#copper aluminum radiator recycling machine

Text

How to remove copper from waste air conditioner radiators?

The waste air conditioner radiators can be separated a large amount of metals out for recycling. As for an ordinary air conditioner radiator, the copper content is about 55%, and the aluminum content is about 40%. For the high-end air conditioner radiators, the copper content can reach to 80%. Well, how to remove copper from waste air conditioner radiators? Today let's discuss the way together.

1. Manual peeling

Use a razor blade or a power saw, cut as close to the copper pipe as you can, to cut the scrap radiator into strips, then shave off the aluminum foil and you will have a clean copper pipe. This method is easy to operate, but its efficiency is low, and it can't process large quantity waste air conditioner radiators. Besides, it's difficult to process multi-layer radiators.

2. Separating copper tubing from aluminum fins

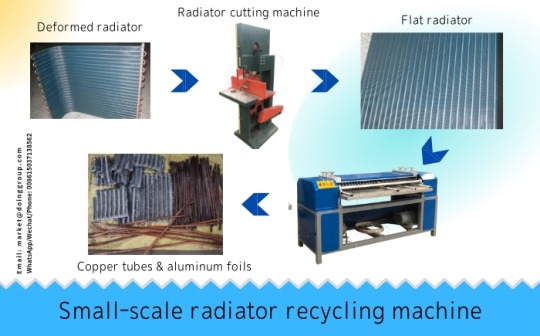

The second way to remove copper from waste air conditioner radiators is using radiator stripping machine. First, you need to cut the waste air conditioner radiators into suitable size single or double-layer radiators by using radiator cutting machine, then put the single or double-layer radiator into radiator stripping machine, it will separate copper tubing from aluminum fins.

Radiator stripping machine is easy to operate and occupies small land, but its efficiency is not pretty high, only 300-500kg/h. Besides, it has some limits, for example, the radiators must be flatted and undeformed, and it can't process car water tanks and industrial condenser.

3. Separating copper pieces from aluminum pieces

At first, the waste air conditioner radiators will be shred or crush into small pieces mixture of copper, aluminum and iron. Then use magnetic separator to remove iron first, after that air separator will separate copper from aluminum according to their different gravity. Finally, the copper will be removed from waste air conditioner radiators.

Air conditioner radiator recycling machine has large processing capacity, varying from 500kg/h to 2000kg/h. In addition, whether it is deformed or flat, single-layer or multi-layer air conditioner radiators, car water tanks, and condensers, it can remove copper from waste radiators easily.

Henan Doing Company is a professional e waste recycling machinery manufacturer, mainly produces e waste recycling machine, like cable/wire recycling machine, circuit board recycling machine, radiator stripping machine, air conditioner radiator recycling machine, etc. with own professional engineers team and factory manufacturing team. And the most important point is that DOING provides one-stop service and has a perfect after-sales service team. So if you want to remove copper from waste air conditioner radiators or other requirement, welcome to contact DOING, we can provide you with the best service!

Contact address:

Email: [email protected]

WhatsApp/Wechat/Phone: +86 150 3713 8562

Website: http://www.copperwirerecyclingmachinery.com/radiator/index.html

0 notes

Text

Optimizing Scrap Management with Metal Shredder

Scrap metal shredder machine known as metal crusher is a heavy duty machine in metal recycling industry, used to shred wide range of scrap like scrap iron, aluminum, copper radiator, automobile parts, drum, refrigerator etc.. Advance hydrau-Tech is India's oldest and largest manufacture of Scrap processing machines designs and manufactures shredder machines of different sizes, characteristics and powers according to the specific needs of the client. We have single shaft, twin shaft and rotary shredder available to process all types of metal scrap. Contact us today for best offer

0 notes

Text

Unlocking the Value of Scrap Metal: A Comprehensive Guide

Welcome to our comprehensive guide on unlocking the value of scrap metal! In today's world, where sustainability and environmental consciousness are gaining increasing importance, recycling scrap metal Melbourne has become a lucrative and environmentally-friendly endeavor.

Whether you're a DIY enthusiast looking to make some extra cash or someone who wants to contribute to the recycling effort, understanding the different types of scrap metal and how to maximise their worth is essential. In this guide, we will walk you through everything you need to know to unlock the potential value of scrap metal.

Understanding Scrap Metal

Definition and Types of Scrap Metal

Scrap metal refers to discarded metal objects or leftover materials that can be recycled and reused. These materials are typically found in various forms, such as old appliances, automotive parts, construction waste, and more. Understanding the different types of scrap metal is crucial as it helps determine their value in the market. The two main categories of scrap metal are ferrous and non-ferrous.

Ferrous metals, like iron and steel, contain iron and are magnetic. They are commonly found in household appliances, machinery, and construction materials. Non-ferrous metals, on the other hand, do not contain iron and are not magnetic. Examples include copper, aluminum, brass, stainless steel, and lead. Non-ferrous metals are widely used in electrical wiring, plumbing, and various other industries.

Popular Sources of Scrap Metal

Scrap metal can be found in numerous places, both inside and outside your home. Old appliances like refrigerators, washing machines, and air conditioners often contain valuable scrap metal components. Automotive parts, such as engines, radiators, and catalytic converters, are also excellent sources of scrap metal. Additionally, construction sites and renovation projects produce a significant amount of scrap metal, including steel beams, copper wires, and plumbing fixtures.

To identify valuable scrap metals among these sources, it's helpful to familiarise yourself with their characteristics. For example, copper is easily recognisable due to its reddish-brown color, while aluminum is lightweight and has a silvery appearance. By knowing what to look for, you can maximise your chances of finding valuable scrap metals.

Assessing Scrap Metal Value

Factors Affecting Scrap Metal Prices

The value of scrap metal is influenced by various factors, including market dynamics, purity, condition, and quantity. Market dynamics, such as supply and demand and economic conditions, play a significant role in determining scrap metal prices. When demand for certain metals is high and supply is limited, prices tend to rise. Economic conditions, such as inflation or recession, can also impact the value of scrap metal.

The purity of a metal is another crucial factor. Scrap metal that is free from impurities, such as rust or other contaminants, is more valuable. Similarly, the overall condition of the metal affects its worth. Clean, undamaged pieces are generally preferred by buyers. Lastly, the quantity of scrap metal you have can also influence its value. Larger quantities often fetch better prices as they are more attractive to buyers.

Researching Current Scrap Metal Prices

To ensure you get the best possible price for your scrap metal, it's essential to stay informed about current market prices. Reliable resources for obtaining up-to-date pricing information include websites dedicated to scrap metal prices, online marketplaces, and local recycling centers. These sources provide valuable insights into pricing trends and can help you make informed decisions about when to sell your scrap metal.

Interpreting pricing trends is equally important. Understanding whether prices are rising, falling, or remaining stable can affect the timing of your sale. For example, if the price of copper is expected to rise in the near future, it might be beneficial to hold onto your copper scrap until the value increases. By staying informed, you can maximise your earnings from scrap metal recycling.

Preparing and Sorting Scrap Metal

Safety Precautions

Before you start handling scrap metal, it's crucial to prioritise safety. Always wear protective gear, such as gloves, goggles, and sturdy shoes, to protect yourself from potential injuries. Scrap metal can have sharp edges, and certain metals may contain hazardous substances. By taking the necessary safety precautions, you can ensure your well-being throughout the recycling process.

Additionally, it's essential to be aware of potential hazards associated with specific metals. For example, lead and mercury are toxic, while aluminum and magnesium can produce flammable gases when exposed to certain chemicals. Educate yourself about the characteristics and potential dangers of the metals you're working with to avoid accidents or health risks.

Sorting Techniques

Sorting scrap metal is a key step in maximising its value. By separating different types of metals based on their composition and value, you can streamline the recycling process and ensure that each metal is sold at its optimal price. Effective sorting techniques include visual inspection, using magnets for ferrous metals, and conducting simple tests to identify non-ferrous metals.

Visual inspection involves examining the appearance, colour, and texture of the metal to identify its type. Using a magnet is particularly useful in distinguishing ferrous metals, as they are magnetic, while non-ferrous metals are not. Conducting simple tests, such as checking the metal's density, can help differentiate between various non-ferrous metals like aluminum and copper. By employing these sorting techniques, you can save time and effort when preparing your scrap metal for sale.

Cleaning and Preparing Scrap Metal for Sale

Cleaning Methods for Scrap Metal

Cleaning scrap metal is essential to remove dirt, rust, or other impurities that may affect its value. Various cleaning techniques can be used depending on the metal type and the extent of contamination. For example, wire brushes or sandpaper can be used to remove rust from ferrous metals, while mild acids or vinegar solutions can effectively clean non-ferrous metals. It's important to choose cleaning methods that are safe for both you and the environment.

When cleaning scrap metal Melbourne, it's crucial to be mindful of the potential presence of hazardous substances. For instance, lead-based paints or coatings may be present on certain metals. In such cases, it's advisable to seek professional assistance or use appropriate protective measures to avoid exposure to harmful materials.

Preparing Scrap Metal for Sale

Preparing scrap metal for sale involves several steps to ensure you receive the maximum value for your materials. First, consider dismantling larger items to separate different metal components. By doing so, you can identify and sort valuable metals more efficiently. Additionally, removing non-metal materials, such as plastic or rubber, from your scrap metal can increase its value.

Separating metals based on their type and purifying them further enhances their value. For example, stripping insulation from copper wires or removing aluminum from steel frames can significantly increase the worth of these metals. Taking the time to prepare your scrap metal properly will result in higher prices when you sell it.

Selling Scrap Metal

Choosing the Right Buyer

Finding a reputable scrap metal buyer or recycling center is crucial to ensure a fair and transparent transaction. Look for buyers who have a good reputation within the industry and are known for their fair pricing practices. Local recycling centers are often a reliable option as they offer competitive prices and are more likely to have a community-oriented approach.

When selecting a buyer, consider factors such as pricing transparency, payment methods, and customer reviews. Transparency in pricing is essential to ensure you're getting a fair deal. Additionally, consider the payment methods offered by the buyer, such as cash or electronic transfers, to ensure it aligns with your preferences. Reading customer reviews and seeking recommendations can also provide insight into the buyer's reputation and reliability.

Negotiating and Finalizing the Sale

Negotiation skills can be valuable when selling your scrap metal. Remember that prices are often negotiable, especially if you have a large quantity or high-quality materials. Researching current market prices and comparing quotes from multiple buyers can give you an advantage during negotiations.

Before finalising the sale, ensure that you have all the necessary documentation and comply with any legal requirements. Some recyclers may require proof of ownership or identification to prevent metal theft. Familiarise yourself with the local regulations regarding scrap metal sales to ensure a smooth and legal transaction.

Conclusion:

Congratulations! You've reached the end of our comprehensive guide on unlocking the value of scrap metal. We hope this guide has equipped you with the knowledge and tools necessary to maximise the worth of your scrap metal.

By understanding the different types of scrap metal Melbourne, assessing their value, and properly preparing them for sale, you can make a significant impact both financially and environmentally. Remember, recycling scrap metal not only benefits you but also contributes to the preservation of our planet's resources. So, go ahead and unleash the potential of your scrap metal!

#Scrap Metal Melbourne#Scrap Metal#Scrap Metals Melbourne#Scrap Metal Recycling#Melbourne Metal Recycling#Scrap Metal Recycling Melbourne

1 note

·

View note

Text

Brass Round Bars: Versatile Alloys for a Wide Range of Applications

Introduction

Brass, a copper-zinc alloy, has been a vital material for centuries due to its unique combination of properties. When shaped into round bars, brass becomes an even more versatile material, suitable for numerous applications across various industries. In this article, we will delve into the key characteristics, applications, and advantages of brass round bars, highlighting their importance in modern engineering and manufacturing.

The Chemistry Behind Brass

Brass is primarily composed of copper (typically ranging from 55% to 90%) and zinc (typically ranging from 10% to 45%), with small amounts of other elements such as lead, tin, or aluminum added to achieve specific properties. The specific alloy composition can be tailored to meet the requirements of diverse applications, making brass a highly adaptable material.

Key Properties

Corrosion Resistance: Brass exhibits excellent resistance to corrosion, particularly in atmospheric and freshwater environments. This property makes it an ideal choice for applications where exposure to moisture is common.

Malleability: Brass is highly malleable, allowing it to be easily shaped, bent, and formed into various geometries. This property is advantageous in manufacturing processes.

Thermal Conductivity: Brass has good thermal conductivity, making it suitable for applications involving heat transfer, such as heat exchangers and radiator cores.

Electrical Conductivity: Brass is an excellent conductor of electricity, making it valuable in electrical and electronic applications, including connectors and terminals.

Aesthetic Appeal: Brass has an attractive golden appearance that doesn't corrode or tarnish easily. This makes it a popular choice for decorative elements in architecture and design.

Applications

Architecture and Construction: Brass round bars are used for architectural accents, including handrails, door handles, and decorative trims, thanks to their aesthetic appeal and corrosion resistance.

Plumbing and Hydraulics: Brass is a common choice for plumbing fittings, valves, and hydraulic components due to its corrosion resistance and ease of machining.

Electrical and Electronics: Brass round bars are used in electrical connectors, terminals, and sockets due to their excellent electrical conductivity.

Musical Instruments: Brass is a primary material in the construction of musical instruments like trumpets, trombones, and saxophones, as it provides a desirable combination of acoustic properties and workability.

Automotive Industry: Brass is utilized in various automotive components, including radiator cores, fuel line fittings, and gearshift knobs due to its thermal conductivity and corrosion resistance.

Advantages of Brass Round Bars

Corrosion Resistance: Brass is highly resistant to corrosion, making it a durable choice for applications exposed to moisture and the elements.

Ease of Machining: Brass is easy to machine, which simplifies the manufacturing process and reduces production time and costs.

Versatility: Brass can be customized with different alloy compositions to suit specific applications, balancing properties such as strength, corrosion resistance, and cost-effectiveness.

Recyclability: Brass is a sustainable material as it is fully recyclable without any loss of properties, contributing to environmental conservation.

Aesthetic Appeal: The attractive appearance of brass adds an element of visual appeal to products and structures.

Conclusion

Brass round bars are a testament to the enduring value of traditional materials in modern engineering and manufacturing. Their unique blend of properties, including corrosion resistance, malleability, thermal and electrical conductivity, and aesthetic appeal, makes them indispensable in a wide range of applications. As industries continue to evolve, brass, with its adaptability and reliability, remains a favored choice for designers and engineers seeking a versatile material that combines functionality with visual appeal.

0 notes

Text

All About Metal Recycling

What is Metal Recycling?

Metal Recycling is the Best practice to save the environment and eliminate landfills. Recycling metals is an all the more monetarily and naturally practical method for getting and using metals as it utilizes less energy than metal creation. Furthermore, metal can endure persistent reusing without losing quality, making it a well-known region for organizations to study while directing a natural waste review. All ferrous metals from iron to hardened steel can be reused, as well as non-ferrous metals like copper, zinc, and aluminum, making it simple for organizations to package salvaged material together for assortment.

The benefits of Metal Recycling Are:-

Economical Benefits

Conserve Natural Resources

Reduce Energy Consumption

Other Environmental Benefits

What are the types of Recyclable Metal?

There are two main types of Recyclable metal

Ferrous Metal - Basically Ferrous Metal is magnetic in Nature and has a high tensile strength which makes them ideal for construction The most widely recognized ferrous metals are solid metal, fashioned iron, amalgam steel, and carbon steel, likewise alluded to as underlying steel. Iron originates before steel by many years. The last option is a composite, developed by adding the previous with carbon. Tractable, malleable, tough, and solid, iron is a weighty yet delicate material, with high warm conductivity. However generally, as far as use, iron has been supplanted by its posterity, steel, a harder metal.

Non-Ferrous Metal- Non-ferrous metals have, as well, been utilized starting from the beginning of civilization. Essential instances of non-ferrous metals are copper, aluminum, nickel, zinc, lead, and tin, in addition to valuable metals like gold, silver, platinum, and palladium. Non-ferrous metals enjoy upper hands over ferrous metals since they are lighter in weight and more pliable.

Aluminum, for example, is lightweight and can be handily projected, manufactured, machined, and welded. Airplanes are fabricated with aluminum, as are bumpers, outlines, cylinders, radiators, and like parts utilized in building automobiles, trucks, boats, and bicycles.

Copper's flexibility, pliability, and high conductivity make it an important metal in sheet material, course, lines, sculptures, and the electrical business as wire and different conveyors. Zinc is most generally used to stir the defensive covering of iron or steel to forestall rust.

The creation of combinations with ferrous and non-ferrous metals is a typical practice. Chromium blended in with steel makes hardened steel, giving expanded strength and giving it consumption opposition. Other combinations are broadly used to lessen material expenses, and others to make lighter-weight material.

What is the use of Metal After Recycling is Done?

Scrap Metal, for example, aluminum steel, metal, copper, and press can be reused more than once to make new items. These new items are utilized in various ways. Some are 'resurrected' as different things yet some might return as the similar items they began as.

Steel is tracked down in ordinary hardware and numerous apparatuses, from vehicle bodies to white products like clothes washers. Since there isn't a cutoff on the times' steel can be reused, it very well may be utilized again to make the above things and that's just the beginning. Your cooler might try and be produced using reused steel! Reused steel can make bike outlines, pipes, train tracks, and significantly more!

Copper mining is exorbitant and utilizes a ton of energy. It's tracked down in the design of most homes and properties and is sought after because of its recyclable purposes. Copper is flexible and when reused can be utilized for anything; from plumbing lines to guttering and electric wires.

Here are only a couple of astounding purposes of reused metals:

Transport - Reused metals are a significant component in the vehicle business, being utilized in building streets, tracks and in any event, for the actual vehicles; roughly 25% of the body of a vehicle is produced using reused metal. Planes use aluminum instead of steel and staggeringly, planes utilize a huge extent of reused aluminum (80% of the casing). Train tracks are generally produced using reused steel as well - which is particularly helpful in view of its expanded strength.

Home Decorations - Metal goods are usually produced using reused metals. The metal can be broken down into anything that the structure required and reused to look spic and span. All that from table tops utilizing enormous clock faces, seats framed from vehicle hats, and dressers produced using plane entryways

Packaging Material- Recycled metals are more often used in developing food packaging and other packaging materials.

What is the Need for Metal Recycling?

Despite the fact that there are a few motivations to reuse, the most significant and essential one is to track down an option in contrast to regular assets. It diminishes the need to work with virgin metal, further saving coal and iron mineral, which are utilized to deliver metal. As per a report, coal represented 43% of worldwide ozone-depleting substance emanations in 2010. Thus, assets, for example, coal should be considered in light of the fact that their burning is a significant reason for an Earth-wide temperature boost. It is likewise realized that most recyclable materials come from modern or business sources. These materials commonly go through reusing framework without numerous issues and are reused into the spotless, top caliber, item grade items that are utilized as feasible substitutes for virgin materials everywhere.

All in all, I might want to call attention to that reusing is the main way for organizations to keep working and secure the eventual fate of the metal assembling industry. Reusing is a straightforward and successful method for showing corporate obligation, and recyclers know about the business' public insight.

0 notes

Text

What is aluminum profile? What are Aluminum profile features?

Aluminum profiles are aluminum rods with different cross-sectional shapes through hot melting and extrusion.

[caption id="attachment_849" align="aligncenter" width="229"]

Aluminium Sliding door&window[/caption]

Aluminum profile features:

1) Corrosion resistance

In most environmental conditions, including air, water (or salt water), petrochemicals and many chemical systems, aluminum can show excellent corrosion resistance.

2) Conductivity

Aluminum profile is often selected because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly twice that of copper.

3) Thermal conductivity

The thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial for the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and automobile cylinder heads and radiators.

4) Non-ferromagnetic

Aluminum profiles are non-ferromagnetic, which is an important feature for the electrical and electronic industries. Aluminum profiles are not spontaneously combustible, which is important for applications involving handling or contact with flammable and explosive materials.

5) Machinability

The machinability of the aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in the various states these alloys have after being produced, the machining characteristics vary considerably, which requires special machine tools or technology.

6) Formability

The specific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change in allowable deformation.

7) Recyclability

Aluminum has extremely high recyclability, and the characteristics of recycled aluminum are almost the same as primary aluminum.

Source: https://www.fscyal.com/what-is-aluminum-profile-what-are-aluminum-profile-features/

1 note

·

View note

Text

What is an radiator recycling machine?

What is an radiator recycling machine?

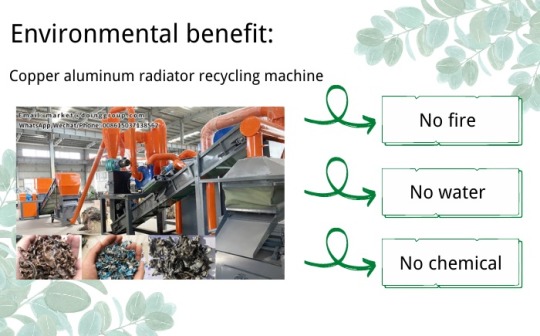

The radiator recycling machine can recycle used radiators in cars or air conditioners. The copper, aluminum and iron contained in it are mainly separated through crushing, magnetic separation and air separation.

How does a radiator recycling machine work?

First is crushing, which replaces the traditional manual dismantling and could save manpower. Then according to the properties of iron, the magnetic separator will separate the iron out first. Next, the copper and aluminum will be separated by air separation because of their different specific gravity. In this way, the copper, aluminum and iron can be efficiently separated for further use.

Advantages of using a radiator recycling rachine:

1. Separation after crushing ensures that the material is separated in a large state, thereby reducing the generation of metal powder and could improve the recovery efficiency of the metal.

2. High degree of automation. The whole line is PLC automation process, which only needs one person to operate.

3. The separation rate is high, could reach to 99%, so the metal separated will be very pure.

4. There is dust collecting device equipped in the whole process, so it could control the dust flying to ensure the clean of the factory.

5. With low investment, and high profit.

6. The voltage can be customized as per your requests.

For more detail of our Cable granulator machine, Check out more Models: V-1200T,V-1200P.Please contact us anytime!

1 note

·

View note

Text

Radiator Copper and Aluminum Separator Market 2022 | Industry Size, Share, Demand And Growth Analysis Report Till 2028

The study on Radiator Copper and Aluminum Separator Market with its type and application sales analysis is very essential for all the decision-makers or strategists operating in this industry. The report is made by analysts with deep industry knowledge and experience. The global, regional, and country annual sales and revenue has been studied for the historical years and estimated for the current year. With the help of analytical tools, primary interviews, and data triangulation the report is enriched with quality data. The qualitative data on the upcoming industry trends with market triggers and risks are covered as a separate section in this comprehensive report.

As understood and analyzed in the global Radiator Copper and Aluminum Separator market report the growth CAGR in the year 2022 to 2028 is showing a promising inclination. The macro and microeconomic conditions are studied and forecast data is anticipated.

Click here to get a FREE Sample PDF Copy of the Radiator Copper and Aluminum Separator Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-59921

As per this report analysis, the Radiator Copper and Aluminum Separator market is expected to show a CAGR (revenue) of xx% between the forecast years and the global market size can cross USD XX million by the end of 2028, growing from USD XX million in the year 2022. This report specifically covers the global market share (sales as well as revenue) of key companies in the Radiator Copper and Aluminum Separator business, as mentioned in a separate Chapter 3.

Regionally, the Radiator Copper and Aluminum Separator market data is studied under the below-mentioned regions and countries – Americas covering (United States, Canada, Mexico, Brazil), APAC covering (China, Japan, Korea, Southeast Asia, India, Australia), Europe covering (Germany, France, UK, Italy, Russia, Spain), Middle East & Africa covering (Egypt, South Africa, Israel, Turkey, and other GCC Countries).

This research study gives a comprehensive overview of market share and growth opportunities of the Radiator Copper and Aluminum Separator market as per type and application. The report also covers key manufacturers’ profiles with sales and gross margin data.

The key manufacturers covered in this report: Breakdown data in Chapter 3.

Enerpat Group

Solid Equipment Company

Amisy

Parovi Machines

Henan Dongying Machinery Equipment Co., Ltd.

Henan Zhong Recycling Technology Co., Ltd.

Henan Qianchuan Heavy Industry Machinery Co., Ltd.

Xi’an Wanze Tianhe Mechanical and Electrical Equipment Co., Ltd.

Gongyi Kerui Machinery Equipment Co., Ltd.

Others

To inquire about report customization, feel free to reach out to our team of expert analysts @ https://www.decisiondatabases.com/contact/ask-questions-59921

This study considers the Radiator Copper and Aluminum Separator value and volume generated from the sales of the following segments:

Segmentation by type: breakdown data from 2017 to 2022, in Section 2.3; and forecast to 2028 in section 11.7.

Single-Unit

Combination

Segmentation by application: breakdown data from 2017 to 2022, in Section 2.4; and forecast to 2028 in section 11.8.

AC Radiator Recycling

Engine Radiator Recycling

Others

The latest developments of the industry and the sales channel, manufacturing process along with the manufacturing cost study is covered in the report.

Key Questions Answered –

What will be the Radiator Copper and Aluminum Separator market CAGR and size between 2022-2028?

Who are the top/leading players of the Radiator Copper and Aluminum Separator market?

What changes are expected in the Radiator Copper and Aluminum Separator market in the next six years?

Which are the top product and leading applications of the Radiator Copper and Aluminum Separator market?

What are the leading market drivers and major risks factors for the Radiator Copper and Aluminum Separator market?

Which region/country leads and foresees highest growth in the next six years?

Purchase the Complete Global Radiator Copper and Aluminum Separator Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-59921

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map clients’ research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details:

DecisionDatabases.com

E-Mail: [email protected]

Phone: +91-93077-28237

Website || Official Blog || Insights Analysis

#Radiator Copper and Aluminum Separator#Radiator Copper and Aluminum Separator Market#Radiator Copper and Aluminum Separator Industry

0 notes

Text

Aluminium Heatsink Profile

https://www.otalum.com/products/aluminium-heatsink-profile.html

Otalum stocks a wide range of extruded aluminium heat sinks and provide aluminium extrusion heat sink profiles to custom designs, available in a range of finishes. If the existing products are not suitable for your needs, our technical team can help you to design your products and realize them.

All extrusions can be supplied as cut, drilled, or machined to customer specifications. As a professional extruded aluminum heatsink manufacturer, Otalum operates the latest CNC drilling and machining centres which provide accurately machined, cost-efficient parts on short cycle-times.

What is a heat sink?

A heat sink is a component that increases the heat flow away from a hot device. It accomplishes this task by increasing the device's working surface area and the amount of low-temperature fluid that moves across its enlarged surface area.

Why Aluminium Heat sink?

An aluminum heat sink profile is the most widely used product for thermal solutions. Following are some reasons why it is so popular.

Characteristics Of Heat Sink

l Good thermal and electrical conductivity

l Low density (about 2.7kg/m³)

l Low weight

l High strength

l Easy malleability

l Easy machining

l Excellent corrosion resistance

l non-magnetic which avoids interference of magnetic fields

l Easy to recycle

Aluminium VS Copper Heat Sink

1.Thermal Conductivity

Copper is more conductive than aluminum. In fact, aluminum only has 60% of the thermal conductivity of copper.

2.Weight

Aluminum accounts for only 30% of the density of copper. This means that the weight can be greatly reduced.

3.Cost

Aluminum is much cheaper than copper. In fact, its cost is about one-third. This can save a lot of cost.

How a Heat Sink Works

The heat sink must protect the electronic equipment and components from overheating. Therefore, they must be made of certain materials with good thermal conductivity.

Most devices that use power electronic equipment require a temperature-controlled environment. Otherwise, they are in danger of overheating, which may affect performance or, more seriously, become a safety hazard.

Essentially, a heat sink profile is a way to dissipate any heat generated from a device or component. This requires an optimal speed to dissipate heat from the source at the same rate as the rate at which the source generates heat.

In fact, optimization is the key to the success of any radiator system. This affects the choice of materials and basic aspects such as complexity, size, quality, and cost.

Therefore, while the selection of materials is crucial, other factors also need to be considered.

Where are Extruded Heat Sinks Used For?

Commercial LED lighting

The extruded heat sink provides effective cooling for the LED (Light Emitting Diode) light source. These radiators are very small and can be mass produced.

Circuit board & PCB (PC board)

By providing a precise combination of vertical and horizontal cooling, aluminum heat sink extrusions provide an effective thermal management process for circuit boards and PCBs. Various thicknesses and customized forms are also easy to achieve.

Electronic instrument or electronic equipment:

The radiator is an indispensable device for electrical appliances, which can effectively dissipate the heat of the output transistor.

Automotive equipment, NEV (New Energy Vehicle)

The radiators used in automotive electronic equipment enable high-density components to operate at stable temperatures under a wide range of environmental conditions.

The purpose of the heat sink is specifically designed to extract heat from the components in the electronic device. The radiator is generally polished, and in most cases, it can be anodized or powder coated to improve surface protection and corrosion resistance.

0 notes

Text

Scrap metal seller in UAE | Scrap Metal yard | Cable Processing

Our Thailand facility, located in Bangkok Free Trade Zone, Samutprakarn, is managed by a professional team of individuals having rich experience in handling all types of metal scrap. With a total area of 40,000 sq. feet, the yard is equipped with advanced technologies, equipment’s & world-class processes to produce recycled scrap metal in compliance with international quality standards.

Established in 2011, the Thailand operation is a non-ferrous scrap recycling facility specializing in copper cable chopping. It handles all grades of copper, aluminum, and brass. The yard has a capacity to handle a volume of around 1500 tonnes per month.

Machines used in the yard

We have the most advanced technology, machinery, and equipment to support the yard functions.

The fully automatic copper cable granulator machine, imported from Italy, is highly efficient and pollution-free. Scrap or waste is compressed into bundles using the bailing machine. We use advanced radioactivity testing machines and XRF analyzers to ensure our products meet the required quality standards and are radiation-free.

Magnetic separation, grinding method, handheld XRF analyzer, electrostatic separators, etc., are used when processing the cargo in the yard. We also have the facility for the detailed chemical analysis of the material in our lab with our Optical Emission Spectrometer. Forklift, grapples, alligator machines,s etc., are also used in our yard

Always committed to the environment

The machines and operational processes set up in our yard for recycling metal scrap are environment-friendly while creating a safe and healthy working environment for our employees. As part of the yard’s waste management, we sell all plastic waste to authorized companies that generate energy from plastic. All other types of waste are collected, processed, and recycled in ways that do not harm the environment. We aim to achieve a net-zero CO2 emission target in the next 5 years and limit the worst effects of climate change.

We have a global business presence with an excellent reputation among our partners. PGI is a vital link to many metal groups in Thailand & East Asia. We offer the best and the most competitive rates while buying scrap metal from individual scrap dealers, industrial suppliers or corporates. We have the capacity to handle any volume of scrap metal and are known for transparent transactions.

Whether you are a corporate or an individual business looking to sell or buy metal scrap, we offer the best, most competitive prices, and we have the capability and resources to handle any metal requirement on a timely basis.

0 notes

Text

Scrap These Items For Some Extra Cash

Many items that we use at home every day actually have secret materials. They contain metals. For a while, your favorite kettle or sofa that you have been using since your 20s should just be thrown away. But instead of throwing them away, there's one more thing you can do to help pave the way to a greener future, and that's to recycle them.

Items made of metals are easy to recycle. Metal waste buyers buy the scrap and give you the best values out of the scrap. Here are some factors to consider while choosing the scrap metal for selling.

Household Appliances

Most homes generally have basic appliances like pots, toasters, washing machines, refrigerators, freezers, sinks and dryers. Whatever device you recycle, most devices are generally, above all, made of metal.

This means that most of these devices can be easily reused. Some of the more metallic and prominent electronic products are refrigerators, dishwashers, and dryers known for white goods.

Copper and Wiring

Copper is invisible in almost all household items and is very valuable if properly recycled. When it comes to copper plumbing, since most water pipe materials are made of it, any kitchen, laundry, bathroom, or place that has plumbing includes some form of copper plumbing.

Instead of throwing away the old extra plumbing, you can recycle it. Copper being the rarest metal in nature holds more value than other metals.

Sinks and taps

Sinks are most commonly made of stainless steel, while taps are mostly made of brass. These materials can be easily recycled. If you're thinking of exchanging them when you redo the kitchen and bathroom.

To recycle sinks and faucets, you can drive to the best metal waste dealers in your city. They will surely help you get rid of the unwanted scrap lying at your place and provide you a good value for it.

Pots And Pans

It is suitable for cooking in pots and pans, but little is known about how simple it is to recycle as most are made of aluminum and cast iron. This is useful when exchanging old tools for new ones.

As metals have the property of not losing its properties even after repeated recycling. You can use them for recycling and earn a good amount out of that.

Vehicles And Tools

Not everyone has a private car, but if you do, you will find several recyclable parts, such as radiators and batteries. Tools such as lawn mowers and leaf blowers also include recyclable motors, as well as other parts and metal types.

You can make money from removing metal parts from old, worn cars and tools.

If you are in Singapore, you are looking for Scrap recycling company in Singapore, LH Metal is the right fit for you.

0 notes

Text

youtube

Electronic Scrap Car Radiator Stripping and Separator Machine can process waste radiators to separate copper and aluminum out.

Free quotation and more information, welcome to contact us.

Email: [email protected]

Whatsapp/Wechat/Phone: +86 150 3713 8562

Website:

http://radiatorseparatorrecycling.com

http://www.copperwirerecyclingmachinery.com/Radiatorheat_sink_recycling_machine/

#radiator recycling machine#copper aluminum radiator recycling machine#separate copper from aluminum#radiator#recycling#copper#aluminum#Youtube

0 notes

Text

How much money can you get from scrapping an air conditioner radiator?

As we known, an air conditioner radiator contains copper and aluminum, which can be recycle and reused with high value. So scrapping an air conditioner radiator can bring much money for you.

If the scrapping an air conditioner radiator within whole, no any disassembly, one small air conditioner can get $6 around on average. However, if we separate the copper tubing and Aluminum sheet from the a scrap air conditioner radiator, then sell again, we can get $20 around. The price of the pure metal we get same as London Metal Exchange minus 8%.

As for the copper tubing within a little or some aluminum or copper doped in aluminum metal, the separation rate can’t reach 100%. The max metal’s value is similar with the scrapping air conditioner radiator. DOING company’s aluminum copper radiator recycling machine can separate the copper and aluminum by 100%. Making the scrapping an air conditioner radiator highest value to recycled and reused.

To ensure higher recycling efficiency we should scrap more air conditioner radiators in unit time. DOING company’s radiator recycling machine can process 4tons waste air conditioner radiators per day. And it separate whole copper tubes from aluminum coating of waste radiators, also keep aluminum in block pieces, easy to collect and sell.

Also DOING radiator recycling machine is applicable to both single and double layers waste radiators with different space sizes between the copper tubes. And easy to operate with safety control, once the worker or any part of the body reach to the setting position or distance to the feeding inlet, the radiator recycling machine would stop working automatically.

In a word: After 100% recycling the metal from scrapping an air conditioner radiator, we can get 3-4times more money than the raw waste.

Whatsapp:0086-150-3713-8562

E-mail: [email protected]

https://www.copperwirerecyclingmachinery.com/

0 notes

Text

The Historical And Economic Significance of Copper Recycling

For thousands of years, copper has been one of the most commonly used metals on earth. As the properties of copper do not degrade despite being recycled several times, products made from copper today could have been around for hundreds to thousands of years ago. Take for example the case with copper scrap, it is a highly prized scrap metal that is valued by recycling businesses. One reason is that it is the best conductor of electricity apart from silver. Thanks to copper’s electrical and thermal conductivity, along with its other great qualities such as high malleability and ductility.

Interestingly, copper has been recycled for a very long time now and it dated back to thousands of BC era. After the technology of copper processing has been improved, it continued to grow as the process of recycling also enhanced. The recycling of copper scrap, for instance, has seen plenty of development, hastening the production of new products made from recycled copper. As recycling processes continued to improve, copper and its alloys were recycled for various purposes. Copper scrap and other metal scrap recycling projects have grown rapidly, making recycling businesses and related industries benefit from them.

When it comes to the economic significance of recycling copper scrap, nearly half of the copper production in the U.S. comes from recycled materials. More than 2 million metric tons of copper used for domestic applications are produced locally through recycling facilities. Among nonferrous metals, copper comes second to aluminum as recycled metal. In terms of composition, about over a half of recycled copper scrap includes new scrap recovery. Other recycled items are chips, machine turnings, cables, damaged radiators, plumbing tubes, among many others. All these items come together in a recycling facility where they will be processed to make a new metal product.

0 notes

Text

Roll of Structural Steel and Plate Fabrications in Major Industries

Steel is known for its high elasticity and ease. It is in the establishment of pretty much every industry and significant segment utilized in structures, foundation, instruments, ships, cars, machines, apparatuses, and weapons. Alongside that, Steel assumes an extremely essential function in manufacture businesses. All significant business areas, for example, Heavy Steel, Petrochemical, Construction, Mining, Food and Dairy, Power Supply and Distribution include Steel creation either in their everyday activity or have utilized it during their underlying arrangement. Thinking about the high strength of steel, we require innovative instruments, for example, laser slicing billboard which is utilized to deal with the crude steel items into something helpful, for example, auxiliary steel radiates, segments, steel lines, areas, and bars.

Let’s look at how these different industries are involved in the entire steel fabricating process.

Substantial Industry

Weighty basic steel creation organizations doing the manufacture cycle for some private, business and mechanical tasks.

Substantial steel structure produced using developed areas, for example, scaffolds and crane supports which can be created by various machines like SAW developed segment.

The auxiliary steel is additionally ordinarily utilized in the development of skyscraper business structures. Different shafts, for example, H-radiates, I-bars, and T-radiates are manufactured at these enterprises.

These structures are utilized as burden bearing individuals.

Weighty Structural Steel Fabrication

Basic Steel Fabrication Construction

Development Industry

Industry Structural Steel Fabrication for Construction Industry is generally thought about as it's the most savvy building asset. In the development business, reasonable material, for example, steel permits structures to be constructed rapidly at a low cost. Since steel comes in different compounds and structures, it very well may be intended to satisfy the needs of each task.

Steel upgrades underway add to the coming of the elevated structure, just as the development of railroads everywhere on the world

The strength and sturdiness of houses, vehicle parks, schools and high rises, most structures all depend on steel. The development business is subject to steel for the correct foundation needs of non-industrial nations by permitting wind-safe and defensive seaside plans.

Petrochemical Industry

Petrochemical Industry Steel Plate Fabrication – There has been an expanded worldwide dependence on worth added ideas particularly in the Petrochemical Industry that has been utilizing Steel Plate Fabrication.

This industry requires changing worth crude materials like oil and gas into different materials that are thusly the crude materials which are utilized in numerous different enterprises.

The classes of prepares utilized here are impeccable, high-strength, carbon, and miniature alloyed. These assistance in the creation of the hardware like pipelines and seaward stages. Such properties of steel help in the energy anticipates for the forthcoming requesting conditions.

Steel Plate Fabrication for Petrochemical

Steel Fabrication for Mining Industry

Mining Industry

Steel Fabrication for Mining Industry – In the Mining Industry Steel Fabrication is very helpful. The primary mining measure includes numerous apparatus and devices that are framed utilizing steel creation.

Mining Industry utilizes entirely different hardware like transports, lifts, lifts. The entirety of this hardware requires strength and adaptability, which no one but steel can give.

Quality manufacture of transport lines ensures toughness and execution for the whole system.

Digging organizations use steel for a more grounded hold in more profound mines where the parallel weight is more prominent.

Being one of the most adaptable metals, a wide scope of surface medicines like hot plunge arousing, powder covering, and painting should be possible with it.

Food and Dairy Industry

Steel Plate Fabrication in Food Industry is generally utilized as it is required for some, designing plan administrations.

A wide scope of food and dairy holders and creation gear are finished by the steel business.

As Stainless steel needs item contact surface surfaces it is generally utilized for food industry manufacture ventures. Its capacity to effectively dismantle the hardware for cleaning and examination gives further advantages to food industry clients.

Protected Metal Feed Storage Fabrication

Steel Fabrication for Power Industry

Power Supply and Distribution Industry

The Steel Fabrication work in Power Supply and Distribution Industry

It can give power plants that are created metals, reactor internals, regulation parts, pressure vessels, tanks, heat exchangers, funneling frameworks, wet stockpiling racks, spent fuel holders, auxiliary backings, and lifting rigs.

Laser Cutting Sign Board Industry

Likewise, on the off chance that we talk about Laser Cut Sign Board, these can be handily produced using acrylic laser cutting and metal laser cutting in aluminum, steel, hardened steel, metal, and copper up to 1mm.

Steel can undoubtedly make a little or gigantic billboard utilized for business purposes

Structural steel is alluded to as the main green basic development material that expands energy productivity and related ecological issues. It is the most favored metal in the development business as it is recyclable and truth be told, has a high stake in the market of mechanical and business structures.

Primary steel dealers in Bangalore are selling the products at quite a reasonable price for their products, compared to the others. They are offering products in SAIL TMT Bars, Rebars, HR and CR sheets, GC galvanized steel sheets,GI Pipes,Steel plates, MS angles, Vsp steel and more.

Resource : https://ksteels.blogspot.com/2020/11/roll-of-structural-steel-and-plate.html

0 notes

Text

Why is Aluminum Metal Fabrication easy and futuristic?

Why is Aluminum Metal Fabrication easy and futuristic?

Some Elements have that inner inbuilt and features which make them the pioneer to lead, and they certainly have that killer workability, and features which made the Metal fabrication Industry more viable and practical.

Aluminum is a gem of metal, which reduced the burden of steel, by giving a great option for building and infrastructures, it came with wonders and completely influenced the manufacturers globally.

Aluminum dived deep and made its presence crucial for giving its magnificent features of structural wellbeing, which are visible in everything it is used for.

Today let’s get a random overlook at Aluminium, and which is the cause for its popularity. What is the Fabrication of aluminium?Why do we need SMAlloys as a supplier of the best Aluminium?

Weight Factor,-Yes, aluminium is much lighter than its competitor, stainless Steel. That alone feature makes it more sort after metal to be used in making machine components, automobile, airplane parts, which have to be light-weighted for better workability. It is 1/3 the weight of steel, amazingly to be selected first.

Corrosion Resistance- Aluminium is good in corrosion resistance but not that good as stainless steel. Although it is a high oxidization feature than most metal after long-duration it may turn white and pit gradually, but it is still a good choice where the water is an eroding factor.

Electric Conductivity- Aluminium is an excellent conductor of electricity. Due to this property and corrosion resistance, it is highly used to make heavy overhead extension wires and is preferred in most cases for copper. Copper is costlier, and Aluminium is super cheap, as an advantage to be taken by the electric industry.

Thermal Conductivity- Aluminium is a super thermal conductor naturally, it can be used till 400 degrees, after that it loses its dignity and become soft. The reason we are using aluminium in car radiators, air conditioner units, and many of our cookware are known today.

Workability- Aluminium is fairly and readily used for making and molding to a different form, due to its soft and easy workability to create sharp, defined, and formidable shapes as per our needs.

Cost-Effective and Eco-Friendly- Aluminium is fairly cheap, compared to stainless steel, making it favourite engineering material for all domestic and industrial purposes. The other factor of its abundant use is the secondary production, its reuse, it can be recycled from scraps and made again. That seems to be a favourite for the environment and reduction of pollution.

Multipurpose Uses- Aluminium is penetrating in almost everything, which is of common use. The presence of Aluminium is the guarantee of strength, corrosion resistance, and easy working capacity with efficiency. Aluminium alloy can be shaped and molded into sheets, pipes, wires, and foils of all kinds and shapes. Aluminium enjoys serving in the vast field of automobile industries, auto parts, utensils, electric wires, and a huge range of frames and construction furniture panels of various forms.

What are the Grades of Aluminium and their Fabrication used?

The knowledge of Aluminium Grades is useful, as they possess, various features as the requirement, the need for the product may be unique in all the applications. That’s why there are many grades of alloyed aluminium like,

Aluminium 1100- it is soft and ductile with excellent workability, it is very pure and is mostly used in food packaging and food processing units.

Aluminium 2100- High machinability and mechanical strength. It is more used in machining parts of fine and detail dimensions requirements.

Aluminium 2014- This grade is regarded as high strength and excellent machining capability and used in aerospace applications, it is an alloy with copper.

Aluminium2024-This alloy of aluminium is used in the more pressure areas and machine ventures where the fatigue resistance is required the most.

Aluminium 3003- this grade is with added manganese as an alloying agent which makes it stronger, corrosion resistance, and workability by far.

Aluminium 5052- It is considered the best corrosion-free grade by engineers, it fatigue strength is incompatible. It is a game-changer when applied in a wet atmosphere and saltwater plants for the best results.

Aluminium 6061, 6063, 7075, are some of the well know grades of aluminium in industrial uses with smart features for better results.

That small detailed info. Must be of great use for taking the best grade for your next project.

Fabrication of aluminium has a great impact in the metallic industry, as the building, framing, assembling, cutting, and bending are done with the latest technology and sophisticated tools.

Apart from the raw manufacturing of aluminium products, there are many skilled and unskilled labors worldwide, giving their services for assembling, finishing, and drawing usable aluminium products at the consumer levels. Like making frames of windows, creating doors, sliders, grills, and other furniture components with tools and small machines.

We have something best to offer, as Aluminium sheets, foils, blocks, wires, and custom dimensions are catered with great expertise by the SMAlloys.

We are the leading flagship in the field of metal and Alloys supplier, manufacturer, and distributer till the doorstep, established in Mumbai.

SMAlloy team is well known to serve, with dedication, extremely advanced manufacturing units, sharp in measurement, and frequent quality check-ups at all stages while producing the Aluminium sheets, blocks, Rods, pipes, tubes, and Foils.

You can gain more information by landing on www.smalloys.com as our official site for the latest updates and offers.

Feel SMAlloys as the guardian and Facilitator for your requirement of Aluminium for profitable product, and progress as by-product.

0 notes