.chemtexltd.com/products-and-solutions/energy-chemicals/

0 notes