#construction chemical manufacturer india

Link

0 notes

Text

SAP Business One for Chemical Industry

With all its benefits, global chemical manufacturing companies are incorporating SAP B1 at an increased rate for chemical production. Not only does it help in improving business efficiency and enhancing collaboration but it also aids in increasing customer satisfaction and increasing revenue by up to 10-30%. With the change in business dynamics and fluctuations in demand, robust ERP software can empower chemical businesses to take advantage of their competition while adhering to safety, quality, and compliance requirements. SAP b1 solutions are already used by nearly 6500 chemical industry businesses and more are soon to follow.

Managing costs effectively is an essential aspect of chemicals and any industry. In the chemical industry, SAP Business One provides intuitive planning and scheduling to manage time and resources efficiently and cut down on business costs to control every aspect. The cost of materials can also be estimated by analyzing the production data history and past purchases in a single click to simplify business processes. SAP chemical industry best practices optimize different processes, improve workflow efficiency, and reduce overtime costs by 48%.

#sap business one#SAP Business One Partner in India#SAP Business One partner#SAP Business One ERP Solution#SAP Business One for Manufacturers#SAP chemical industry#ERP Software#best erp software#best erp software in india#food beverage erp software#erp software for construction#erp#enterprise software#ERP Solution#SAP ERP#erp for small business#erp development company#erp consulting services#enterprise resource planning#erpsystem

2 notes

·

View notes

Text

Silicone Manufacturer For Construction Industry In India

We develop high quality silicones for the construction industry, suitable for all your needs and requirements.

#Silicone Manufacturer For Construction Industry In India#Specialty Chemicals Manufactures In India#Performance Resil

0 notes

Text

Tips for Restoring Old Tiles: Reviving the Beauty of Vintage Flooring

Vintage tiles can add a touch of timeless elegance to any space, be it a historic home or a modern apartment. However, over time, these treasured tiles may lose their luster due to wear and tear. Restoring old tiles requires careful attention and a gentle touch to revive their original beauty without causing any damage. In this article, we'll provide you with Yoast-approved tips for restoring old tiles, helping you bring back the charm of vintage flooring and preserve its allure for years to come.

Assess the Condition of the Tiles

Before diving into the restoration process, it's essential to assess the current condition of the tiles. Check for any cracks, chipping, or missing pieces. Determine the type of tile material, as different materials may require specific restoration techniques. Assessing the state of the tiles will help you plan the restoration process accordingly and set realistic expectations.

Thorough Cleaning

The first step in restoring old tiles is a thorough cleaning to remove years of dirt, grime, and old sealant. Start by sweeping or vacuuming the tiles to get rid of loose debris. Next, use a mild detergent or a pH-neutral tile cleaner mixed with warm water to gently clean the surface. Avoid harsh chemicals that may damage the tiles. For stubborn stains, make a paste with baking soda and water and apply it to the affected areas. Let it sit for a few minutes before scrubbing with a soft brush.

Repairing Cracks and Chips

To restore the tiles to their former glory, addressing cracks and chips is crucial. Use a high-quality tile filler or epoxy resin to repair minor cracks and chips. Fill the damaged areas carefully and smooth out the surface with a putty knife. Allow sufficient drying time before proceeding with the next step.

Removing Old Sealant

Old tiles are often protected with layers of sealant, which can become discolored and dull over time. Removing the old sealant is essential before applying a new one. Use a sealant remover or a mixture of equal parts vinegar and water to dissolve the old sealant. Be patient, as this process may take some time. Once the old sealant is removed, clean the tiles again to ensure a fresh surface for the new sealant.

Restoring Grout Lines

Grout plays a crucial role in vintage tile restoration. Inspect the grout lines for any signs of mold or discoloration. Use a grout cleaner or a mixture of baking soda and water to clean the grout lines thoroughly. For severe grout issues, consider regrouting the entire floor. Choose a grout color that complements the tiles and gives them a refreshed appearance.

Applying New Sealant

After cleaning and repairing the tiles, it's time to apply a new sealant to protect and enhance their beauty. Choose a high-quality, breathable sealant suitable for the tile material. Apply the sealant evenly using a clean cloth or brush, following the manufacturer's instructions. Allow the sealant to dry completely before walking on the restored floor.

Conclusion

Restoring old tiles is a labor of love that rewards you with a stunning and timeless vintage flooring. By following these Yoast-approved tips, you can successfully revive the beauty of vintage tiles and create an exquisite backdrop for your living spaces. Remember to take your time, use gentle cleaning methods, and choose high-quality products for the best results. With proper care, your restored vintage tiles will continue to charm and delight for generations to come.

1 note

·

View note

Text

ECMAS is known as one of the premium concrete admixture manufacturers in India. Get absolute strength, enhanced workability, and durability for your concrete buildings with ECMAS concrete admixtures.

#construction chemical companies#concrete admixtures manufacturers#admixture companies in india#concrete

0 notes

Photo

Prominent & Leading Manufacturer from Delhi, we offer anti termite /chlorpyriphos ec 20% and chlorophpyriphos.We are a leading Manufacturer of Anti Termite Chemical (7200k), Talk to the best Anti Termite Chemical in Delhi today for all your queries. Call now 91-11-2702 4086 / 4586, +91-93 1270 5186 or Email us at [email protected].

https://vividindiachemicals.com/anti-termite-chemical.html

#Vivid India Chemicals#Best Chemical Manufacturer in delhi#best construction chemical manufacturer in delhi#Anti Termite Chemical in Delhi#Anti Termite Chemical manufacturer in Delhi

0 notes

Text

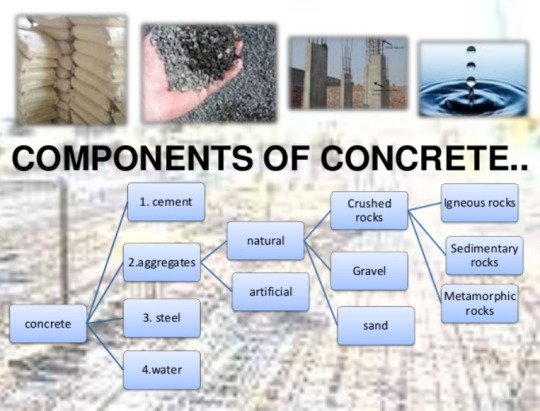

What Are The Components Of Concrete

We will explore the components of concrete and how they work together to create a durable and versatile material. Construction chemical suppliers will discuss the different types of cement, aggregates, and admixtures used in concrete production, as well as their effects on the strength and durability of the finished product.

Finally, we will look at the different methods used to test the quality of concrete so that you can make an informed decision about the best material for your project. By the end of this article, you will better understand the different components of concrete and how they work together to create a robust and reliable material.

Concrete is a composite material composed of various components, including cement, aggregates, and multiple admixtures, blended in specific ratios to create a robust and durable material. As per the top waterproofing companies in India, concrete has become an invaluable part of modern construction, offering various structural and decorative uses in small and large-scale projects.

Concrete is a building material made from cement, aggregate (gravel and sand), water, and other additives combined and poured into molds or forms and allowed to harden.

Types of Concrete:

1. Ready-mix Concrete: Ready-mix concrete is prepared at a concrete plant and then delivered to the worksite in a cement mixer truck.

2. Roller-compacted Concrete: Roller-compacted concrete is a form of concrete made with a stiffer mix and then consolidated with a roller for a denser, more robust final product.

3. Shotcrete: Shotcrete is a type of concrete sprayed from a particular nozzle onto a surface or into a form.

4. Precast Concrete: Precast concrete is a type of concrete that is poured into a form at the concrete plant and then shipped to the worksite in its final form.

Different Components of Concrete and their Functions

1. Aggregates are the most crucial component of concrete and make up the bulk of the mixture. They provide strength, stability, and structural integrity to the concrete mix. Aggregates come in different types, such as sand, gravel, crushed stone, and recycled materials. Depending on the concrete mix, different types of aggregates can be used to enhance the strength and other properties of the material.

2. Cement is the binding agent in concrete and holds the other components together. It also helps to give the concrete mix its strength, workability, and durability. Different types of cement can be used for various applications, depending on the desired strength and other characteristics of the concrete.

3. Water is used to mix and activate the concrete ingredients. It helps to create the chemical reaction necessary for the material to harden and gain strength. Too much or too little water can affect the strength and other properties of the concrete.

4. Admixtures are added to the concrete mix to provide improved workability, increased temperature resistance, and chemical and biological agents. Admixtures can also reduce the amount of cement, water, and other materials required, thus making the concrete mix more economical.

How it Affects the Strength of Concrete

Cement is the crucial ingredient in concrete, which gives it its strength. Cement is a powdery substance made of limestone, clay, and other materials that are heated and ground into a fine powder. As per the best waterproofingcompany, this powder is mixed with water, sand, and gravel to create a paste that binds the materials together.

In conclusion, concrete is a highly durable and versatile material that consists of four essential components: cement, water, aggregate, and admixtures. Each concrete element impacts the material's durability, strength, and workability. Without one of concrete admixture manufacturers, concrete would not have the same properties and would not be as effective as it is today. Therefore, it is essential to understand the concrete components to use the material in construction projects properly.

#concrete admixture manufacturers#best waterproofing company#top waterproofing companies in India#Construction chemical suppliers

0 notes

Text

Flat Liquor Bottle Single Side Labeling Machine

Company Overview:

Shiv Shakti Machtech is a Supplier, Exporter, and Manufacturer of Flat Liquor Bottle Single Side Labeling Machine.

The Flat Bottle Single Side Labeling Machine can handle various container shapes, including flat, round, oval, hexagonal, and rectangular.

It is designed to apply single stickers to bottles, controlled by PLC and a touch screen. This machine is ideal for labeling square, flat, oval, and round containers used in medicine, daily chemicals, food, cultural supplies, and electronics.

Bottles are fed into the machine via a feeding belt. An electric eye sensor detects the bottle and sends a signal to the labeling control system.

The label dispensing motor processes the signal and applies the label at the appropriate time. The label is reinforced as the product passes through the cover device, completing the labeling action.

Specifications:

Flat Liquor Bottle Single Side Labeling Machine

Label Gap: Maintains a maximum gap of 3mm between two labels.

Country of Origin: Made in India.

Speed: Capable of labeling up to 90 bottles per minute.

Brand: Shiv Shakti Machtech

Material: Constructed from Stainless Steel 304.

Conveyor Height: Set at 850mm.

Weight: Approximately 200kg.

Bottle Type: Suitable for all types of flat surface products.

Automation Grade: Fully automatic.

Usage/Application: Designed for sticker labeling.

Shiv Shakti Machtech is a Flat Liquor Bottle Single Side Labeling Machine served worldwide, including,

Algeria, Angola, Antigua and Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain,

Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina

Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic

Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia,

Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia,

Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea,

Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius,

Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal,

Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal,

Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia,

South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania,

Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United

States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe.

For further details or inquiries, feel free to reach out to us.

View Product: Click Here

Read the full article

#Ahmedabad#Exporter#ExporterofFlatLiquorBottleSingleSideLabelingMachine#FlatLiquorBottleSingleSideLabelingMachine#FlatLiquorBottleSingleSideLabelingMachineinAhmedabad#FlatLiquorBottleSingleSideLabelingMachineinIndia#Manufacturer

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Epoxy Insulators in the Rail Industry: Meeting the Demands of Modern Transportation

Within the domain of contemporary transportation, the railway sector assumes a crucial function in facilitating the efficient and sustainable movement of individuals and commodities. In order to effectively meet the dynamic requirements of the business, there exists a perpetual necessity for innovation and enhancement across all facets of rail infrastructure. Epoxy insulators have evolved as a significant component that plays a critical role in enhancing the reliability and efficiency of rail systems. Ensure uninterrupted rail operations with the durability of epoxy insulators manufactured and supplied by Radiant Enterprises - the best Epoxy insulator for third rail manufacturer in India!

This blog post aims to examine epoxy insulators and their ability to fulfil the requirements of contemporary transport within the rail sector.

Understanding the Role of Epoxy Insulators:

Epoxy insulators are a category of electrical insulators employed for the purpose of isolating and providing structural support to electrical conductors, hence impeding the passage of electric current through them. Electrical systems are frequently employed throughout several industries, such as the railway sector, with the primary objective of guaranteeing the secure and dependable functioning of these systems. Within the rail sector, these insulators are predominantly employed in railway electrification systems, fulfilling many essential roles.

· High Voltage Insulation:

The provision of high voltage insulation is a key function of epoxy insulators within the rail sector. The electrification of rail systems on a global scale has led to a growing dependence on high-voltage overhead lines as the primary source of power for electric locomotives. Epoxy insulators play a crucial role in preserving a secure distance between high-voltage lines and the structures that support them, thereby mitigating electrical leakage and safeguarding the well-being of passengers.

· Mechanical Strength:

Railway systems are exposed to adverse climatic conditions, encompassing severe temperature variations, vibrations, and mechanical strain. Epoxy insulators are widely recognised for their remarkable mechanical strength and resilience, rendering them highly suitable for deployment in railway applications. The electrical infrastructure is designed to endure the demanding conditions of continuous train movements, hence preserving its integrity and functionality.

· Corrosion Resistance:

Corrosion resistance is a critical factor to consider in railway infrastructure due to its frequent exposure to moisture, chemicals, and various corrosive substances. Epoxy insulators are engineered to possess a high level of corrosion resistance, hence guaranteeing an extended operational lifespan and reducing the need for frequent maintenance. The corrosion resistance of rail systems is of utmost importance as it plays a critical role in ensuring uninterrupted operation, hence reducing both downtime and repair expenses. Experience the reliability of electrical solutions. Connect with Radiant Enterprises to Import Epoxy insulators in France!

· Lightweight Design:

Contemporary rail systems are consistently endeavouring to minimise weight and enhance energy efficiency. Epoxy insulators are preferred due to their lightweight construction, which enhances the overall effectiveness of the system. The decreased weight of these insulators results in reduced energy consumption and enhanced sustainability, so they match seamlessly with the objectives of contemporary transportation.

· Customization and Versatility:

Epoxy insulators have the capability to be customised according to the specific demands of railway systems, hence enabling flexibility in both design and implementation. Epoxy insulators provide the capability to be tailored in order to effectively address the distinct requirements of various projects, including high-speed rail lines, commuter train networks, and freight rail systems. The ability to adapt is crucial in order to ensure optimal operation of rail systems in diverse settings.

· Safety and Reliability:

The rail sector places utmost importance on safety, and the utilisation of epoxy insulators is integral to guaranteeing secure operations. These insulators effectively mitigate the potential hazards and operational disturbances in train services by offering dependable insulation and preventing electrical failures. Passengers and operators may place trust in the safety and reliability of electric train networks. Empower your railway projects with the best quality and durable 25 KV epoxy insulators. Get in touch with Radiant Enterprises - one of the most trusted 25 KV Epoxy Insulators for Railways manufacturers in India to learn more!

Longevity and Cost Efficiency:

The strategic decision for rail operators is to invest in durable and long-lasting components, considering longevity and cost efficiency. Epoxy insulators possess the advantageous characteristic of having an extended operational lifespan, hence mitigating the necessity for frequent replacements and the subsequent financial burdens associated with such replacements. The extended lifespan of these options renders them a financially advantageous selection over time, thereby harmonising with the fiscal limitations commonly associated with railway initiatives.

Final Thoughts:

Epoxy insulators have become an essential component in the rail sector, effectively addressing the requirements of contemporary transportation. The suitability of these systems for railway electrification is attributed to their capacity for high voltage insulation, resilience in challenging climatic circumstances, resistance to corrosion, and provision of customisation choices. In addition, the lightweight nature of these designs serves to enhance energy efficiency and promote sustainability, so they match seamlessly with the objectives of the business.

The increasing development and growth of the rail sector necessitates the significant involvement of epoxy insulators in guaranteeing the dependability, security, and effectiveness of electric train systems. Through the use of cutting-edge technologies such as epoxy insulators, the railway sector is well-positioned to confront forthcoming difficulties and maintain its pivotal role in contemporary transportation. From power distribution to industrial applications, Imports cycloaliphatic epoxy insulators in France from a trusted manufacturer and supplier, Radiant Enterprises!

#Epoxy insulator for third rail manufacturer in India#Imports Epoxy insulators in France#25 kv epoxy insulator for railways manufacturers In India#Imports cycloaliphatic epoxy insulators in France

7 notes

·

View notes

Text

Stainless Steel 304 Coils Stockists In India

Title: Exploring the Versatility of Stainless Steel 304 Coils: A Comprehensive Guide

Introduction:

Stainless steel is a ubiquitous material known for its durability, corrosion resistance, and versatility in various applications. Among the numerous grades available, Stainless Steel 304 stands out as a popular choice for its excellent properties. This article delves into the world of Stainless Steel 304 Coils, examining their composition, characteristics, and diverse applications.

Section 1: Composition and Properties

1.1 Chemical Composition:

Breakdown of key elements in Stainless Steel 304 Coils.

Impact of chromium and nickel on corrosion resistance.

Other alloying elements and their contributions.

1.2 Mechanical Properties:

Tensile strength, yield strength, and elongation.

High-temperature performance.

Comparison with other stainless steel grades.

Section 2: Manufacturing Process

2.1 Hot vs. Cold Rolling:

Explanation of hot rolling and cold rolling processes.

Effects on coil thickness, surface finish, and mechanical properties.

2.2 Annealing Process:

Importance of annealing in enhancing corrosion resistance.

Annealing temperature and duration.

Section 3: Applications

3.1 Automotive Industry:

Use of Stainless Steel 304 Coils in exhaust systems and automotive components.

Corrosion resistance in harsh environmental conditions.

3.2 Construction Sector:

Applications in structural elements, facades, and roofing.

Aesthetics and durability in architectural designs.

3.3 Food and Beverage Industry:

Hygienic properties of Stainless Steel 304 Coils.

Common applications in food processing and storage.

3.4 Chemical and Petrochemical:

Resistance to corrosive chemicals and harsh environments.

Use in pipelines, tanks, and chemical processing equipment.

Section 4: Advantages and Challenges

4.1 Advantages:

Excellent corrosion resistance.

High strength and durability.

Ease of fabrication and maintenance.

4.2 Challenges:

Susceptibility to chloride-induced corrosion.

Cost considerations compared to other stainless steel grades.

Section 5: Maintenance and Care

Best practices for maintaining the integrity of Stainless Steel 304 Coils.

Cleaning methods and corrosion prevention.

Conclusion:

In conclusion, Stainless Steel 304 Coils offer a compelling combination of corrosion resistance, mechanical strength, and versatility. Whether in automotive, construction, or food industries, these coils continue to play a crucial role in various applications. Understanding their composition, manufacturing process, and proper maintenance is key to unlocking their full potential in diverse settings.

2 notes

·

View notes

Link

#construction chemical companies#construction chemical manufacturer india#tile adhesive manufacturers#tile adhesive manufacturers in india

0 notes

Text

Achieving Optimal Performance with High-Quality IBR Fitting and Flanges What You Need to Know

In the complex world of industrial operations, achieving optimal performance is paramount. When it comes to steam and power generation systems, the choice of components plays a crucial role. IBR (Indian Boiler Regulations) Fittings and Flanges are integral parts of these systems, ensuring efficiency and safety. As a leading IBR Fitting and Flanges distributor in Vadodara and a trusted IBR Fitting and Flanges dealer in Gujarat, Tube Trading Co. recognizes the importance of these components. In this blog post, we will delve into the key aspects of IBR fittings and flanges, shedding light on how the right choice can contribute to achieving peak performance in industrial settings.

Understanding IBR Fittings and Flanges

What is IBR?

The Indian Boiler Regulations (IBR) are a set of regulations governing the design, fabrication, and inspection of boilers and related components in India. IBR compliance is mandatory for manufacturers and users of boilers and associated equipment to ensure safety and quality standards.

IBR Fittings

IBR fittings are components designed to connect and control the flow of fluids within a steam or power generation system. These fittings must adhere to IBR standards to guarantee their reliability and safety in high-pressure environments. Examples of IBR fittings include bends, elbows, tees, reducers, and valves.

IBR Flanges

Flanges are essential components that connect pipes, valves, and other equipment in a steam or power system. IBR flanges, compliant with IBR regulations, are designed to withstand high pressure and temperature conditions. They provide a secure and leak-proof connection between different sections of a piping system.

Importance of High-Quality IBR Fittings and Flanges

Safety Compliance

In industries where steam and power generation are critical processes, safety is non-negotiable. IBR regulations are in place to ensure that the components used in these systems meet stringent safety standards. Choosing high-quality IBR fittings and flanges from a reputable distributor in Gujarat is essential for compliance and to mitigate the risk of accidents.

Reliability and Durability

The harsh conditions of industrial operations demand components that can withstand high temperatures, pressures, and corrosive environments. High-quality IBR fittings and flanges are constructed from materials that offer exceptional durability, ensuring a longer lifespan and minimal downtime for maintenance.

Efficient Performance

The efficiency of a steam or power generation system depends on the seamless operation of its components. Inferior fittings and flanges can lead to inefficiencies, including leaks and pressure drops, resulting in decreased system performance. By choosing top-notch IBR fittings and flanges from a reliable distributor in Vadodara, industrial operators can optimize the performance of their systems.

Applications of IBR Fittings and Flanges

Power Plants

In power plants, where steam is a primary component in electricity generation, IBR fittings and flanges are extensively used. These components help regulate the flow of steam and ensure the integrity of the entire system.

Chemical and Petrochemical Industries

Industries dealing with chemicals and petrochemicals operate in demanding environments. IBR fittings and flanges play a crucial role in maintaining the integrity of piping systems that transport hazardous substances.

Refineries

Refineries, involved in processing crude oil into various products, rely on high-pressure steam for many processes. IBR fittings and flanges are vital in ensuring the safe and efficient operation of these steam systems.

Textile and Food Processing Units

In textile and food processing, where steam is used for various purposes, IBR fittings and flanges are employed to guarantee the reliability and safety of steam transport.

Choosing the Right IBR Fitting and Flanges Distributor

Selecting the right distributor is as crucial as choosing the right components for your industrial applications. As a reputable IBR Fitting and Flanges distributor in Vadodara, Tube Trading Co. stands out for several reasons:

Extensive Product Range

We offer an extensive range of IBR fittings and flanges, catering to diverse industrial needs. Our products are sourced from trusted manufacturers, ensuring quality and reliability.

Compliance with Standards

All our IBR fittings and flanges comply with Indian Boiler Regulations and other relevant industry standards. We prioritize safety and performance in every product we offer.

Technical Expertise

Our team of experts possesses in-depth technical knowledge about IBR fittings and flanges. We provide valuable insights and guidance to help our clients make informed decisions.

Timely Delivery

At Tube Trading Co., we understand the importance of timely delivery in industrial settings. We ensure that our clients receive their orders promptly, minimizing downtime and disruptions.

Conclusion

In the intricate tapestry of industrial operations, the choice of IBR fittings and flanges can significantly impact the efficiency, safety, and reliability of steam and power systems. Tube Trading Co., as a trusted IBR Fitting and Flanges distributor in Vadodara and a reputable IBR Fitting and Flanges dealer in Gujarat, takes pride in being a reliable partner for industries across the region. Our commitment to quality, safety, and customer satisfaction sets us apart in the competitive landscape.

If you are in search of high-quality IBR fittings and flanges to enhance the performance of your industrial processes, look no further than Tube Trading Co. Contact us today for all your IBR fitting and flange requirements, and let us contribute to the success and efficiency of your operations.

#IBR Fitting and Flanges distributor in Gujarat#IBR Fitting and Flanges distributor in Vadodara#IBR Fitting and Flanges dealer in Gujarat#Steel Companies#Steel Industry#Construction Material#Stainless Steel#business#India#Gujarat#Vadodara

6 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

The Science of Corrosion Protection: Ammonium Tetra Molybdate at Work

Corrosion is a widespread issue that impacts numerous businesses, resulting in substantial financial losses and expenses related to maintenance on an annual basis. In response to this challenge, scholars and professionals in the field have been persistently endeavouring to develop novel strategies aimed at safeguarding metallic constructions against the detrimental effects of corrosion. Ammonium Tetra Molybdate, a potent corrosion inhibitor, has garnered much attention as a potential remedy. Experience the quality and effectiveness of the quality products offered by Palvi Chemicals – an excellent Ammonium Tetra Molybdate manufacturer in India.

This blog post aims to examine the scientific principles underlying corrosion protection and investigate the mechanisms by which Ammonium Tetra Molybdate functions to preserve the integrity of metal surfaces.

Understanding Corrosion:

Corrosion can be defined as the process through which metals undergo deterioration as a result of chemical reactions occurring between the metals and their surrounding environment. The aforementioned phenomenon is a naturally occurring process when a metal has a reaction with oxygen, moisture, and various other elements, resulting in the formation of oxides, hydroxides, or salts on the surface of the metal. Corrosion can have significant repercussions, including structural collapse, diminished performance, and the need for expensive repairs or replacements.

In order to effectively address corrosion, it is imperative to possess a comprehensive understanding of the underlying mechanisms that contribute to this phenomenon. There exist multiple forms of corrosion, namely uniform, galvanic, pitting, and crevice corrosion, each exhibiting unique attributes and origins. Uniform corrosion is characterised by an even distribution of corrosion across the whole surface of the metal. On the other hand, pitting corrosion is identified by the formation of small, localised holes or pits. Empower your international business with premium Ammonium Tetra Molybdate export services offered by Palvi Chemicals – the most trusted Ammonium Tetra Molybdate exporter in UAE.

The Role of Corrosion Inhibitors:

Corrosion inhibitors are chemical compounds that are specifically formulated to safeguard metal surfaces by impeding the chemical reactions that initiate and propagate corrosion processes. These inhibitors function in diverse ways, including the formation of a protective coating on the metal surface, modification of electrochemical processes, or neutralisation of corrosive substances. Ammonium Tetra Molybdate (ATM) is an example of a highly effective inhibitor.

The Science Behind Ammonium Tetra Molybdate:

Ammonium Tetra Molybdate, commonly referred to as ATM or ATMP, is a white crystalline powder that has notable corrosion-inhibiting characteristics. Corrosion protection is frequently employed across diverse sectors such as aerospace, automotive, and marine, with the aim of safeguarding vital metallic elements against degradation. Stay ahead in your global industry. Partner with Palvi Chemicals – one of the recognised Ammonium Tetra Molybdate traders in UAE.

· Passivation:

Passivation is a key technique employed by ATM to mitigate the effects of corrosion. Passivation is a process that entails the development of a thin layer of oxide on the surface of a metal, which serves as a protective barrier against subsequent corrosion. The ATM process facilitates the formation of a durable and firmly attached oxide film on the surface of the metal by its interaction with the metal. The film serves as a protective barrier, effectively impeding the access of corrosive chemicals to the metal substrate.

· Synergistic Effects:

Synergistic effects can be observed when ATM is used with other corrosion inhibitors, resulting in an enhanced effectiveness of the inhibitors. When ATM is mixed with zinc and phosphate-based inhibitors, it has the potential to offer enhanced corrosion protection. The observed synergy is a consequence of the intricate interplay among various inhibitors, leading to the formation of a protective layer on the metal that exhibits enhanced durability and longevity.

· Reduced Oxygen Permeation:

One other mechanism by which ATM effectively mitigates corrosion is through the reduction of oxygen permeability to the surface of the metal. Oxygen plays a pivotal role in numerous corrosion reactions, and the restriction of its availability by Ammonium Tetra Molybdate (ATMs) effectively retards the corrosion process to a considerable extent.

Applications of Ammonium Tetra Molybdate:

Ammonium Tetra Molybdate is extensively utilised in many industries due to its notable ability to provide corrosion prevention. Unlock international opportunities with Palvi Chemicals your trusted Ammonium Tetra Molybdate supplier in UAE. Reach out to the expert team for a seamless and efficient export partnership!

Aerospace Industry: In the aerospace industry, Ammonium Tetra Molybdate (ATM) systems are employed to safeguard vital aircraft components, including aluminium alloys, against corrosion in challenging environmental conditions.

Automotive Sector: The automotive sector utilises automotive coatings and treatments to enhance the durability of cars and mitigate expenses associated with maintenance.

Marine Industry: The utilisation of Ammonium Tetra Molybdate (ATMs) in the marine industry serves as a protective measure for ship hulls and various components that are susceptible to the corrosive effects of seawater.

Infrastructure: ATMs are employed in safeguarding critical components of infrastructure such as bridges, pipelines, and other essential pieces, with the aim of mitigating corrosion and so assuring their sustained longevity.

Final Thoughts:

Corrosion is an enduring and financially burdensome issue that impacts a wide range of industries. A comprehensive comprehension of the scientific principles underlying corrosion protection is crucial in the development of efficacious remedies. Ammonium Tetra Molybdate possesses notable passivation capabilities, exhibits synergistic effects, and demonstrates the capacity to mitigate oxygen permeability, rendering it a potent asset in the battle against corrosion.

The efficiency of this technology in protecting the integrity of metal structures and components is highlighted by its wide range of applications in diverse industries. This, in turn, results in cost savings and enhanced durability. The adoption of novel corrosion inhibitors such as ATM represents a progressive approach towards safeguarding the durability and dependability of metallic resources amongst the adversities posed by corrosion. Ensure the reliability of your chemical supply. Partner with Palvi Chemicals – one of the leading Molybdenum chemicals manufacturers in India for top-quality Ammonium Tetra Molybdate products. Reach out for more information.

#Ammonium Hepta Molybdate exporter in UAE#Ammonium Hepta Molybdate manufacturer in India#Ammonium Hepta Molybdate traders in UAE#Ammonium Hepta Molybdate supplier in UAE#Molybdenum chemicals manufacturers in India

6 notes

·

View notes

Text

ECMAS is known as one of the premium concrete admixtures manufacturers in India. Get absolute strength, enhanced workability and durability for your concrete buildings with ECMAS concrete admixtures.

#admixture companies in india#concrete admixture manufacturer#concrete#construction chemical companies#construction

0 notes