#erp software yarn manufacturers

Text

What is ERP and how can it be implemented in a manufacturing company?

ERP, or Enterprise Resource Planning, is a software suite designed to improve the efficiency, productivity and profitability of a company. ERP systems aim to automate many of the day-to-day processes of a business, such as accounting, inventory management, customer service and supplier relationships. By streamlining and integrating these key business processes, ERP can improve the overall performance of an organization.

For a manufacturing company, ERP can be used to streamline and automate many of its operations. ERP can be used to integrate the different departments in the company, such as procurement, inventory control, production, finance, and sales. This integration allows for more effective communication and collaboration between teams, resulting in improved efficiency and productivity. ERP can also be used to manage supply chain management, giving the company greater control over its suppliers and their deliveries.

ERP can also be used to improve the accuracy of data, allowing for better decision making. By tracking data from different departments and using advanced analytics, ERP can give a company a better understanding of its performance and identify areas for improvement. ERP can also be used to create detailed reports and give the company an accurate view of its operations.

Implementing ERP in a manufacturing company requires careful planning and execution. Companies must consider their specific needs and goals before selecting and implementing an ERP system. Once the system is in place, companies must ensure proper training is provided to staff and that the system is regularly monitored and updated. Companies must also ensure they are following the laws and regulations related to data security and privacy. By taking these steps, manufacturing companies can enjoy the benefits of ERP and improve their operations.

#ERP Software for zari manufacturer#ERP Software for zari manufacturing#erp software for yarn texturizers#erp software for yarn traders#erp software for yarn dyers#erp software for yarn management#accounting software for textile#erp software yarn manufacturers#erp software for purchase management#erp software for sales management#stringerp

0 notes

Text

Boost Garment Efficiency with LaabamOne Software

In the fast-paced garment industry, efficiency and precision are paramount. LaabamOne's garment ERP software offers comprehensive solutions designed to streamline operations, enhance productivity, and improve profitability. By leveraging advanced technology and real-time data insights, LaabamOne empowers garment manufacturers to achieve operational excellence and stay ahead of the competition.

Order Management: Simplify Order Handling & Tracking

Efficient order management is crucial for garment businesses to meet customer demands and maintain smooth operations. LaabamOne's apparel manufacturing software simplifies order handling and tracking, ensuring that orders are processed accurately and delivered on time. This software provides a centralized platform to manage orders, track their status, and coordinate with production teams, leading to improved customer satisfaction and repeat business.

Production Planning: Optimize Workflows, Meet Deadlines

LaabamOne's textile production management software enables garment manufacturers to optimize production workflows and meet deadlines consistently. By providing tools for detailed production planning and scheduling, this software helps businesses allocate resources effectively, minimize bottlenecks, and ensure timely completion of orders. The result is a streamlined production process that enhances overall efficiency and output.

Inventory Control: Maintain Stock Levels & Avoid Waste

Effective inventory management is vital for reducing costs and avoiding production delays. LaabamOne's garment ERP software offers robust inventory control features that help businesses maintain optimal stock levels and avoid waste. With real-time visibility into fabric, yarn, and finished goods inventory, manufacturers can make informed decisions about purchasing and stock replenishment, leading to better inventory turnover and reduced carrying costs.

Quality Assurance: Ensure Consistent Quality Throughout Production

Maintaining high-quality standards is essential for garment manufacturers to build brand reputation and customer loyalty. LaabamOne's apparel manufacturing software includes quality assurance modules that ensure consistent quality throughout the production process. By tracking quality metrics and implementing standardized inspection procedures, businesses can identify and address defects early, reducing rework and enhancing product quality.

Data-Driven Insights: Make Informed Decisions for Your Garment Business

In today's data-driven world, having access to accurate and timely information is critical for making informed business decisions. LaabamOne's cloud-based garment software provides real-time data insights that help garment manufacturers analyze key performance indicators, identify trends, and make strategic decisions. Whether it's optimizing production schedules, reducing manufacturing costs, or improving inventory management, data-driven insights empower businesses to achieve their goals.

Conclusion

LaabamOne's garment ERP software is a powerful tool designed to boost efficiency, streamline operations, and enhance profitability for garment manufacturers. By simplifying order management, optimizing production planning, maintaining effective inventory control, ensuring consistent quality, and providing data-driven insights, LaabamOne helps businesses navigate the complexities of the garment industry with ease. Embrace LaabamOne to take your garment manufacturing operations to the next level and achieve sustainable growth.

For More Details

9994842010

#textilesoftware#textileproductionmanagementsoftware#apparelmanufacturingsoftware#improvetextileproductionefficiency#reducetextilemanufacturingcosts#optimizetextileinventorymanagement#Garmentmanufacturingsoftware#cloudbasedtextilesoftware#textileERPsoftware#LaabamOnetextilesoftware#LaabamOne Garment ERP Software India#Apparel Production Management Software India#TextileManufacturingERPSoftwareIndia#FashionIndustryERPSystemIndia#StreamlineGarmentManufacturingIndia#InventoryManagementforGarmentIndustryIndia#CloudBasedApparelERPSolutionsIndia#BestERPforGarmentManufacturersIndia#LaabamOnevsOtherGarmentERPSoftware#AffordableGarmentERPSoftwareIndia

0 notes

Text

Advantages and Features of a Textile Erp

In the previous edition of this blog, we understood the operational problems in Textile Industries and the need for an ERP for Textile Industries. Now let us try to understand are advantages of Textile ERP if it is implemented efficiently at your manufacturing unit.

Advantages of implementing ERP

Quality Check of Raw MaterialsThe root of manufacturing is the quality of its raw materials. There is no room for any kind of compromise as it will affect the entire production. To match this criteria quality control in ERP can be used. We have to opt for the desired quality of the raw materials. With this raw materials have to clear a quality test then only they are approved for further production. Using ERP software all the stages of production undergo quality checks.

Increase in salesMaximum clients submit requests for repeated orders. Production, cost and delivery influence the orders. Cost is one of the reasons for losing the client. You can grab this opportunity and offer lower costs using ERP to draw clients’ attention.

Cost savingsThe company offering discounts undergoes a loss of 2% of its sales value which results in surplus production. Adopting quality control of ERP can cut off the overabundant production of products as the company will be sure about the quality and quantity of the raw materials.

Features of DataNote ERP for Textile Industry

Operation-wise accessory information

Production -Machine wise & operator-wise (Rate as per operation/process-wise)

Wastage & Consumption of material during the production process

Quality Parameter wise-Inward QC / WIP QC / FG QC / WIP QC

SOP while issuing material

Production status of orders already in production

Costing details for each product (yarn, fabric, dyed fabric)

Lab dips details to ensure proper shade of the dyed yarn or dyed fabric

Delivery dates and order quantity of various orders

ERP for Textile industry is known for its versatility, and companies have resorted to using the latest technologies that aid in making their work easier and efficient. Companies have started adopting business process reengineering (BPR) activities. They started implementing total productive maintenance (TPM), just-in-time (JIT), supply chain management (SCM), and a lot of inventory management techniques like EOQ, VED, and ABC analysis.

DataNote ERP software to decide the best possible business strategy, effective pricing strategy, real-time achievable business goals, demand management, better finance control, and identification of early trends in sales and marketing.

This Blog is Already Published in Advantages of Textile Erp

Contact No: +91 97370 45567

Email: [email protected]

0 notes

Text

Role of Indian Textile Industry in the Economy

Indian textile industry is one of the biggest in the world and it has a massive base of textiles manufacturing and raw materials. The Indian economy is dependent to a significant extent on the textile trade and manufacturing sector along with the other important industries. India earns almost 27% of its foreign exchange income by exporting clothes and textiles only. This particular sector contributes to around 14% of the industrial production and 3% of the GDP (gross domestic product) of India. The textile industry also contributes approximately 8% of the total excise revenue collected in the country. It also generates 21% of the total employment generated in India.

Role played by the textile industry in Indian economy

Textile industry plays a significant role in the context of the Indian economy. In recent years, the usage of garment manufacturing ERP software has made it even more efficient. In terms of output it is one of the most crucial and biggest sectors in the economy. In fact, this can be said in context of factors such as employment and foreign exchange earnings as well. Following are some statistics to highlight its contribution to Indian economy:

20% of industrial production

9% of excise collections

18% of employment in industrial sector

almost 20% of the total export earnings of the country

4% of the GDP

Almost 35 million people are employed in the sector which makes it the second highest employer in India. The sector also has a direct connection with the rural economy. It also plays a crucial role of important fiber crafts and crops such as the following:

cotton

wool

silk

handicraft

hand loom

They employ millions of artisans and farmers in semi-urban and rural areas. It is estimated that one out of every 6000 people in India is directly dependent on the industry. It also helps that India has several factors working in its favor when it comes to the textile sector.

For starters, it has abundant availability of labor and raw materials. It also helps that it is using garment ERP software, a sure sign of progress. When it comes to global cotton trade it is the second biggest player. It also has the biggest cotton acreage in the world – almost nine million hectares are devoted to the activity. It is also the third biggest producer of cotton fiber in the world. In terms of staple fiber production, it ranks fourth in the world – when you think of production of polyester yarn it ranks fourth in the world. The textile industry is labor intensive too and this is why India has an advantage in this regard.

So, as you can see for yourself, the textile industry of India, has a significant presence of the context of the country’s economy as well! In fact, the same can be said of the international textile economy too! Its contribution to the country’s economy is evident in terms of the contribution that it makes to different areas such as industrial production, foreign exchange earnings, and employment generation.

Having reputed clients in Kolkata, Tiruppur, Ludhiana, Ahmedabad, Delhi and Jaipur MunimjiERP is one of the best Garment/Textile ERP Software Providers in India..

0 notes

Text

Why is ERP software needed for the textile industry

Every industry has its own ERP that is specially designed to support its respective workflow. Here let’s discuss how the textile gets benefited from an ERP solution-

Streamlining manufacturing process

Advanced inventory management system

Hassle-free handling of daily payments and other transactions

Enhancement in the supply chain management

The textile industry is an ever-blooming manufacturing industry across the globe. From yarn making to the manufacturing of clothes, from the collection of raw material to the delivery of manufactured textile products to customers falls under the textile industry.

If you are looking for complete textile stock and business management software, then this answer will help you alot.

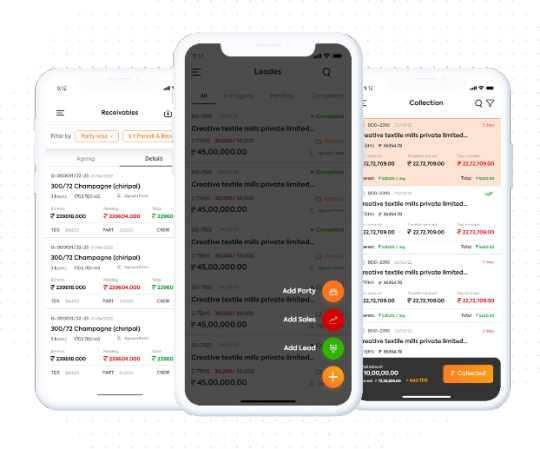

Nowadays, for every textile business VastraApp is the Must-have technology.

VastraApp is the best stock and inventory management app for textile businesses. This is the most innovative inventory management system and complete solution to run your textile business in a better way. It is easy to use mobile app which allowing you to spend more time growing your business than managing it.

This App gives you a complete report of stock and inventory in just one click. Inventory and stock management feature in VastraApp is specially designed to help textile businesses.

VastraApp is the top inventory management solution trusted by thousands of textile businesses. No doubt that VastraApp is the revolutionary Mobile app for textile businesses.

Using VastraApp you can track your entire stock reports in your mobile without depending on any staff member. Also you can track and monitor your textile business designs and material stock anytime anywhere whether you are at home or office

VastraApp enables you to stay connected 24/7 with your business.

If you would like to know more about this innovative mobile application check here :

Visit for more info: https://vastraapp.com/

Phone/WhatsApp Number: +91 80 87 21 22 23

Download from here:-

Android:

https://play.google.com/store/apps/details?id=com.vastra

iOS:

https://apps.apple.com/in/app/vastra-app/id1429785393

1 note

·

View note

Text

Blend it an ERP software (an asset) in your Garments Business – increase Revenue and Productivity !

A Garment Manufacturing ERP software is specially designed for the garments industry that helps garment manufacturers in managing all complex business processes into making them simple - from managing day-to-day business inventories/activities, production, sales orders, marketing & sales, costing, and other miscellaneous tasks.

Store all data in a centralized software Garment Mantra, a creative garments software, can help you to store all your vital data points in a centralized location and lets one share them with the team members and business partners. The info can be accessed at any time, from any location by employees to make improved business decisions.Managing Inventory and Order Tracking Handling supply chains and orders can be done for the garments industry. Though, the software makes the process easy and smooth. One can track interactions with suppliers to better manage the warehouse and get an overview of inventory, stock availability of raw materials, so that the business can fulfill customers’ orders on time.

Customer Relationship Management

Integrating a CRM software with the Garments ERP system, one can gain deep insights into the customer journey, thus, understanding their needs and demands. Companies can track interactions and communication with customers and use various trends and insights to build long lasting and meaningful relationships with your customers. Maintaining great relationships with customers builds trust and satisfaction.Cost regulation Maintaining costs in the garments manufacturing industry can effectively be done using apparel manufacturing software. It offers automation that can help you to reduce human errors and operational costs of a business. It helps replace the old and outdated manual processes and digitizes the process, which is required in today’s day and age.

The garments industry concentrates on designing and/or manufacturing of clothes and the distribution and use of the manufactured garments.The apparel industry has undergone various changes over time. It wants to carry out business in a systematic way. For this change to happen, an ERP software should be used as it plays an important role, mainly in data processing and organization.‘Garments’ is used in the ‘context’ of ‘Manufacture/Sale of Clothes/Apparel.’ ‘Mantra’ is a ‘Sound/Vibration’ – A Solution to a Problem! Garments Mantra is an ERP software system which organizes the unorganized Garments Manufacturing Industry by Managing end-to-end Inventory.It brings about Digital Transformation of the Garments Manufacturing Process.

It helps streamline & automate the operational process, and reduces repetitive work, providing easy access to information.Our Dashboard is customizable, flexible & easily accessible to help you make smart decisions. It is flexible, fast to implement, easy to use, proven to deliver significant and measurable improvements in delivery, productivity, inventory, speed, and cost.

Versatile Features

* Real-Time Inventory Update.

* Purchase Order Management.

* Sales Order Management.

* Production Management.

* Cost Sheet.

* CRM.

The Garment industry faces a number of challenges in key business operations like customers’ needs, inventory control, and cost management. Only an automated apparel management software has the ability to deliver better visibility and insights into main business operations. Garments Mantra is the Best ERP for the Garments and Apparel Industry.INTEGRATION Garments companies are huge and divided into various departments. Scheduling machines cycle times and batch sizes are a challenging one. Garments Mantra enables efficient collaboration and communications.FROM ONE TO MANY The Garments industry uses a few raw materials to manufacture countless finished products. It must be done efficiently and in real time through ERP.

TRACEABILITY Garments Mantra helps in searching a particular fiber or yarn lot across the manufacturing processes starting from a finished good. INVENTORY MANAGEMENT From manufacturing to sales, Inventory Management is the key to efficiency in a business process. Garments Mantra will assure hassle-free order management and improved customer satisfaction.SHORT DELIVERY TIMELong production processes and short delivery time requires planning concepts driven from a partially defined demand and not from a finished item. It will be easily done by Garments Mantra.REPORTING For arriving at fulfilled business decisions, it is important for the industry to analyze reports on regular intervals. Hence, having an ERP software like Garments Mantra, generates relevant reports in real time.

Manage every aspect of your garment manufacturing process with Garments Mantra - Plan production, selling, buying, quality control, and manage inventory efficiently, all in one place.

This ERP software is unique and ideal for digitizing & streamlining your garments manufacture process, making it effective, and helping your business stand out.

We hope your garments manufacturing company will find value in our software – Garments Mantra, a creative all-inclusive garments software!

Cheers

1 note

·

View note

Text

Online tracking of engineering change orders with electronic routings for approvals

Online tracking of engineering change orders with electronic routings for approvals. System generated BOM's and routings for configured products. System generated production schedules from MRP module. Automatic yielding for finished goods and BOM components/ingredients. Where used and mass replace capabilities. System generated work orders for make to order environments. Fully attributed inventory from order entry through production and shipping. Online order promising by exploding the multi-level BOM, reviewing BOM stocking Nylon Poy Yarn levels, and production space. Online messaging for production managers on plant floor exceptions. Integrated dashboards for management's KPI's.

According to Cutlers article, Finding an ERP (enterprise resource planning) system which addresses the idiosyncratic nature of food manufacturing is not easily accomplished. Despite claims, promises, and elements for success, few ERP vendors are comprehensive in providing the full spectrum of needed functionality.

Founded in 1990 and headquartered in Toledo, Ohio, Technology Group International is a proven technology leader delivering Tier 1 application software functionality at a price performance level that can be readily accepted by organizations of all sizes. Specializing in software solutions for small and mid-market manufacturing and distribution companies, TGIs integrated Enterprise Series software suite is a complete business process management solution. The product offering includes Enterprise Resources Planning (ERP), Manufacturing Resource Planning (MRP), Supply Chain Management (SCM), Warehouse Management System (WMS), Advanced Planning and Scheduling (APS), Decision Support System (DSS), Business Intelligence (BI), Manufacturing Execution System (MES), and eCommerce. TGI implements, maintains, enhances, and supports its packaged distribution and manufacturing software solutions directly and via its channel partners.

0 notes

Text

Progress of Intelligent Yarn Spinning Technology in China-Juniper Publishers

Abstract

The paper reviews the history, current situation and prospect of the Intelligent Yarn Spinning (IYS) technology in China, and points that IYS is the trend and keep developing in the futrue.

Keywords: Intelligent yarn spinning (IYS); Intelligent management (IM); Digital workshop of yarn spinning

Opinion

China is the largest country in textile production. There are more than 120M spinning spindles rotating and producing nearly 19M tons of yarns in the country every year. A dramatic change took place in the past 10 years to China textile industry. Intelligent Yarn Spinning (IYS) technology comes into trend in yarn manufacturing and has been promoted to the trade and stands firm.

Necessity of the intelligent yarn spinning (IYS) technology

To upgrade the textile industry, increase efficiency, guarantee quality and improve the international competition, the owners of the Chinese textile mills realized that intelligent technology might help them achieve their goals ten years ago. To the owners of the spinning mill, it seems to be more urgent since they face the shortage of workers, increment of wages and high employee turnover rate due to bad workshop environment and strenuous manual labor. From 2012 to 2016, the labor force population has decreased almost 3.65M each year in China [1]. The decrease might get to balance 10 years later. The worse thing is that the younger generation workers would rather not endure the hard work and the bad environment as the elder generation did. The owners of the textile mills have to seek the replacement by intelligent yarn spinning technology.

History

China government pays much attention to intelligentization of textile industry. As early as in 2001, the 10th five-year development program of China textile industry required that the main textile mills should digitize their manufacturing, designing, management and sales. In 2004, 28 developing fields and 10 key equipment for China textile industry were released. Among them, 4 developing fields were related to digitizing and all the 10 key equipment were related to digitization. Afterwards, the 11st-five year, 12nd-five year and 13rd-five year program are all describing the prospect of intelligentization of the Industry. According to the latest 13rd-five year program, a lot of pilot yarn mills will be set up, realizing automation within whole processes, digital monitoring and management, transporting the materials and semi-products automatically [2]. The labor productivity of the pilot spinning mills with intelligent manufacturing was increased by more than 30%, the production cycle of product development was reduced by more than 20%, the defective product rate decreased by 30% and the employment dropped to 20 workers/ 10000 spindles.

Characteristics

Intelligent yarn spinning includes developing and equipping the digitalized machines, monitoring and managing the whole processes automatically. There are 2 aspects to consider:

Continuity of yarn manufacturing processes: The salient characteristics of the IYS system are the continuity of the yarn manufacturing processes, intelligent control of spinning process, intelligent monitoring of workshop environment and automatic distribution of materials and semi-products. By IYS, digital workshop of yarn spinning can be setup, and the goals to satisfy the high quality, high yield, high efficiency, low energy consumption, less labor and reducing the labor intensity are achieved. The digital workshop of yarn spinning is the integration of digitization of production equipment, digitization of production process and digitization of management.

PLC controller, counter, LCD screen, servo drives, etc. are widely used in individual digital spinning equipment by mechanical and electrical integration. All the machines are connected by networks to transport information.

An intelligent design has been completed to realize computer aided cotton assorting, arranging of cotton bags, picking and blowing-carding unit, lapping-doubling-combing combined unit, roving-spinning-winding unit, bobbin automatic staking, packaging and warehousing, therefore, less than 30 workers are required for 10000 spinning spindles.

In some systems, unwrapping cotton bale can be automatic. Blow-carding unit is widely applied to reduce the weight irregularity and unevenness of slider. Automatic doffing, automatic inserting roving bobbin, automatic keeping end of roving and transport roving bobbin to spinning frame have been completed successfully on a roving frame. The automatic doffing of ring spinning frame, automatic inserting yarn tube, automatic repiecing and keeping end of yarn, automatically delivering the yarn tube to the automatic winding machine have been completed as well. In an automatic winding machine, automatic bobbin changing, automatic repiecing, automatic guiding end, automatic knotting, automatic inspection of yarn defects and cutting, automatic winding, automatic tube yarn delivery, bobbin automatic sorting has been accomplished.

In jet vortex spinning system and the rotor spinning system, one or more processes in doubling, roving or winding is canceled , therefore, the yarn is produced from the slider to the cone yarn directly, which means the efficiency of spinning can be improved further:

After winding, the cone yarn automatic packaging system shall be prescribed by the automatic weighing machine, automatic bag filling machine, automatic strapping machine, and automatic sealing membrane stack unit. The cones of yarn are accurately weighed by an automatic weighing machine, and then the abnormal tubes are temporarily marked overweight and ultra-light. Automatic sealing bagging machine is used to encapsulate the cones of yarn in plastic film and pack the cones into the yarn bag for transporting or warehousing.

Intelligent management (IM): Intelligent Management (IM) system is an indispensable part of IYS system. IM system changes the original management mode and ideology of running enterprise, therefore, workers, equipment and software system are integrated and interconnected. Usually, IM system mainly consists of data collection, data transmission and system functions. IM automatically realizes the collection of data of spinning equipment, spinning production data of the main auxiliary equipment in real-time, online and offline data of quality, data of workshop environment, data of equipment energy consumption, personnel data, etc., then builds enterprise data platform, ensures the production data sharing between ERP and IM system. System functions of IM include equipment online monitoring, power monitoring, environment monitoring, remote control, production scheduling, order management, equipment management, quality management, energy management and integration with ERP system, etc.

On the basis of advanced sensor technology, communication technology, big data, cloud computing and Internet technology, IM system can issue early warning texts and automatically control equipment operation. Through analyzing the data of equipment operation, production data ,energy consumption online, IM system helps optimize management of enterprise, reduce energy consumption, improve the shortcomings of traditional quality control method , stabilize and improve the quality of products. IM system can also be integrated with ERP to generate reports of production and trace the orders automatically. Customers can easily learn about the real-time order progress and quality of the product through Internet.

As soon as enterprise uses IYS system, the product quality is stable and the consistency is terrific, and the production efficiency has been greatly improved.

Application and effectiveness

By using IYS technology, spinning efficiency has been improved enormously. In 1987, as many as 360 workers were needed to operate a textile mill with 10000 spindles in China, and the number of workers decreases to 80 in 2016 [3]. To some very modern mills, the number is only 20. For example in a ring spinning mill of Weiqiao Group, the largest textile mill in the world, 20 workers are required for each 10000 spindles while another textile mill of Ruyi Group needs 15 workers. Huaxing textile mill in Shandong needs only 9 workers, which helps the mill won the first Class Prize 2016 of award for scientific and technological advancement by China National Textile And Apparel Council (CNTAC). Yid a Group sets up a 30000 spindles compact spinning mill at Chang ji in Xinjiang, requires only 45 workers. As for rotor spinning, Litai Silk Road Textile Mill of Jin sheng Group in Xinjiang needs only 6 workers to accomplish the equivalent output. According to the statistics by CNTAC, 2.3M spindles are totally run under IYS system in 2015 and 24.8M spindles are equipped with automatic doffing equipment while 5M spindles are equipped in the roving-spinning-winding unit.

Prospect

The State Council of China issued "Made in China 2025 strategy" in 2015, aiming to accelerate Intelligent manufacturing engineering and key equipment engineering. Meanwhile, The Belt and Road strategy was put forward. Xinjiang area, as the link connecting China and the mid-Asia, west Asia and Europe, began to develop yarn spinning industry because Xinjiang is the largest cotton producing area and plants the best quality cotton. Due to the strategy of " transmitting the spindle from the east area to the west area", yarn mills of 13.6M spindles were setup within 3 years with the encouragement of the government by reducing the taxes and energy costs. Most of the mills are equipped with the latest spinning assembling lines. At the same time, yarn mills at the traditional area have to transform the old machines to the intelligent equipment to adapt the new situation. According to China textile machinery association, the main business revenue of the textile machinery industry was increased by 12.74% and the total profit was increased by 23.11% from Jan 2017 to June 2017. It is estimated that 60M spindles will be equipped on automatic doffing system by 2020, accounting 50% of the production capacity. With the increasing of the spinning speed, the number of the total spinning spindles in China might drop below 100M. Even so, according to this trend, yarn spinning industry will still keep developing IYS at high speed for at least 10 years.

Difficulties

Discontinuity of the some spinning process: Although IYS aims to produce yarn in a continuing production, some processes are interrupted at most IYS system in China. The automatic connections from carding to drawing, from drawing to roving, or from doubling to drawing then to combing seems to be not so important since the labor cost is relative low especially when the enormous investment shall be paid. Automatic Guide Vehicle (AGV) is used as a replacement. Being set by software, AGV will run at the given route carrying semi-products or empty cans or bobbins among the machines. AGV, equipped with infrared obstacle avoidance sensor or ultrasonic obstacle avoidance sensor, is guided by magnetic point navigation control method and Radio Frequency Identification (RFID) technology to ensure the walking precision and the safe performance of the workshop.

Tian men textile machinery Co Ltd begin to develop the new drawing frame with double connectors. Several carding machines are connected to a drawing machine by slider cache device, which can isolate the upstream and downstream supply problem caused by the stop between the carding and drawing, and ensure that the carding machine and the drawing machine work well. Similarly, the drawing machine connects the following roving as well [4].

Yarn breakage in spinning: Currently, it is still necessary to deal with the yarn breakage of ring spinning machine manually, especially when it is a must to guide the yarn through the ring, the guide and yarn hook. The piecing procedure is still to complicate and the automatic piecing is not yet realized. That is why the amount of labor used in ring spinning is three to four times higher than rotor spinning and vertex spinning. It is key technique to solve if the efficiency of ring-spin technology to be improved. If the technique is realized, the true unmanned workshop will appear within 5 years.

Conclusion

Applying intelligent yarn spinning technology represents the general trend, which helps China keep its preponderance in producing yarn. China has made a great achievement in intelligent yarn spinning technology, and the yarn spinning industry will keep its development at high speed for at least 10 years.

To know more about our Journal click on fashion technology advances

To know more about open access journals click on Juniper Publishers

#Juniper publishers publishing group#Open access Journals#Juniper Publishers e-pub#fashion and technology articles#fashion technology advances#fashion technology trends

0 notes

Text

Textile ERP software

Textile ERP software is a type of enterprise resource planning (ERP) software specifically designed for the textile industry. This software helps textile companies manage their operations, from sourcing raw materials to delivering finished products, by integrating various business processes and functions into a single system.

Some of the key features of textile ERP software include:

Material management: To manage the procurement and inventory of raw materials, such as fibers, yarns, and fabrics.

Production planning and control: To plan and control the production process, from raw material to finished product.

Sales and distribution management: To manage sales activities and distribution, including order management, invoicing, and shipping.

Financial management: To manage financial operations, such as accounting, budgeting, and reporting.

Quality control: To ensure that products meet quality standards and customer requirements.

Textile ERP software can help textile companies increase efficiency, improve visibility into operations, and make better-informed decisions. When choosing textile ERP software, it is important to consider the specific needs and requirements of your organization and to choose a solution that is well-suited to your industry.

#accounting software for textile#erp software for purchase management#erp software for sales management#ERP Software for zari manufacturer#ERP Software for zari manufacturing#erp software for yarn texturizers#erp software for yarn traders#erp software for yarn dyers#erp software for yarn management#erp software yarn manufacturers

0 notes

Text

Boost textile efficiency with LaabamOne software

Boost textile efficiency with LaabamOne software by optimizing inventory, streamlining production planning, reducing costs, and ensuring consistent quality. LaabamOne's cloud-based textile ERP provides real-time data insights, helping you make informed decisions for improved productivity and profitability. Embrace LaabamOne to elevate your textile business operations.

Inventory Management: Optimize fabric, yarn, and finished goods stock

Effective inventory management is crucial in the textile industry. With LaabamOne, you can easily optimize textile inventory management by keeping track of fabric, yarn, and finished goods stock in real time. This ensures that you always have the necessary materials on hand without overstocking, reducing storage costs and minimizing waste.

Production Planning: Streamline workflows and meet deadlines

LaabamOne's textile production management software helps you streamline workflows and efficiently plan production schedules. By integrating apparel manufacturing software into your operations, you can ensure that your production processes run smoothly and deadlines are met consistently. This leads to improved productivity and customer satisfaction.

Cost Reduction: Minimize waste and improve profitability

Reducing waste is a key factor in lowering manufacturing costs. LaabamOne textile software allows you to track and manage resources effectively, helping you identify areas where waste can be minimized. By using garment manufacturing software, you can implement best practices that lead to significant cost reductions and increased profitability.

Quality Control: Ensure consistent quality throughout production

Maintaining high-quality standards is essential in the textile industry. LaabamOne's textile ERP software includes robust quality control features that ensure consistency throughout the production process. By monitoring quality at every stage, you can quickly address any issues and maintain the reputation of your brand.

Data-Driven Insights: Make informed decisions for your textile business

Access to accurate, real-time data is critical for making informed business decisions. LaabamOne's cloud-based textile software provides comprehensive analytics and reporting tools that give you valuable insights into your operations. By leveraging this data, you can make strategic decisions that drive growth and improve efficiency.

LaabamOne textile software is designed to empower textile and apparel manufacturers by providing the tools needed to optimize production, reduce costs, and ensure quality. As a leading provider of Indian textile ERP software, LaabamOne is committed to helping businesses in the textile industry achieve operational excellence and sustainable growth. Whether you're looking to improve textile production efficiency or reduce manufacturing costs, LaabamOne has the solutions you need.

By integrating LaabamOne's textile production management software, you can streamline your operations, meet deadlines, and improve profitability. The software's inventory management capabilities ensure that you always have the necessary materials on hand, reducing waste and storage costs. With its robust quality control features, you can maintain high standards throughout the production process.

conclusion :

LaabamOne textile software offers comprehensive solutions tailored to the needs of the textile industry. By optimizing inventory, streamlining production planning, reducing costs, and ensuring quality, LaabamOne empowers businesses to thrive in a competitive market. Embrace the power of LaabamOne textile software to boost your textile business efficiency and achieve sustainable growth.

For More Details

https://www.laabam.one/ 9994842010

#textilesoftware#textileproductionmanagementsoftware#apparelmanufacturingsoftware#improvetextileproductionefficiency#reducetextilemanufacturingcosts#optimizetextileinventorymanagement#Garmentmanufacturingsoftware#cloudbasedtextilesoftware#textileERPsoftware#LaabamOnetextilesoftware

0 notes

Text

Ultra-Strong Art remote monitoring ificial Muscles Made From Carbon Nanotubes

www.inhandnetworks.com

In order to showcase ultra-strong artificial muscles, Ray Baughman from the University of Texas at Dallas and his colleagues built a catapult.

The scientists published their findings in the journal Science. The device contains yarns similar in diameter to human hair, spun from carbon nanotubes and soaked in paraffin wax. When a current is passed through the yarn, the wax heats up and expands. As the yarn swells, its particular helical weave causes it to shorten, and the muscle contracts. As it cools, the yarn relaxes and returns to its original length. When coiled lightly or heated to high enough temperatures, wax-free yarns behave in the same fashion.

The torque produced by the twisting and untwisting of the yarns is sufficient to power a miniature catapult. The yarn can haul 200 times the weight that a natural muscle of the same size can, an retail d generates more torque than a large electric motor if compared by weight. Currently, the available manufacturing t industrial networking echniques have limited the weight of the yarn. They can make yarn that lifts up 50 grams. That doesn’t sound like much, but researchers have shown the nanotube yarns lifting loads as much as 50,000 times greater than their own weight.

The yarn could be used as actuators in microfluidic systems or as components in optical cameras, within 2 years. They could also be used as intelligent sensors.

Video courtesy of The Alan G. MacDiarmid NanoTech Institute, The University of Texas at Dallas.

InHandGo Photothermal torsional actuation of a half-wax-filled fermat carbon nanotube yarn

[via Nature]

Tags: cellular modem ethernet, 4g LTE router, 3g wireless router, 4g LTE router with SIM card, cellular router vendor, verizon 4g LTE router, best industrial wifi router, 4g modem router, 4g modem router wifi, att 4g router, cellular router wifi, industrial multi sim cellular router, m2m cellular router, verizon industrial router, 4g lte gateway, 4g lte modem, industrial cellular vpn router, industrial 3g m2m, industrial l2tp cellular router, industrial ethernet router, plc router, 12vdc lte router, 4g lte router dual SIM, multi SIM LTE router, cellular router manufacturer, edge gateway, industrial iot gateway, overhead line sensor, distribution line sensor, distribution line fault detection, medium voltage smart grid sensor, MV smart grid sensor, smart grid sensor, power line sensor, power sensor, MV sensor, Grid Fault Detection, Line Monitoring, Grid Analytics, Predictive Grid Analytics, Grid Monitoring, Grid Analytics System, Power Fault Detection, Advanced Grid Analytics, Intelligent Line Monitoring, distribution fault detection, smart vending machine, smart vending solutions, QR code vending machine, telemetry vending machine, intelligent vending machine, touch screen for vending machine, vending software, cashless vending, coupon vending machine, iot vending machine, vending machine card reader, POS vending machine, smart vending machine software, credit card vending machine, Industrial router, cellular router, 4g router, LTE router, 3g router, M2M router, wireless router, wireless m2m router, wireless m2m, Industrial Wireless M2M, Industrial Wireless M2M Router, Industrial Wireless M2M products, M2M wireless producdts, WiFi M2M Router, Industrial Wireless M2M gateway, industrial IoT router, industrial IoT gateway, industrial LTE router, Industrial router, cellular router, 4g router , LTE router, 3g router , M2M router, wireless router, wireless m2m router, WiFi M2M Router, Industrial Wireless M2M Router, M2M IoT router, industrial wireless router, industrial M2M router, industrial LTE router, Industrial VPN router, Dual SIM M2M router, M2M gateway, IoT gateway, Industrial router, low cost industrial router , low cost cellular router, low-cost LTE router, low-cost M2M router, compact industrial router, low-cost cellular router , cellular router, low-cost 4g router , LTE router, 3g router , M2M router, wireless router, wireless m2m router, WiFi M2M Router, Industrial Wireless M2M Router, M2M IoT router, industrial wireless router, industrial M2M router, industrial LTE router, Industrial VPN router, Dual SIM M2M router, M2M gateway, IoT gateway, LTE Cat 1 router, Embedded LTE Cat 1 router, Industrial LTE Cat 1 router, Verizon Embedded modem, Verizon Embedded router, Overhead Line Monitoring, Distribution Power Line Monitoring, Fault detection & location, Grid Analytics System, Remote Machine Monitoring & Maintenance System, IoT Remote Monitoring, Prognostics and Health Management, Remote connectivity, Remote Maintenance, Smart Vending, smart vending, InHandGo, retrofit, touchscreen vending, cashless vending, cloud VMS, Transformer Monitoring, Transformer Monitoring, substation monitoring, grid LTE router, wireless communication, smart grid, Remote Automation, Remote Automation, Secure remote networks, web SCADA, Remote Diagnostics, Remote PLC programming, Intelligent Traffic Enforcement, Intelligent Traffic Enforcement, wireless networking, cellular router, Wireless ATM Solution, Wireless ATM, ATM Remote Diagnostic, prestashop 多语商城, opencart 外贸商城, 网页设计, 网站建设, 企业建站, 商城网站, 集团网站, 海外网站, 营销网站, 网站推广, 华人网站建设, 华人网站维护, 华人网络兼职, china webdesign, webdesign, seo, joomla web design, 香港網頁設計, 網站建設, 企業建站, 商城網站, 集團網站, 海外網站, 營銷網站, 網站推廣, web design, joomla webdesign, wordpress webdesign, opencart webdesign, magento webdesign, durpal webdesign, vtiger crm, adempiere erp, compiere erp, hosting, domains, vps, email marketing, joomla 网页设计, wordpress 建站, magento 大型外贸商城, durpal 门户网站, seo 网站推广, 网站自然排名, joomla 網站製作, wordpress 定制開發, opencart 維護修改, prestashop 模板修改, magento 培訓實施, durpal 定制修改, seo 營銷推廣, 外鏈收錄排位, joomla, wordpress, opencart, prestashop, magento, durpal, zencart, crm, erp, edm, marketing, joomla template, wordpress themes, magento themes, opencart themes, prestashop themes, 崀山, 崀山科技, 崀山科技全球服务中心, LangShan Technology Global Service Center, LangShan Technology, langshantech, LangShan, china webdesign, 網頁製作, 網頁設計, 企业建站, 企業建站, 在線商城, 營銷網站, 網站推廣, 網站營銷,

#3g shutdown#4g lte modem#azure iot gateway#cellular connectivity#cellular iot#Cellular Networks Migrating#coupon vending machine#credit card vending machine#Digital Signage Connection

0 notes

Video

ERP for Textile Industry Pridesys IT Ltd by pridesysit

Via Flickr:

Our Pridesys ERP is the best textile software helps to increase the quantity produced and efficiency of your manufacturing process. It keeps records of any changes and also helps to detect any technical errors. Our Pridesys ERP keeps accurate records of your payments and receipts and also help to improve networking and collaboration. But the main reason why our Pridesys ERP is considered as the best textile solution is because it helps to reduce cost. Our Pridesys ERP is programmed in such a way that enables you to pre-plan your steps ahead and thus help to cut down your cost by a huge margin. Our Pridesys ERP is your best textile software solution.To know more, visit:http://bit.ly/erp-for-textile-industry #erp #textile #industry #clothes #yarn #textileindustries

#ERP for Textile industry#erp modules for textile industry#best erp software for textile industry#ERPfortextile#best Textile solution#best Textile software#Best ERP for Textile industry#Best ERP for Textile#Most implemented Textile software#best Textile solution for Bangladesh#best Textile software for Bangladesh

0 notes

Text

Cotton fights back

“Synthetic fibres have been associated with performance innovation for too long and we are now showcasing innovative technologies that will inspire brands with new ideas for cotton and cotton-blended fabrics,” said CCI executive director Bruce Atherley at the show. “The objective is to inspire everyone in the textile business to think about the many opportunities with US cotton.”Copper infusionAmong partners is Argaman Technologies with its CottonX skincare technology. This infuses 100% natural cotton with a copper compound which helps promote skin regeneration and collagen synthesis, for smoother and healthier-looking skin.There are no coatings involved in the processing of 100% cotton and later in 2018 Argaman plans to introduce a flame retardant cotton based on the same process, which could have a big impact on the home textiles market.Hologenix, from US partner Celliant is meanwhile a patented technology for imbuing fabrics with a natural blend of minerals which aim to recycle the body’s own energy, resulting in improved thermal regulation and more restorative sleep.Peppermint oilThailand’s Life Materials is a specialist in the development and production of antimicrobial additives and treatments. Its Life Natural technology is based on renewable plant extract – peppermint oil – to deliver long-lasting freshness to textiles by inhibiting bacteria. The treatment is extremely durable and will last for 50 wash cycles, making it competitive with existing treatments for synthetic fibre-based fabrics.The US non-profit trade association Cotton Council International (CCI) is linking up with a range of partners to introduce new performance properties that are usually associated with synthetics to Cotton USA-branded fabrics.

In the 2017/2018 season, an estimated 26.5 million tons of cotton will be produced on a surface of 33 million hectares. At present eight countries account for around 87% of all production – India, China, The USA, Pakistan, Brazil, Uzbekistan, Turkey and Australia.

In 2017, US exports are estimated to have been 3.2 million tons, making it the largest cotton supplier worldwide.

Nevertheless, cotton continues to lose ground globally to synthetics, and especially to PET polyester from China. In total, some 52 million tons of PET fibre was manufactured in 2017.

In PET fibre production, China surpassed the rest of the world’s output by 2005 and doubled that of the rest of the world by 2012. Of the twelve largest PET fibre producers in the world, nine of them are Chinese, and of the three non-Chinese companies, two have operations in China. These are all highly integrated operations, and raw materials for PET production – particularly PTA – are much cheaper in China due to overcapacity.

PET’s phenomenal growth has been despite overwhelming evidence of a consumer preference for cotton and now, working with partners, CCI is driving a campaign to develop new fabric variants that can be exploited by the 750 global licensees of its Cotton USA brand.

At the recent Heimtextil home textiles show in Frankfurt, the ‘What’s New in Cotton?’ display featured a range of new developments with partners.

A patented process for creating dissolvable yarns with enhanced characteristics and a low environmental impact has been developed by Italy’s Solucell. Through its use, SolucellAir cotton yarns are being engineered with sophisticated hollow channel structures. This results in fabrics that are light weight, soft touch, thermo-regulating and possess moisture management properties via a manufacturing route that is entirely free of chemicals.

French biotechnology company Proneem is also partnering with Cotton USA brands for sustainable anti-dust mite technologies which repel harmful organisms, while on the processing front, India’s Welspun showcased an innovation called Wel-Trak within the ‘What’s New in Cotton?’ display.

This patented new system has been developed to ensure both brands and consumers can trace the provenance of cotton raw materials all the way through the supply chain – from farm to the retail shelf – by employing;

Automated data capture using RFID.

Customised software for validation.

Robust IT and ERP systems to enable smooth operations across all stages of production.

Strengthened physical and systems controls which streamline the tracking process.

“Our customers across the globe are very excited about Wel-Trak,” said Welspun CEO and joint managing director Dipali Goenka. “Having a mechanism in place that will enable them to track the source of the final product right back to the specific farm it comes from definitely adds value and transparency to the whole process.”

Welspun has established a partnership with Oritain Global, a leader in the use of scientific traceability, which will provide independent validation of Welspun’s supply chain enabling the company to identify the origin of all of the cotton fibre used in its home textile products.

Chemical fingerprints

Based on its analysis, Oritain has created a database of unique ‘chemical fingerprints’ for special cotton variants such as Egyptian, US Supima and Australian cotton. This will be extended to include Organic and American Upland cottons. This database enables Oritain to verify a sample against its stated origin and allows Welspun to conduct tests at various stages of its manufacturing process and verify the origin of cotton at each stage, to ensure the authenticity of its final products.

Here are Cotton Ball Supplier from Asia Taiwan, please visit our showroom right now.

0 notes

Text

EPR Activity Sept17

SAP S/4 HANA, INFOR M3, UNIT4, QAD, SAGE X3, Aptean ROSS, Epicor... VER EN BROWSER

Ingeniería española BAC selecciona ERP Unit4 Business World On!

Empresa de servicios de Ingeniería BAC con sede en Barcelona ha seleccionado el ERP Unit4 Business World On! para la gestión financiera, los recursos humanos y el control de proyectos.

Leer más »

25-Jul-2017

Web

Mercadona implementa SAP S/4 Hana, SAP Retail y SucessFactors

El gigante español de la distribución Mercadona ha cerrado un acuerdo con SAP España para la puesta en marcha durante los próximos cinco años en la nube privada de SAP de SAP S/4 Hana, SAP Retail y ...

Leer más »

03-Jul-2017

Web

Grupo Lledó gestionará 800.000 € anuales de notas de gastos con Sarce Travel [Nota de Prensa]

La multinacional española de iluminación Grupo Lledó ha decidido gestionar sus 800.000 euros anuales en notas de gastos con el software de Sarce Travel. La empresa tiene 150 empleados en el departamento comercial y facturó 48 millones ...

Leer más »

25-Set-2017

Web

Fabricante fragancias español selecciona ERP SAP S/4HANA

La consultora SAP española Stratesys ha finalizado la primera fase de la implementación del ERP SAP S/4Hana en la química fabricante de fragancias Esencias Moles en los departamentos de finanzas, compras y ventas. ...

Leer más »

25-Jul-2017

Web

Quonext implementará el ERP Sage X3 en la farmacéutica Laboratorios VIR

La consultora IT Quonext pondrá en marcha el ERP Sage X3 en la farmacéutica española Laboratorios VIR para Gestión integral de la empresa y la producción.

Leer más »

25-Jul-2017

PDF

Impresia Ibérica actualiza a Aptean Ross ERP [Case Study en pdf]

El grupo gráfico más importante de la Península Ibérica Impresia Ibérica (Grupo Circle Printers) ha actualizado en 2 meses su viejo ERP Ross a la nueva versión. Publicamos un case study en el que se explican las ...

Leer más »

26-Set-2017

Web

El Colegio de Médicos de Cantabria implanta el ERP Exact Globe

El Colegio de Médicos de Cantabria (COMCAN) está implementando el Portal de Clientes para asociados con Synergy y el ERP Exact Globe.

Leer más »

10-Jul-2017

Web

Diputació de Lleida hace con Robotics la Gestión horaria de sus 500 empleados

Robotics ha implementado en la Diputació de Lleida su sistema para la gestión del tiempo y control de accesos que permite a la entidad pública gestionar de manera centralizada todas sus sedes de forma innovadora. ...

Leer más »

30-Jun-2017

Web

Productor de yogures y lácteos español selecciona ERP Infor M3

Importante productor de lácteos y yogures catalán La Fageda ha seleccionado el ERP Infor M3 para renovar su sistema de gestión. La consultora iStone hará la implantación.

Leer más »

12-Jul-2017

Web

Empresa portuguesa de Aguas gestiona RRHH y Talento de 400 empleados con Talentia HCM

La compañía portuguesa de Aguas Indaqua ha seleccionadoTalentia HCM para la gestión de RRHH y el Talento de sus más de 400 empleados.

Leer más »

22-Ago-2017

Web

Sacyr gestiona más de 30.000 empleados con Oracle HCM Cloud

La multinacional española de ingeniería y construcción Sacyr gestiona más de 30.000 empleados con Oracle HCM

Leer más »

15-Ago-2017

Web

Meliá Hoteles utiliza la Optimización de precios de Duetto

La multinacional hotelera Meliá Hoteles ha implementado el software de optimización de precios GameChanger y de "Revenue Intelligence" ScoreBoard de Duetto.

Leer más »

30-Jun-2017

Web

Fabricante de amortiguadores industriales y sistemas hidráulicos migra a QAD Cloud ERP

Los clientes industriales de QAD siguen migrando al ERP Cloud. En este caso el fabricante americano de ERP ha informado que el fabricante de amortiguadores industriales Oleo Internacional y el fabricante de sistemas hidráulicos Savery Hydraulics, pertenecientes ...

Leer más »

28-Jul-2017

Web

Gigante logístico alemán DB Schenker integra ERP y online con Magic Integration

Magic Software Enterprises, a global provider of software platforms for enterprise mobility, cloud applications, and business integration, announced today that DB Schenker, the world’s leading global logistics provider, has implemented the leading-edge Magic xpi Integration Platform as ...

Leer más »

28-Jul-2017

Web

Accesorios y ropa deportiva francés Chausport selecciona ERP Infor CloudSuite Fashion

Infor, a leading provider of beautiful business applications specialized by industry and built for the cloud, today announced that Chausport, supported by HereWeGo Consulting, has chosen Infor CloudSuite Fashion (based on Infor M3). After a tender procedure ...

Leer más »

28-Jul-2017

Web

Grupo téxtil indio implementa SAP S4 HANA

Yash Technologies, a leading application and infrastructure management services organisation, has completed SAP S4 HANA 1610 ERP implementation for Mafatlal Industries. Mafatlal Industries is a leading textile company for a complete range of products consisting of yarn ...

Leer más »

28-Jul-2017

Web

Consejería de Los Angeles invierte 68 Millones USD en CGI Advantage ERP

CGI announced its selection by the Los Angeles County Office of Education (LACOE) for the modernization of financial and human resources IT systems that support California's largest Office of Education. Under a US$68.7 million, 5-year contract, CGI ...

Leer más »

28-Jul-2017

Web

Alimentaria USA de 240 empleados selecciona Dynamics 365 frente a SAP e Infor

Merit Solutions, a provider of global supply chain solutions based on the Microsoft Dynamics 365 platform, announces today that V&V Supremo Foods, Inc. (V&V Supremo) has chosen to implement the Microsoft Dynamics 365 platform.

Leer más »

25-Jul-2017

Web

Fabricante armamentístico israelí Rafael implementa Product Cost Management de Apriori

aPriori, the leading provider of automated product cost management (PCM) software solutions, has been selected by Rafael Advanced Defense Systems a leading worldwide manufacturer and provider of military defense products and related services. Rafael will start ...

Leer más »

24-Jul-2017

Web

Dematic automatiza en Francia con AutoStore 5º almacén de 4murs de 700m2 y 23.000 cubetas

Retailer francés de decoración y pinturas 4murs, con más de 120 tiendas en Francia, va a automatizar sistema de pedidos de su 5º almacén en Europa con el sistema AutoStore de Dematic-Egemin.

Leer más »

24-Jul-2017

Web

Global Logistics Provider C.H. Robinson Selects ONE20's F-ELD as an ELD Solution for Contracted Carriers

ONE20, the industry's first free membership community built exclusively for professional truck drivers, has entered into an Enterprise Agreement with C.H. Robinson, a Fortune 500 leading third party logistics provider headquartered in Eden Prairie, Minn. that provides ...

Leer más »

03-Jul-2017

Web

Juguetera Miniland gestiona 13.000 pedidos mensuales con Gestión Almacenes de AS Software

El fabricante alicantino de productos para niños Miniland ha terminado la implementación del sistema de Gestión de Almacenes de AS integrándolo con su ERP SAGE X3.

Leer más »

04-Jul-2017

Web

Consultora IT alemana primera en usar SAP S/4 HANA sobre Google Cloud Platform

Sovanta, consultora IT alemana con base en Heidelberg, ha sido la primera empresa a nivel mundial en utilizar SAP S/4 Hana en Google Cloud Platform.

Leer más »

07-Jul-2017

Web

Importante distribuidor de fruta UK selecciona ERP IFS Applications 9

IFS, the global enterprise applications company, announces that W.B. Chambers, the grower, importer and packer of quality fruits, has chosen IFS Applications 9 to automate and monitor processes and support rapid growth across the business.

Leer más »

14-Jul-2017

Web

Kyocera Europa gestionará sus servicios de soporte y mantenimiento con IFS Servicios

Kyocera Document Solutions Europe implantará IFS Gestión de Servicios para la gestión del soporte a clientes.

Leer más »

14-Jul-2017

Web

Las 250 tiendas de Cole Haan gestionan órdenes con Aptos Enterprise Order Management

Aptos announced Cole Haan LLC has selected the cloud-based Aptos Enterprise Order Management solution to enhance its best-in-class omni-channel retail operations. Cole Haan leverages the Aptos Singular Commerce platform, including Aptos Store for point of sale and mobile ...

Leer más »

14-Jul-2017

Web

Cadena 450 pizzerias USA implementa sistema de pedidos online Onosys

Onosys announced that long-time client, Round Table Pizza, has chosen Onosys as the brand-wide digital ordering solution for the pizza chain’s 450 locations. Round Table Pizza has been working with Onosys since 2008, and in addition to ...

Leer más »

24-Jul-2017

Web

Italiana SEA pone SAP Hybris en la Cloud híbrida de IBM

SEA, a leading Italian airports operator and IBM announce a seven-year service agreement to consolidate and manage SEA's IT infrastructure on a hybrid IT environment that integrates the IBM Cloud.

Leer más »

08-Ago-2017

Web

Fabricante alemán de componentes de plástico para el automóvil invierte 1,6 millones en ERP IFS

IFS, the global enterprise applications company, announces that GERHARDI Kunststofftechnik, a leading provider of galvanized and technically sophisticated plastic parts, has decided to implement IFS Applications 9 . The contract comprises licenses and services valued at 1,68 ...

Leer más »

09-Ago-2017

Web

Tata actualiza Dubai Duty Free a Oracle Retail 16 en 8 meses

In less than 8 months, Dubai Duty Free completed its upgrade of Oracle Retail Merchandising System, Price Management, Invoice Match, Sales Audit, Warehouse Management, Store Inventory Management and Retail Insights from Release 12 to Release 16. The ...

Leer más »

15-Set-2017

Web

Empresa sueca de mantenimiento de edificios pone a 400 usuarios ERP en cloud de IFS

La empresa sueca Ocab de mantenimiento de edificios y aparatos en empresas y particulares, con más de 650 empleados, ha seleccionado la versión cloud del ERP IFS Applications 9 para la gestión integral de la empresa y ...

Leer más »

19-Set-2017

Web

Fabricante malasio de placas solares selecciona Epicor ERP

Solarvest Energy Sdn Bhd, empresa fabricante de placas solares de Malasia, ha implantado la última versión del ERP de Epicor para continuar su expansión en el mercado del sudeste asiático.

Leer más »

19-Set-2017

Web

Fabricante Qatarí de muebles e interiores implementa Epicor ERP

La empesa Quatarí Havelock AHI, especializada en la fabricación de muebles, e interiores, contaba en la última década con una solución de gestión hecha en casa que ha sido sustituida por el software ERP de Epicor. ...

Leer más »

25-Set-2017

Web

Malta invierte 11,6 M Euros en ERP de Unit4

El Gobierno de Malta invertirá 11,6 millones de euros en implementar el ERP Unit4 Business Word en todos sus ministerios y departamentos para afrontar el cambio de un sistema de criterio de caja a un criterio de ...

Leer más »

26-Set-2017

PDF

Pastelera USA implanta QAD Cloud

La pastelera USA Sinbad Foods ha implantado QAD Cloud ERP para la gestión integral de la empresa.

Leer más »

26-Set-2017

Web

Téxtil USA implementa NetSuite Retail Apparel en 144 días

Draper James , retail americano de "estilo sureño" y con un fuerte negocio online, ha implementado el ERP NetSuite’s Retail Apparel en apenas 144 días.

Leer más »

26-Set-2017

Web

Téxtil china de 25.000 empleados migra de Infor M3 a Infor CloudSuite

El Fabricante de moda con base en Hong Kong TAL Apparel Limited ha terminado la primera fase de su proyecto de migración del ERP onpremise Infor M3 al ERP Cloud Infor CloudSuite que comenzó en abril del ...

Leer más »

26-Set-2017

Web

Fabricante componentes electrónicos USA integra sistema código barras inventario con Dynamics 365 for Operations

El fabricante de componentes electrónicos americano Bel Fuse va a implementar integrado con Dynamics 365 for Operations el sistema de código de barras para inventarios DSI ScanWorkX en sus factorías de Gong Ming, Eslovaquia, Hong Kong y ...

Leer más »

22-Ago-2017

Web

El Arsenal monta su ecommerce con SAP Hybris Commerce

El Arsenal Football Club ha puesto en marcha su tienda online ArsenalDirect.com con SAP Hybris Commerce, permitiendo a los aficionados realizar compras más rápidas desde cualquier lugar y en cualquier momento, y pudiendo elegir entre diversas opciones ...

Leer más »

16-Ago-2017

Web

Fabricante suizo de lavadoras industriales actualiza a ERP IFS Applications 9

El fabricante suizo de lavadoras y secadoras industriales Schulthess Maschinen AG, que lleva trabajando con el ERP IFS desde hace una década, ha actualizado a la última versión del ERP, la IFS Applications 9.

Leer más »

09-Ago-2017

Web

Distribuidora industrial USA selecciona ERP Epicor Prophet 21 por pricing e inventario

Epicor Software Corporation, a global provider of industry-specific enterprise software to promote business growth, today announced Koehler Rubber & Supply Co. has chosen the award-winning Epicor Prophet 21 as its new enterprise resource planning (ERP) solution to ...

Leer más »

09-Ago-2017

Web

Retailer francés Monoprix con 250 tiendas integra Determine Source to Pay con SAP

Determine, the pioneering leader in global Source-to-Pay and Enterprise Contract Lifecycle Management (ECLM) Cloud Platform solutions, is helping leading French retail group Monoprix achieve flexibility, simplicity and ease of use on the Determine Cloud Platform.

Leer más »

09-Ago-2017

Web

Condado USA gasta 40 millones de USD en ERP Oracle y aún no logra arrancarlo

After working around the clock on a multi-million dollar upgrade to the county’s financial management system, the troubled enterprise resource planning (ERP) project recently ran into a slew of more problems. Over the last several years, the county ...

Leer más »

10-Ago-2017

Web

Atento ahorra un 60% en mantenimiento SAP y evita actualizar a S/4 al cambiar SAP por Rimini Street

Rimini Street, especialista en mantenimiento de ERP SAP y Oracle, ha publicado una interesante nota de prensa en la que explica cómo la multinacional Atento se ha ahorrado un 60% anual en costes de mantenimiento desde que ...

Leer más »

10-Ago-2017

Web

Grupo saudí SAB Holding comienza implementación de SAP S/4 Hana en IBM Cloud

El grupo saudí SAB Holding va a implementar SAP S/4 Hana sobre IBM Cloud en 16 compañías del grupo tras la puesta en marcha de la solución en su división de construcción e ingeniería, Ruwad Civil ...

Leer más »

10-Ago-2017

Web

Fabricante de cocinas UK implementa ERP IFS Applications 9

IFS, la compañía global de aplicaciones empresariales, anuncia que Sigma 3, el fabricante y minorista de cocina, implementará IFS Applications 9 para mejorar la planificación y apoyar el crecimiento del negocio.

Leer más »

10-Ago-2017

Web

Distribuidora USA de ferretería implementa ERP Epicor Prophet por su integración con ecommerce

La distribuidora de maquinaria y material de Wisconsin Welders Supply Company está implementando el ERP especializado en distribución Epicor Prophet 21 para su gestión integral.

Leer más »

15-Ago-2017

Web

Empresa USA de test de equipos electrónicos selecciona IFS como ERP de "Engineer-to-order"

La compañía norteamericana de test de equipos electrónicos Circuit Check ha seleccionado a IFS Applications como su sistema ERP.

Leer más »

15-Ago-2017

Web

Tiendas de California Rainbow Ag implantan el Retail Management Epicor Eagle N Series

La cadena de 2 tiendas del norte de California Rainbow Agricultural Services ha implementado el sistema de Retail management Epicor Eagle N Series.

Leer más »

26-Set-2017

Web

Fabricante USA de dispositivos médicos Shine implementa QAD Cloud ERP

El fabricante USA de dispositivos médicos SHINE Medical Technologies ha seleccionado QAD Cloud ERP para la gestión financiera.

Leer más »

1 note

·

View note

Text

ERP software for yarn management

Welcome! Evernote is your all-in-one solution for productivity: it’s where your notes, to-dos, schedule, and important documents all come together. Let’s start by planning your day inside this note, and you’ll be one step closer to your goals.

Most knitters and crochets are well aware of the many benefits of using yarn. As the name suggests, yarn is a strip of fiber that you can use to make clothes or other textile products. It is usually associated with being lightweight and air- or water-permeable. However, there is more to yarn than meets the eye. It can be a useful tool for artists, designers, and others who want to make unique products. This article will tell you about some of the best erp software solutions available for yarn management. It will also teach you some essential knowledge about this versatile fiber that you might not know.

Yarn Management With Stringerp

Yarn management is relatively a new area of business, and it was only invented about 100 years ago. For most of human history, different countries and continents had their own names for the various threads used in making clothes and other textile products. However, it was not until the 20th century that cotton, wool, and other fibers started becoming more commonly used. This is when the idea of utilizing different colors and strengths of yarn grew in popularity. Today, there are specific colors designated for specific uses. For example, there is bright white yarn and regular white yarn. The former is suitable for use in making clothes while the latter is more suitable for use in making artificial flowers and wreaths.

Why Stringerp?

If you are looking for an Erp software solution to help you manage your yarn, then you should consider Stringerp. They are one of the oldest suppliers of erp software for yarn management on the market. They currently have over 100,000 clients around the world, and they serve over 500,000 individual businesses. The company's software is built on the principles of being secure, fast, and user-friendly. This is combined with the functionality of being able to track orders, monitor invoices, and export and import data.

What Is Order Taking And How Does It Work?

Order taking is where you enter the details of your upcoming orders. It is a very important part of the software, as it serves as the foundation for the entire system. When you first log in to the program, you will see the standard screen that usually comes with any Erp software. From here, you can either enter a shopping cart, which will track all the goods you add to your order, or you can manually type in the items. If you decide to go the manual route, you will have to input the quantity for each item as well as the unit price. When you are finished, click the Confirm button, and the order will be placed.

What About Tracking?

Tracking is very important, as it helps you keep track of your suppliers and products. You can choose to either use barcodes or Radio-Frequency Identification (RFID) for tracking, but the choice is up to you. Barcodes are universal and easy to use, but they can only be scanned using a barcode scanner or other similar device. The RFID tags are embedded in the items to be tracked, so they are easily identifiable by reading them with a RFID reader. This makes them more secure and allows for more accurate tracking.

Setting Up Invoices And Paying Bills

Invoices are important, as they help you keep track of your sales and billing information. You can set them up to be automatically generated from your order taking, or you can create them manually. When you have generated an invoice, you can either print it or download it as a friendly PDF document. You can also set a grace period before bills are due, and the system will remind you when payments are due.

What About Product And Vendor Management?

This is where you keep track of the products you have in stock and ready to ship as well as those that are awaiting approval from a vendor or customer. Depending on your configuration, you can either enter the product information manually or search for it using an inventory management software tool. For example, you can use the Barcode Scanner to scan in either direction:

Up: To enter product info for a product that is already in stock, or

Down: To enter product info for a product that you have in hand.

The advantage of this feature is that you do not have to worry about double-entry bookkeeping. Simply enter the item at the top of the list, and the system will automatically populate the remaining cells with product information.

Importing And Exporting Data

This is where you can efficiently transfer data to and from other systems and applications. The best part is that you can synchronize data across multiple platforms, so that everyone involved in the operation has the same version of the facts.

Secure And Simple To Use

This is one of the major selling points of this particular software. Stringerp has designed their system with the security of the user in mind. There are 2 main ways to secure your data: 1) Use a unique username and password for every user; 2) Use a secure hash algorithm for generating your passwords. The first step in logging in is to type in your username and password, and then click the Login button. From here on out, you will be backed-up with a dashboard, which displays all the important information related to your orders and accounts. It is very user-friendly and accessible.

You can also take a peek at the Help section of the software if you are stuck or unsure on how to use certain features. The String ERP is also available 24/7 via Live Chat, email, or phone call. This way, you can get your questions answered promptly and help is never more than a click away.

#ERP Software for zari manufacturer#ERP Software for zari manufacturing#erp software for yarn texturizers#erp software for yarn traders#erp software for yarn dyers#erp software for yarn management#accounting software for textile#erp software yarn manufacturers#erp software for purchase management#erp software for sales management

0 notes

Text

Get real-time analysis of the on-hand inventory of raw material and finished goods with an easy-to-use String ERP software. The program uses your raw materials as well as finished products to give you an instant breakdown of your stock. String ERP software for yarn texturizers gives you a view of the financial and physical state of your operations as well as the flow of raw materials to final products. With String ERP, your operations are easy to manage and efficient which means that you can concentrate on business.

#erp software for yarn texturizers#erp software for yarn traders#erp software for yarn dyers#erp software for yarn management#accounting software for textile#erp software yarn manufacturers#erp software for purchase management#erp software for sales management#ERP Software for zari manufacturer#ERP Software for zari manufacturing

0 notes