#fab automation systems

Explore tagged Tumblr posts

Text

Photo by Arnold Newman.

“[W]e built a little studio at home to save the drive up and down the M4. And the studio is really very nice — little plug for Eddie Veale of Audiotech because he did a fantastic job and it sounds really nice. You know, because most home studios have a lot of trouble, you know. And it’s not really practical in some cases for people to have a home studio.” - George Harrison, Capital Radio, 1974 “Of all the former ‘Fabs,’ to use his customary term, George Harrison has remained the greatest creative homebody. […] George has rolled out of bed and returned again and again to Friar Park Studios, Henley-on-Thames (or F.P.S.H.O.T., for short) to tinker, compose and do his formal recording. […] Besides 'Cloud Nine,’ George recorded the 'Dark Horse,’ '33 1/3’ and 'George Harrison’ albums in his F.P.S.H.O.T. atelier, located in what was formerly a ballroom of the house. 'The studio was installed round 1971 and there’s been a few updates, cause when I originally put the studio in it was a 16-track. In terms of the monitoring system, after all those years in the Abbey Road EMI Studios, I put in Altec speakers. My experience in Abbey Road was that whenever the Beatles worked there and we thought we had a great sound, we’d play it back on the Altecs and it sounded terrible — ordinary. So they’re very boring in a way — and this must sound strange — but they’re also accurate! See, the Altecs don’t flatter the sound; it’s not easy to get good bass and drum sounds with them. But when I built my studio I didn’t want hype. I wanted what I’m hearing to be what it is. That way, when you play it back anyplace else it sounds fantastic! […] I’ve since made F.P.S.H.O.T. into a 24-track board. […] I’m going to get a few different choice modules made soon, but I don’t really want to go for a brand new SSL board and all that. Automation is nice in some respects, but I got my first skills at Abbey Road, so I prefer the old components, and spending a friendly weekend getting the manual mix you want. Just as I much prefer my ancient Fender Strat.’” - Musician, November 1987 (x)

#George Harrison#quote#quotes by George#quotes about George#FPSHOT#Friar Park#1970s#Harrison songwriting#Harrisongs#fits queue like a glove

61 notes

·

View notes

Text

Largest Laundry Franchise — Fabrico

Franchising in India is booming — and for good reason. With people leaning toward branded services, trusted systems, and consistent quality, franchise businesses in India have become the new gold rush. And when it comes to laundry franchises, one name is turning heads all across the country: Fabrico.

So, why is Fabrico franchise being called the largest laundry franchise in India? What’s making it the go-to brand in both metro and non-metro cities? Let’s dive deep into this clean business opportunity.

Meet the Giant — Fabrico

Started with a vision to make professional laundry services affordable and accessible, Fabrico is now the fastest-growing laundry chain in India.

From just a few outlets to dozens across multiple cities, Fabrico has redefined how urban and semi-urban India perceives dry cleaning and laundry. Whether it’s their clean branding, eco-friendly chemicals, or doorstep delivery — Fabrico is winning customer trust daily.

Why Fabrico is the Largest Laundry Franchise in India

Pan-India Presence: Fabrico has rapidly scaled across Tier 1, Tier 2, and Tier 3 cities — places like Lucknow, Jaipur, Indore, Patna, and Nagpur now proudly host Fabrico franchises.

Franchise Growth Rate: It has outpaced traditional laundry brands in India by offering a seamless, tech-enabled franchise model that’s easy to operate.

Customer Base: With thousands of repeat customers every month, Fabrico has turned laundry from a boring chore into a premium, reliable service.

Fabrico’s Business Model

The genius of the Fabrico franchise lies in its simplicity.

Centralized Cleaning Units: While customer drop-offs happen at outlets, Fabrico manages cleaning through regional hubs.

App-Driven Operations: Track pickups, manage customer preferences, and automate billing through their proprietary software.

Models: Customers can opt for affordable monthly plans, ensuring recurring income for franchisees.

Affordable Entry into a Profitable Industry

Want to enter a business with low investment but high returns?

Fabrico’s model is one of the best franchise businesses in India with an initial investment starting around ₹10–15 lakhs depending on the format and city.

In Tier 2 and Tier 3 cities, you can break even in under 18 months, making it ideal for budding entrepreneurs looking to own a stable, essential service business.

In-House Training and Operational Support

Worried about having zero laundry experience? Don’t be.

Fabrico offers 360° training for all new partners.

Franchisees get marketing material, staff training, equipment setup, and regular business audits to ensure profitability.

They also offer real-time tech support and a dedicated operations manager for every franchise.

Benefits of Owning a Fabrico Franchise

Here’s why becoming a Fabrico partner is one of the smartest moves today:

Fully Automatic Machines: Less labor dependency and higher efficiency.

Green Chemicals: Environmentally safe, customer-approved.

Recurring Business: Clothes need cleaning every week — Fabrico ensures recurring demand.

Flexible Formats: From kiosk models to mega-laundry hubs.

Franchise Business in India — A Growing Trend

India’s franchise market is projected to hit USD 140 billion by 2027, and laundry is one of the unsaturated yet essential segments.

With rising urbanization and limited time for daily chores, services like Fabrico are becoming daily necessities. People want hygienic clothes, and they want them cleaned fast — with Fabrico, it’s done within 24–48 hours.

Fabrico vs Other Laundry Franchises

Bottom line: Fabrico offers the best of both worlds — tech + trust.

Customer-Centric Approach

What sets Fabrico apart? Their obsession with customer delight.

Pickup & Delivery Within 24 hrs

Mobile App for Real-Time Tracking

Affordable Subscription Plans for Students and Families

This user-friendly experience leads to repeat orders, better retention, and higher profits for franchisees.

How to Apply for Fabrico Franchise

Step 1: Visit Fabrico’s official website Step 2: Click on ‘Franchise’ Step 3: Fill in the form with your city and contact details Step 4: Attend a business consultation call Step 5: Visit their headquarters and finalize the setup

Real Stories: Successful Fabrico Franchise Owners

Take Ajay from Indore. He started a Fabrico outlet with ₹18 lakhs and made ₹2.3 lakhs net profit in his 6th month.

Or Preeti from Bhopal — she operates three units now and employs 11 locals.

These stories are proof that Fabrico isn’t just another brand — it’s a wealth-building engine.

From First Outlet to Franchise Empire

Many Fabrico partners start with one unit and scale to multiple in just a few years. Why?

Low attrition rate

High demand

Centralized supply chain

Marketing assistance from HQ

The Future of Laundry Franchising in India

Fabrico plans to expand into 300+ locations by 2026. They’re also innovating with:

AI-based customer service

Drone-based delivery trials

Water recycling systems

If you’re thinking about joining this wave, now’s the time.

Conclusion

If you’re looking for the best franchise business in India that combines essential services, modern tech, and scalable returns — Fabrico is the name to trust. It’s more than just washing clothes — it’s about building a brand, creating jobs, and cashing in on a business with guaranteed demand.

The largest laundry franchise in India is here, and it’s called Fabrico. Will you be part of it?

❓FAQs

1. What is the minimum investment required for a Fabrico franchise? Around ₹28–35 lakhs depending on location and format.

2. Can I open a Fabrico franchise without any prior laundry experience? Absolutely! Fabrico provides full training and support.

3. How long does it take to start earning profits? Most franchisees break even within 18–24 months.

4. What cities is Fabrico currently expanding to? Fabrico is actively expanding into Tier 2 and Tier 3 cities across India.

5. Is Fabrico a sustainable and eco-friendly business? Yes, Fabrico uses green chemicals and promotes water recycling in its cleaning processes.

#dry cleaning#fabrico#laundry#dry cleaners#drycleaners#drycleaners service#laundry near me#laundry services#laundry franchise

0 notes

Text

🛠️ Revamp Your Dubai Home: Couch Repair, Fitted Wardrobes & Stylish Bedroom Curtains

Transforming your home in Dubai doesn't simply mean purchasing new goods, you may want to also breathe new life into your existing possessions and optimize your efficiency. Whether it's revamping a favorite couch, having custom wardrobes installed, or simply refreshing your bedroom with beautiful curtains, the right services can absolutely increase comfort, function and style. Here is how to update your home with the essential upgrades.

🪑 Couch Repair Services in Dubai: Bring Your Sofa Back to Life

Why Couch Repair?

Your sofa is often the centerpiece of your living room, supporting countless moments of relaxation and entertainment. Rather than replacing it, repair services offer:

Cost-effective solutions—upholstery repairs cost far less than new furniture.

Sustainability benefits—repairing reduces waste and environmental impact.

Preserving sentimental value—retain comfort and familiarity while refreshing the look.

Common Couch Repairs

Frame repairs: Fixing loose joints, broken rails, or structural sag.

Spring and cushion restoration: Replacing worn coils or foam for support.

Reupholstery: Updating fabric with new, durable material.

Stain removal and cleaning: Professional deep-cleaning for hygiene and freshness.

What to Look For

Experienced technicians with before/after portfolios.

Quality materials like hardwood frames and high-density foams.

Optional upgrades—stain-resistant fabrics or enhanced cushioning.

Warranty on both labor and materials.

Efficient timeline—some repairs completed within a few days.

🧱 Fitted Wardrobe Design Dubai: Tailored Storage for Every Home

Benefits of Fitted Wardrobes

Fitted wardrobes make the most of your bedroom’s space, offering:

Personalized dimensions: Ideal fit even in awkward nooks or sloped ceilings.

Customized organization: Sections for clothes, shoes, accessories, and more.

Premium aesthetics: Integrated design that complements your décor.

Long-term value: Higher appeal for resale and rental interest.

Design Features to Consider

Door types: Choose from sliding, hinged, bi-fold, or pocket doors.

Material choices: MDF with veneer, high-gloss laminate, or natural wood finishes.

Internal layout: Adjustable shelves, pull-out drawers, valet rods, and shoe racks.

Lighting options: LED strips under shelves or motion-activated lights.

Accessory add-ons: Full-length mirrors, tie racks, and premium handles.

The Design Process

Consultation & measurement

Design proposal with 3D renderings

Material selection

On-site installation by carpentry experts

Final inspection and handover

🛏️ Bedroom Curtains in Dubai: Elegant Window Dressing & Comfort

Dubai Furniture Company offers a comprehensive range of bedroom curtains, including custom, sheer, blackout, and cotton options—ideal for privacy, insulation, and decorative style .

What Makes Their Curtains Stand Out?

Blackout curtains for optimal sleep quality and darkness .

Cotton curtains are valued for their durability and ease of maintenance.

Sheer curtains that provide gentle light while maintaining privacy.

Bespoke designs tailored to your bedroom's aesthetic and dimensions.

Competitive pricing with professional installation options.

Choosing the Right Curtains

Blackout: Ideal for night workers or light-sensitive sleepers—block light and reduce noise.

Thermal/Cotton: Excellent for Dubai’s climate—balancing warmth and ventilation.

Sheer + blackout layering: Flexibility in light control and style.

Eyelet (grommet), pinch-pleat, or rod-pocket styles to match your décor.

Proper installation: Rod bracket placement above the window frame enhances height perception.

Professional Installation Tips

Ensure accurate measurement—curtains should be 1.5–2× window width and typically touch or slightly pool the floor.

Opt for motorized systems when convenience and automation are desired.

Choose high-quality rods and finials for durability and visual consistency.

Request and inspect fabric samples before finalizing.

🌟 Integrating All Three Services for a Cohesive Home Upgrade

Step 1: Audit What You Have

Identify sofas with signs of wear, cramped closets, and outdated curtains. Rank them by urgency and impact.

Step 2: Plan Your Budget & Timeline

Balance each component—couch repairs might cost AED 500–1,500+, fitted wardrobes AED 2,000–10,000+, curtains AED 300–2,000+. Obtain multiple quotes and bundle services where possible.

Step 3: Harmonize Design & Materials

Recovered sofas should complement the wardrobe finishes and curtain fabrics.

Choose colors that tie together—warm neutrals, rich wood tones, or bold contrasts.

Step 4: Schedule Efficiently

Start with couch repair, then wardrobe installation, then curtain fitting. This prevents damage and ensures seamless completion.

🏠 Real-Life Makeover Example

Villa in Al Barsha:

Sofa reupholstered with premium linen-look fabric.

Fitted wardrobe in white gloss laminate with integrated lights and mirrors.

Layered blackout and sheer curtains in pale grey.

Results:

Sofa rejuvenated at 30% of replacement cost.

Bedroom visually expanded, well-organized, and clutter-free.

Enhanced ambiance, thermal comfort, and sleep quality with curtains.

Why Choose Local Dubai Specialists?

Expertise in Gulf climate: Materials suited for heat and humidity.

Custom solutions: Tailored service ensures perfect fit and harmonious design.

End-to-end service: From design consultation to aftercare support.

Warranty & Guarantee: Peace of mind with backed workmanship.

✅ Final Tips Before You Begin

Task

Recommendation

Inspect furniture

Address worn frames or fabrics early

Measure precisely

For wardrobes & curtains, accuracy matters

Request samples

Test fabric, laminate, or upholstery colors

Bundle installations

Cost-saving and cohesive outcomes

Quality service

Prioritize providers with verified reviews & portfolios

Let the Dubai Furniture Company Elevate Your Home

From sofa restoration to fitted wardrobe craftsmanship and luxurious bedroom curtains, these upgrades revitalize spaces aesthetically and functionally. Reach out to Dubai Furniture Company today for personalized consultations, expert installation, and a refreshed, comfortable living environment.

0 notes

Text

Transforming Semiconductor Manufacturing Using Intelligent Industrial Control Systems

Semiconductors are the foundation of today’s technology, enabling the operation of devices ranging from smartphones to cutting-edge AI systems. As global demand for high-performance chips surges, chipmakers are under increasing pressure to scale production and innovate rapidly. Here is where Smart manufacturing comes into the picture.

Smart manufacturing is revolutionizing the semiconductor industry by introducing advanced, data-driven production methods. By integrating automation, artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), manufacturers are unlocking new levels of precision, responsiveness, and operational efficiency. Far from being just a trend, this shift is crucial for staying competitive in a rapidly evolving tech landscape.

With real-time data analytics and digitally connected systems, chip production is becoming quicker, more adaptable, and more cost-effective. It marks an essential shift in how semiconductors are designed, fabricated, and delivered to meet the demands of the digital age.

The convergence of automation, data intelligence, and digital control is quite essential. Nowhere is this more evident than in semiconductor manufacturing, where nanometer-level precision, speed, and scalability define success. At the heart of this transformation lies intelligent industrial control systems, a new breed of interconnected, adaptive, and data-rich control technologies that redefine how industrial operations are monitored and optimized.

As the demand for high-performance chips accelerates, semiconductor manufacturers are under immense pressure to boost production and maintain precision. Smart manufacturing is emerging as a game-changer, and at its core are Intelligent Industrial Control Systems (IICS) — blending automation, AI, and real-time analytics to create smarter, faster, and more reliable semiconductor fabs.

Smart Manufacturing: A Strategic Shift Traditional manufacturing can no longer meet the complexity and scale required by today’s semiconductors. Smart factories leverage systems like Distributed Control Systems (DCS), SCADA, and Programmable Logic Controllers (PLCs), layered with Advanced Process Control (APC) and IoT-enabled sensors. These allow for predictive maintenance, energy-efficient processes, and real-time quality control.

Why Intelligent Control Systems Matter In chip production, even a micron-level deviation can lead to massive losses. Intelligent control systems dynamically adjust variables, reducing downtime and waste. Leading companies like TSMC and Intel are already adopting these systems to optimize yield and time to market.

Key Benefits

Higher Yield: AI-powered APC reduces variability

Faster Time to Market: Real-time data boosts production speed

Energy Efficiency: Smart power supplies reduce operational costs

Predictive Maintenance: IoT sensors detect faults early

Compliance: SCADA systems offer traceability for audits

Real-World Impact A Singapore-based fab achieved a 15% reduction in scrap rates and 11% improvement in uptime within 6 months of integrating IICS.

Conclusion: To remain competitive in the age of AI, EVs, and 5G, semiconductor companies must embrace intelligent manufacturing. ACL Digital provides scalable, secure industrial control solutions that drive ROI and future-readiness.

As semiconductor demand surges, driven by AI chips, electric vehicles (EVs), and 5G infrastructure, manufacturers can no longer afford to rely on legacy systems. Intelligent industrial control systems offer not only automation but also adaptability, resilience, and a platform for continuous innovation. Smart manufacturing in semiconductors isn’t just about machines but about making better decisions faster. And that’s only possible when your control systems are as advanced as the products you’re building.

Ready to upgrade your fab with intelligent automation?

Contact us at [email protected] to explore how we can enhance your workplace transformation.

This blog was originally published on the website www.acldigital.com

0 notes

Text

Global High Voltage Power Supply for Electrostatic Chuck Market

High Voltage Power Supply for Electrostatic Chuck Market Analysis:

The global High Voltage Power Supply for Electrostatic Chuck Market size was valued at US$ 280 million in 2024 and is projected to reach US$ 485 million by 2032, at a CAGR of 8.1% during the forecast period 2025-2032

High Voltage Power Supply for Electrostatic Chuck Market Overview

This report provides a deep insight into the global High Voltage Power Supply for Electrostatic Chuck market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc. The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global High Voltage Power Supply for Electrostatic Chuck Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market. In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the High Voltage Power Supply for Electrostatic Chuck market in any manner.

High Voltage Power Supply for Electrostatic Chuck Key Market Trends :

Rising Semiconductor Demand The growing demand for semiconductors in consumer electronics and automotive sectors is boosting the need for reliable electrostatic chuck power supplies.

Miniaturization of Electronic Components As electronic devices become smaller and more complex, precision in wafer handling is critical, driving demand for high-performance HV power supplies.

Adoption of Smart Manufacturing Semiconductor fabs are rapidly adopting smart manufacturing practices, fueling the demand for advanced and automated power supply systems.

Increasing Display Panel Production The expanding display industry, especially OLED and micro-LEDs, is creating new application avenues for HV power supplies in electrostatic chucks.

Focus on Energy Efficiency Manufacturers are investing in energy-efficient and compact power supply designs to reduce operational costs and footprint.

High Voltage Power Supply for Electrostatic Chuck Market Regional Analysis :

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

High Voltage Power Supply for Electrostatic Chuck Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments. Key Company

Creative Technology Corporation

Matsusada Precision Inc.

Advanced Energy

P.R.A. Co.,Ltd.

XP Power

PSTEK

Gripping Power, Inc.

Spellman

Hung Hui Technology

Market Segmentation (by Type)

Benchtop Type

Rack Mount Type

Module Type

Market Segmentation (by Application)

Semiconductor Process

Display Process

Market Drivers

Booming Semiconductor Industry The continuous growth in semiconductor device production is directly increasing the use of electrostatic chucks in wafer processing, driving market growth.

Growing Demand for Advanced Display Panels With increasing investments in high-end displays and flexible screens, the display process application is witnessing significant uptake.

Technological Advancements in HV Power Supplies Innovations like precise voltage control, remote monitoring, and miniaturized designs are making HV power supplies more efficient and desirable.

Market Restraints

High Cost of Advanced Systems The initial investment for high-end, precision HV power supplies remains a barrier for small-scale fabs and new entrants.

Complexity in Integration and Maintenance Installing and maintaining high voltage systems require technical expertise and regular calibration, which can slow adoption.

Limited Awareness in Emerging Markets Developing regions often lack awareness and infrastructure to adopt advanced electrostatic chuck systems, limiting market penetration.

Market Opportunities

Expansion in Asia-Pacific Semiconductor Hubs Countries like China, South Korea, and Taiwan are investing heavily in semiconductor fabs, opening massive growth opportunities.

Collaborations with Display Manufacturers Partnerships between HV power supply providers and display panel producers can accelerate innovation and adoption.

Eco-Friendly and Compact Designs R&D focused on sustainable, energy-efficient, and compact solutions can attract new customers and meet regulatory standards.

Market Challenges

Volatile Raw Material Prices Fluctuations in raw material costs affect the pricing and profitability of HV power supply systems.

Intense Market Competition Global and regional players compete aggressively, pushing prices down and pressuring margins.

Regulatory and Safety Standards Meeting international safety and quality certifications can delay product launches and increase compliance costs.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the High Voltage Power Supply for Electrostatic Chuck Market

Overview of the regional outlook of the High Voltage Power Supply for Electrostatic Chuck Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Related Reports:

0 notes

Text

The Silent Enabler: How IC Substrates Power the Semiconductor Revolution

Breaking Down the IC Substrate Ecosystem

The global IC substrate market has transformed into a $14.6 billion industry (Yole Développement 2025), driven by three core technology segments:

Advanced Packaging Platforms

2.5D/3D IC substrates now enable 12-layer interposers with <1μm alignment precision

Fan-out wafer-level packaging (FOWLP) achieves 0.8μm line/space resolution

Heterogeneous integration substrates support 10+ chiplet configurations

Material Science Breakthroughs

Low-loss dielectrics (Dk<3.0 @ 100GHz) from 8 major chemical suppliers

Nanocomposite thermal interface materials with 15W/mK conductivity

Photosensitive dielectric films enabling 2μm laser patterning

Cutting-Edge Manufacturing Innovations

Leading manufacturers have deployed:

AI-Optimized Production

Neural networks reducing warpage by 40% through real-time parameter adjustment

Digital twin systems predicting yield with 98.7% accuracy

Automated optical inspection achieving 50 defects per billion opportunities

Sustainable Manufacturing

Closed-loop chemical recycling recovering 92% of process materials

Plasma treatment replacing chemical desmear in 35% of facilities

Waterless cleaning systems reducing H2O usage by 8,000 tons/month per fab

Transformative Applications

AI/ML Hardware

NVIDIA's Blackwell GPU platform uses IC substrates with:

8μm microbump pitch

16-layer build-up structure

3D through-silicon via (TSV) integration

Automotive Electronics

Tesla's Dojo 2 training system incorporates:

45μm coreless substrates

Embedded decoupling capacitors

10μm ultra-fine line circuitry

Emerging Technology Frontiers

Quantum Computing

Cryogenic substrates operating at 4K with:

Superconducting niobium interconnects

Quantum-limited loss dielectrics

Magnetic field shielding layers

Biomedical Interfaces

Neural implant substrates featuring:

500nm flexible polyimide circuits

Biocompatible gold metallization

10-year in-vivo stability

Frequently Asked Questions

Why are IC substrates crucial for chiplet designs?

They provide:

Known-good-die (KGD) testing infrastructure

Ultra-short inter-chiplet links (<100μm)

Thermal stress buffering between heterogeneous dies

How do IC substrates enable 6G communications?

Through:

Terahertz waveguides with 0.001dB/mm loss

Antenna-in-package integration

3D electromagnetic shielding structures

What's the roadmap for IC substrate technology?

Key milestones include:

2026: 1μm line/space volume production

2028: Photonic interposer commercialization

2030: Molecular-scale self-assembling substrates

1 note

·

View note

Text

Semiconductor Industry Drives Growth in ICP-MS Systems Market

The semiconductor industry is entering a new era of complexity with shrinking device nodes, multilayered architectures, and growing sensitivity to material purity. In this evolving environment, Inductively Coupled Plasma Mass Spectrometry (ICP-MS) systems have become essential for semiconductor manufacturers. These systems provide high-resolution, multi-element analysis at ultra-trace levels, enabling manufacturers to detect and eliminate even minute contaminants during production.

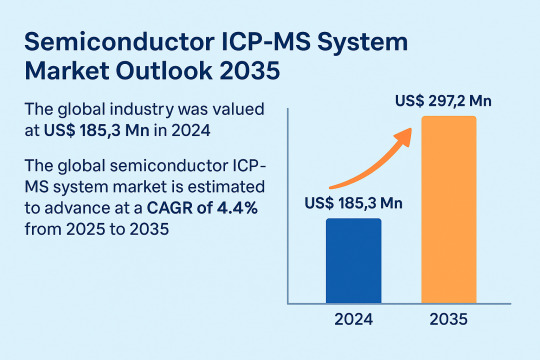

Valued at US$ 185.3 Mn in 2024, the global semiconductor ICP-MS system market is projected to reach US$ 297.2 Mn by 2035, showcasing a robust CAGR of 4.4%. This growth is largely attributed to rising demand for advanced semiconductor manufacturing technologies, yield improvement measures, and regional investments in R&D.

Market Drivers & Trends

Increasing Focus on Yield Improvement and Defect Reduction As semiconductor devices become more complex and miniaturized, even the slightest impurity can result in performance degradation or device failure. ICP-MS systems enable trace-level detection of contaminants in raw materials, wafers, and finished chips. This precise analysis helps in reducing defects and improving overall production yields, which is crucial for applications in sectors such as automotive electronics, aerospace, and medical devices.

Rising Demand for Advanced Manufacturing Processes The global surge in 5G deployment, AI integration, electric vehicles, and consumer electronics demands highly efficient and pure semiconductor components. As a result, semiconductor fabs are investing in advanced analytical instrumentation like ICP-MS to support next-generation chip fabrication.

Regulatory Pressure & Environmental Monitoring With increasing global focus on environmental protection, the semiconductor industry is required to comply with stringent material safety and emission standards. ICP-MS systems are pivotal in this context, offering compliance assurance through accurate trace element detection.

Latest Market Trends

Shift Toward High-Resolution Systems: In 2024, High Resolution ICP-MS accounted for 54.1% of the market share and is expected to grow at a CAGR of 4.8%. These systems are highly valued for their enhanced sensitivity and ability to detect ultratrace elements critical to semiconductor reliability.

Process Automation and Smart Integration: Recent systems are being designed with enhanced software, automation, and remote monitoring features. This aligns with the semiconductor industry's push toward Industry 4.0 adoption and process optimization.

Triple Quadrupole ICP-MS Gaining Momentum: For applications involving complex matrices, Triple Quadrupole ICP-MS is emerging as a preferred solution due to its accuracy, lower detection limits, and interference removal capabilities.

Key Players and Industry Leaders

Key companies shaping the semiconductor ICP-MS system landscape include:

Agilent Technologies Inc.

Thermo Fisher Scientific Inc.

PerkinElmer Inc.

Shimadzu Corporation

Analytik Jena GmbH

Applied Spectra

Teledyne CETAC Technologies

Eurofins Scientific

Intertek Group, Inc.

Nu Instruments

Skyray Instruments USA, Inc.

These players are actively investing in product innovation, strategic collaborations, and R&D initiatives to strengthen their market presence.

Recent Developments

In October 2024, Thermo Fisher Scientific launched the iCAP MX Series ICP-MS, which includes single and triple quadrupole systems. Designed for environmental and industrial laboratories, these instruments improve trace element detection capabilities across various materials, supporting high-stakes applications including semiconductor fabrication.

Agilent Technologies continues to expand its modular platforms with enhanced software and data analytics tools to aid real-time quality monitoring in semiconductor manufacturing lines.

Gain a preview of important insights from our Report in this sample –

Market Opportunities

Emerging Applications in AI and EVs: As AI chips and EV power modules become mainstream, the need for ultra-clean, high-performance semiconductors will increase. ICP-MS systems are vital in ensuring the required material standards.

Integration with Smart Fab Technology: Growing interest in automated, sensor-driven semiconductor fabs presents opportunities for integrating ICP-MS systems into digital twins and predictive maintenance platforms.

Growth in Outsourced Semiconductor Manufacturing: The rise of fabless companies and semiconductor foundries is creating new demand for analytical instrumentation that supports cross-vendor process validation.

Future Outlook

Looking ahead, the semiconductor ICP-MS system market is expected to evolve in tandem with semiconductor technology advancements. Miniaturization trends, increasing need for zero-defect manufacturing, and regulatory compliance will drive long-term growth. Additionally, increased R&D activity in material science and nanotechnology will fuel innovation in ICP-MS instrumentation and applications.

Market Segmentation

The global market is segmented by:

Offering: Hardware (detector, pump, torch, cones), Software, and Services

Technology: Quadrupole Based ICP-MS, Multicollector ICP-MS, High Resolution ICP-MS, Single/Triple Quadrupole ICP-MS

Deployment: Benchtop, Floor-standing

Installation: Laboratory, Process

Application: Wafer, Slurry, Process Chemicals, Organic & Metal Analysis

End-use: Integrated Device Manufacturers (IDM), Foundries

Regional Insights

Asia Pacific leads the global market, accounting for 52.4% share in 2024, and is expected to maintain its dominance with a CAGR of 4.8%. Major semiconductor powerhouses such as Taiwan, South Korea, China, and Japan are driving this leadership through extensive production infrastructure and R&D investments.

North America: The presence of key industry players and innovation hubs makes it a significant contributor.

Europe: Countries like Germany and France are investing in local semiconductor production and analytical instrumentation.

Rest of World: Markets in ASEAN and India are emerging, driven by electronics demand and investment-friendly policies.

Why Buy This Report?

In-depth analysis of the global semiconductor ICP-MS system market dynamics, trends, and forecasts through 2035

Comprehensive company profiles and recent strategic developments

Regional and country-level market breakdowns

Technological segmentation and future outlook by deployment, application, and end-use

Insights into competitive landscape and market share by key players

Cross-segment and value chain analysis for informed decision-making

Frequently Asked Questions (FAQs)

Q1. What is the market size of the semiconductor ICP-MS system market in 2024? A1. The market was valued at US$ 185.3 Mn in 2024.

Q2. What is the projected market value by 2035? A2. It is expected to reach US$ 297.2 Mn by 2035.

Q3. What is the CAGR for the forecast period 2025–2035? A3. The market is projected to grow at a CAGR of 4.4%.

Q4. Who are the leading players in this market? A4. Major companies include Agilent Technologies, Thermo Fisher Scientific, PerkinElmer, and Shimadzu Corporation, among others.

Q5. Which region dominates the market? A5. Asia Pacific is the leading region, driven by strong semiconductor manufacturing activity.

Q6. What trends are shaping the market? A6. Trends include rising demand for high-resolution systems, smart fab integration, and increasing regulatory compliance needs.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Semiconductor Manufacturing Equipment Market Drivers Shaping Global Industry Growth and Technological Innovation Trends

The semiconductor manufacturing equipment market plays a crucial role in the broader semiconductor industry by providing the essential machinery and tools used to produce integrated circuits and microchips. These chips power everything from smartphones and computers to automobiles and medical devices. Understanding the primary market drivers behind this sector reveals why it continues to experience rapid growth and why manufacturers, suppliers, and investors are keenly focused on its development.

Growing Demand for Advanced Semiconductor Devices

One of the most significant drivers of the semiconductor manufacturing equipment market is the soaring demand for advanced semiconductor devices. The rapid adoption of technologies such as 5G, artificial intelligence (AI), cloud computing, and the Internet of Things (IoT) has drastically increased the need for high-performance chips. These technologies require smaller, faster, and more energy-efficient chips, prompting semiconductor manufacturers to upgrade their equipment and processes continuously.

Advanced semiconductor nodes, such as 7nm and below, require highly sophisticated equipment to maintain precision and yield. As chipmakers push the boundaries of Moore’s Law, the complexity of wafer fabrication grows, necessitating cutting-edge lithography machines, etching tools, and deposition systems. The growing demand for these next-generation chips directly fuels the semiconductor manufacturing equipment market.

Technological Innovations and Industry Trends

The semiconductor equipment market is heavily influenced by continuous technological innovation. Equipment manufacturers are investing substantially in research and development to create tools that can handle the increasing complexity of chip fabrication. Innovations such as extreme ultraviolet (EUV) lithography have revolutionized the ability to produce smaller nodes, which are essential for advanced semiconductor devices.

Additionally, there is a strong emphasis on automation and smart manufacturing within semiconductor fabs. The integration of AI and machine learning technologies into manufacturing equipment helps improve process control, enhance yield rates, and reduce production costs. These trends drive equipment upgrades and new installations, positively impacting the market.

Rising Investments in Semiconductor Fabrication Facilities

Governments and private enterprises worldwide are increasing investments in semiconductor fabrication plants, often called fabs. These capital-intensive facilities require state-of-the-art manufacturing equipment to produce chips at scale. Recent geopolitical shifts and supply chain concerns have prompted countries to promote domestic semiconductor production, leading to a surge in fab construction projects.

Substantial financial commitments by countries such as the United States, China, South Korea, and the European Union aim to secure supply chains and foster technological self-reliance. The establishment of new fabs and expansion of existing ones directly boosts demand for semiconductor manufacturing equipment, as manufacturers must procure the latest tools to build competitive production lines.

Growing Use of Semiconductors Across Diverse Industries

The expanding application of semiconductor devices across various industries also propels the demand for semiconductor manufacturing equipment. Beyond traditional consumer electronics, sectors such as automotive, healthcare, aerospace, and industrial automation increasingly rely on advanced chips.

The automotive industry's transition toward electric vehicles (EVs) and autonomous driving technologies requires complex semiconductor solutions. These demand significant fabrication capabilities, encouraging chipmakers to invest in sophisticated equipment. Similarly, healthcare innovations, including wearable devices and diagnostic tools, further expand the market scope for semiconductor manufacturing machinery.

Demand for Miniaturization and Enhanced Performance

Consumer expectations for smaller, lighter, and more powerful electronic devices compel semiconductor manufacturers to develop chips with greater functionality in smaller form factors. Achieving this miniaturization involves advanced equipment capable of handling nanoscale fabrication.

The performance requirements of modern applications, such as augmented reality (AR), virtual reality (VR), and high-speed data processing, intensify the need for innovative manufacturing tools. The drive for enhanced chip performance encourages equipment manufacturers to innovate and supply tools that enable high precision, reduced defects, and improved throughput.

Environmental and Energy Efficiency Regulations

Stringent environmental regulations and growing emphasis on sustainability have a considerable impact on the semiconductor manufacturing equipment market. Semiconductor fabs consume significant amounts of energy and water and generate waste during production.

To comply with environmental standards and reduce operating costs, fabs seek advanced equipment that supports cleaner and more energy-efficient manufacturing processes. Equipment providers respond by designing systems that minimize chemical usage, optimize power consumption, and facilitate waste reduction, further fueling market growth.

Supply Chain Challenges and Strategic Equipment Sourcing

Recent supply chain disruptions have highlighted the importance of robust semiconductor manufacturing capabilities. Companies are investing in advanced equipment to localize and secure chip production, mitigating risks associated with global dependencies.

This strategic shift supports the demand for semiconductor manufacturing tools domestically and regionally. Equipment manufacturers benefit from increased orders as semiconductor producers diversify their manufacturing bases, aiming for supply chain resilience.

Rising Demand for Specialty Chips and Customization

The growing requirement for specialty and custom-designed chips for specific applications also drives the semiconductor manufacturing equipment market. Chips tailored for AI acceleration, graphics processing, and cybersecurity necessitate distinct fabrication processes.

To accommodate these demands, fabs require flexible and specialized equipment capable of producing diverse chip types. This diversification pushes equipment manufacturers to innovate and expand their product portfolios, stimulating market expansion.

In summary, the semiconductor manufacturing equipment market is propelled by a combination of rising demand for advanced semiconductor devices, technological innovation, increased fab investments, expanding industry applications, and regulatory factors. The market’s growth trajectory is supported by the relentless push toward miniaturization, improved performance, and sustainability. As global demand for semiconductors continues to rise, driven by evolving technologies and industries, the semiconductor manufacturing equipment market is poised for sustained expansion and dynamic transformation.

#SemiconductorManufacturingMarket#ChipTechnology#SemiconductorEquipment#TechInnovation#AdvancedSemiconductors

0 notes

Text

Wafer Sorters Market to Reach $582.9 Million by 2035

According to the latest research by DataString Consulting, the global Wafer Sorters market is projected to grow from $320.1 million in 2024 to $582.9 million by 2035, registering a compound annual growth rate (CAGR) of 5.6% over the forecast period.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/wafer-sorters-market-research-report

The increasing adoption of semiconductor testing, photovoltaic manufacturing, MEMS production, and integrated circuit (IC) fabrication is driving this robust market expansion.

Key Applications and Demand Drivers

Wafer Sorters play an essential role in the semiconductor manufacturing process by automating wafer handling and improving process throughput, accuracy, and contamination control. Primary areas of use include:

Semiconductor Testing: Enables high-speed, high-precision wafer identification and placement.

Photovoltaic Cell Production: Supports consistent wafer sorting to meet high-efficiency standards.

MEMS and IC Manufacturing: Ensures clean handling in highly sensitive production environments.

The demand surge is further amplified by the global shift toward miniaturized electronics, 5G infrastructure, and advanced driver-assistance systems (ADAS), all of which depend on streamlined wafer processing workflows.

Industry Trends Fueling Growth

The market is witnessing technological advancements in wafer sorter designs, including:

AI-driven sorting systems for predictive maintenance and reduced downtime

IoT-enabled devices for real-time data acquisition and monitoring

Integration with Industry 4.0 frameworks for enhanced automation and process transparency

These innovations are enabling manufacturers to handle increasing wafer sizes, higher throughput requirements, and stringent yield expectations in modern fabs.

Competitive Landscape

The Wafer Sorters market is highly competitive and features a range of global leaders who are continuously innovating and forming strategic partnerships to maintain a technological edge. Prominent companies include:

Applied Materials Inc.

Brooks Automation Inc.

Disco Corporation

EV Group

Hitachi High-Technologies Corporation

Kulicke and Soffa Industries Inc.

Lam Research Corporation

Nikon Corporation

Rudolph Technologies Inc.

SCREEN Semiconductor Solutions Co. Ltd.

Tokyo Electron Limited

Ulvac Inc.

These companies are investing in R&D to deliver next-generation wafer sorters with greater modularity, energy efficiency, and compatibility across fab ecosystems.

Regional Growth Outlook

North America and Asia-Pacific remain the two most dynamic regions for the Wafer Sorters market, driven by:

Strong presence of semiconductor fabrication plants

Government support for chip self-sufficiency

Increased consumer demand for electronic devices and automotive innovations

Key markets such as the U.S., China, Japan, Taiwan, and South Korea lead in both technology adoption and production volume. Meanwhile, India, Brazil, and South Africa are emerging as attractive destinations for market expansion due to evolving local semiconductor ecosystems and favorable government policies.

Supply Chain Evolution

As demand intensifies, the Wafer Sorters supply chain—from raw materials and component manufacturing to machine assembly and end-use deployment—is expected to undergo significant transformation. Companies are likely to:

Invest in local sourcing and nearshoring

Strengthen partnerships with OEMs and system integrators

Adopt flexible manufacturing models to respond faster to custom demands

These adaptations will help players stay competitive and ensure uninterrupted delivery in an increasingly complex and globalized supply environment.

Market Segmentation Highlights

The market study by DataString Consulting offers detailed insights across key segments, including:

Product Type: Fully-Automated, Semi-Automated, Manual

End-Users: Foundries, IDM Manufacturers, R&D Labs

Usage Frequency: High-Throughput, Low-Volume/Prototype

Technology Integrated: Optical Sensors, RFID, AI/ML-Enhanced

Pricing Models: Entry-Level, Mid-Range, Premium

These segmentations allow stakeholders to pinpoint high-growth opportunities and align investments accordingly.

About DataString Consulting

DataString Consulting is a trusted name in strategic market research, offering tailored insights for both B2B and B2C enterprises. We support our clients in TAM expansion, go-to-market strategy, and competitive intelligence by analyzing trends, customer behavior, and market dynamics across more than 15 industries and 60 sub-industries.

With over 30 years of combined leadership experience, our team delivers precise, data-backed strategies that filter out noise and help clients capitalize on actionable opportunities.

We deliver industry-specific market research solutions designed to reduce the time between product development and market fit—ensuring our clients stay ahead in rapidly evolving sectors.

0 notes

Text

Industry 4.0 on the Rise: Smart Factory Market to Surpass $220B by 2034 🏭📈

Smart Factory Market is on a strong upward trajectory, projected to grow from $86.2 billion in 2024 to an impressive $221.7 billion by 2034, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the global push towards digital transformation, with manufacturers adopting advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), robotics, and machine learning to automate operations, reduce downtime, and boost productivity. Smart factories represent the evolution of traditional manufacturing into intelligent, self-optimizing environments that enhance decision-making through real-time data and analytics.

Market Dynamics

Smart factory solutions are revolutionizing industries by improving operational efficiency, ensuring product quality, and supporting sustainability goals. The market’s backbone lies in manufacturing execution systems (MES), predictive maintenance tools, and automated quality control. Factors fueling growth include the increasing demand for industrial automation, advancements in connectivity (5G and edge computing), and the need for energy-efficient production systems.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20453

However, challenges such as high initial setup costs, cybersecurity risks, and integration of legacy infrastructure can slow adoption, especially among small and medium-sized enterprises. Despite these hurdles, the potential return on investment through long-term cost savings and improved throughput continues to drive implementation across sectors like automotive, aerospace, healthcare, and electronics.

Key Players Analysis

The market landscape is shaped by industry giants including Siemens AG, Schneider Electric, Honeywell International Inc., ABB, Rockwell Automation, Emerson Electric, and Mitsubishi Electric. These companies are investing heavily in R&D to stay ahead in a rapidly evolving field. Their solutions span from control devices and sensors to AI-enabled software platforms that enhance factory agility.

Meanwhile, emerging innovators like Factory Sense, Smart Fab Solutions, and Digitize Manufacture are introducing niche products that cater to customizable and flexible production environments. These players are leveraging smart data, modular architecture, and collaborative robotics to appeal to a growing customer base that values adaptability and innovation.

Regional Analysis

North America leads in smart factory adoption, particularly the United States, which boasts robust industrial infrastructure and a strong focus on digital transformation. The region’s automotive and aerospace industries are significant adopters of smart technologies, driven by stringent quality requirements and performance optimization.

Europe closely follows, with countries like Germany and the UK driving growth through Industry 4.0 initiatives and regulations aimed at sustainable manufacturing. The region’s emphasis on carbon reduction, energy efficiency, and green technologies supports the expansion of smart factory solutions.

The Asia-Pacific region is emerging as the fastest-growing market. China, Japan, and South Korea are at the forefront, supported by rapid industrialization, government incentives, and a massive electronics manufacturing base. With strong demand for consumer goods and rising labor costs, the adoption of smart technologies in these economies is accelerating significantly.

Recent News & Developments

The market has recently seen a surge in strategic collaborations and partnerships aimed at enhancing technological capabilities. Leading firms are integrating AI and IoT into core operations, improving factory uptime and production flexibility. The shift toward cloud-based deployment models and hybrid systems has gained momentum, offering scalability and real-time remote access to critical operations.

Additionally, there’s growing interest in cybersecurity frameworks to safeguard sensitive industrial data. New solutions emphasize resilience, with embedded machine learning models that detect anomalies and prevent potential disruptions. Furthermore, global regulatory focus on environmental sustainability is driving innovation in low-emission and energy-efficient smart manufacturing systems.

Browse Full Report : https://www.globalinsightservices.com/reports/smart-factory-market/

Scope of the Report

This report offers a comprehensive look into the Smart Factory Market, covering historical trends (2018–2023) and future forecasts (2025–2034). It provides qualitative and quantitative insights across segments such as technology (AI, IIoT, Big Data), deployment models (on-premise, cloud, hybrid), and end users (automotive, food & beverages, electronics, etc.).

Beyond market size and growth projections, the report delves into regional performance, competitive landscape, emerging players, and regulatory dynamics. Key development strategies like mergers, acquisitions, new product launches, and cross-industry collaborations are also evaluated. With its rich data analysis, the report equips stakeholders with strategic insights to navigate the evolving smart manufacturing landscape.

Discover Additional Market Insights from Global Insight Services:

High Speed Cable Market : https://www.globalinsightservices.com/reports/high-speed-cable-market/

Advanced Semiconductor Packaging Market ; https://www.globalinsightservices.com/reports/advanced-semiconductor-packaging-market/

Agricultural Lighting Market : https://www.globalinsightservices.com/reports/agricultural-lighting-market/

Air Quality Monitoring System Market ; https://www.globalinsightservices.com/reports/air-quality-monitoring-system-market/

Industrial Robotics Market : https://www.globalinsightservices.com/reports/industrial-robotics-market/

#smartfactory #industry40 #automation #manufacturingtechnology #iotinmanufacturing #artificialintelligence #predictivemaintenance #robotics #digitaltransformation #industrialautomation #iiot #mes #cloudmanufacturing #cybersecurity #smartmanufacturing #bigdata #machinelearning #edgecomputing #plc #erp #smartfactories #automotiveindustry #electronicsmanufacturing #aerospaceinnovation #supplychainoptimization #realtimemonitoring #energyoptimization #sustainablemanufacturing #processautomation #futureofmanufacturing #connectedfactory #intelligentautomation #smartfactorysolutions #manufacturinginnovation #cobots #cloudintegration #datadrivenmanufacturing #remotemonitoring #digitalsupplychain #greentechnology #manufacturingefficiency

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Faridabad’s Leading Belt Conveyor Companies You Should Know

In today’s fast-paced industrial environment, efficient material handling is not just an operational requirement but a competitive advantage. Belt conveyors—a staple in manufacturing, logistics, and warehousing—are critical to ensuring smooth product flow and reducing manual handling time. When it comes to sourcing these essential systems in India, Faridabad stands out as a leading manufacturing hub.

This blog explores the top belt conveyor companies in Faridabad, highlighting their strengths, innovations, and what sets them apart. If you’re looking to invest in a high-performance conveyor solution, this guide will help you make an informed decision.

Why Faridabad Is a Belt Conveyor Manufacturing Hub

Part of the Delhi-NCR industrial belt and situated in Haryana, Faridabad has made a name for itself as a manufacturing hub for machinery and equipment. Its prominence in the belt conveyor manufacturing industry is a result of several factors:

Well-developed industrial infrastructure

Proximity to Delhi, Gurgaon, and major logistics corridors

Access to skilled labor and engineering talent

Presence of diverse industries driving demand

Supportive government policies for MSMEs and exporters

Thanks to this ecosystem, many belt conveyor manufacturers in Faridabad are now serving both domestic and global markets with world-class products.

What Makes a Good Belt Conveyor Manufacturer?

Before we delve into the top companies, here are the criteria that make a conveyor manufacturer stand out:

Engineering expertise and customization capability

High-quality raw materials and precision fabrication

Advanced automation integration (motors, PLCs, sensors)

Customer-centric approach with timely delivery

Strong after-sales support and spare parts availability

Compliance with safety and quality standards (ISO, CE)

Now, let’s look at the companies in Faridabad that embody these traits.

Top Belt Conveyor Companies in Faridabad

1. Neo Conveyors

Neo Conveyors is one of the most recognized names in the conveyor system manufacturing sector in Faridabad. Known for their custom-engineered belt conveyors, they cater to industries like cement, food processing, mining, packaging, and more.

Key Strengths:

Custom designs for bulk material handling

High-performance conveyors with minimal maintenance

Export-ready systems with CE certifications

2. Conveline Systems Pvt. Ltd.

Conveline Systems specializes in modular conveyor solutions, including belt conveyors, roller conveyors, and inclined systems. Their systems are widely used in e-commerce, warehousing, and packaging industries.

Key Features:

Modular, plug-and-play designs

Quick lead times and scalable systems

High-quality belts and automation-ready features

3. Jay Engineering

Established for over 20 years, Jay Engineering is known for its heavy-duty and precision conveyors. They manufacture industrial-grade belt conveyors for tough environments like foundries and assembly lines.

USP:

Rugged construction with high load capacities

Turnkey project execution with layout planning

Long-life motors and accessories

4. Saifi Con-Fab System Pvt. Ltd.

A pioneer in conveyor technology, Saifi Con-Fab offers advanced belt conveyor solutions for industries ranging from food to electronics. Their R&D-focused approach ensures innovative designs and automation integration.

Highlights:

In-house design and engineering team

Belt conveyors with integrated sensors and safety systems

Strong service support across India

5. Essar Engineers

Essar Engineers delivers a range of material handling equipment, with belt conveyors as one of their core offerings. Their strength lies in delivering high-quality products with fast turnaround times.

Specialties:

Standard and custom belt conveyors

Powder-coated and stainless steel options

Cost-effective and durable solutions

Key Features of Belt Conveyors from Faridabad

Belt conveyors manufactured in Faridabad offer a blend of quality, reliability, and cost-efficiency. Here are some common features:

✅ Sturdy Frame Construction

Made from mild steel, aluminum, or stainless steel for durability and resistance to corrosion.

✅ Custom Belt Materials

Options include PVC, rubber, modular plastic, and food-grade belts depending on the application.

✅ Adjustable Speeds and Height

Motorized speed control with VFDs and adjustable-height frames for operational flexibility.

✅ Portability and Compact Design

Many companies offer portable or foldable conveyors for smaller facilities.

✅ Automation-Ready

For smooth automation, sensors, smart controllers, and PLC systems are integrated.

Applications of Belt Conveyors

Many different businesses use belt conveyors manufactured in Faridabad:

Automotive: Assembly line movement and component transfer

FMCG: Carton and pouch transport in packaging lines

E-commerce & Warehousing: Sorting and order fulfillment

Pharmaceuticals: Clean, contamination-free product handling

Mining & Cement: Heavy-duty material transfer

Food Processing: Hygienic conveyors with wash-down features

Their adaptability and versatility make them essential across sectors.

Why Choose Faridabad Manufacturers?

Here’s why companies across India and abroad trust Faridabad belt conveyor manufacturers:

📈 Proven Experience

Many companies have decades of experience and serve top national brands.

💡 Engineering Expertise

Access to modern tools like AutoCAD, SolidWorks, and simulation testing ensures quality.

🌍 Export Capability

Several firms export to Middle East, Africa, and Southeast Asia, indicating trust and scalability.

💸 Competitive Pricing

Compared to imported systems, Faridabad manufacturers offer high performance at a lower cost.

🔧 Reliable After-Sales Support

Prompt service and availability of parts ensure minimal downtime.

Things to Consider Before Buying

The following should be taken into account while selecting a belt conveyor system:

The kind and volume of information that needs to be conveyed

The type and amount of information that must be communicated

Required speed and length of the conveyor

Inclination or level transfer

Environmental factors (temperature, moisture, hygiene)

Power source and space availability

Most manufacturers in Faridabad offer free consultations and site visits to recommend the right solution.

Final Thoughts

If you’re looking to optimize your material handling operations, belt conveyors are a smart investment—and there’s no better place to source them than Faridabad. With a blend of innovation, affordability, and manufacturing excellence, Faridabad’s conveyor companies are meeting the evolving needs of industries across India and beyond.

Whether you're a small business or a large enterprise, the right conveyor partner from Faridabad can help boost your productivity and operational efficiency.

📞 Ready to Upgrade?

Get in touch with Faridabad’s leading belt conveyor manufacturers today for customized solutions and expert guidance.

Address: Plot No. 7, Gali no 2 Sahupura Industrial Area, Near Bypass, Faridabd-121004 Haryana (India)

Phone No. : 9958352003

#BeltConveyor#BeltConveyorManufacturer#ConveyorManufacturerFaridabad#MaterialHandlingEquipment#IndustrialConveyors#FaridabadIndustry#ConveyorSystemsIndia#ManufacturingSolutions#FactoryAutomation#BeltConveyorIndia#CustomConveyor#IndustrialMachinery#MadeInIndia#EngineeringSolutions#VashnaviConveyor#FaridabadManufacturers#AutomationEquipment#HeavyDutyConveyors#SmartMaterialHandling#ConveyorBeltSystem

0 notes

Text

High-Quality AAC Block Machine | Automatic & Efficient Block Production

An AAC block machine is a high-performance industrial system designed to manufacture Autoclaved Aerated Concrete (AAC) blocks used in modern construction. These machines automate the process of mixing raw materials, casting, cutting, and curing, ensuring consistent quality and high output. Ideal for producing lightweight, durable, and eco-friendly building blocks, AAC machines significantly reduce labor costs and construction time. With advanced technology, low maintenance requirements, and energy-efficient operations, they are suitable for large-scale production in both commercial and residential projects. Investing in an AAC block machine enhances productivity, promotes sustainability, and meets the growing demand for efficient construction materials.

#aac plant manufacturer#aac block machinery manufacturer#aac block plant cost#AAC block manufacturing machine cost#aac block machine#aac block#aac bricks plant cost

0 notes

Text

Humidity Control Sachet Wrap in the Pharmaceutical Industry: Compliance & Performance

In the pharmaceutical industry, product stability is everything. From tablets to capsules, excess moisture can compromise drug efficacy and shelf life. That’s why humidity control sachets, enclosed in high-performance wraps, are a critical part of pharmaceutical packaging.

Importance of Sachet Wraps

Humidity control sachet wraps act as a barrier and delivery system, allowing desiccants like silica gel or molecular sieves to absorb moisture effectively without contaminating the product. The right wrap material ensures both compliance and consistent performance.

Key Features of Pharmaceutical-Grade Sachet Wraps

Dust-Free & Non-Shedding: Prevents cross-contamination

Breathable Yet Secure: Allows moisture vapor in while containing desiccants

FDA & USP Compliant: Meets global pharmaceutical packaging standards

Compatible with High-Speed Machinery: Supports automated packaging lines

Materials Commonly Used

Tyvek® for medical-grade safety

Non-woven fabric for breathable, cost-effective options

Laminated film for high moisture-barrier needs

Final Thoughts

For pharmaceutical companies, choosing the right humidity control sachet wrap ensures regulatory compliance and protects product integrity. At Favourite Fab, we provide custom sachet solutions tailored to the demanding needs of the pharma industry—where performance and precision are non-negotiable.

0 notes

Text

🏭 Rise of the Smart Factory: $221.7B Market by 2034 Sounds Unreal (But It’s Not)

Smart Factory Market is on a rapid growth trajectory, poised to expand from $86.2 billion in 2024 to $221.7 billion by 2034, clocking a CAGR of 9.9%. This surge is powered by the convergence of AI, IoT, robotics, and big data analytics within manufacturing ecosystems. Smart factories revolutionize production by enabling real-time monitoring, predictive maintenance, and automated decision-making, turning traditional plants into agile, efficient, and intelligent hubs of productivity. As digital transformation sweeps across sectors, smart factory solutions are no longer optional — they’re essential for staying competitive in a dynamic industrial landscape.

Market Dynamics

Key market drivers include the widespread adoption of Industry 4.0, the rising need for efficiency and automation, and growing concerns around energy consumption and sustainability. Industries are now leaning into technologies that cut operational costs, optimize workflows, and enable customized, data-driven production.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20453

However, the market faces challenges such as high initial investments, cybersecurity vulnerabilities, and a skills gap in the workforce. Legacy infrastructure is also a roadblock for some companies looking to transition quickly. Despite these hurdles, smart factories are becoming increasingly accessible, thanks to government support, modular solutions, and scalable cloud-based platforms.

Key Players Analysis

Major players are heavily investing in R&D and strategic alliances to lead the smart factory wave. Companies like Siemens AG, Schneider Electric, ABB, Honeywell, and Mitsubishi Electric dominate the landscape with integrated solutions that combine software, hardware, and services. These giants focus on digital twins, AI-powered robotics, and end-to-end automation. Meanwhile, emerging innovators like Smart Fab Solutions, Intelli Plant Technologies, and Pro Efficient Technologies are disrupting traditional models with niche offerings in AI integration, cloud robotics, and modular factory solutions. Strategic partnerships and customized deployment models are key trends in gaining market edge and client retention.

Regional Analysis

Asia-Pacific leads the global smart factory market, driven by rapid industrialization, massive government backing, and a tech-forward manufacturing base in China, Japan, and South Korea. These nations are heavily investing in smart grids, AI in manufacturing, and advanced robotics, making the region a hotbed for innovation. North America, led by the United States, benefits from strong digital infrastructure, Industry 4.0 adoption, and innovation-driven sectors like automotive and aerospace. In Europe, the focus is on energy efficiency, sustainability, and smart production lines underpinned by strict environmental regulations. Germany and the UK are investing significantly in smart factory R&D, aligning with EU-wide digital goals.

Recent News & Developments

The Smart Factory Market has seen groundbreaking advancements recently. Integration of AI, IoT, and ML is now enabling predictive analytics, zero-downtime maintenance, and autonomous operations. A notable trend is the spike in demand for cybersecurity as interconnected systems become targets for cyber threats. Pricing strategies are evolving — solutions are becoming more customizable and scalable, encouraging adoption among SMEs. Additionally, many companies are exploring green manufacturing solutions, with a focus on reducing carbon emissions and energy consumption. Strategic alliances, M&As, and tech-driven collaborations are reshaping the competitive landscape across the globe.

Browse Full Report : https://www.globalinsightservices.com/reports/smart-factory-market/

Scope of the Report

This report covers a comprehensive analysis of the smart factory market, segmented by type, product, services, technology, components, application, process, deployment models, and end-user industries. It provides both quantitative data and qualitative insights into current market trends, growth potential, and competitive benchmarking. The report evaluates value chains, conducts PESTLE and SWOT analyses, and maps regional and global opportunities. Key focus areas include local competition, regulatory compliance, cross-segmental strategies, and supply-demand forecasting. The report offers actionable intelligence for stakeholders, empowering them to identify lucrative areas for investment, innovation, and market expansion.

Discover Additional Market Insights from Global Insight Services:

Agricultural Lighting Market : https://www.globalinsightservices.com/reports/agricultural-lighting-market/

Air Quality Monitoring System Market : https://www.globalinsightservices.com/reports/air-quality-monitoring-system-market/

Industrial Robotics Market : https://www.globalinsightservices.com/reports/industrial-robotics-market/

Printed Electronics Market : https://www.globalinsightservices.com/reports/printed-electronics-market/

Current Sensor Market : https://www.globalinsightservices.com/reports/current-sensor-market/

#smartfactory #industry40 #iiot #aiinmanufacturing #industrialautomation #robotics #iotintegration #predictivemaintenance #digitaltransformation #manufacturinginnovation #cloudcomputing #smartmanufacturing #automatedproduction #mes #plm #erp #cybersecurity #industrialrobots #machinevision #bigdataanalytics #augmentedreality #sustainablemanufacturing #energyoptimisation #factoryofthefuture #digitaltwins #industrialai #realtimemonitoring #edgecomputing #intelligentfactories #airobotics #automationsolutions #smartmachines #connectedfactory #manufacturingtrends #supplychainautomation #greenmanufacturing #smartmaintenance #manufacturingai #4ir #techdrivenfactory #manufacturingefficiency

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

🚀𝗗𝗶𝗱 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄?

In semiconductor fabs, even the welds have to be flawless.💡

🔧Orbital welding is key to building ultra-clean, high-purity piping systems that carry critical process gases. Its fully automated, hands-free precision meets the zero-contamination standards of Class 1 cleanrooms, where the future of microchips is made. 🧠💻

#DidYouKnow #Semiconductors #OrbitalWelding #CleanroomTech #ChipManufacturing #HighPurityPiping #PrecisionEngineering

#orbital welding technology#orbital welding courses#orbital welding training#orbital welding#welding automation#orbital welding program#welding technology#semiconductor

0 notes

Text

Global Wet Cleaning Equipment Market to Reach US$ 5.23 Billion by 2032

Wet Cleaning Equipment Market Analysis:

The global Wet Cleaning Equipment Market size was valued at US$ 3.47 billion in 2024 and is projected to reach US$ 5.23 billion by 2032, at a CAGR of 5.9% during the forecast period 2025-2032

Wet Cleaning Equipment Market Overview

The U.S. market size for Wet Cleaning Equipment is estimated at USD 520 million in 2024, while China is projected to reach USD 740 million in the same year.

The Single Wafer Wet Cleaning Equipment segment is expected to reach USD 1,320 million by 2032, growing at a CAGR of 6.9% during the forecast period 2025–2032.