#double toggle jaw crusher

Text

Jaw Crusher Manufacturers - Stone Crusher Machine Plant

KV Metal Gold Crush is engaged in manufacturing industrial Jaw Crusher and Stone Crusher We specialize in providing Best Material Handling, Jaw Stone Crusher Machine

#sand making machine manufacturer#stone crusher machine manufacturer#jaw crusher machine manufacturer#jaw crusher machine#vibrating screen machine manufacturer#jaw crusher manufacturers#single toggle jaw crusher#double toggle jaw crusher#stone crusher manufacturers#jaw crusher plant manufacturers#stone jaw crusher machine#double toggle jaw crusher manufacturers#jaw stone crusher machine#stone crusher machine plant#stone crusher plant manufacturers#single toggle jaw crusher manufacturers#double toggle stone crusher#m-Sand Making Making#100 tph Stone Crusher Plant#50 tph Stone Crusher Plant#200 tph Stone Crusher Plant#250 tph Stone Crusher Plant#500 tph Stone Crusher Plant with cone crusher#105 tph Stone Crusher Plant#two stage plant manufacturer#three stage plant manufacturer#four stage plant manufacturer

0 notes

Text

Top Jaw Crusher Manufacturer in Indore - Jaw Crusher Machines

Find the top jaw crusher manufacturers, suppliers, dealers, traders and exporters in India Get contact details to buy Jaw Crusher machine at a reasonable price

#jaw crusher manufacturer#stone crusher manufacturer#double toggle jaw crusher#jaw crusher machines#stone crusher machine plant

0 notes

Text

Jaw Crusher Machine Manufacturers and Suppliers in India - R-Techno

Looking for a reliable jaw crusher in Gujarat? Look no further than R-Techno, India's leading manufacturer and supplier of high-quality jaw crushers. Our jaw crushers are designed to easily crush even the toughest materials, making them the perfect choice for a wide range of applications.

At R-Techno, we understand the importance of quality and durability for jaw crushers. That's why all of our products are made from the finest materials and undergo rigorous testing to ensure they meet the highest standards. Whether you need a jaw crusher for mining, construction, or recycling, R-Techno has the perfect solution for you.

Visit: https://www.royaltechnoindia.com/products/single-toggle-grease-type-jaw-crusher

#jaw crusher in gujarat#Double Toggle Oil Type Jaw Crusher Gujarat#Single toggle grease type jaw crusher Rajasthan#Double toggle oil type jaw crusher in gujarat#types of jaw crusher#jaw crusher suppliers#jaw crusher machine manufacturers in india#best jaw crusher in india#jaw crusher machine manufacturers

0 notes

Text

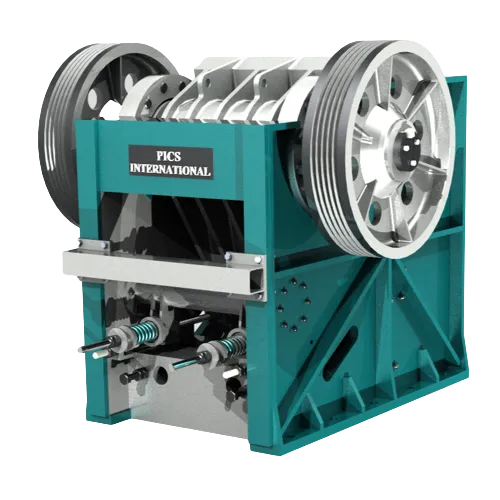

Pics International

We Engineer, We Manufacture,

We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes

Text

Jaw Crusher Market 2022 Increasing Demand with Leading Player

The research reports provide deep insights into the global market revenue, market trends, macro-economic indicators, and governing factors, along with market attractiveness per market segment. The report provides an overview of the growth rate of Jaw Crusher market during the forecast period, i.e., 2022–2030. The report, most importantly, identifies the qualitative impact of various market factors on market segments and geographies. The research segments the market on the basis of product type, application type, technology type, and region. To offer more clarity regarding the industry, the report takes a closer look at the current status of various factors, including but not limited to supply chain management, distribution Trade, channels, supply and demand, and production capability differ across countries.

Get Exclusive Sample Pages of this Report @ https://iconmarketresearch.com/inquiry/sample/IMR1315

Jaw Crusher Market Company Profiles Analysis:

Sandvik AB (Sweden)

Terex Corporation (US)

Metso Corporation (Finland)

thyssenKrupp (Germany)

HARTL CRUSHER (Austria)

FLSmidth (Denmark)

IROCK CRUSHERS (US)

McLanahan (US)

Lippmann-Milwaukee, Inc. (US)

Komatsu Ltd. (Japan)

Westpro Machinery (Canada)

WIRTGEN GROUP (Germany)

Astec Industries, Inc. (US)

The Weir Group PLC (UK)

Eagle Crusher Company, Inc. (US)

Note – The Covid-19 (coronavirus) pandemic is impacting society and the overall economy across the world. The impact of this pandemic is growing day by day as well as affecting the supply chain. The COVID-19 crisis is creating uncertainty in the stock market, massive slowing of supply chain, falling business confidence, and increasing panic among the customer segments. The overall effect of the pandemic is impacting the production process of several industries. This report on ‘Jaw Crusher Market’ provides the analysis on impact on Covid-19 on various business segments and country markets. The reports also showcase market trends and forecast to 2030, factoring the impact of Covid -19 Situation.

Market Segmentation:

Jaw Crusher Market Size, Share & Trends Analysis Report By Swing Jaw Pivoting Position (Blake Jaw Crusher, Dodge Jaw Crusher, and Universal Jaw Crusher), Toggle (Double and Single), Application (Mining, Aggregate, Demolition, Industrial, Construction, and Environmental), Global Industry Insights, Trends, and Forecast, 2021-2028.

For More Discount Details @ https://iconmarketresearch.com/inquiry/discount/IMR1315

Regional Framework

The report provides a detailed overview of the industry including both qualitative and quantitative information. It provides an overview and forecast of the global Jaw Crusher Market based on various segments. It also provides market size and forecast estimates from the year 2022 to 2028 with respect to five major regions. The Jaw Crusher Market by each region is later sub-segmented by respective countries and segments. The report covers the analysis and forecast of 18 countries globally along with the current trend and opportunities prevailing in the region.

Promising Regions & Countries Mentioned in The Jaw Crusher Market Report:

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Major Features of Jaw Crusher Market Report:

Save and reduce time carrying out entry-level research by identifying the growth, size, leading players and segments in the global Jaw Crusher market.

Highlights key business priorities in order to assist companies to realign their business strategies.

The key findings and recommendations highlight crucial progressive industry trends in the global Jaw Crusher market, thereby allowing players across the value chain to develop effective long-term strategies.

Develop/modify business expansion plans by using substantial growth offering developed and emerging markets.

Scrutinize in-depth global market trends and outlook coupled with the factors driving the market, as well as those hindering it.

Enhance the decision-making process by understanding the strategies that underpin commercial interest with respect to client products, segmentation, pricing and distribution.

Purchase a Copy of this Study @ https://iconmarketresearch.com/inquiry/buying/IMR1315

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

About Us:

Icon Market Research is a one-stop industry research provider of actionable intelligence. Through our syndicated and consulting research services, we help our clients get solutions to their research requirements. We specialise in industries such as Semiconductor and Electronics, Aerospace and Défense, Energy, Automotive and Transportation, Healthcare, Manufacturing and Construction, Media and Technology, Chemicals, and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Gaurav B

E-mail: [email protected]

Phone: (+1) 812 506 4440.

0 notes

Text

How To Choose The Right Jaw Crusher

You are likely to be a veteran of the sand, stone, and gravel industries. This means you be aware of the many kinds of crushing equipment. The type of crusher you need such as jaw, cone, impact or gyratory will depend on the place you're working as well as the product you're producing.

The crusher's design and capacities also determine what part of your process it will fit. To perform the required reduction of material there are many crushers at different sites. Each kind of mill liners foundry is unique and is unique and has distinct strengths and advantages.

This article focuses on compression-style jaw crushers, which are most often employed in the primary stage of a crushing circuit. Cone crushers may be utilized in place of jaw crushers. We'll also talk about the reasons why cone crushers are preferred over jaw crushers.

What is a Jaw crusher?

Jaw crushers can be referred to as "rock breakers" that refers to their power and strength. Because they can be capable of breaking even the most challenging and most massive material into smaller fragments Jaw crushers are nearly only used for primary crushers. Jaw crushers offer many advantages such as:

The capability to handle a variety of kinds of materials, such as hard granite as well as reclaimed asphalt pavement (RAP), without requiring as much wear as the primary impact crushers.

Usually, the output is minimal fine material and dust.

The environment friendly primary gyratory crusher is better than secondary gyratory.

Jaw crushers are a good choice in tight spaces like underground mining or mobile crushing due to their size.

What are the Different Types Of Jaw Crushers?

Jaw crushers are a classic crusher model that has been in use for more than 200 years. Jaw crushers have experienced many technological advances through the years. They're nowadays more durable, less difficult to move and less likely to cause choke. Through time, these design adjustments have resulted in a device that's basic enough in its operating principle that it will never become obsolete.

youtube

The main equipment manufacturers provide two kinds of jaw crushers. Although they produce similar outputs, their swing jaw movements are what makes them different.

Double Toggle - Blake Type or Overhead Pivot Moving

Double toggle jaw crushers featuring double toggles, similar to the Blake style, named after Eli Whitney Blake, who invented the first mechanical jaw crusher that was effective, have been popular for crushing abrasive, hard and hard stones, and sticky feeds. These jaw crushers have high energy-efficiency. The overhead pivot style further reduces wear and tear on crusher surfaces in comparison to the Blake design.

Single Toggle--Overhead Eccentric Motion

The single toggle jaw crusher is less than the double toggle version. However, it can accept larger feed sizes. Technological improvements solved the feed size issue, and now these machines are famous for how rapidly they function. While they are more prone to wear than double toggle crushers, spare parts are readily available and affordable.

What's the way a Jaw Crusher work?

Although jaw crushers work differently but the fundamental principle of their operation are the same. All jaw crushers reduce large sized rocks ore, or different materials by means of a compression. The stationary breaking surface is a fixed jaw that is placed in a V-shaped arrangement. The swing jaw, which is movable and presses against the stationary plate, creates an upward pressure on feed materials.

The output gap is located at the bottom V-aligned jaw plates. It determines the dimension of the jaw crusher's finished product. The rock stays in the jaws until it becomes small enough to pass through the gap.

Which are Better: Jaw or Cone Crushers?

While jaw crushers may continually be a wise shredder parts stage choice for many operations however, modern cone crushers are being used in their place due to their the versatility. Both jaw crushers and cone crushers function by compressing material and reducing them by squeezing until they break into pieces.

Cone crushers' advantage offer over jaw crushers is the ability to create a cubical product that is comparable with impact crushers. Cone crushers are traditionally employed as secondary, and, from time to time, tertiary crushing stations.

The context is essential when deciding whether one crusher is better than the other. It all comes down to your production goals and needs.

0 notes

Link

Suppliers of Stone Crusher

Manufacturers of Crusher

#Manufacturer of Double Toggle Oil Jaw Crusher#Manufacturers of Crusher#Suppliers of Stone Crusher#Crushers production companies#Crusher Manufacturing companies#Manufacturer and suppliers of Crushers#Single Toggle Grease Crusher#Manufacturer of Crusher Spare Parts#Sand Making Machine Manufacturers#Mobile Crusher Manufacturers#Mobile Crusher Suppliers#stone crushers companies#Cone Crusher manufacturer#stone Crusher manufacturer#Sand making plant manufacturer#stone crusher impector manufacturer#single toggle grease jaw crusher#double toggle grease jaw crusher

1 note

·

View note

Link

Are you looking for the trusted double toggle jaw crusher manufacturers in India? MechTech Engineers offers elaborate range of both double toggle jaw crusher and single toggle jaw crusher for crushing solutions. For more info, call on 9099211112.

0 notes

Photo

Mewar Hitech is a leading Manufacturers and Suppliers of Crusher. Mewar Hitech Engineering LTD known as Best Stone Crusher company at affordable price.

http://mewarhitech.com/

Suppliers of stone crusher

Manufacturer of Double Toggle Oil Jaw Crusher

Manufacturer of Crushers

Manufacturers of Crusher

Suppliers of Stone Crushers

#Suppliers of stone crusher#Manufacturer of Double Toggle Oil Jaw Crusher#Manufacturer of Crushers#Manufacturers of Crusher#Suppliers of Stone Crushers

0 notes

Text

Jaw crusher Machine Manufacturer by The Malwiya Engineering Works

The Malwiya Engineering Works Company - We are a trusted name in the industry among Supplier of Jaw Crusher in India for designing and supplying high-performance, low maintenance and robust jaw crushers. These are primarily used in the mining, aggregates and recycling industries. Our jaw crushers are capable of crushing even the hardest of stones. The Malwiya Engineering Works is Best Manufacturer of Jaw Crusher in India, an ISO 9001:2008 certified company, delivers the state-of-the-art jaw crushers with minimum maintenance for hard, tough, abrasive material and overload high capacity.

Single Toggle Jaw Crusher Manufacturer

The Malwiya Engineering Works is a one of the prominent Single Toggle Jaw Crusher in India with advanced features for optimized performance, easy maintenance. We are committed to providing you with the best designing and supplying of Single Toggle Jaw Crusher Manufacturers in India from many years, and we know exactly what you need in order to boost your productivity. Our products are safe and easy to operate while delivering optimal output and efficiency.

Valued as a reliable manufacturer, supplier and exporter, we render the premium quality of Single Toggle Jaw Crusher to our esteemed clients. Appreciated for their easy operation and low maintenance, the rendered single toggle jaw crushers make use of single blade for crushing purposes. For manufacturing the rendered single toggle jaw crusher, we make use of latest machinery.

Our Single toggle jaw crusher Manufacturer is made of high-quality cast steel with highly durable components and parts. We, being a renowned name among single toggle jaw crusher deliver crushers ideal for hilly terrain and mobility requirements. Single toggle jaw crushers offer lower maintenance compared to double-toggle jaw crushers. Single toggle jaw crushers find application in mining, quarrying and recycling industry.

Double Toggle Jaw Crushers

Double Toggle Jaw Crusher Manufacturers in India are preferred for crushing ususually hard, abrasive rocks and other materials like ferroalloys and glass. They differ substantially from other types of crushers. There is no rotary motion in the crushing cycle and all crushing is done by compression of the feed material between two massive jaws plates. The moving jaw compresses the material against the stationary jaw. Jaw plates can be either smooth or corrugated.

WORKING PRINCIPLE & ADVANTAGES OF DOUBLE TOGGLE JAW CRUSHER :

Double Toggle Jaw Crushers have one jaw fixed, while the other pivots about a top hinge. This moving jaw is shaped to move firmly and squarely against the material. There is no rubbing or grinding. The moving jaw is very well balanced, so 95% of the drive motor power is ued for crushing. While only 5% of the power is needed to move the jaw itself. As a result of this high mechanical efficiency, double Toggle Jaw Crushers require smaller size motors, keeping power costs down. Behind the stationary jaw are shims, used to adjust the distance between the lower ends of the jaws (closed side setting). The setting determines the output product size. There is also an arrangement of safety arm for protection from us-crushables accidental overloads.

CRUSHING APPLICATIONS OF DOUBLE TOGGLE JAW CRUSHER :

· Granite

· Lime stone

· Ferro Alloys

· Black Trap Rock

· Coal / Coke

· Carborundum

· River Gravel

· Iron ore

· Emery

· Blast Furnace Slag

· Manganese ore

· Bauxite

· Cupriferous slag

· Qaurtzite

· Calcium Carbide

Contact us:

Email-id: [email protected]

Mobile no: +91-9829042530

Website: https://themalwiyaengineeringworks.com/

#Best Manufacturer of Jaw Crusher in India#Supplier of Jaw Crusher in India#Single Toggle Jaw Crusher in India#Best Roller Crusher Supplier in India#Ball Mill Manufacturers in India#Roller Crusher Supplier in India#Ball Mill Supplier in India#Single Toggle Jaw Crusher Manufacturers in India#Double Toggle Jaw Crusher Manufacturers in India#Pulverizer Manufacturer in India#Plate Bending Machine India#Iron Ore Grinding Machine in India#Barytes Grinding Machine in India#Raymond Mill Supplier in India#Best Coal Crusher Machine in India

0 notes

Text

KV Metal Gold Crush is engaged in manufacturing industrial Crushers and Vibrating Screens. We specialize in providing Best Material Handling, Jaw & Stone Crusher Machine

#sand making machine manufacturer#stone crusher machine manufacturer#jaw crusher machine manufacturer#jaw crusher machine#vibrating screen machine manufacturer#jaw crusher manufacturers#single toggle jaw crusher#double toggle jaw crusher#stone crusher manufacturers#jaw crusher plant manufacturers#stone jaw crusher machine#double toggle jaw crusher manufacturers#jaw stone crusher machine#stone crusher machine plant#stone crusher plant manufacturers#single toggle jaw crusher manufacturers#double toggle stone crusher#m-Sand Making Making#100 tph Stone Crusher Plant#50 tph Stone Crusher Plant#200 tph Stone Crusher Plant#250 tph Stone Crusher Plant#500 tph Stone Crusher Plant with cone crusher#105 tph Stone Crusher Plant#two stage plant manufacturer#three stage plant manufacturer#four stage plant manufacturer

0 notes

Text

Top Jaw Crusher Manufacturer in Indore - Jaw Crusher Machines

Find the top jaw crusher manufacturers, suppliers, dealers, traders and exporters in India Get contact details to buy Jaw Crusher machine at a reasonable price

#jaw crusher manufacturer#stone crusher machine#double toggle jaw crusher#jaw crusher machines#stone crusher machine plant

0 notes

Text

Innovative Jaw Crusher Manufacturer in Gujarat - R-Techno

Jaw crusher manufacturer Gujarat. Discover cutting-edge jaw crusher solutions by R-Techno, a leading manufacturer based in Gujarat. With a focus on innovation and superior quality, R-Techno offers a wide range of jaw crushers that are designed to deliver exceptional performance and efficiency. Explore our advanced jaw crusher models today to revolutionize your crushing operations.

Call Today: +91 94273 55384, +91 97256 69755

Visit: https://www.royaltechnoindia.com/products/jaw-crusher-oil-type-manufacturer

#jaw crusher manufacturers in india#jaw crusher in gujarat#types of jaw crusher#jaw crusher india#jaw crusher machine manufacturers in india#double jaw crusher#best jaw crusher in india#jaw crusher machine manufacturers#single toggle jaw crusher

0 notes

Text

#Concrete Recycler Manufacturer in India#Concrete Recycler Manufacturer in Gujarat#Construction Equipments Manufacturer in India#Construction Equipments Manufacturer in Gujarat

0 notes

Text

Just How Do Jaw Crushers Work?

A jaw-crusher is a type crusher, included of the jaw and also jaw placed in a V-shape. The movable jaw compresses material against the rigid jawand beating the material. The substance leaves the jaw throughout the bottom of the crusher otherwise called the discharge opening. Altering the discharge launching controllers the product size created by the crusher.

Jaw-crushers are utilized at the primary period of content reduction for example stone quarries, sand and dirt, mining, building and demolition recycling, structure aggregates, metallurgy, and chemical businesses. If you would like jaw crusher spares on your jaw-crushers, you may consider to see qimingmachinery website.

A jaw crusher's flywheel, toggle plates, forcing engine provide and crank out the crushing motion, and pitman shaft.

The pressure used in jaw crushers for wearing down rock is reached from the 2 jaws of the crusher. One jaw is fixed while the other motions on and back and forth can be know like a swing jaw. The swing jaw is transferred by means of a cam or pitman mechanism, acting in the manner of a lever. The distance between the two jaws is called the crushing chamber. The motion of this swing jaw might be tiny, and is repeated as necessary to break the issue down. A shaft developing an outrageous motion that causes the close of the gap is moved by A weighted flywheel. Qimingmachinery may be the most notable reputable provider of sandvik jaw crusher parts. You will get this products with no doubt.

Jaw crushers need to be more constructed also are heavy-duty machines. The outer frame is manufactured of steel or cast iron. The jaws by on their own are usually assembled from solid steel. They are fitted using liners that are made of manganese metal.

A dual toggle jaw-crusher is more larger, with much more moving pieces and reduced productivity than modern single toggle jaw-crushers. In a double click jaw-crusher, the bizarre lies beneath the jaw. This has two effects, when rock continues to be loaded it keeps the way and one opposite effect is a small plane of movement to get its swinging jaw which leads to the lack of growth. The jaw motions like a door that is hinged on top and is staying pushed open and pulled closed. One plate goes contrary to the bottom of the eccentric arm towards the underparts of the the swinging jawand also the flip toggle plate extends contrary to the other side of the base of the bizarre arm into a point towards front of the jaw-crusher frame. To find out crusher jaw plates you may hunt online.

In contrast, the single toggle jaw crusher contains fewer shafts and bearings and also one toggle that goes from the bottom of the thoracic jaw into a predetermined level in the back of the jaw crusher. The bizarre is situated at the peak of the swinging jaw and also can be a portion of the shaft. The advantage of this is that the jaw includes two motions that are currently happening at the same time. It has the swinging door motion the dual toggle includes, but also includes the up and down motion from the eccentric. This allows a higher productivity speed.

1 note

·

View note

Text

Exactly How Perform Jaw-Crushers Function?

A jaw crusher can be really a style crusher, comprised of a jaw and also moving jaw positioned at a V-shape. The jaw compresses material against the rigid jaw, beating the cloth into the desirable measurement. The substance leaves the jaw through the base of the crusher otherwise known as the discharge opening. Transforming the release launching controls the item size made by the crusher.

Jaw crushers are mainly utilized in applications at the stage of material reduction, including metallurgy, sand and sand, mining, building and demolition recycling, construction aggregates, rock quarries, and chemical businesses. In the event you desire metso jaw crusher parts to the jaw crushers, you may take into account to see qimingmachinery website.

A jaw-crusher's flywheel, toggle plates, pitman rotating shaft, and forcing engine offer and produce the motion.

The stress used in jaw-crushers for breaking rock is reached from both 2 jaws of the crusher. 1 jaw is repaired while another motions on and back and can be know being a swing jaw. The swing jaw is transferred by a cam or pitman mechanism, behaving in the manner of a lever. The distance between your two jaws is known as the crushing room. The movement of this swing jaw could be modest, and so is repeated as essential to crack the matter down. A flywheel goes a shaft creating an motion which results in the closing of this gap. Qimingmachinery may be the most effective reputable provider of crusher jaw plates. You may order this tools without any doubt.

Jaw-crushers will need to be more constructed also are heavy duty machines. The outer framework is usually built from steel or cast iron. The jaws on their own are constructed from forged metal. They are fitted using liners that are made of manganese steel.

A dual click jaw crusher is more larger, with much more moving pieces and lower productivity compared to modern toggle jaw crushers. In a double click jaw-crusher, the bizarre is located behind the swinging jaw. It's two impacts, it keeps the way when stone is being rich and one effect is really a restricted plane of movement for the jaw that leads to the deficiency of productivity. The jaw motions like a door that is currently staying pushed open and is hinged on top and pulled closed. 1 plate extends contrary to the underparts of the the bizarre arm for the base of the the swinging jaw, the toggle plate goes from the opposite side of the base of the arm into some point towards front of the jaw crusher framework. For find out jaw crusher wear parts you can search internet.

By comparison, the single toggle jaw-crusher includes fewer bearings and bottoms and only 1 toggle which goes from the bottom of the swinging jaw to some predetermined position at the back part of the jaw-crusher. The eccentric is directly located on top of the swinging jaw and also can be part of the rotating shaft. The reward of this is that the jaw has two motions that are taking place in an identical time. It even has the same swinging door motion that the dual toggle includes, however, also includes up the up and downward movement in the bizarre. It allows a higher productivity rate.

1 note

·

View note