#data in tegration

Explore tagged Tumblr posts

Text

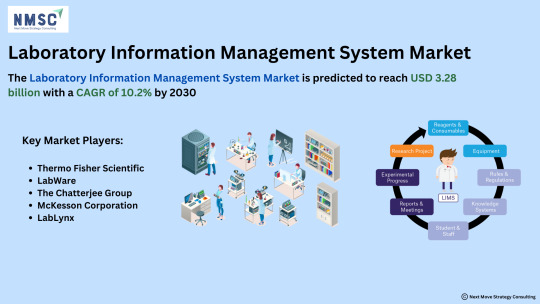

𝙄𝙣-𝘿𝙚𝙥𝙩𝙝 𝙎𝙩𝙪𝙙𝙮 𝙤𝙛 𝙩𝙝𝙚 𝙇𝙖𝙗𝙤𝙧𝙖𝙩𝙤𝙧𝙮 𝙄𝙣𝙛𝙤𝙧𝙢𝙖𝙩𝙞𝙤𝙣 𝙈𝙖𝙣𝙖𝙜𝙚𝙢𝙚𝙣𝙩 𝙎𝙮𝙨𝙩𝙚𝙢 (𝙇𝙄𝙈𝙎) 𝙈𝙖𝙧𝙠𝙚𝙩

𝙂𝙚𝙩 𝙖 𝙁𝙍𝙀𝙀 𝙎𝙖𝙢𝙥𝙡𝙚: https://www.nextmsc.com/laboratory-information-management-system-market/request-sample

As the world of laboratory management continues to evolve, the 𝙇𝙖𝙗𝙤𝙧𝙖𝙩𝙤𝙧𝙮 𝙄𝙣𝙛𝙤𝙧𝙢𝙖𝙩𝙞𝙤𝙣 𝙈𝙖𝙣𝙖𝙜𝙚𝙢𝙚𝙣𝙩 𝙎𝙮𝙨𝙩𝙚𝙢 (𝙇𝙄𝙈𝙎) 𝙈𝙖𝙧𝙠𝙚𝙩 is experiencing transformative growth. With advancements in technology and an increased focus on efficiency and data integrity, LIMS solutions are becoming indispensable across various industries.

𝙆𝙚𝙮 𝙄𝙣𝙨𝙞𝙜𝙝𝙩𝙨:

𝙈𝙖𝙧𝙠𝙚𝙩 𝙀𝙭𝙥𝙖𝙣𝙨𝙞𝙤𝙣: The LIMS market is on a rapid ascent, driven by the need for streamlined operations and enhanced data management.

𝙏𝙚𝙘𝙝𝙣𝙤𝙡𝙤𝙜𝙞𝙘𝙖𝙡 𝙄𝙣𝙣𝙤𝙫𝙖𝙩𝙞𝙤𝙣𝙨: Integration with cloud computing, AI, and IoT is revolutionizing how laboratories manage and analyze data.

𝙍𝙚𝙜𝙪𝙡𝙖𝙩𝙤𝙧𝙮 𝘾𝙤𝙢𝙥𝙡𝙞𝙖𝙣𝙘𝙚: Enhanced capabilities to meet stringent regulatory requirements are propelling the adoption of LIMS.

𝙒𝙝𝙮 𝙄𝙩 𝙈𝙖𝙩𝙩𝙚𝙧𝙨: Efficiency & Accuracy: LIMS solutions optimize workflow, reduce errors, and ensure precise data tracking.

𝘿𝙖𝙩𝙖 𝙎𝙚𝙘𝙪𝙧𝙞𝙩𝙮: Advanced systems offer robust security features to protect sensitive information.

𝙎𝙘𝙖𝙡𝙖𝙗𝙞𝙡𝙞𝙩𝙮: LIMS can be tailored to meet the needs of small labs and large research facilities alike.

𝙆𝙚𝙮 𝙋𝙡𝙖𝙮𝙚𝙧𝙨:

Thermo Fisher Scientific

LabWare

The Chatterjee Group

McKesson Corporation

LabLynx

Computing Solutions

Labworks LLC

Illumina

Novatek International

Agilent Technologies, Inc.

𝘼𝙘𝙘𝙚𝙨𝙨 𝙁𝙪𝙡𝙡 𝙍𝙚𝙥𝙤𝙧𝙩: https://www.nextmsc.com/report/laboratory-information-management-system-market

As we look towards the future, the LIMS market is poised for continued innovation and growth, paving the way for more efficient and effective laboratory management.

Let’s stay ahead of the curve and explore the exciting opportunities within the LIMS landscape!

#LIMS#laboratory management#data in tegration#innovation#marke tgrowth#tech trends#data security#market research#market trends#healthcare

0 notes

Text

The Essence of the Clay Disintegration Process and Realization Ways - Juniper publishers

Journal of Insights in Mining Science & Technology

Abstract

The power estimation of a disintegration process of clay is given based on the physical phenomena of interaction of thin particles in the clay unit. The method of volumetric processing of the disintegration process is proposed. Now the perspective directions in ore dressing is the acoustic method. An acoustic method of clay processing allows treatment all volumes of materials. The results of experimental researches of various types of clay raw material are given. The power parameters of a disintegration process are estimated.

Keywords: Clay; Disintegration; Particle binding structure

Highlights

a. The acoustic principle of disintegration is due to the proportionality of the particle size, the nature of the connection between particles in clay aggregates and wave low-frequency processing.

b. Complete disintegration of clay is possible with the use of three-dimensional processing.

c. The energy costs of real disintegration are 2 to 3.5 times higher than the theoretical.

Introduction

The receipt of commercial products from the mineral resources of clay materials has a wide range of applications: gold from placers, the production of ceramic products, refractory materials, building materials, etc. When working with clay, the first operation is disintegration. Applied disintegration equipment in technological complexes has high energy indices [1-4]. Virtually all technological processes are based on the mechanical principle of processing. The existing methods of clay disintegration are very energy-consuming and labor-intensive. Moreover, the equipment for disintegration has a restriction on the content of clay. Thus, technological complexes for extracting gold from placers cannot be profitable for the development of sands with a clay content of more than 25-40% due to high losses with incomplete disintegration. To date, almost all available placers with a clay content of less than 50% have been worked out.

However, significant gold reserves remain in the primary zones of weathering (oxidation zone) and in placer deposits with a high clay content [5]. A characteristic feature of the weathering crust is a high clay content (up to 90-100%). The gold content in weathering crusts can be 5 g/t and more [6]. The involvement of such deposits in operation is possible with a reduction in costs for the process of disintegration. If we take into account the nature

of particle bonds in clay aggregates, then we must abandon the mechanical principle of destruction of clay aggregates.

For such small sizes of clay particles (1-3 μm) disintegration based on mechanical treatment of the material will not ensure complete disintegration. The clay material is a set of mineral particles physically bound in a common skeleton through water [7,8]. Water in the structure of clay plays the main binding role. Water can be in the adsorbed state and under the conditions of film water (Figure 1).

In a layer of adsorbed water, allocate a layer snug against the surface of a particle, which have properties like a solid body (thickness 1-3 molecules) and somatic layer having some mobility (thickness 10 - 20 molecules). The film water forms a film atop adsorbed water. The film water presence is determined by the excess of humidity of the breed above by its maximal hygroscopicity.

A more rational methods, which are commensurate with the particle size in clay aggregates, for disintegration are methods of volume effect [7-9]. To assess the applicability of the methods of volumetric disintegration, it is necessary to estimate the magnitude of the energy impact for breaking the bonds between the particles.

Estimation of Power Consumption at Disintegration Process

The mineral particles of aggregate are strongly kept in a skeleton by intermolecular forces of an attraction. Basically, it is forces of a superficial tension. In clay material than the particle has less in size, then the more it has of relative surfaces. Consequently, it has stronger contact to adjacent particles. The clay aggregate strength provides the contact of particles among themselves through an area of a layer adsorbed water. The connection of particles through the medium of film water will cause their relative mobility. The connection of clay particles through the medium of free water will cause their full independence in the system. The connection forces are determined by the power of one contract and their number, and do not depend from properties of clay particles in the mix.

The mathematical expression [9] determine the force of one contact between clay particles of the spherical form:

2 12 /ma AF ⋅⋅ =

Where,

A - Van der Waals’ constant (takes into account a nature of cooperating bodies),

a - radius of an element,

m - thickness of dispersion layer of medium between particles.

The potential energy of an attraction between two particles of the spherical form is determined by the expression:

m à Àq 12 /⋅ −=

The specific potential energy of interaction will be determined by the following expression:

ma A Q o o ⋅⋅ − = 12 χ

where: 0 χ - common number of contacts of interaction.

The clay particles have the various forms and sizes [8]. The greatest connection force of particles is observed in their interaction at a level of an enclosure-adsorbed water (aggregate condition of clay). Kinetic energy of on the level of adsorbed water corresponds corresponds to the quantity of heat of wetting a surface [8] (116.10-3 J/m2) (Figure 1a). The least force interaction lies in the limits of a double layer of film water (Figure 1b). The full absence of connection between particles may be achieved if a presence of adjacent particles is outside distance of a double layer of adsorbed water plus double layer of film water (Figure 1c) (absolute disintegration).

Absolute disintegration of clay requires power consumption in size of destruction energy of all connections of interaction. The volume of disintegration energy will have an essential difference depending on a share of clay aggregates presence of units in an initial material and from the sizes of initial clay particles. The absolute disintegration of clay aggregates of kaolin clay from the account of destruction of Van der Waals’ attractive force will occur through applying of energy of the order ~ 300 kJ/m3.

The disintegration essence consists in achievement of complete disclosing of surface of extracting minerals. For the technological purposes the achievement absolute clay disintegration has not always been necessary. For example, the washing of a lump material, should supply removal clay pug from a surface of the pieces. Thus, the part of a clay material can remain in a clay aggregate condition and it is not reflected in result of washing. At gravitational extraction of gold from gold-bearing sand the disintegration is necessary for all material up to the minimal size in ~ 30 micron. For gold extraction by flotation method the size of particles in pulp should not exceed 3 - 5 micron. The basic result of a process of washing is the achievement of full disintegration for further technological operation with mineral raw material. Thus, a degree of disintegration, which suffice of complete surface disclosing of extracting component for used technology of processing has name as full disintegration. The necessary values of energy for full disintegration will be essential to change depending on required product size. The rough characteristic of energy expenses for disintegration of kaolin clay depending on the various sizes of particle is given in (Figure 2).

The greatest energy (~ 400 kJ/m3) is required to be applied for clay disintegration up to product size in 1 micron. Such order of size of power expenses is characteristic for aggregating (adsorbed) of a clay condition trend 1). At initial loosely packed clay condition the disintegration energy up to the similar sizes, is re duced essentially (~ 70 KJ/m3) (Figure 2, trend 2). The results of experimental data of full destruction of connections between clay particles in bentonite clay by shock wave method [7], researchers of acoustic technology in field of dressing and our experiments (see further) confirm the order of size power consumption of clay disintegration [9].

The characteristic of power consumption for the clay disintegration process is based on theoretical account of the forces of a superficial tension of Van der Waals’. Thus, the estimation of meanings of power disintegration consumption represents a theoretical account of the ideal process of unitary destruction of influence contact forces. Given the power characteristics of a disintegration process, characterize the order of size of energy, which is necessary for applying for loosening of particles.

The real disintegration process represents the more complex mechanism. First, the all clay materials have a thixotropic property. The restoration of the broken connections between particles takes place always and very quickly. The speed of their renewal after infringement is commensurable with the speed of the break. The regeneration of connections between particles can occur through the covering of adsorbed and film water and to become isolated only on a layer of free water. Only at connections on free water there is no mutual influence of particle.

The achieved condition of relative freedom of particles is possible during the long period of time. As a rule, it is enough of this period of time not only for the subsequent technological process of extraction, but also it is required of additional technical and technological intervention for directed sedimentation in slurry pond. The absolute disintegration in real process is provided rather difficultly. The disintegration process is poorly controllable in volume.

If to supervise the submission of capacity (even with account of efficiency), the part of a material will achieve a stage of absolute disintegration, the size of other parts can remain considerably exceeded of required fineness. At non-uniform distribution of useful component (the particles of gold in gold-bearing sand of placer deposit) are probable overoptimism high losses. For similar conditions of gold-bearing sand dressing the achievement of a repeatedly exceeding degree of disintegration is more acceptable.

The size was determined mean by really using disintegration method. The analysis of disintegration methods shows advantages of acoustic processing of clay. The principle of acoustic influence allows achieving high meanings of oscillatory speed and acceleration in the large technological volumes in high sound pressure. At the passage of acoustic fluctuations, the spatial skeleton of a processable material collapses from the high speed of deformation, which take a place owing to break of pressure and movement speed of particles to jump.

The distinctive feature of an acoustic method of disintegration is at the capacity of a wave exceeding critical meaning, in a medium where appear the shock waves of local action are formed which causing highly destroying influences on objects, contiguous to this zone. In acoustic methods the low-frequency range is more acceptable. First of all, the basic advantage acoustic treatment in a low-frequency range is a low factor of attenuation of waves [7], it allows to process a material in the large technological volumes.

Because of the thixotropic properties of clay, a single disruption of the bonds between the particles is not enough. In the space between the particles in the case of broken bonds, free water must be introduced. Only in this case the connection will be closed to a new free level. Due to the fact that clays have thixotropic properties, then a single disruption of the bonds between the particles is not enough.

All connections are restored. In the space between the particles in the case of broken bonds, free water must be introduced. Only in this case the connections of the particles will be closed at a new free level. Only acoustic processing is not enough. The delivery of water to the clay particles in aggregates can be carried out by vibration or mixing. The researches processing of a clay material in a way of acoustic influence in laboratory installation is shown a basic opportunity of application of such method in scales accepted to use in industrial conditions (Figure 3).

Laboratory installation generates low-frequency fluctuations in the range of 23 – 28 Hz by clasping an elastically compressed plate in the working chamber. This version of the generation of acoustic pulses is accompanied by vibration mixing. Processing can be carried out in flow mode. The results of laboratory studies have shown that the use of this method provides complete disinfection of pure clay material in 3 – 5 times lower costs with minimal water consumption per process (in limit 1:1).

Conclusion

In accounts of potential energy of interaction of disperse particles the only basic molecular Van der Waals’ attractive forces are taken into account (without electrosuperficial equilibrium forces of pushing away). With account of the natural size of particles of clay material the absolute disintegration requires application of energy influence not less than 300 kJ/m3. This meaning of necessary energy does not take into account such properties of a researched material as thixotropy and geological features of a place of natural material localization and mineral composition. Nevertheless, the order of size of energy allows to predict power parameters of the ore dressing process. Among existing disintegration methods and means of a clay material a method of acoustic processing favorably differs. On the experimental setup, the actual specific energy costs were higher than the theoretical theoretical ones by 2 to 3.5 times. During experimental researches on laboratory installation was established, that most difficultly collapse. This clay type has very thin particles. The efficiency of disintegration of hidromica clay grows at 15 %, and of montmorillonite clay - at 30 % in comparison with kaolin clay.

To Know More About Insights in Mining Science & Technology click on: https://juniperpublishers.com/imst/index.php

To Know More About Open Access Journals Please click on: https://juniperpublishers.com/index.php

#Juniper Publishers#peer review journals#Juniper publishers reviews#Open access journals#Mining science and technology

0 notes

Text

Multiomics data analysis using tensor decomposition based unsupervised feature extraction --Comparison with DIABLO--

Multiomics data analysis is the central issue of genomics science. In spite of that, there are not well defined methods that can integrate multomics data sets, which are formatted as matrices with different sizes. In this paper, I propose the usage of tensor decomposition based unsupervised feature ex-traction as a data mining tool for multiomics data set. It can successfully in-tegrate miRNA expression, mRNA expression and proteome, which were used as a demonstration example of DIABLO that is the recently proposed advanced method for the integrated analysis of multiomics data set. http://dlvr.it/R1mgVr

0 notes

Text

ABB Acquires Tekomar Enabling Better Performance For Marine Customers

ABB Turbo Systems Ltd. has signed an agreement to acquire Tekomar Group Ltd. headquartered in Winterthur, Switzerland. ABB will further develop Tekomar’s digital solution for engine analytics and advisory systems enabling better performance for marine customers. Advancing ABB capabilities in performance modelling and analysis, this acquisition will also further extend the group’s ABB AbilityTM portfolio of digital products and services. The transaction is expected to be closed during Q4 2017.

With this acquisition, ABB extends its digital portfolio with a propulsion performance monitoring so-lution targeted at two-stroke main engines and auxiliary engine applications. The solution will be in-tegrated into ABB’s established vessel optimization system, further enabling ship management com-panies to know more about their vessel operations and achieve more from their fleets for better busi-ness performance. It also offers a platform for cooperation with the engine licensors and builders.

Image Credits: abb.com

Proven in the field, the operators of over 1,000 ships are already benefiting from this performance monitoring and advisory solution. It provides operators with recommendations for achieving opti-mized and original levels of engine performance. With this expertise from Tekomar, ABB is further advancing its marine industry and vessel operations experience to enhance value for customers.

Oliver Riemenschneider, Managing Director, ABB Turbocharging explained, “This acquisition is exactly the right fit with the existing strengths and capabilities of ABB in the marine industry, and with our strategic vision for developing value-driven digital solutions. As a global market player, ABB is perfectly positioned to bring to the highly globalized and demanding marine market a holistic digital solution for vessel and ship management. Tekomar’s solution is proven, well-established and a valuable exten-sion to our existing solutions. Our goal is to further empower customers to achieve the benefits of improved performance, reduced fuel consumption, and lower emissions, together with ABB.”

Juha Koskela, Managing Director, ABB Marine & Ports added, “This newly acquired solution from Tekomar rapidly increases the pace at which ABB strengthens its digital marine services portfolio. We are a key part of this digital industry transformation which brings true connectivity of vessels, meas-urement and monitoring, advanced solutions and powerful software for real actionable insights. What our customers gain from these next level solutions is increased productivity, driving their future prof-itability and competitive strength.”

Beat Güttinger, Tekomar co-founder and Head of Global Sales & Marketing, commented on the acquisi-tion, “The market reach of ABB and its heritage as an industrial market leader makes this a natural step for taking our Tekomar XPERT solution forward globally. As the marine industry embraces the oppor-tunities of digitalization for all aspects of optimization and performance improvement, this is an ex-citing time for the advancement of our solutions. We are looking forward to realizing what Tekomar and ABB can do together.”

Extending the ABB Group offering in digitalization, the performance monitoring of ship propulsion, including turbochargers will be embedded into ABB AbilityTM. ABB AbilityTM is integrated Industrial Internet platform, cloud infrastructure and solution portfolio based on ABB’s leading expertise in technologies, industries and digital to allow businesses to harness the power of industrial data.

Reference: abb.com

Report an Error

from Storage Containers https://www.marineinsight.com/shipping-news/abb-acquires-tekomar-enabling-better-performance-marine-customers/ via http://www.rssmix.com/

0 notes

Text

The Essence of the Clay Disintegration Process and Realization Ways - Juniper Publishers

Journal of Insights in Mining Science and Technology

The Essence of the Clay Disintegration Process and Realization Ways

Abstract

The power estimation of a disintegration process of clay is given based on the physical phenomena of interaction of thin particles in the clay unit. The method of volumetric processing of the disintegration process is proposed. Now the perspective directions in ore dressing is the acoustic method. An acoustic method of clay processing allows treatment all volumes of materials. The results of experimental researches of various types of clay raw material are given. The power parameters of a disintegration process are estimated.

Keywords: Clay; Disintegration; Particle binding structure

Highlights

a. The acoustic principle of disintegration is due to the proportionality of the particle size, the nature of the connection between particles in clay aggregates and wave low-frequency processing.

b. Complete disintegration of clay is possible with the use of three-dimensional processing.

c. The energy costs of real disintegration are 2 to 3.5 times higher than the theoretical.

Introduction

The receipt of commercial products from the mineral resources of clay materials has a wide range of applications: gold from placers, the production of ceramic products, refractory materials, building materials, etc. When working with clay, the first operation is disintegration. Applied disintegration equipment in technological complexes has high energy indices [1-4]. Virtually all technological processes are based on the mechanical principle of processing. The existing methods of clay disintegration are very energy-consuming and labor-intensive. Moreover, the equipment for disintegration has a restriction on the content of clay. Thus, technological complexes for extracting gold from placers cannot be profitable for the development of sands with a clay content of more than 25-40% due to high losses with incomplete disintegration. To date, almost all available placers with a clay content of less than 50% have been worked out.

However, significant gold reserves remain in the primary zones of weathering (oxidation zone) and in placer deposits with a high clay content [5]. A characteristic feature of the weathering crust is a high clay content (up to 90-100%). The gold content in weathering crusts can be 5 g/t and more [6]. The involvement of such deposits in operation is possible with a reduction in costs for the process of disintegration. If we take into account the nature

of particle bonds in clay aggregates, then we must abandon the mechanical principle of destruction of clay aggregates.

For such small sizes of clay particles (1-3 μm) disintegration based on mechanical treatment of the material will not ensure complete disintegration. The clay material is a set of mineral particles physically bound in a common skeleton through water [7,8]. Water in the structure of clay plays the main binding role. Water can be in the adsorbed state and under the conditions of film water (Figure 1).

In a layer of adsorbed water, allocate a layer snug against the surface of a particle, which have properties like a solid body (thickness 1-3 molecules) and somatic layer having some mobility (thickness 10 - 20 molecules). The film water forms a film atop adsorbed water. The film water presence is determined by the excess of humidity of the breed above by its maximal hygroscopicity.

A more rational methods, which are commensurate with the particle size in clay aggregates, for disintegration are methods of volume effect [7-9]. To assess the applicability of the methods of volumetric disintegration, it is necessary to estimate the magnitude of the energy impact for breaking the bonds between the particles.

The Essence of the Clay Disintegration Process and Realization Ways

Estimation of Power Consumption at Disintegration Process

The mineral particles of aggregate are strongly kept in a skeleton by intermolecular forces of an attraction. Basically, it is forces of a superficial tension. In clay material than the particle has less in size, then the more it has of relative surfaces. Consequently, it has stronger contact to adjacent particles. The clay aggregate strength provides the contact of particles among themselves through an area of a layer adsorbed water. The connection of particles through the medium of film water will cause their relative mobility. The connection of clay particles through the medium of free water will cause their full independence in the system. The connection forces are determined by the power of one contract and their number, and do not depend from properties of clay particles in the mix.

The mathematical expression [9] determine the force of one contact between clay particles of the spherical form:

2 12 /ma AF ⋅⋅ =

Where,

A - Van der Waals’ constant (takes into account a nature of cooperating bodies),

a - radius of an element,

m - thickness of dispersion layer of medium between particles.

The potential energy of an attraction between two particles of the spherical form is determined by the expression:

m à Àq 12 /⋅ −=

The specific potential energy of interaction will be determined by the following expression:

ma A Q o o ⋅⋅ − = 12 χ

where: 0 χ - common number of contacts of interaction.

The clay particles have the various forms and sizes [8]. The greatest connection force of particles is observed in their interaction at a level of an enclosure-adsorbed water (aggregate condition of clay). Kinetic energy of on the level of adsorbed water corresponds to the quantity of heat of wetting a surface [8] (116.10-3 J/m2) (Figure 1a). The least force interaction lies in the limits of a double layer of film water (Figure 1b). The full absence of connection between particles may be achieved if a presence of adjacent particles is outside distance of a double layer of adsorbed water plus double layer of film water (Figure 1c) (absolute disintegration).

Absolute disintegration of clay requires power consumption in size of destruction energy of all connections of interaction. The volume of disintegration energy will have an essential difference depending on a share of clay aggregates presence of units in an initial material and from the sizes of initial clay particles. The absolute disintegration of clay aggregates of kaolin clay from the account of destruction of Van der Waals’ attractive force will occur through applying of energy of the order ~ 300 kJ/m3.

The disintegration essence consists in achievement of complete disclosing of surface of extracting minerals. For the technological purposes the achievement absolute clay disintegration has not always been necessary. For example, the washing of a lump material, should supply removal clay pug from a surface of the pieces. Thus, the part of a clay material can remain in a clay aggregate condition and it is not reflected in result of washing. At gravitational extraction of gold from gold-bearing sand the disintegration is necessary for all material up to the minimal size in ~ 30 micron. For gold extraction by flotation method the size of particles in pulp should not exceed 3 - 5 micron. The basic result of a process of washing is the achievement of full disintegration for further technological operation with mineral raw material. Thus, a degree of disintegration, which suffice of complete surface disclosing of extracting component for used technology of processing has name as full disintegration. The necessary values of energy for full disintegration will be essential to change depending on required product size. The rough characteristic of energy expenses for disintegration of kaolin clay depending on the various sizes of particle is given in (Figure 2).

The Essence of the Clay Disintegration Process and Realization Ways

The greatest energy (~ 400 kJ/m3) is required to be applied for clay disintegration up to product size in 1 micron. Such order of size of power expenses is characteristic for aggregating (adsorbed) of a clay condition trend 1). At initial loosely packed clay condition the disintegration energy up to the similar sizes, is re duced essentially (~ 70 KJ/m3) (Figure 2, trend 2). The results of experimental data of full destruction of connections between clay particles in bentonite clay by shock wave method [7], researchers of acoustic technology in field of dressing and our experiments (see further) confirm the order of size power consumption of clay disintegration [9].

The characteristic of power consumption for the clay disintegration process is based on theoretical account of the forces of a superficial tension of Van der Waals’. Thus, the estimation of meanings of power disintegration consumption represents a theoretical account of the ideal process of unitary destruction of influence contact forces. Given the power characteristics of a disintegration process, characterize the order of size of energy, which is necessary for applying for loosening of particles.

The real disintegration process represents the more complex mechanism. First, the all clay materials have a thixotropic property. The restoration of the broken connections between particles takes place always and very quickly. The speed of their renewal after infringement is commensurable with the speed of the break. The regeneration of connections between particles can occur through the covering of adsorbed and film water and to become isolated only on a layer of free water. Only at connections on free water there is no mutual influence of particle.

The achieved condition of relative freedom of particles is possible during the long period of time. As a rule, it is enough of this period of time not only for the subsequent technological process of extraction, but also it is required of additional technical and technological intervention for directed sedimentation in slurry pond. The absolute disintegration in real process is provided rather difficultly. The disintegration process is poorly controllable in volume.

If to supervise the submission of capacity (even with account of efficiency), the part of a material will achieve a stage of absolute disintegration, the size of other parts can remain considerably exceeded of required fineness. At non-uniform distribution of useful component (the particles of gold in gold-bearing sand of placer deposit) are probable overoptimism high losses. For similar conditions of gold-bearing sand dressing the achievement of a repeatedly exceeding degree of disintegration is more acceptable.

The size was determined mean by really using disintegration method. The analysis of disintegration methods shows advantages of acoustic processing of clay. The principle of acoustic influence allows achieving high meanings of oscillatory speed and acceleration in the large technological volumes in high sound pressure. At the passage of acoustic fluctuations, the spatial skeleton of a processable material collapses from the high speed of deformation, which take a place owing to break of pressure and movement speed of particles to jump.

The distinctive feature of an acoustic method of disintegration is at the capacity of a wave exceeding critical meaning, in a medium where appear the shock waves of local action are formed which causing highly destroying influences on objects, contiguous to this zone. In acoustic methods the low-frequency range is more acceptable. First of all, the basic advantage acoustic treatment in a low-frequency range is a low factor of attenuation of waves [7], it allows to process a material in the large technological volumes.

Because of the thixotropic properties of clay, a single disruption of the bonds between the particles is not enough. In the space between the particles in the case of broken bonds, free water must be introduced. Only in this case the connection will be closed to a new free level. Due to the fact that clays have thixotropic properties, then a single disruption of the bonds between the particles is not enough.

All connections are restored. In the space between the particles in the case of broken bonds, free water must be introduced. Only in this case the connections of the particles will be closed at a new free level. Only acoustic processing is not enough. The delivery of water to the clay particles in aggregates can be carried out by vibration or mixing. The researches processing of a clay material in a way of acoustic influence in laboratory installation is shown a basic opportunity of application of such method in scales accepted to use in industrial conditions (Figure 3).

The Essence of the Clay Disintegration Process and Realization Ways

Laboratory installation generates low-frequency fluctuations in the range of 23 – 28 Hz by clasping an elastically compressed plate in the working chamber. This version of the generation of acoustic pulses is accompanied by vibration mixing. Processing can be carried out in flow mode. The results of laboratory studies have shown that the use of this method provides complete disinfection of pure clay material in 3 – 5 times lower costs with minimal water consumption per process (in limit 1:1).

Conclusion

In accounts of potential energy of interaction of disperse particles the only basic molecular Van der Waals’ attractive forces are taken into account (without electrosuperficial equilibrium forces of pushing away). With account of the natural size of particles of clay material the absolute disintegration requires application of energy influence not less than 300 kJ/m3. This meaning of necessary energy does not take into account such properties of a researched material as thixotropy and geological features of a place of natural material localization and mineral composition. Nevertheless, the order of size of energy allows to predict power parameters of the ore dressing process. Among existing disintegration methods and means of a clay material a method of acoustic processing favorably differs. On the experimental setup, the actual specific energy costs were higher than the theoretical theoretical ones by 2 to 3.5 times. During experimental researches on laboratory installation was established, that most difficultly collapse. This clay type has very thin particles. The efficiency of disintegration of hidromica clay grows at 15 %, and of montmorillonite clay - at 30 % in comparison with kaolin clay.

To Know More About Insights in Mining Science & Technology Please click on: https://juniperpublishers.com/imst/index.php

To Know More About Open Access Journals Please click on: https://juniperpublishers.com/index.php

#Mining Science & Technology#juniper publishers#Mining Technology#Open Access Journals#Journal of mining science#Juniper publisher reviews#Peer review Journals

0 notes