#feed pellet cooler

Text

SKLN Counterflow Cooler

SKLN Counterflow Cooler Introduction

The cooling of pellets is an indispensable process in the granulation section. Our SKLN serious counterflow cooler is adopted to cool the pellets with high temperature and moisture. Hot air touches hot pellets and cool air touches cool pellets to avoid the pellet surface crack caused by sudden cooling produced by direct touching between cool air and hot…

View On WordPress

0 notes

Text

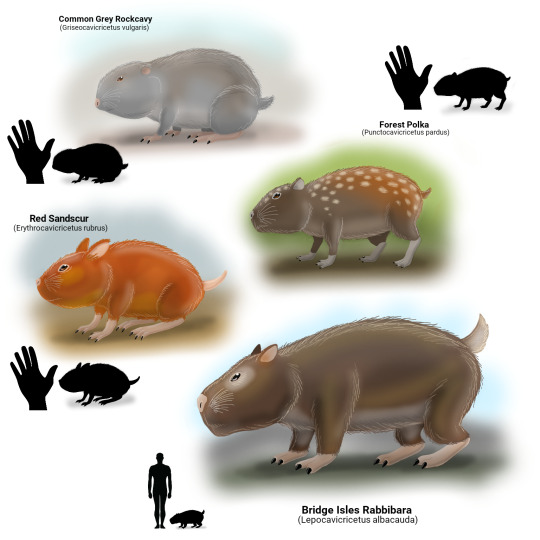

The Early Temperocene: 135 million years post-establishment

Guinea Mimics: The Gwinnies

The Cavioidecricetidae, also known as the gwinnies, are a group of duskmice belonging to the same clade as the hammibals and the pondrats, though of closer relation to the pondrats than the hammibals: having diverged sometime in the Middle to Late Rodentocene. The gwinnies are primarily small herbivores, in essence having taken over the niches occupied by the basal gouties and the broadheads during the Early Rodentocene, and adapted to feed on a wide array of foliage, such as roots, leaves, stems and flowers of the various grasses and cloverferns that grow across the world. They process these plant material with the help of hindgut fermentation, allowing them to extract nutrition from even the hardest-to-digest vegetation: however, a consequence of this is that they are required to ingest their droppings a second time in order to absorb their full nutritive content. Mother gwinnies thus produce these special pellets in greater amounts in the few weeks after weaning, as these processed, nutritious pellets are usually her offsprings' introduction to consuming solid food.

Throughout their long history, the gwinnies have not become as diverse as most other duskmice clades, but have persisted nearly across the globe in various niches of "small herbivorous rodent" in many different biomes. Breeding all year round, and producing relatively well-developed young per litter that are born fully-furred and open their eyes in a week or two, they, like most other duskmice, are rather low in most food chains and fear many predators, and thus defend themselves by digging burrows, hiding in crevices, and generally reproducing in large numbers to ensure the survival of a few.

One of the most abundant species in the Temperocene is the common grey rockcavy (Griseocavicricetus vulgaris) which is found throughout temperate regions, primarily in mountainous areas with plentiful small gaps among cliffs and ledges for it to seek shelter in. A nocturnal species with small eyes, it prefers to emerge under cover of dark, finding food with the aid of its powerful sense of smell and sensitive whiskers, and gorging itself all evening before retreating to its den by morning, with a stash of additional food it carries in its cheek pouches in order to feed on while seeking shelter during the day when predators abound.

In tropical forests, meanwhile, one may find a similar yet quite different relative: the forest polka (Punctocavicricetus pardus). This species, in contrast, is active during the day, and scampers about the forest floors of tropical jungle on its relatively-long legs, foraging for the low-growing shrubs and cloverferns found in the ground level and the understory. Here, there is abundant cover among the plants, tree roots and fallen logs, and its primary camouflage comes in the form of pale blotches on its body that mimic the speckled, dappled light on the forest floor, breaking up its outline and making it more difficult to see when it freezes in place to hide from threats. In addition to leaves and stems, the polka also relishes fallen fruit dropped from the canopy: making it an important seed-disperser that scatters tree seeds far and wide in places that are favorable for them to sprout.

In open deserts and arid semidesert, in the meantime, during the times when Beta alone in the sky casts the landscape in a brilliant red, the red sandscur (Erythrocavicricetus rubrus) emerges from its den to search for food. Like many animals in the desert, it avoids the searing rays of Alpha by emerging at a period of time when its dimmer, cooler twin instead reigns the sky. As the presence of a red secondary sun has favored the evolution of trichromat vision in many lineages, including predators, so too have prey evolved to hide under these conditions, with red-colored fur originating from erythrism: an unusual increase of red pigment in an animal's pelage that with Beta-twilight as a regular phenomenon became an unexpected survival advantage and thus became the normal state of many species. Well-concealed in the crimson light, the red sandscur is hardly conspicuous as it searches out desert succulents both as a source of food and water.

Most gwinnies of the Temperocene are quite conservative in build, having changed little from their early ancestors, but one significant exception dwells on a small chain of islands between the continents of South Ecatoria and Arcuterra: the Bridge Isles rabbibara (Lepocavicricetus albacauda). The largest of the gwinnies, at roughly twelve kilograms, it grew to such large sizes due to the isolation of its habitat from the mainland, and in the absence of competition grew to an enormous size, comparatively speaking. With its only threats being aerial ones from opportunistic predatory ratbats, it simply grew too large to be carried away by them, and while young may be occasionally vulnerable, adults face little threat and are generally unfazed as they graze on the abundant grasses in the Bridge Isles. The rabbibara, while continuing to survive well into the Middle Temperocene, would find its range restricted to the two northmost islands as its populations disappeared in the southernmost ones due to a period of unstable fluctuations in local food availability. Its absence in those areas, however, would favor a far stranger creature to take its place and become the dominant herbivore of the isles: the zeebeedee (Megalornithomys spp.), a grazing pterodent that, in the absence of predators, also grew to enormous proportions and abandoned its flight entirely.

--------------

39 notes

·

View notes

Text

I love Warframe, so much.

The super fluid, only touch the ground to start another parkour sequence, the floor is lava, bouncing off walls and flying across rooms and down hallways style of movement.

The >utterly overwhelming< number of weapons available. Primaries range from bows (Paris, Dread) to rocket launchers (ogris) grenade launchers (penta, tonkor), a handheld laser cannon (opticor), spicy bows (Lenz and Bramma are both rocket launchers cosplaying as bows), an 18th century naval cannon (zarr), machine guns with a 200 round magazine (soma prime) and machine guns that get more accurate the longer you fire (Tenora my beloved), innately suppressed smg (baza). You want a chaining lightning gun that will kill the guy you’re aiming at, and the next two rooms of people via daisy chains? Amprex. if you need a tactical weapon for grouping enemies the Mutalist cernos shoots an arrow full of grabby tentacles that brings enemies together for group hugs. Do you need a rifle to hunt cthulu T-Rexes (eidolons)? Rubico (Prime) or, my favorite, Kuva Chakkhurr - a black powder musket that shoots moderately slow projectiles, high skill high reward, you land a shot, it’s gonna feel it. Here’s a goody - Tigris (Prime) - it’s a double barreled shotgun, with a duplex trigger - you squeeze the trigger, it fires one round, you release the trigger, it fires the second! really interesting to play with, though with the changes to shotgun status a few years ago it’s no longer the powerhouse it was, though quite potent. Phenmor is also one of my favorites, a precision semi auto rifle, land a couple headshots to charge it, and it evolves into an archgun (gun for mecha or exosuits, bigger, and badder) that’s basically a minigun. Corinth (prime) is cool, primary fire is crit based shotgun, alt fire shoots an air burst grenade you can manually detonate over enemies heads (prime version, regular corinth is locked at 20m detonation). Kohm is an auto shotgun that spoils up like a minigun, the higher the spool the more pellets it shoots, very ammo hungry, but man if it isn’t satisfying to point down a hallway and watch it fill with red mist. Astilla is a shotgun that shoots glass slugs that explode on impact. Arcs Plasmor shoots solid walls of energy. like straight up, point down hallway, and you shoot a bright blue (ur energy color) brick wall of plasma. you can’t miss. Simulor is a gun that shoots miniature black holes. Trumna charges it’s alt fire with the literal souls of the enemies you kill. Shedu and Bubonico are the weapon arm cannons of sentient (enemy robot faction) that we ripped off and stole.

secondaries are have a bit less variety, but we’ve still got oodles of goodies

Pandero, a pocket sniper rifle, this lil handcannon is hella accurate for reaching out to touch someone, and alt fire dumps the entire magazine in an automatic burst. Laetum is the cooler pandero, land a few headshots and it evolves into an automatic assault rifle. Lex (Prime) was my starchart clearing gun, back in the day. space deagle. Nukor (and it’s cooler older sister Kuva Nukor (Kukor)) are similar to the amprex in that they chain to enemies, however they also have the quirk of having the highest critical damage in the game, with the lowest critical chance. (there’s shenanigans you can do to force them to crit, making them devestating). Pyrana (Prime) is an auto shotgun, it’s got high spread and high rate of fire, but get in their face and drop mag and see the magic. Zakti (Prime) shoots small needles that explode in clouds of aoe gas after a moment, really good for priming status effects and swapping to melee or primary to take advantage of. Euphona Prime - look, i love it, it’s not great, you gotta build it exclusively for the slug firemode or for the shotgun fire mode. it’s really cool, you should try it if you can, but it’s solidly just okay. Sepulcrum feeds on the souls of its victims to power its alt fire, and it’s just a massive beefy fuckin pistol straight out of 40K. Tenet Spirex force procs impact, and with the hemorrhage mod you can guarantee you turn some of those impact procs into bleed procs for DOT damage. Athodai is straight up like retro sci-fi laser pistol, it shoots beams, and alt fire has a big burst of energy aoe in front of you. Twin Kohmak are like the kohm, but smaller, and akimbo, for pocket dakka. Twin Grakata MOAR DAKKA. A beloved meme gun in the warframe community. just two fuckin bullet hoses that will eat your ammo faster than you can find it. truly one of the guns of all time, and a joy to fire.

and don’t think for a moment i’m going to forget about melees lmao.

we got Nikanas (space katana - nikana (prime) , skiajati ), we got greatswords(Gram (prime), Galatine (prime)), we got throwing glaives(Glaive(prime) Xoris), we got gun blades (like think those bizarre renaissance era swords with guns built into the hilts? got it? yeah, those, but space-y. redeemer (prime), sarpa), we have claws (venka) , we have sword & board (silva & aegis) scythes (reaper prime), hammers (heliocor, jat kittag), dual blades up the wazoo, single daggers, dual daggers, fist weapons, fist and feet weapons, war fans (quassus, arum spinosa), staves (Bo, pupacyst), tonfa (kronen), a gigantic saw (ghoulsaw), rapiers (endura, ), blade & whips (atterax, lacera)

#warframe#long post#totally normal about this game#also i own almost every weapon#i’m missing the most recent 5

28 notes

·

View notes

Text

Precautions for the use of npk production line granulator

The npk fertilizer production line mainly includes feeder, disc mixer, chain crusher, granulator, drum dryer, drum cooler, drum screener, finished product warehouse, automatic packaging machine, belt conveyor, Dust settling chamber, heat exchanger, etc. The granulator is an important part of the production of granular npk fertilizer. Common granulators include double roller granulator, drum granulator, disc granulator machine, etc. The granulator is simple to operate, low energy consumption, long service life, Strong wear resistance, has been recognized by many customers, but most customers do not pay much attention to the maintenance of the machine, which leads to machine failure, which seriously affects the service life and production efficiency of the machine.

1. Workers should feed the material evenly, do not change the quantity and quantity, which will affect the quality and output of pellets.

2. Check all parts frequently to see if the screws are loose, if they are loose, they should be firm in time.

3. The oil needs to be changed frequently. If the oil is not changed for a long time, oxides will be produced, which will enter some materials and affect the service life of the machine.

4. The wearing parts should be replaced frequently during the fertilizer granulation process. The long-term use of the machine will cause the wearing parts to wear out, and the parts must be replaced before the wearing parts are completely unusable.

5. Do not overload the machine for a long time. Machines, like humans, also need rest. Reasonable rest of the machine will prolong the service life.

6. The bearing rises stably, stop the machine in time to check the reason.

7. It is strictly forbidden to use stone, iron mixed into the material, so as not to damage the drum.

8. Gear oil should be replaced regularly, generally every 4 months, according to the manufacturer's requirements and actual use.

3 notes

·

View notes

Text

Raw material preparation stage

Wheel Loader Feeding Hopper: Used for loading and initial storage of raw materials.

Cage Crusher (especially urea mill) : If urea needs to be added, use this device for grinding.

Compost fermentation stage

Windrow Compost Turning Machine : It is used for turning compost, increasing oxygen exposure and promoting microbial activity.

Chain Crusher: In the composting process, the bulk material is further crushed.

Compost Crusher: Suitable for the crushing of semi-wet materials.

Stirring phase

Horizontal Ribbon Mixer: Used for mixing different compost materials and microbial agents.

Double Shafts Paddles Mixer: for more even mixing.

Granulation stage

Fertilizer Granules Compaction Machine: It is suitable for squeezing compost materials into granules.

Flat-Die Pellet Machine: forming particles by pressing.

Rotary Drum Granulator: Roll in the drum to form spherical particles.

Disc Granulator: Particles are formed on a disk by rolling and friction.

Drying and cooling stage

Rotary Dryer Machine: Used to reduce the moisture content of particles.

Rotary Cooler Machine: cooling the dried particles to ensure product quality.

Screening and packaging stage

Rotary Screening Machine: Screens particles to ensure dimensional consistency.

Vibration Screening Machine: Further screening to remove fine particles or impurities.

Powder Fertilizer Packing Machine : Packaging the materials after screening.

Granules Fertilizer Packing Machine : Packaging granular fertilizer.

Through the above equipment configuration, a complete oil palm compost fermentation and granulation production line can be built to achieve automatic production from raw material processing to final products.

0 notes

Text

Raw material preparation stage

Wheel Loader Feeding Hopper: Used for loading and initial storage of raw materials.

Cage Crusher (especially urea mill) : If urea needs to be added, use this device for grinding.

Compost fermentation stage

Windrow Compost Turning Machine : It is used for turning compost, increasing oxygen exposure and promoting microbial activity.

Chain Crusher: In the composting process, the bulk material is further crushed.

Compost Crusher: Suitable for the crushing of semi-wet materials.

Stirring phase

Horizontal Ribbon Mixer: Used for mixing different compost materials and microbial agents.

Double Shafts Paddles Mixer: for more even mixing.

Granulation stage

Fertilizer Granules Compaction Machine: It is suitable for squeezing compost materials into granules.

Flat-Die Pellet Machine: forming particles by pressing.

Rotary Drum Granulator: Roll in the drum to form spherical particles.

Disc Granulator: Particles are formed on a disk by rolling and friction.

Drying and cooling stage

Rotary Dryer Machine: Used to reduce the moisture content of particles.

Rotary Cooler Machine: cooling the dried particles to ensure product quality.

Screening and packaging stage

Rotary Screening Machine: Screens particles to ensure dimensional consistency.

Vibration Screening Machine: Further screening to remove fine particles or impurities.

Powder Fertilizer Packing Machine : Packaging the materials after screening.

Granules Fertilizer Packing Machine : Packaging granular fertilizer.

Through the above equipment configuration, a complete oil palm compost fermentation and granulation production line can be built to achieve automatic production from raw material processing to final products.

1 note

·

View note

Text

Feeding Frenzy: Nutrition Tips for Happy and Healthy Koi

With their vibrant colors and graceful movements, Koi fish are a favorite among pond enthusiasts. To keep these beautiful creatures healthy and happy, providing them with the right nutrition is essential. Feeding Koi isn't just about tossing food into the pond; it involves understanding their dietary needs and habits. This article delves into crucial nutrition tips for Koi, ensuring they thrive in your pond.

Understanding Koi Nutritional Needs

Koi are omnivorous, meaning they eat both plant and animal matter. Their diet should include proteins, carbohydrates, fats, vitamins, and minerals, each vital to their growth, health, and coloration.

Proteins: Essential for growth and repair, proteins should comprise a significant portion of a Koi's diet. Fish meal, shrimp, and other aquatic animals are excellent protein sources. During the warmer months, when Koi are more active, they require higher protein levels.

Carbohydrates: These provide energy for daily activities. Koi can digest plant-based carbohydrates like wheat germ, rice, and corn. However, it's important not to overfeed carbohydrates as it can lead to obesity and water quality issues.

Fats: Fats are necessary for energy and the absorption of vitamins, so fats should be included in moderation. Fish oil and other aquatic fats are suitable sources. Too much fat can cause health problems, so balance is key.

Vitamins and Minerals: Vitamins like A, C, D, E, and K, as well as minerals such as calcium and phosphorus, are crucial for overall health. These nutrients support immune function, bone health, and vibrant coloration. High-quality commercial Koi foods are usually fortified with these essential nutrients.

Choosing the Right Koi Food

Selecting the right food is fundamental to maintaining Koi's health. Here are some types of Koi food to consider:

Pellets: Commercial pellets are popular because they are formulated to provide balanced nutrition. They come in different sizes to accommodate Koi of various ages and sizes. Floating pellets are preferred as they allow you to observe your Koi while they feed, ensuring each fish gets its share.

Sticks and Flakes: These are similar to pellets but come in different shapes and textures. Sticks can be fun for Koi to chase, while flakes are suitable for smaller Koi.

Treats and Supplements: Koi enjoy a variety of treats like earthworms, shrimp, and vegetables. These can be fed occasionally to provide enrichment and variety. Supplements like spirulina can enhance coloration and health.

Feeding Tips for Optimal Health

Proper feeding techniques are as crucial as the food itself. Here are some tips to ensure your Koi get the most out of their diet:

Feed in Moderation: Overfeeding can lead to poor water quality and health issues. A general rule is to feed only what the Koi can consume within five minutes. Remove any uneaten food to prevent it from decomposing and polluting the water.

Seasonal Feeding: Koi's metabolism changes with water temperature. They are more active in warmer months and require more food, especially protein-rich diets. In cooler months, their metabolism slows, and they need less food, focusing more on easily digestible options like wheat germ.

Observe and Adjust: Pay attention to your Koi's behavior and health. If you notice lethargy, changes in coloration, or health issues, adjust your diet or feeding routine.

Feed Consistently: Establish a regular feeding schedule. Koi can become stressed if feeding times are erratic. Consistency helps them maintain a healthy routine and reduces competition for food.

Maintaining Water Quality

Good nutrition goes hand-in-hand with excellent water quality. Overfeeding and poor feeding habits can deteriorate water quality, leading to health problems for your Koi. Regularly check water parameters like ammonia, nitrite, and pH levels. Use filtration systems and perform water changes to keep the pond environment clean and healthy.

Common Feeding Mistakes to Avoid

Avoid these common mistakes to ensure your Koi stays healthy:

Feeding Low-Quality Food: Cheap, low-quality food often lacks essential nutrients and can cause health problems. Invest in high-quality commercial Koi food.

Inconsistent Feeding Times: Irregular feeding can stress Koi and affect their health. Stick to a consistent schedule.

Overfeeding: This can lead to obesity and water quality issues. Feed in moderation and adjust based on your Koi's activity levels and season.

Ignoring Individual Needs: Different Koi may have different nutritional needs. Pay attention to the needs of each fish, especially if you have a mix of young and old Koi.

Feeding Koi properly ensures they remain healthy, vibrant, and active. By understanding their nutritional needs, choosing the right food, and following proper feeding techniques, you can create a thriving environment for your Koi. Remember, a well-fed Koi is a happy Koi, and their dazzling display will be a testament to your dedication and care.

0 notes

Text

Sewellia lineolata is one of the ballitorid hillstream fishes, that are endemic to Asia. They are not "plecos" or loricarids, nor suckers or catostomids, as they are often confusingly labelled in aquarium retail. Loricarids and catostomids are found in other parts of the world. Often they are called a loach, which is fair, because they nest deeply within the traditional, pre-cladistic assemblage, called Cobitidae. Historically, they were regarded as distinct from the loaches.

S. lineolata are collected from Southeast Asian upland waters, which must always be well oxygenated, though not neccessarily as fast moving assume sources indicate, because these fish are found in pools beside riffles, as, well as in the actual rapids. In the wild, they live on gravel, bedrock, and sand substrates, with few submerged plants. Sewellia make an excellent focus for a biotope setup.

This species grows to about 6 centimeters, or 2 and a 1/4 inches. The trade names for S. sewellia, are the reticulated, tiger, and gold ring hillstream fish. For all I know, other species may be traded under these names. Care for all the imported species and morphs of Sewellia sp , is believed to be the same.

S. lineolata have small mouths for fishes their size, and feed on algae, biofilm, and very small invertebrates. In the aquarium this species will eat algae wafers, micro pellets of the sort offered to shrimp, and defrosted invertebrate based foods. These are not considered difficult fishes to feed, and they have no ability nor inclination, to prey on ornamental tank cohabitants.

I don't know the water parameters where they are collected from the wilds, but in the aquarium, their proper care is well established. Their water ought to be moderately hard, and its pH should be about neutral, with the temperture a bit lower than is usual for a tropical tank, with somewhere between 20 to 23 degrees centigrade being a good temperture to maintain.

In the wild they are diurnal, and spend time grazing and foraging, in unshaded water, so I imagine some daytime temperture tolerance greater than that - but its important to know, they experience cooler tempertures by night, and should not be confused with tropical fishes. Permanent exposure to tempertures over 24 degrees, has been noted to lead to emaciation.

They also experience seasonality in the wild, not only of temperture but of rainfall, with run off depositing organics into the water during the rainy season, surely affecting the water chemistry they experience. My point is, these are hardy loaches that tolerate a range of tempertures and water chemistries, only if the needs of oxygenation are met.

But the ability of fish like Sewellia sp. to temporarily tolerate high tempertures, on a daily or seasonal basis, should not be willfully misunderstood and abused, by people who want yo treat them as though they were tropical fishes. These are "coldwater tropicals".

#Sewellia lineolata#hillstream fishes#Coldwater tropicals#reticulated hillstream fish#gold ring hillstream fish#tiger hillstream fish#loaches

0 notes

Text

Moisture Management in Animal Feed

Feed moisture content varies and is often altered during feed milling. Moisture loss is problematic for producers and end users, significantly impacting nutrient distribution, inventory loss, feed costs, yield, and profitability.

Addressing moisture loss is not as simple as adding moisture back into the feed mixing process. Water has high surface tension, often resulting in poor absorption by feed if added directly, allowing water to flash off in the press and cooler or remain free.

Uneven or incomplete water absorption in feed causes issues such as low pellet quality, nutrient segregation, and spoilage. High and low moisture content in feed is problematic. High moisture reduces throughput, increases the energy required by the pellet-making process leads to feed spoilage and creates dense brittle pellets. However, low moisture reduces yields and increases fines, nutrient formulation and easily broken pellets.

Proper moisture management helps in good quality pellet and feed utilization, reduces process loss, prevents feed spoilage, and improves batch yield through reduced shrink. Effectivemoisture optimisation and management in feed require the producer to examine the factors impacting moisture level throughout the feed mixing and pellet-making process.

Surface tension reduction

When you add only water to the feed mix in a pelleting line, it can cause problems like lumps or clogs because the water doesn't spread evenly. This affects the quality of the animal food in terms of taste, texture, and how long it lasts.

To fix this, you need to make the water spread out more evenly. You can do this by making the water droplets smaller so they soak into the feed better. This helps the feed absorb enough water during processing.

Mould Control and Shelf-Life Extension

Propionic acids have been used for last 40 years as a mould inhibitor and shelf-life extension. However, it is very corrosive, and research proves that a blend of organic acids has a broader spectrum of anti-microbial activity than just propionic acid

Fylax is a synergistic blend of organic acids and surfactants. Organic acids reduce moulds to maintain the nutrient value and prolong the shelf life of raw materials, compound animal feed and pet foods. Moisture management agents act to optimise the distribution of Fylax throughout the feed and increase its water-binding capacity. This improves both its anti-mould effect as well as feed mill efficiency.

Fylax Forte-HC contains a patent-pending new technology, called ActiProp®. ActiProp increases the porosity of moulds’ cell walls, while its components destabilise the cell membrane. As this effect supports better accessibility of organic acids, the cell’s internal pH decreases, inhibiting its growth and eventually killing the mould cell. This mode of action is driven by the synergy of four key components delivered in the most effective quantities:

Benefits

Propionic acid - A highly effective broad-spectrum organic acid that attacks moulds

A buffering agent - This reduces evaporation and the corrosive nature of the propionic acid, enabling a prolonged effect and safer handling

A moisture management agent - This supports better spread and may facilitate the intake of organic acids inside the mould cells

Phytochemicals - These compounds derived from palm splitting have proven high synergy with propionic acid.

#animal nutrition#animalhealth#animal feed#dairy#poultry#mycotoxin risk#trace minerals#feed additives

0 notes

Text

youtube

Cremach Pvt. Ltd. (CPL) is a Project Engineering Company for Animal Feed plants based in Vadodara. CPL specializes in turnkey projects for animal feed-making machines, such as Cattle Feed plants, Poultry Feed Plant, Fish Feed Plant, and Shrimp Feed Plant.

Our high-quality milling machinery designed for the compound feed industry includes a Hammer Mill, Industrial Mixer, Pellet Mill, Crumbler, Countercurrent Cooler, and Material Handling Equipment. With the experience of over 4 decades, the company excels in the design, fabrication, supply, installation, automation, and commissioning of animal feed process machinery.

Cremach Private Limited 448/1 GIDC Makarpura Vadodara 390010 Reach us on +91 99099 84960

Email: [email protected]

Website: https://cremach.in/

#animal feed#cattle feed plants#poultry feed#fish feed#cremach#shrimp feed#cattle feed machine plant supplier#manufacturing#Youtube

0 notes

Text

To produce pellets, you must very first grind the raw material right into a uniform consistency.

Supply Pellet Production Series

A fuel pellet production line can be a set of machines that allows you to turn various kinds of raw biomass materials into wood or maybe feed pellets. Those materials can then be used pertaining to heating and electric power generation. As having any business enterprise, there are certain facts to consider before making a move to start your own pellet line. Fuel Pellet Production Line Manufacturers The chief considerations are the availability of the reliable supply associated with raw material along with a market for your own finished product. The species of material you choose to process will also are likely involved in your complete costs.

To produce pellets, you must very first grind the raw material right into a uniform consistency. This really is done with some sort of hammer mill or even a pellet mill. After that, the material need to be dried. This can be accomplished by getting the material throughout an oven or perhaps using evaporator technology to cut out moisture from your material.

The next step could be to create a pellet press which will compress the material into pellets. The press must be able to withstand high quantities of pressure as well as temperature, and it have to be large enough to support the desired pellet dimensions. Once the pellets are formed, they must become cooled and dried before they usually are stored or purchased.

Once the pellets are created, it’s important to know what kind of burner you have around to use all of them. Most pellet stoves are made to burn wooden, so it’s important in order that your pellets are going to be compatible with that particular kind of fuel. Grass pellets, such as, are often less desirable as a heating fuel all around health contain more ash than wood pellets. If you plan on selling a person's pellets for use to be a fuel source, then it’s best to use a pellet stove that's specifically designed for those purposes.

Pellet production requires a great deal of energy, both for drying the damp feedstock in order to power the systems itself. You must spend some time experimenting with your raw material and equipment so that you can find a mixture that reliably produces pellets on the proper quality in addition to density. Pellet presses can build a very large volume of heat, so they need to be properly insulated to guard the machinery and workers from problems.

Small Pellet Creation Line

A complete pellet generation line typically involves a hammer mill/crusher, dryer, conveyor, pellet appliance, conterflow cooler and also pellet packaging unit. The line is often modified to include other parts and equipment seeing that needed. It enables you to process a various raw materials, which include crop straw, type grass, sawdust, peanut shells, bran, rice husk and bamboo bedding wastes.

The approach to creating fuel pellets might be complex and time-consuming, but it is one who can offer a significant return on investment. The key is always to have a good knowledge of the processes involved in each stage, therefore you must be prepared invest some money to get the right equipment. With proper preparing, you can easily begin your path in order to success.

0 notes

Text

How to use straw to produce biomass pellet fuel?

Biomass pellets are produced using farming waste and different straws by squashing, expulsion and drying at a specific temperature. Biomass pellet fuel has great monetary, ecological and social advantages as a substitute for non-sustainable fills like coal and oil. Check it out pellet straw

Need of biomass pellet fuel energy

Energy and climate are confronting serious emergencies. Consequently, changing the energy utilization structure and forestalling air contamination have turned into a significant issue for the manageable improvement of society and economy. It is pressing to muster clean gumption to supplant fossil energy like coal and oil. As a sustainable and clean energy, biomass energy has drawn in increasingly more consideration. Biomass energy alludes to the energy put away in the life form. Green plants store energy inside living beings by changing over sun based energy into substance energy through chlorophyll. For instance, straw, as a biomass natural substance, has extraordinary potential for profound turn of events. The usage of biomass can be partitioned into numerous sorts. Handling biomass into little pellet fuel is a high level method of biomass use. Debris delivered after ignition is a decent normal manure. As of now, biomass pellet fuel gasification ignition is a clean and harmless to the ecosystem burning mode, which is of extraordinary importance to decrease poison discharges and safeguard the barometrical climate. The sulfur content of biomass pellet fuel is under 1/10 of that of coal. It can actually diminish the emanation of sulfur dioxide in the air by supplanting coal burning. Check it out eucalyptus as firewood

straw pellets

Guideline and innovative course of straw pellets

Biomass pellet fuel is a sort of pellet fuel with high calorific worth, great strength, low toxin content, stable execution and great turbidity. Biomass pellet fuel is a sort of pellet fuel which is handled from crop squander (straw, and so on) through cutting edge creation innovation. The particular mechanical interaction is as per the following. Buy the pine wood for firewood

Assortment of yield squander (straw, and so forth) - drying - smashing - fixing - hot pressure - framing - granulation - sacking - capacity

Arrangement strategies for straw pellets

Utilizing corn straw and rice straw as unrefined components. Dry the unrefined components to a reasonable dampness content, the dried natural substances are squashed by a smasher. After the powder natural substances are added with water, blending equally with blender and controlling the dampness content. The homogeneous blend is relaxed by steam and moved to the pellet factory for expulsion and pelletization. The straw pellets are passed on to the cooler for cooling and screening. The completed items are stuffed in unique polypropylene-overlaid woven packs. Buy the best heating pellets

Straw pellet plant

Specialized pointers and advancement of straw pellets

The innovation of yield straw pellet fuel has a place with the application field of biomass energy. With next to no added substances, the harvest straw is made into pellet fuel, which has high thickness, high framing rate and high calorific worth. The item can be utilized not just for unique boilers, warming heaters, chimneys and different powers, yet additionally as feed for domesticated animals. Buy the banacali epal eur

Benefit investigation of straw pellets

Monetary, ecological and social advantages

Costs are assessed through natural substance expenses, fuel and power expenses, wages and advantages, deterioration of hardware, interest on credits, and so forth. Compute the benefit in light of deals. check epal euro pallet

The ill-advised removal of harvest straw will contaminate the climate somewhat. The pellet fuel produced using crop straw is singed in an exceptional gasification kettle. The warm proficiency is 81%. The outflow of CO2 and SO2 is close to nothing. It can supplant non-sustainable energizes like coal and oil, and diminish the effect of waste on the climate. firewood poplar

The consummation of the venture can build ranchers' pay, yet in addition extend work and lessen social joblessness. Pellet fuel can supplant non-sustainable power and settle the energy emergency. It has specific social advantages for building a supportable energy framework and advancing public monetary turn of events. beech for firewood

Application possibilities of straw pellets

Biomass pellet fuel involves squander crops as natural substances. Neighborhood materials and creation lessen the transportation cost of agrarian waste and contamination in the transportation cycle. Biomass pellet fuel has the qualities of energy saving, ecological assurance and non-sustainable assets saving, which lightens the logical inconsistency between the lack of power and oil. With the promotion and use of biomass fuel boilers, the interest for biomass pellet fuel will undoubtedly increment significantly. As a perfect and sustainable power source, it can likewise endeavor to further develop item quality, decrease creation costs and foster supporting items. It has a splendid future. beech for firewood

0 notes

Text

Which Corydoras catfish is famous for its bright green coloration and is commonly called the "Emerald Cory"?

Types of Corydoras Catfish: The Emerald Cory - A Vibrant Delight

Introduction:

Corydoras catfish are fascinating freshwater fish known for their unique appearance and peaceful nature. Among the numerous species of Corydoras, one particular variant stands out for its striking green coloration and is commonly referred to as the "Emerald Cory." In this article, we will explore the different types of Corydoras catfish and delve into the characteristics that make the Emerald Cory so famous.

Understanding Corydoras Catfish

Corydoras catfish belong to the Callichthyidae family and are native to South America. These small, bottom-dwelling fish are widely loved by aquarium enthusiasts for their peaceful temperament and ability to thrive in a community tank. They possess a distinct feature of an armored plating called "scutes," which provides them with protection.

The Emerald Cory (Corydoras splendens)

The Emerald Cory (Corydoras splendens) is an exceptionally popular variant of Corydoras catfish due to its stunning bright green coloration. Also known as the Green Corydoras, it is widely sought after by aquarists for its eye-catching appearance and amiable behavior. Let's take a closer look at the defining characteristics of this remarkable fish.

Read more : -

Appearance:

The Emerald Cory boasts a unique shade of bright green that sets it apart from other Corydoras species. Its body features a sleek and streamlined shape, with a light-colored underbelly. The vibrant green coloration extends from its head to its tail, making it an enchanting addition to any aquarium.

Size:

On average, the Emerald Cory reaches a length of around 2 to 2.5 inches (5-6 cm). Their small size makes them suitable for most community tanks, as they can comfortably coexist with other peaceful fish species.

Behavior:

Like other Corydoras catfish, the Emerald Cory is known for its calm and docile nature. They are primarily bottom-dwellers, constantly scavenging the substrate for food. These social creatures thrive in groups, so it is recommended to keep them in shoals of at least six individuals.

Care and Tank Requirements:

The Emerald Cory is relatively easy to care for, making it an excellent choice for both beginner and experienced aquarists. They prefer a well-maintained aquarium with a sandy substrate, as their sensitive barbels can be damaged by rough gravel. Providing ample hiding spots with plants, rocks, or driftwood is essential to ensure their comfort.

Feeding:

In the wild, Emerald Corys are omnivorous, feeding on small invertebrates and plant matter. In an aquarium setting, they readily accept a varied diet consisting of high-quality sinking pellets, frozen or live foods like bloodworms, brine shrimp, and vegetable matter. A balanced diet ensures their overall health and color vibrancy.

Breeding:

Breeding the Emerald Cory can be a rewarding experience. They are egg layers and can lay several hundred eggs at a time. To encourage spawning, replicate their natural environment by providing low lighting and slightly cooler water temperatures. Once the eggs are laid, they should be removed to a separate breeding tank to protect them from being eaten by the adults.

Conclusion:

The Emerald Cory (Corydoras splendens) stands out among the various types of Corydoras catfish due to its stunning bright green coloration. This species captivates aquarists with its mesmerizing appearance and peaceful demeanor, making it a sought-after addition to freshwater aquariums. By providing suitable care and a conducive environment, aquarists can enjoy the beauty and charm of the Emerald Cory while contributing to the conservation of this unique species.

Remember, as with any fishkeeping endeavor, it is crucial to conduct thorough research and consult with knowledgeable experts to ensure the well-being of your aquatic pets.

Visit now : -

Read more : -

0 notes

Text

Molasses mixing machines price

Molasses mixing machines price Our History Founded in 2011 Yangzhou Hycox Industrial Co.,Ltd is located in Yangzhou City, Jiangsu Province, China. We are a professional Company specializing in design, research, manufacturing, sales and service. Our business scopes include feed machinery (Hammer mill, Mixer, Liquid adding system, Pellet mill, Feeder, Conditioner, Crumbler, Series Rota-shake sifter, SFJZ series vibrating sifter, functions if for distributing granular and powdery materials. Self-lock structure, accurate and reliable positioning with guiding pipe, automatic dust cleaning in the machine, compact structure, small space occupation, ease of maintenance. Heavy duty construction, simple and reliable for years of operation. Easy installation and low maintenance. Spout area varied from 100x100 ~ 800x800 cm2. Widely used for material feeding or discharging in feed, food, flour, chemical, mineral, metallurgy, cement industries. 鈼哖ermanent magnet sleeve: Made in stainless steel. Powerful iron removal performance without power consumption. Magnetic field intensity鈮?000GS; iron removal efficiency 鈮?9%. Widely employed in the material receiving system of feed mills, grain storage facilities and etc 鈼咰leaner: Simple structure, ease of cleaning and maintenance. Aspiration system for assistant cleaning. Suitable for large impurity removal in a material receiving system in feed mills, grain storage facilities etc. 鈼哠ilo: used to storage grains, wood chips, silage, cement, sand. The silo have temperature instrument, moisture instrument, level indicator, etc. the capacity is between 10T to 10000T. Production Equipment Main equipment: Hammer mill-Mixer-Pellet mill- Crumbler-Series Rota-shake sifter-SFJZ series vibrating sifter-Extruder-Dryer-Cooler-Dust collector, Bucket elevator-Packing machine-Screw conveyor, Drag conveyor-Distributor-Permanent magnet sleeve-Cleaner, Silo. Production Market South America 79% Africa: 8% Europe: 3% Middle East: 10% Our Service We export to different continents and regions, such as South America, Africa, Asia, Europe, and all our customers are satisfy with our: Prices, Services, Quality products.Molasses mixing machines price website:http://www.hycoxfeedmachine.com/

0 notes

Text

The animal feed mill use pellet feed product cooling machine, new design counter flow cooler

0 notes