#eddycurrenttesting

Explore tagged Tumblr posts

Text

Automated Eddy Current Testing Machine - Magkraftndt

An Eddy Current Testing Machine is an automated machine that uses electromagnetic fields to detect surface and subsurface defects in metallic parts. This system enables fast, accurate, and non-contact inspection based on computerized techniques, which in turn promotes quality control and productivity.

#magkraftndt#eddycurrenttesting#nondestructivetesting#materialtesting#inspectiontechnology#mpimachine#magneticparticletestingmachine#demagnetizermachine#magnafluxmachine#mpimachinemanufacturer

0 notes

Text

NDT Inspection Services - Best NDT Inspection

When it comes to ensuring the safety, reliability, and quality of your assets, there's no room for compromise. That’s why businesses across industries trust Best NDT Inspection for their NDT Inspection Services. We deliver accuracy and dependability to every project thanks to our years of experience and staff of knowledgeable professionals.

Comprehensive NDT Inspection Services You Can Rely On

At Best NDT Inspection, we offer a full range of NDT Inspection Services designed to detect defects, prevent failures, and ensure compliance with industry standards. Whether you’re working in construction, oil and gas, manufacturing, or aerospace, our services are tailored to meet your unique needs.

Our capabilities include:

Magnetic Particle Inspection (MPI)

Our Magnetic Particle Inspection service is perfect for detecting surface and slightly subsurface defects in ferromagnetic materials. This method is fast, effective, and crucial for identifying cracks that might otherwise go unnoticed. Whether it’s welds, castings, or forgings, we ensure that your components are free from critical flaws.

Penetrant Testing (PT)

When it comes to detecting surface-breaking defects in non-porous materials, Penetrant Testing is one of the most trusted methods. At Best NDT Inspection, we use advanced penetrants and techniques to spot cracks, leaks, and other imperfections that could compromise your product’s quality and performance.

Ultrasonic Testing (UT)

Internal defects don’t stand a chance with our Ultrasonic Testing solutions. By using high-frequency sound waves, we can locate flaws deep within materials without causing any damage. Best NDT Inspection provides accurate, reliable UT services for critical components where internal integrity is essential.

Eddy Current Testing (ECT)

For fast, non-invasive inspections, Eddy Current Testing is a game-changer. Our ECT services are ideal for detecting surface cracks, corrosion, and material thickness variations, especially in conductive materials. We combine technology with expertise to deliver precise results, helping you make informed decisions about maintenance and repair.

Why Partner with Best NDT Inspection?

Experienced Professionals: Our technicians are highly trained and certified, bringing hands-on knowledge to every inspection.

Cutting-Edge Technology: We invest in the latest tools and methods to ensure accuracy and efficiency.

Customized Solutions: Every project is different, and we tailor our inspection plans to meet your specific needs.

Commitment to Quality: At Best NDT Inspection, your safety and success are our priorities.

Contact Us Today

Don't leave safety and quality to chance. Whether you need Magnetic Particle Inspection, Penetrant Testing, Ultrasonic Testing, or Eddy Current Testing, Best NDT Inspection is your trusted partner for world-class NDT Inspection Services.

Phone: 65-84797783

Visit: https://www.bestndtinspection.com/ndt-inspection/

#ndtinspection#ndtservices#bestndtinspection#ultrasonictesting#magneticparticleinspection#penetranttesting#eddycurrenttesting

0 notes

Text

The Potential Of Ultrasonic And Eddy Current Testing For Wind Turbines

Wind turbines are a rising resource of renewable energy with countries across the world turning more concerned regarding energy utilisation. Financiers, project stakeholders and energy regulators need confidence that they can depend on a wind turbine before utilising it in their project. There are several areas of wind turbines that need routine checkups, for instance, inspecting the gear teeth and bearings, or identifying defects and corrosion. NDT or nondestructive testing gives experts the capacity to discover inconsistencies despite not having to use damaging testing measures.

Ultrasonic Tests

Ultrasonic NDT tests are frequently leveraged to examine blades of wind turbines.

Adaptable inspection methods are particularly applicable to wind turbines, because the blade geometries as well as further elements of the turbines comprise uneven geometries and surfaces. Primarily, blades usually have thick attenuation and are made up of compound materials, which is why testing becomes a challenge. Materials that may be present within a turbine blade include:

Typical materials that are found within a turbine blade:

Steel

Iron

Resin

Aluminium

Fibreglass

Turbine blades tend to endure intense stress while functioning and furthermore they also come with inbuilt flaws during manufacture. These flaws can be difficult to detect when you don’t have the proper equipment. Nevertheless, phased array ultrasound is exclusively created to detect and analyse minor flaws minutely.

What's more, advanced ultrasonic systems involve forceful pulses designed to pierce through heavy weld materials, probing into concealed issues that would have kept being unnoticed.

Eddy Current Test

This NDT testing is a viable alternative that is becoming more and more popular for testing wind turbines. Eddy Current Test equipment can identify anomalies on a near-surface and surface level. In the same way as ultrasonic tests, ECT superior in comparison to other NDT tests because it does not call for the use of harmful chemicals or a continual source of electricity. Sophisticated ECT equipment is easily transportable (certain compact instruments can even be held by analysts) and offer single-pass probe features that enable analysts to meticulously cover a big testing area without investing too much time.

Also, just as specific UT techniques provide advantages that typical ultrasonic testing do not offer, likewise specific ECT methods have advantages over conventional eddy current systems. That is why eddy current array (ECA) is being leveraged these days, as it delivers a highly in-depth level of inspection of irregular and flat surfaces. This system supports surface array probes designed to examine welds made up of a range of material types and geometries. Using an ECA probe, analysts can identify cracking and corrosion easily.

Wind turbine manufacturers have to show their turbines work as required under all conditions. NDT tests like Eddy Current testing and ultrasonic testing have proven to be efficient and effective methods to make sure your turbines comply with all pertinent international standards. Testing consultants will guide you through the whole process, ensuring that you gauge your turbine’s performance and challenges.

0 notes

Link

Regular eddy current inspection helps to minimize downtime and allows component replacement/repair to be done on a non-emergent schedule. Maintaining equipment properly and regularly helps to mitigate long-term costs.Read to know more.

0 notes

Photo

Eddy Current Testing is a versatile #NDT method that can be used to detect (near) surface defects in conductive materials without removing the coating. Contact #cutechgroup for more!

Check More - https://bit.ly/312nH1a

Email us - [email protected]

#eddycurrent #eddycurrenttesting #ndtinspection #NDTservices #NDTcompany

0 notes

Text

🔍 Eddy Current Testing in Singapore – Reliable, Accurate, and Non-Destructive! 🔍

Looking for precise Eddy Current Testing (ECT) in Singapore? At Best NDT Inspection, we specialize in detecting surface and sub-surface defects in conductive materials with high accuracy.

✅ Detect cracks, corrosion, and material defects ✅ Non-invasive and highly sensitive inspection ✅ Ideal for aerospace, automotive, and power industries

Ensure safety and quality with expert ECT services in Singapore! Contact us today.

📞 Call: [65-84797783] 🌐 Visit: https://www.bestndtinspection.com/

0 notes

Text

🔍 Eddy Current Testing: Precision in Every Pulse! 🔍

At Best NDT Inspection, we bring you the cutting-edge technology of Eddy Current Testing (ECT) to detect even the smallest flaws in conductive materials. Whether it’s surface cracks, corrosion, or conductivity variations, our expert team ensures accurate and reliable results without compromising the integrity of your components.

✨ Why Choose Eddy Current Testing?

✅Non-destructive and safe ✅Fast and precise detection ✅No need for extensive preparation ✅Ideal for a wide range of industries

🔗 Discover the power of Eddy Current Testing with us!

Visit us: www.bestndtinspection.com

Contact: 65-84797783

0 notes

Link

Eddy current testing is a non-destructive testing (NDT) inspection method used for a variety of purposes, including for flaw detection, material and coating thickness measurements, material identification and establishing the heat treatment condition of certain materials.

0 notes

Link

Eddy current array (ECA) is a nondestructive testing technology that provides the ability to electronically drive multiple eddy current coils, which are placed side by side in the same probe assembly.

0 notes

Photo

Eddy Current Testing - Training & Certifications Check our Schedule - https://bit.ly/2VxS4ul Register Today @ https://bit.ly/3clRcyX Enquire - [email protected] #certifications #eddycurrent #eddycurrenttesting #eddycurrenttraining #eddycurrentcertifications #eddycurrentcourses #NDTtraining #NDTcourses #cutechtraining #cutechcourses #ETcourses #ETtraining

0 notes

Photo

𝐄𝐝𝐝𝐲 𝐂𝐮𝐫𝐫𝐞𝐧𝐭 𝐖𝐞𝐥𝐝 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 Enables rapid scanning of welded structures, for detection of cracking in ferrous components, without the need to remove coatings. Check more derails @ https://bit.ly/2SZ0KXx Ring for more - +65 66650187 #eddycurrenttesting #eddycurrentwelding #eddycurrent #eddycurrentWeldingInspection #NDTServices #NDTCompany #advancedNDTservices #cutechgroup #NDTinspectionservices

0 notes

Photo

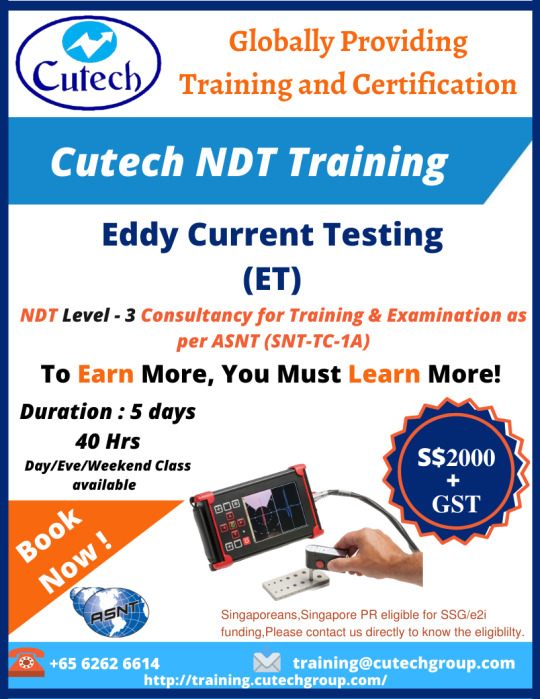

𝐄𝐝𝐝𝐲 𝐂𝐮𝐫𝐫𝐞𝐧𝐭 𝐓𝐞𝐬𝐭𝐢𝐧𝐠 (𝐄𝐓)

Training Courses & Certification @ 𝐂𝐮𝐭𝐞𝐜𝐡 𝐓𝐫𝐚𝐢𝐧𝐢𝐧𝐠.

𝐅𝐨𝐫 𝐌𝐨𝐫𝐞 𝐃𝐞𝐭𝐚𝐢𝐥𝐬 : Email - [email protected] Call us - +65 6262 6614 Location📍 https://bit.ly/2FOPsyW

Get Training and Certification @ Cutech Training!

#training #certification #courses #ET #eddycurrenttesting #ETCourse #NDTtraining #NDTtrainingSingapore #cutechETtraining

0 notes