#harting han connectors

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

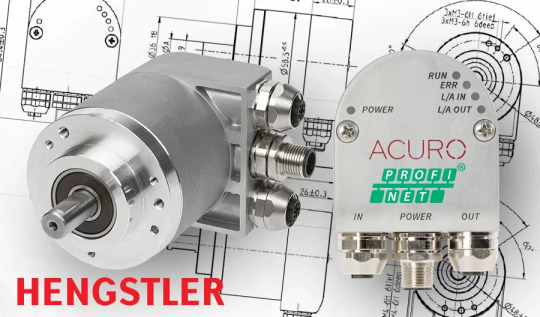

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes

Text

Best Harting Connectors Suppliers

NS Engineers is the leading Harting authorized distributors in India. Our extensive inventory boasts a diverse selection of top-tier Harting modular connectors including Harting han s connectors, Harting ethernet connectors, Harting han 1a compact connectors, and euromap connectors. As best Harting connectors suppliers, we are committed to offering high-quality products that cater to your specific requirements.

#Harting Modular Connectors#Modular Connectors#Harting Connectors Suppliers#Harting Han S Connectors#Harting Ethernet Connectors#Harting Han 1A Compact Connectors#Euromap Connector suppliers

2 notes

·

View notes

Text

21033216420 4 Position Circular Connector Receptacle, Female Sockets Solder

Category: Connectors, Interconnects, Circular Connectors

Mfr: INGKE Technology

Brand: HARTING

Series: Han® M12

Package: Bulk

Product Status: Active

Connector Type: Receptacle, Female Sockets

Number of Positions: 4

Shell Size - Insert: M12-4

Shell Size, MIL: -

Mounting Type: Panel Mount, Through Hole

Mounting Feature: Bulkhead

Termination: Solder

Fastening Type: Threaded

Orientation: A

Primary Material: Metal

Shell Material: Zinc Die Cast

Shell Finish: -

Contact Finish - Mating: Gold

Color: Silver

Ingress Protection: IP67 - Dust Tight, Waterproof

Material Flammability Rating: -

Features: -

Shielding: -

Current Rating (Amps): -

Voltage Rating: 250V

Cable Opening: -

Operating Temperature: -40°C ~ 85°C

Backshell Material, Plating: -

Contact Material: Copper Alloy

Contact Finish Thickness - Mating: -

Insert Material: Polyamide (PA), Nylon

Applications: -

Lead Time: 1-2 weeks

INGKE Main products:

1).100/1000/2.5G/5G/10G Base-T (with POE/POE+, 30w,60w,90w, 720mA,900mA) RJ45 connector cross Pulse,Halo,Belfuse,Wurth,TE,Molex,Amphenol …

2).Circular Connectors(M5,M8,M12) compatible with TE,NorComp,ODU,HOLIN,LEMO,Amphenol LTW,Lumberg Automation,

Phoenix contacts, CONEC,Hirose, Bulgin ,Pepperl+Fuchs…

3).We can offer OEM & ODM services and mould modification according your requirements.

INGKE also produce substitute such as 1962410000 1864730000 1944570000 21033221411 1201095002 1201095001

vera.ingke(at)gmail.com

0 notes

Text

Optimus Control Industry PLT added 13 new products on 3/2/2020

Optimus Control Industry PLT

CAMOZZI (3)

CAMOZZI SOLENOID VALVES Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

CAMOZZI PNEUMATIC CYLINDER Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

CAMOZZI DISTRIBUTOR Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING (10)

HARTING RFID PRODUCTS Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING HAN MODULAR CONNECTORS Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING D SUB CONNECTORS Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING INDUSTRIAL ETHERNET SWITCHES Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING INDUSTRIAL ETHERNET CABLE Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING MICA Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING PCB CONNECTORS Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING CIRCULAR CONNECTORS Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING INDUSTRIAL CONNECTORS HAN Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

HARTING DISTRIBUTOR Malaysia Thailand Singapore Indonesia Philippines Vietnam Europe USA

0 notes

Photo

Solar thermal power plants, such as the one in the Spanish Sierra Nevada, use thousands of individual mirrors to focus sunlight onto a single point in a tower. There, with the help of several thousand mirrors, the power of the sun is harnessed for renewable energy. HARTING supports solar power towers with robust, reliable Han and PushPull connectors for supplying power and data.

#solar power#solar thermal#renewableresources#renewable power#renewable electricity#renewable energy

0 notes

Text

The role of the connector

With the development of technology, people's quality of life is getting higher and higher, and electronic products such as TV, telephone, and computer are gradually spreading to people's daily lives, so connectors are widely used. As long as there are electronic products in the home, the connector is generally used.

The connector of the connector is mainly used to connect data, signals and power between network equipment and mechanical facilities. It is inseparable in daily life or industrial production.Industrial connectors are often used in harsher environments than indoor wall outlets, but we don't notice them. Here's what you can do to see what connectors are easy to ignore. First, in terms of rail transit, such as on a train or a high-speed train, how can you talk more stably, browse the web faster, or watching high-definition shows? We often know how important it is to be in a daze on the train, and the connector is responsible for the stable transmission of the signal, allowing you to enjoy smooth WiFi. When watching an event, such as a tennis match, the connector can be mounted on the referee's chair and connected to the referee's computer to ensure normal power and communication. It can be said that the game went smoothly, and the connector was indispensable. When watching a show, such as a pop rock concert, aatrical performance or a musical, the connector provides reliable, robust signal transmission, and an exciting performance is inseparable from it. In power stations, especially in outdoor switching equipment, industrial connectors perform their unique performance. It is often exposed to the sun, wind, dust, rain and ice to provide a safe connection to the control cabinet. Reliable, tried-and-tested connectors are particularly popular in terms of wind energy, such as the fan's pulping system. On the robot, the connector is also inseparable. Due to the presence of the connector, the robot becomes easier to operate and easier to automate. In the production process, such as 3-5 axis machining center for CNC control, boring, milling, drilling machinery, the multi-axis linkage CNC system can not be separated from the connector, open USB, TCP / IP network DNC processing and data transmission . In fact, lathes, plastic processing machinery, printing presses, metal processing and wood processing machinery, electric cranes, semiconductor manufacturing equipment, food, and beverage processing and packaging machinery use connectors to connect power, signal and data. . This is a Siemens distributed drive product. The left drive and the right motor are connected by an orange cable. The ends of the cable are connected to the HARTING connector. It is conceivable that if the connector is not used and the fixed cable is used, the equipment on the left and the right sides will not only be fixed in the distance, but if it is necessary to move or transport, it is extremely inconvenient to move the two devices together. With the connector to connect, the two devices can be packaged and transported separately, and it is quite convenient to split at any time! The advantage of the connector is that the connector is interspersed with it in our living field, or it is clear or fuzzy. The clearest manifestation is the embodiment of the mechanical connector, the instrument with the interface at both ends, plays the role of connection. The advantages of the connector make it expand in the field of application in life, and it also shows a different role. The convenience brought to our life cannot be underestimated. What advantages does the connector have? First, The bridge function of the connector and its convenience. The connection function of the connector changes the gap of the large space of the global space, and connects the combination of the large space, thereby realizing the connection between the three-dimensional planes and realizing the unity of the plane. This is the biggest advantage of the connector, and is small. ,Convenience. Secondly, the connector is simple and precise. Once it is found to have connection problems, it is easy to repair and replace. Moreover, the connector can be upgraded quickly, and the internal components can be refurbished and replaced. This is a cost-saving and safety guarantee for the entire project. More important meaning. Again, it is easy to repair and upgrade quickly. Finally, the flexible design of the connector is one of the main criteria we chose. The connector is designed to be small, easy to install, easy to remove, and guarantees its safety and integrity. Classic theory. Therefore, connectors as an electromechanical component play a huge role in our lives, providing a bridge connecting systems, subsystems or components, transmitting signals or energy, which is an indispensable product of electrical and electronic products, realizing this shore and the other shore. The combination, like a bridge, propped up the entire road. Since the connector is so important, how can we choose a connector of our own in practical applications?

(Image from the internet)

How to choose the connector that suits you? In fact, the connector is good or bad. In fact, it mainly depends on where the connector is mainly used and what performance needs to be met, because each connector is designed and developed. The focus is on the so-called "the best for yourself." So, if you want to choose a good connector, you can consider the following aspects. 1. What type of connector is connected? Where to use these issues is the first consideration, which determines the type of industrial connector selected. Because of the wide variety of connectors, the same company has many types of connectors, such as HARTING Technology Group, including industrial connectors Han®, PCB connectors, I / O connectors and fiber optic data line systems. A variety of connectors. Therefore, as users need to understand their own needs and choose the connector that can meet their needs. 2, the performance of the connector After selecting the type of connector, it is necessary to determine what environment the connector works in and what features need to be met, such as the temperature, humidity, and durability of the connector working environment, transmission speed and so on. Because even if you choose which type of connector to use, there are many connectors in the same type that can satisfy different performances. So the second step in the selection is to determine what features the connector needs to meet. 3, the third step of the quality selection of the connector is also a very important step, because at this time the user already knows what kind of connector he needs, and finally needs to determine which connector to buy. Because the different manufacturers produce connectors with different materials and different production processes, the quality of the connectors produced will definitely differ. As the demand of users continues to increase, nowadays the connectors of different brands appear on our side, so that we don't know how to choose. At this time, the power of the brand will come into play. There are only a handful of companies with better connectors in the market. It is a test of time. So choosing a good brand connector is often equivalent to choosing a good quality connector. For example, HARTING Corporation focused on the development and production of connectors as early as 1945. It is now one of the world's largest manufacturers of connectors and connectors, and its connectors are also the most popular brands on the market. one. Now you know how to choose the right connector. Interpersonal interconnections between people, and industrial interconnections require reliable contact through mechanical and mechanical, mechanical and non-mechanical tight connections, so connectors are extremely important for industrial development. It is more important to choose a good connector.

Konnra Electronics has accumulated rich experience in the manufacture of connectors, has a complete production line, can effectively guarantee the advancement of the connector series orders, timely delivery to the user's hands, and we promise every user every electronic The connector product is free of charge within one year, so users don't have to worry about after-sales problems. If you are looking for a connector partner, maybe we are a good choice.

0 notes

Link

0 notes

Text

하르팅 Han 1A 커넥터, iF 디자인 워드 2020 수상

하르팅 Han 1A 커넥터, iF 디자인 워드 2020 수상 - 아이씨엔매거진

하르팅(HARTING) 테크놀로지 그룹의 Han 1A 커넥터 시리즈 제품이 올해 세계적으로 뛰어난 디자인 상인 iF DESIGN AWARD를 수상했다고 밝혔다. 수상 제품인, HARTING의 Han® 1A 커넥터 시리즈는 ‘전기 커넥터(Electrical Connector)’ 부문의 ‘제품(Product)’ 분야에서 수상했다.

독일 하노버에 있는 iF 국제 포럼 디자인(iF International Forum DesignGmbH)이 iF DESIGN AWARD를 주관한다. iF 라벨은 세계적으로 뛰어난 디자인 서비스로 유명하며, iF DESIGN AWARD는 전 세계에서 가장 중요한 디자인 상 중 하나다. 출품작들은 전문 개념 뿐만 아니라 제품, 포장, 통신 및 서비스 설계, 아키텍처 및 내부 아키텍처…

View On WordPress

0 notes

Text

Choosing the Right Profinet Encoder: Characteristics and Best Practices

Profinet Encoder

Multitier encoders with fieldbus, outright encoders collection MEM-Bus, best quality hengstler profinet encoders profile Specifications V4.1 version 3.162 related to Profidrives, demands of the Application Courses 3 and 4, RT Actual Time and IRT Isochronous Real Time Transmission Mode, common telegrams 81, 82, 83, 84, the customer telegram 860, encoders actual time diagnostic function makes sure the gadget state consistent monitoring, MEM-Bus encoders, multitier version with 29-bit resolution, Different mechanical versions are offered. The electric link is provided by 3 M12 adapters, the stout aluminium instance guarantees a high defence level. The building technology allows for high acceleration and rate worth’s and gives the transducer a long life.

Profinet Encoder Characteristics:

Fieldbus user interface: Profinet

Encoder Account V4.1 Variation 3.162

Application courses 3–4

Transmission settings (RT and IRT)

Conventional telegrams 81, 82, 83, and 84

Customer telegram 860

Aluminium situation

Defence level: IP67; shaft side: IP65

Resolution: 29 little bit

PROFINET-ready outright encoders function separately and are non-reactive.

Network frameworks are commonly subject to regular modifications, e.g., in the case of new robotics with constant changes of tools or expansions during procedures. PROFINET-ready outright encoders, Design A58HE (blind hollow birthed) and Version A58SE (shaft), are developed for harsh factory and plant atmospheres.

Conveniently designed right into a wide array of applications, these encoders plug straight right into a connect with marginal requirements and work in different setups, consisting of bus, ring, and star setups that can proceed interaction in the event of a line break.

As absolute encoders, they keep absolute position information even after a power loss, assisting in quick system healing at start-up without the requirement for system re-homing. Prepared for Market 4.0 and the Industrial Internet of Things, data exchange between the Model A58HE, Setting A58SE, and other applications has no influence on the control loophole.

These encoders are non-reactive and can function independently from the PLC or master, moving information through network entrances to various other automation networks and sites, as well as the cloud for analysis.

Encoders with Profane Communications

Encoder Products Company showcased its brand-new Design A58HE and Version A58SE, which are multi-turn, Ethernet-ready outright encoders made for rough manufacturing facilities and plant environments. Along with Ether pet cat Deterministic Interaction, the versions A58HE and A58SE now supply PROFINET communication procedures as well.

These encoders are especially suited to applications where fieldbus connectivity is needed and the encoder has to maintain absolute placement information after power-off occasions. The Model A58HE is a 58 mm encoder in a blind hollow-birthed construction, and the Model A58SE is a 58 mm shaft encoder readily available with either a securing flange or synch flange, in both compact and sturdy arrangements. The portable version is the most compact Ether feline or PROFINET-capable encoder readily available.

“Both the A58HE and A58SE encoders are easily made into a wide variety of applications," claims Sarah Walter, electric designer and EPC Technical Applications Manager. "And with the new heavy-duty design and the new small model—which is one of the most compact devices available on the market—they are unbelievably flexible mechanically. What actually sets our encoders apart, however, is their high accuracy. These absolutes will provide you with accurate activity comments whenever.

Conclusion

Sr. Indus Electro Systems Pvt. Ltd.: The non-reactive and independent operation of these encoders, coupled with their capability to deal with network portals, facilitates efficient information exchange within the network and also extends to cloud-based evaluation. As shown by Encoder Products Company's A58HE and A58SE designs, these encoders satisfy the demands of different applications, offering portable and sturdy configurations to accommodate diverse mechanical demands.

On the whole, the Profinet Encoder series stands out for its adaptability, reliability, and high performance, making it a beneficial component in the developing landscape of industrial automation.

#profinet encoders#Profinet Encoders Distributors#cable assemblies#maxon distributors india#harting han connectors#hengstler encoders

0 notes

Text

The Importance of Connectors in Industrial Robots

inserted in the head of the robot with appropriate connection technology. These interfaces connect the robot to the internal network of the factory through the communication controller.

The space on the production line is becoming more and more compact, and the robots are becoming smaller and smaller. Especially when the robots work in high temperature environment and have special requirements for connection technology in harsh environment, the role of connectors becomes more important. According to different requirements, connectors are mainly used in the following situations of industrial robots:

1.Highly integrated interfaces save space for robots

Robot manufacturers face two major challenges in developing new applications, such as lines:

Robots need more and more sensing sensors. In order to operate more complex assemblies, they must be smaller and more flexible. Han #industrial connectors can support the development of such robotic systems through miniaturization and ensuring shielded data transmission

High Density Interface Connector with Hybrid Configuration

In addition to electrical signals, modular connectors can also transmit compressed air, light waves and large currents. As a "hybrid" interface, they accomplish the task of several small individual interfaces. In order to make the best use of the space in the connector, Haoting continuously increases the interface density of Han-Modular < modular connector. For example, Han D </ Han DD < high pin number connector sockets, up to 216 pins, transmission power or signal up to 10A/150 V.

The second example is the Han high density module: when full load, there are 25 pins in the module, which can transmit 4A/50V signal. Other HAN modules with higher contact density are also being developed.。

An Integrated Shell for Robots

For example, Han #72 DD is often used in industrial ovens. When the width is 78 or 85 mm, the Han #72 DD socket provides 72 pins, which can transmit both signals and electricity. In addition, Haoting recently developed a Han K 32/55 connector, which has 32 power or signal pins (10A/250 V) in addition to 55 signal pins (4A/50 V). This "hybrid" connector does not require more space than Han 72 DD. In order to reduce costs and save space, robots need to reduce the number of interfaces as much as possible. According to the principle of "two in one", such an interface in the 10B standard housing is enough to meet the needs of power and signal control of an industrial robot.

Reducing the Height of Robot Interface

Haoting's newly developed Han < HP Direct product can reduce the height of the robot interface. Han < HP Direct replaces the enclosure with a flange on which the enclosure can be fixed. A connection side, usually one with a common joint, is set in the foot of the robot, which reduces the overall height。

Han < 10 HP Direct provides more space: the shell is nearly two centimeters higher than the high-structure version of Han < B. Hence, the new Han < K 32/55 with 87 contacts is easy to operate and can be comfortably inserted into the housing, including cables. In addition, the increase in space is due to the use of fixed screws. For users who do not want to use a tool-free locking system, the highest density of the Han-Modular connector, i.e., the Han DD Quad module, remains the best solution for the robot interface.

2.Miniaturization to the last millimeter

Valve terminals are an integral part of the pneumatic automation system. Today's devices usually use fieldbus to communicate, allowing for the integration of various electrical functions. In addition to considering the flow rate, one of the key product characteristics is the need for compact design. Festo (Fisto) is the inventor of the valve island and today has become one of the world's leading suppliers of pneumatic and electrical automation technology. Festo developed a new VTUG valve island using Har-flex < PCB connector series of Haoting. The valve island has a higher flow rate and a more compact design.

Through its compact design of 1.27 spacing, the connector can save more space when designing the equipment. Especially important for Festo, Haoting's 30 pins can provide accurate pin count for the company. The whole product family can provide any even number of pins between 6 and 100, which is the standard of Haoting customers.

Despite increasing miniaturization, connectors are characterized by high robustness. In addition to the reinforced wall thickness of the inserts, the additional side mounted SMT fixtures ("compaction") always ensure a safe connection with the PCB, making the connector very suitable for industrial electronic equipment.

The har-flex connector with the highest flexibility of equipment design can be used for linear and inclined PCB connections and IDC cable connections

3.Simultaneous transmission of data, signals and electricity

Reliable transmission of data, signals and power in all performance ranges is one of the basic requirements of industrial applications. The new HARTING PushPull signal connector always meets these requirements in a unified connector system.

According to the guidelines of PROFIBUS User Organization and AIDA (German Automobile Manufacturer Automation Program), Han PushPull Variant 14 is the preferred connector for distributed automation systems in data transmission and power supply fields.

t is widely used in connection technology, operation application, sensor or imaging element, especially in the application of industrial robots in highly automated automobile welding and line. Although all defined criteria for data areas require separate signal and data communication processes. In addition to power supply and standard communication, analog, digital, bus and low voltage signal transmission must be guaranteed.

HARTING PushPull transmits 5A rated current at 10 contacts, with a conductor cross-sectional area of up to 0.75 mm. In order to ensure electromagnetic anti-interference ability, the contact plug-in is completely shielded as RJ45 data connector, which can connect shielded cables. The locking function of PushPull ensures reliable connection of connectors. When inserting, a "click" indicates correct locking.

PushPull signal connectors can also handle hybrid applications. For example, part of the contact surface can be used to transmit electricity, while other contacts can be used for communication. PushPull signal connectors are used in the PushPull Variant 14 and Variant 4 series defined by IEC 61076-6-107. PushPull signal connector is defined according to IEC 61076-6-107 and has two types of size: PushPull Variant 14 and Variant 4.

Simple wiring on site is the key. PushPull signal connectors are pre-assembled at delivery, thus minimizing the number of user-separated components. Connectors are installed by inserting each pin into a pre-assembled insulating plug-in.

Just press the insulating plug-in to lock it to the final position and fix the crimping pin in place. Users can easily correct any errors that occur after installing insulation plug-ins. Using factory prefabricated cable assemblies of different lengths can reduce the workload of on-site processing.

4.Power supply for laser cutting system

Laser cutting systems do provide high precision in modern manufacturing. For the power supply of these systems and for control purposes, the laser system designers believe in reliable HARTING connectors. The use of lasers is becoming more and more important in mechanical manufacturing, especially in the automotive industry. HARTING connectors contribute to the accuracy and reliability of these laser systems. In addition, they provide the possibility of rapid replacement of system components in case of failure.

Strong connectors and enclosures protect plug-ins from dirt, dampness and welding sparks, which are quite common in manufacturing processes. For example, Han < 24E socket with cage shrapnel connection is just suitable for this current transmission requirement. Through this connector, 24 contacts in a housing can be realized for power transmission. The cage shrapnel connection is very useful in the process of the machine and can provide very high vibration stability.

Sensitive signals needed for laser system control can be transmitted by using Han-Modular Quintax plug, which has very good shielding and attenuation function and can protect these sensitive signals from any existing electromagnetic interference, thus helping to ensure the reliability of the whole laser sy

0 notes

Text

The Importance of Connectors in Industrial Robots

inserted in the head of the robot with appropriate connection technology. These interfaces connect the robot to the internal network of the factory through the communication controller.

The space on the production line is becoming more and more compact, and the robots are becoming smaller and smaller. Especially when the robots work in high temperature environment and have special requirements for connection technology in harsh environment, the role of connectors becomes more important. According to different requirements, connectors are mainly used in the following situations of industrial robots:

1.Highly integrated interfaces save space for robots

Robot manufacturers face two major challenges in developing new applications, such as lines:

Robots need more and more sensing sensors. In order to operate more complex assemblies, they must be smaller and more flexible. Han #industrial connectors can support the development of such robotic systems through miniaturization and ensuring shielded data transmission

High Density Interface Connector with Hybrid Configuration

In addition to electrical signals, modular connectors can also transmit compressed air, light waves and large currents. As a "hybrid" interface, they accomplish the task of several small individual interfaces. In order to make the best use of the space in the connector, Haoting continuously increases the interface density of Han-Modular < modular connector. For example, Han D </ Han DD < high pin number connector sockets, up to 216 pins, transmission power or signal up to 10A/150 V.

The second example is the Han high density module: when full load, there are 25 pins in the module, which can transmit 4A/50V signal. Other HAN modules with higher contact density are also being developed.。

An Integrated Shell for Robots

For example, Han #72 DD is often used in industrial ovens. When the width is 78 or 85 mm, the Han #72 DD socket provides 72 pins, which can transmit both signals and electricity. In addition, Haoting recently developed a Han K 32/55 connector, which has 32 power or signal pins (10A/250 V) in addition to 55 signal pins (4A/50 V). This "hybrid" connector does not require more space than Han 72 DD. In order to reduce costs and save space, robots need to reduce the number of interfaces as much as possible. According to the principle of "two in one", such an interface in the 10B standard housing is enough to meet the needs of power and signal control of an industrial robot.

Reducing the Height of Robot Interface

Haoting's newly developed Han < HP Direct product can reduce the height of the robot interface. Han < HP Direct replaces the enclosure with a flange on which the enclosure can be fixed. A connection side, usually one with a common joint, is set in the foot of the robot, which reduces the overall height。

Han < 10 HP Direct provides more space: the shell is nearly two centimeters higher than the high-structure version of Han < B. Hence, the new Han < K 32/55 with 87 contacts is easy to operate and can be comfortably inserted into the housing, including cables. In addition, the increase in space is due to the use of fixed screws. For users who do not want to use a tool-free locking system, the highest density of the Han-Modular connector, i.e., the Han DD Quad module, remains the best solution for the robot interface.

2.Miniaturization to the last millimeter

Valve terminals are an integral part of the pneumatic automation system. Today's devices usually use fieldbus to communicate, allowing for the integration of various electrical functions. In addition to considering the flow rate, one of the key product characteristics is the need for compact design. Festo (Fisto) is the inventor of the valve island and today has become one of the world's leading suppliers of pneumatic and electrical automation technology. Festo developed a new VTUG valve island using Har-flex < PCB connector series of Haoting. The valve island has a higher flow rate and a more compact design.

Through its compact design of 1.27 spacing, the connector can save more space when designing the equipment. Especially important for Festo, Haoting's 30 pins can provide accurate pin count for the company. The whole product family can provide any even number of pins between 6 and 100, which is the standard of Haoting customers.

Despite increasing miniaturization, connectors are characterized by high robustness. In addition to the reinforced wall thickness of the inserts, the additional side mounted SMT fixtures ("compaction") always ensure a safe connection with the PCB, making the connector very suitable for industrial electronic equipment.

The har-flex connector with the highest flexibility of equipment design can be used for linear and inclined PCB connections and IDC cable connections

3.Simultaneous transmission of data, signals and electricity

Reliable transmission of data, signals and power in all performance ranges is one of the basic requirements of industrial applications. The new HARTING PushPull signal connector always meets these requirements in a unified connector system.

According to the guidelines of PROFIBUS User Organization and AIDA (German Automobile Manufacturer Automation Program), Han PushPull Variant 14 is the preferred connector for distributed automation systems in data transmission and power supply fields.

t is widely used in connection technology, operation application, sensor or imaging element, especially in the application of industrial robots in highly automated automobile welding and line. Although all defined criteria for data areas require separate signal and data communication processes. In addition to power supply and standard communication, analog, digital, bus and low voltage signal transmission must be guaranteed.

HARTING PushPull transmits 5A rated current at 10 contacts, with a conductor cross-sectional area of up to 0.75 mm. In order to ensure electromagnetic anti-interference ability, the contact plug-in is completely shielded as RJ45 data connector, which can connect shielded cables. The locking function of PushPull ensures reliable connection of connectors. When inserting, a "click" indicates correct locking.

PushPull signal connectors can also handle hybrid applications. For example, part of the contact surface can be used to transmit electricity, while other contacts can be used for communication. PushPull signal connectors are used in the PushPull Variant 14 and Variant 4 series defined by IEC 61076-6-107. PushPull signal connector is defined according to IEC 61076-6-107 and has two types of size: PushPull Variant 14 and Variant 4.

Simple wiring on site is the key. PushPull signal connectors are pre-assembled at delivery, thus minimizing the number of user-separated components. Connectors are installed by inserting each pin into a pre-assembled insulating plug-in.

Just press the insulating plug-in to lock it to the final position and fix the crimping pin in place. Users can easily correct any errors that occur after installing insulation plug-ins. Using factory prefabricated cable assemblies of different lengths can reduce the workload of on-site processing.

4.Power supply for laser cutting system

Laser cutting systems do provide high precision in modern manufacturing. For the power supply of these systems and for control purposes, the laser system designers believe in reliable HARTING connectors. The use of lasers is becoming more and more important in mechanical manufacturing, especially in the automotive industry. HARTING connectors contribute to the accuracy and reliability of these laser systems. In addition, they provide the possibility of rapid replacement of system components in case of failure.

Strong connectors and enclosures protect plug-ins from dirt, dampness and welding sparks, which are quite common in manufacturing processes. For example, Han < 24E socket with cage shrapnel connection is just suitable for this current transmission requirement. Through this connector, 24 contacts in a housing can be realized for power transmission. The cage shrapnel connection is very useful in the process of the machine and can provide very high vibration stability.

Sensitive signals needed for laser system control can be transmitted by using Han-Modular Quintax plug, which has very good shielding and attenuation function and can protect these sensitive signals from any existing electromagnetic interference, thus helping to ensure the reliability of the whole laser sy

0 notes

Text

The Importance of Connectors in Industrial Robots

inserted in the head of the robot with appropriate connection technology. These interfaces connect the robot to the internal network of the factory through the communication controller.

The space on the production line is becoming more and more compact, and the robots are becoming smaller and smaller. Especially when the robots work in high temperature environment and have special requirements for connection technology in harsh environment, the role of connectors becomes more important. According to different requirements, connectors are mainly used in the following situations of industrial robots:

1.Highly integrated interfaces save space for robots

Robot manufacturers face two major challenges in developing new applications, such as lines:

Robots need more and more sensing sensors. In order to operate more complex assemblies, they must be smaller and more flexible. Han #industrial connectors can support the development of such robotic systems through miniaturization and ensuring shielded data transmission

High Density Interface Connector with Hybrid Configuration

In addition to electrical signals, modular connectors can also transmit compressed air, light waves and large currents. As a "hybrid" interface, they accomplish the task of several small individual interfaces. In order to make the best use of the space in the connector, Haoting continuously increases the interface density of Han-Modular < modular connector. For example, Han D </ Han DD < high pin number connector sockets, up to 216 pins, transmission power or signal up to 10A/150 V.

The second example is the Han high density module: when full load, there are 25 pins in the module, which can transmit 4A/50V signal. Other HAN modules with higher contact density are also being developed.。

An Integrated Shell for Robots

For example, Han #72 DD is often used in industrial ovens. When the width is 78 or 85 mm, the Han #72 DD socket provides 72 pins, which can transmit both signals and electricity. In addition, Haoting recently developed a Han K 32/55 connector, which has 32 power or signal pins (10A/250 V) in addition to 55 signal pins (4A/50 V). This "hybrid" connector does not require more space than Han 72 DD. In order to reduce costs and save space, robots need to reduce the number of interfaces as much as possible. According to the principle of "two in one", such an interface in the 10B standard housing is enough to meet the needs of power and signal control of an industrial robot.

Reducing the Height of Robot Interface

Haoting's newly developed Han < HP Direct product can reduce the height of the robot interface. Han < HP Direct replaces the enclosure with a flange on which the enclosure can be fixed. A connection side, usually one with a common joint, is set in the foot of the robot, which reduces the overall height。

Han < 10 HP Direct provides more space: the shell is nearly two centimeters higher than the high-structure version of Han < B. Hence, the new Han < K 32/55 with 87 contacts is easy to operate and can be comfortably inserted into the housing, including cables. In addition, the increase in space is due to the use of fixed screws. For users who do not want to use a tool-free locking system, the highest density of the Han-Modular connector, i.e., the Han DD Quad module, remains the best solution for the robot interface.

2.Miniaturization to the last millimeter

Valve terminals are an integral part of the pneumatic automation system. Today's devices usually use fieldbus to communicate, allowing for the integration of various electrical functions. In addition to considering the flow rate, one of the key product characteristics is the need for compact design. Festo (Fisto) is the inventor of the valve island and today has become one of the world's leading suppliers of pneumatic and electrical automation technology. Festo developed a new VTUG valve island using Har-flex < PCB connector series of Haoting. The valve island has a higher flow rate and a more compact design.

Through its compact design of 1.27 spacing, the connector can save more space when designing the equipment. Especially important for Festo, Haoting's 30 pins can provide accurate pin count for the company. The whole product family can provide any even number of pins between 6 and 100, which is the standard of Haoting customers.

Despite increasing miniaturization, connectors are characterized by high robustness. In addition to the reinforced wall thickness of the inserts, the additional side mounted SMT fixtures ("compaction") always ensure a safe connection with the PCB, making the connector very suitable for industrial electronic equipment.

The har-flex connector with the highest flexibility of equipment design can be used for linear and inclined PCB connections and IDC cable connections

3.Simultaneous transmission of data, signals and electricity

Reliable transmission of data, signals and power in all performance ranges is one of the basic requirements of industrial applications. The new HARTING PushPull signal connector always meets these requirements in a unified connector system.

According to the guidelines of PROFIBUS User Organization and AIDA (German Automobile Manufacturer Automation Program), Han PushPull Variant 14 is the preferred connector for distributed automation systems in data transmission and power supply fields.

t is widely used in connection technology, operation application, sensor or imaging element, especially in the application of industrial robots in highly automated automobile welding and line. Although all defined criteria for data areas require separate signal and data communication processes. In addition to power supply and standard communication, analog, digital, bus and low voltage signal transmission must be guaranteed.

HARTING PushPull transmits 5A rated current at 10 contacts, with a conductor cross-sectional area of up to 0.75 mm. In order to ensure electromagnetic anti-interference ability, the contact plug-in is completely shielded as RJ45 data connector, which can connect shielded cables. The locking function of PushPull ensures reliable connection of connectors. When inserting, a "click" indicates correct locking.

PushPull signal connectors can also handle hybrid applications. For example, part of the contact surface can be used to transmit electricity, while other contacts can be used for communication. PushPull signal connectors are used in the PushPull Variant 14 and Variant 4 series defined by IEC 61076-6-107. PushPull signal connector is defined according to IEC 61076-6-107 and has two types of size: PushPull Variant 14 and Variant 4.

Simple wiring on site is the key. PushPull signal connectors are pre-assembled at delivery, thus minimizing the number of user-separated components. Connectors are installed by inserting each pin into a pre-assembled insulating plug-in.

Just press the insulating plug-in to lock it to the final position and fix the crimping pin in place. Users can easily correct any errors that occur after installing insulation plug-ins. Using factory prefabricated cable assemblies of different lengths can reduce the workload of on-site processing.

4.Power supply for laser cutting system

Laser cutting systems do provide high precision in modern manufacturing. For the power supply of these systems and for control purposes, the laser system designers believe in reliable HARTING connectors. The use of lasers is becoming more and more important in mechanical manufacturing, especially in the automotive industry. HARTING connectors contribute to the accuracy and reliability of these laser systems. In addition, they provide the possibility of rapid replacement of system components in case of failure.

Strong connectors and enclosures protect plug-ins from dirt, dampness and welding sparks, which are quite common in manufacturing processes. For example, Han < 24E socket with cage shrapnel connection is just suitable for this current transmission requirement. Through this connector, 24 contacts in a housing can be realized for power transmission. The cage shrapnel connection is very useful in the process of the machine and can provide very high vibration stability.

Sensitive signals needed for laser system control can be transmitted by using Han-Modular Quintax plug, which has very good shielding and attenuation function and can protect these sensitive signals from any existing electromagnetic interference, thus helping to ensure the reliability of the whole laser sy

0 notes

Text

The Importance of Connectors in Industrial Robots

inserted in the head of the robot with appropriate connection technology. These interfaces connect the robot to the internal network of the factory through the communication controller.

The space on the production line is becoming more and more compact, and the robots are becoming smaller and smaller. Especially when the robots work in high temperature environment and have special requirements for connection technology in harsh environment, the role of connectors becomes more important. According to different requirements, connectors are mainly used in the following situations of industrial robots:

1.Highly integrated interfaces save space for robots

Robot manufacturers face two major challenges in developing new applications, such as lines���

Robots need more and more sensing sensors. In order to operate more complex assemblies, they must be smaller and more flexible. Han #industrial connectors can support the development of such robotic systems through miniaturization and ensuring shielded data transmission

High Density Interface Connector with Hybrid Configuration

In addition to electrical signals, modular connectors can also transmit compressed air, light waves and large currents. As a "hybrid" interface, they accomplish the task of several small individual interfaces. In order to make the best use of the space in the connector, Haoting continuously increases the interface density of Han-Modular < modular connector. For example, Han D </ Han DD < high pin number connector sockets, up to 216 pins, transmission power or signal up to 10A/150 V.

The second example is the Han high density module: when full load, there are 25 pins in the module, which can transmit 4A/50V signal. Other HAN modules with higher contact density are also being developed.。

An Integrated Shell for Robots

For example, Han #72 DD is often used in industrial ovens. When the width is 78 or 85 mm, the Han #72 DD socket provides 72 pins, which can transmit both signals and electricity. In addition, Haoting recently developed a Han K 32/55 connector, which has 32 power or signal pins (10A/250 V) in addition to 55 signal pins (4A/50 V). This "hybrid" connector does not require more space than Han 72 DD. In order to reduce costs and save space, robots need to reduce the number of interfaces as much as possible. According to the principle of "two in one", such an interface in the 10B standard housing is enough to meet the needs of power and signal control of an industrial robot.

Reducing the Height of Robot Interface

Haoting's newly developed Han < HP Direct product can reduce the height of the robot interface. Han < HP Direct replaces the enclosure with a flange on which the enclosure can be fixed. A connection side, usually one with a common joint, is set in the foot of the robot, which reduces the overall height。

Han < 10 HP Direct provides more space: the shell is nearly two centimeters higher than the high-structure version of Han < B. Hence, the new Han < K 32/55 with 87 contacts is easy to operate and can be comfortably inserted into the housing, including cables. In addition, the increase in space is due to the use of fixed screws. For users who do not want to use a tool-free locking system, the highest density of the Han-Modular connector, i.e., the Han DD Quad module, remains the best solution for the robot interface.

2.Miniaturization to the last millimeter

Valve terminals are an integral part of the pneumatic automation system. Today's devices usually use fieldbus to communicate, allowing for the integration of various electrical functions. In addition to considering the flow rate, one of the key product characteristics is the need for compact design. Festo (Fisto) is the inventor of the valve island and today has become one of the world's leading suppliers of pneumatic and electrical automation technology. Festo developed a new VTUG valve island using Har-flex < PCB connector series of Haoting. The valve island has a higher flow rate and a more compact design.

Through its compact design of 1.27 spacing, the connector can save more space when designing the equipment. Especially important for Festo, Haoting's 30 pins can provide accurate pin count for the company. The whole product family can provide any even number of pins between 6 and 100, which is the standard of Haoting customers.

Despite increasing miniaturization, connectors are characterized by high robustness. In addition to the reinforced wall thickness of the inserts, the additional side mounted SMT fixtures ("compaction") always ensure a safe connection with the PCB, making the connector very suitable for industrial electronic equipment.

The har-flex connector with the highest flexibility of equipment design can be used for linear and inclined PCB connections and IDC cable connections

3.Simultaneous transmission of data, signals and electricity

Reliable transmission of data, signals and power in all performance ranges is one of the basic requirements of industrial applications. The new HARTING PushPull signal connector always meets these requirements in a unified connector system.

According to the guidelines of PROFIBUS User Organization and AIDA (German Automobile Manufacturer Automation Program), Han PushPull Variant 14 is the preferred connector for distributed automation systems in data transmission and power supply fields.

t is widely used in connection technology, operation application, sensor or imaging element, especially in the application of industrial robots in highly automated automobile welding and line. Although all defined criteria for data areas require separate signal and data communication processes. In addition to power supply and standard communication, analog, digital, bus and low voltage signal transmission must be guaranteed.

HARTING PushPull transmits 5A rated current at 10 contacts, with a conductor cross-sectional area of up to 0.75 mm. In order to ensure electromagnetic anti-interference ability, the contact plug-in is completely shielded as RJ45 data connector, which can connect shielded cables. The locking function of PushPull ensures reliable connection of connectors. When inserting, a "click" indicates correct locking.

PushPull signal connectors can also handle hybrid applications. For example, part of the contact surface can be used to transmit electricity, while other contacts can be used for communication. PushPull signal connectors are used in the PushPull Variant 14 and Variant 4 series defined by IEC 61076-6-107. PushPull signal connector is defined according to IEC 61076-6-107 and has two types of size: PushPull Variant 14 and Variant 4.

Simple wiring on site is the key. PushPull signal connectors are pre-assembled at delivery, thus minimizing the number of user-separated components. Connectors are installed by inserting each pin into a pre-assembled insulating plug-in.

Just press the insulating plug-in to lock it to the final position and fix the crimping pin in place. Users can easily correct any errors that occur after installing insulation plug-ins. Using factory prefabricated cable assemblies of different lengths can reduce the workload of on-site processing.

4.Power supply for laser cutting system

Laser cutting systems do provide high precision in modern manufacturing. For the power supply of these systems and for control purposes, the laser system designers believe in reliable HARTING connectors. The use of lasers is becoming more and more important in mechanical manufacturing, especially in the automotive industry. HARTING connectors contribute to the accuracy and reliability of these laser systems. In addition, they provide the possibility of rapid replacement of system components in case of failure.

Strong connectors and enclosures protect plug-ins from dirt, dampness and welding sparks, which are quite common in manufacturing processes. For example, Han < 24E socket with cage shrapnel connection is just suitable for this current transmission requirement. Through this connector, 24 contacts in a housing can be realized for power transmission. The cage shrapnel connection is very useful in the process of the machine and can provide very high vibration stability.

Sensitive signals needed for laser system control can be transmitted by using Han-Modular Quintax plug, which has very good shielding and attenuation function and can protect these sensitive signals from any existing electromagnetic interference, thus helping to ensure the reliability of the whole laser sy

0 notes

Text

The Importance of Connectors in Industrial Robots

inserted in the head of the robot with appropriate connection technology. These interfaces connect the robot to the internal network of the factory through the communication controller.

The space on the production line is becoming more and more compact, and the robots are becoming smaller and smaller. Especially when the robots work in high temperature environment and have special requirements for connection technology in harsh environment, the role of connectors becomes more important. According to different requirements, connectors are mainly used in the following situations of industrial robots:

1.Highly integrated interfaces save space for robots

Robot manufacturers face two major challenges in developing new applications, such as lines:

Robots need more and more sensing sensors. In order to operate more complex assemblies, they must be smaller and more flexible. Han #industrial connectors can support the development of such robotic systems through miniaturization and ensuring shielded data transmission

High Density Interface Connector with Hybrid Configuration

In addition to electrical signals, modular connectors can also transmit compressed air, light waves and large currents. As a "hybrid" interface, they accomplish the task of several small individual interfaces. In order to make the best use of the space in the connector, Haoting continuously increases the interface density of Han-Modular < modular connector. For example, Han D </ Han DD < high pin number connector sockets, up to 216 pins, transmission power or signal up to 10A/150 V.

The second example is the Han high density module: when full load, there are 25 pins in the module, which can transmit 4A/50V signal. Other HAN modules with higher contact density are also being developed.。

An Integrated Shell for Robots

For example, Han #72 DD is often used in industrial ovens. When the width is 78 or 85 mm, the Han #72 DD socket provides 72 pins, which can transmit both signals and electricity. In addition, Haoting recently developed a Han K 32/55 connector, which has 32 power or signal pins (10A/250 V) in addition to 55 signal pins (4A/50 V). This "hybrid" connector does not require more space than Han 72 DD. In order to reduce costs and save space, robots need to reduce the number of interfaces as much as possible. According to the principle of "two in one", such an interface in the 10B standard housing is enough to meet the needs of power and signal control of an industrial robot.

Reducing the Height of Robot Interface

Haoting's newly developed Han < HP Direct product can reduce the height of the robot interface. Han < HP Direct replaces the enclosure with a flange on which the enclosure can be fixed. A connection side, usually one with a common joint, is set in the foot of the robot, which reduces the overall height。

Han < 10 HP Direct provides more space: the shell is nearly two centimeters higher than the high-structure version of Han < B. Hence, the new Han < K 32/55 with 87 contacts is easy to operate and can be comfortably inserted into the housing, including cables. In addition, the increase in space is due to the use of fixed screws. For users who do not want to use a tool-free locking system, the highest density of the Han-Modular connector, i.e., the Han DD Quad module, remains the best solution for the robot interface.

2.Miniaturization to the last millimeter

Valve terminals are an integral part of the pneumatic automation system. Today's devices usually use fieldbus to communicate, allowing for the integration of various electrical functions. In addition to considering the flow rate, one of the key product characteristics is the need for compact design. Festo (Fisto) is the inventor of the valve island and today has become one of the world's leading suppliers of pneumatic and electrical automation technology. Festo developed a new VTUG valve island using Har-flex < PCB connector series of Haoting. The valve island has a higher flow rate and a more compact design.

Through its compact design of 1.27 spacing, the connector can save more space when designing the equipment. Especially important for Festo, Haoting's 30 pins can provide accurate pin count for the company. The whole product family can provide any even number of pins between 6 and 100, which is the standard of Haoting customers.

Despite increasing miniaturization, connectors are characterized by high robustness. In addition to the reinforced wall thickness of the inserts, the additional side mounted SMT fixtures ("compaction") always ensure a safe connection with the PCB, making the connector very suitable for industrial electronic equipment.

The har-flex connector with the highest flexibility of equipment design can be used for linear and inclined PCB connections and IDC cable connections

3.Simultaneous transmission of data, signals and electricity

Reliable transmission of data, signals and power in all performance ranges is one of the basic requirements of industrial applications. The new HARTING PushPull signal connector always meets these requirements in a unified connector system.

According to the guidelines of PROFIBUS User Organization and AIDA (German Automobile Manufacturer Automation Program), Han PushPull Variant 14 is the preferred connector for distributed automation systems in data transmission and power supply fields.

t is widely used in connection technology, operation application, sensor or imaging element, especially in the application of industrial robots in highly automated automobile welding and line. Although all defined criteria for data areas require separate signal and data communication processes. In addition to power supply and standard communication, analog, digital, bus and low voltage signal transmission must be guaranteed.

HARTING PushPull transmits 5A rated current at 10 contacts, with a conductor cross-sectional area of up to 0.75 mm. In order to ensure electromagnetic anti-interference ability, the contact plug-in is completely shielded as RJ45 data connector, which can connect shielded cables. The locking function of PushPull ensures reliable connection of connectors. When inserting, a "click" indicates correct locking.

PushPull signal connectors can also handle hybrid applications. For example, part of the contact surface can be used to transmit electricity, while other contacts can be used for communication. PushPull signal connectors are used in the PushPull Variant 14 and Variant 4 series defined by IEC 61076-6-107. PushPull signal connector is defined according to IEC 61076-6-107 and has two types of size: PushPull Variant 14 and Variant 4.

Simple wiring on site is the key. PushPull signal connectors are pre-assembled at delivery, thus minimizing the number of user-separated components. Connectors are installed by inserting each pin into a pre-assembled insulating plug-in.

Just press the insulating plug-in to lock it to the final position and fix the crimping pin in place. Users can easily correct any errors that occur after installing insulation plug-ins. Using factory prefabricated cable assemblies of different lengths can reduce the workload of on-site processing.

4.Power supply for laser cutting system

Laser cutting systems do provide high precision in modern manufacturing. For the power supply of these systems and for control purposes, the laser system designers believe in reliable HARTING connectors. The use of lasers is becoming more and more important in mechanical manufacturing, especially in the automotive industry. HARTING connectors contribute to the accuracy and reliability of these laser systems. In addition, they provide the possibility of rapid replacement of system components in case of failure.

Strong connectors and enclosures protect plug-ins from dirt, dampness and welding sparks, which are quite common in manufacturing processes. For example, Han < 24E socket with cage shrapnel connection is just suitable for this current transmission requirement. Through this connector, 24 contacts in a housing can be realized for power transmission. The cage shrapnel connection is very useful in the process of the machine and can provide very high vibration stability.

Sensitive signals needed for laser system control can be transmitted by using Han-Modular Quintax plug, which has very good shielding and attenuation function and can protect these sensitive signals from any existing electromagnetic interference, thus helping to ensure the reliability of the whole laser sy

0 notes

Photo

#tecnewsTuesday! The use of the "standard" increases flexibility when connecting components to larger units. Read here how HARTING set the standard for industrial interfaces at an early stage with the Han® connector:

0 notes

Text

HARTING Han 1A industrial connectors

The Han 1A industrial connector from HARTING is made of high-performance plastic, lightweight and requires little space. It is suitable for IP20 connections in switch cabinets as well as for outdoor requirements, as when closed it achieves the IP65 protection class. Due to its modularity and a variety of different deployment scenarios, it is particularly suitable for sensors, small drives and lighting.

Han industrial connectors allow for rear mounting of interfaces in switch cabinets in wind turbines. With this option, all connection-related work steps can be done from within the switch cabinet. In addition, many installation steps can be upstreamed into assembly, saving man-hours worked by technicians in the facility. The rear mounting option is available for both the Han B metal and Han B plastic housings. This allows the user to improve the manufacturing process of the wind turbine.

source http://sustainabilitymatters.net.au/content/energy/product/harting-han-1a-industrial-connectors-828355445

from WordPress https://davidkent.home.blog/2019/09/12/harting-han-1a-industrial-connectors/

0 notes