#heat pump efficiency chart

Text

Unlock the secrets of hot water heat pump efficiency and optimize your water heating system. Learn how to maximize energy savings with heat pump efficiency. Dive in now!

#hot water heat pump efficiency#heat pump efficiency#heat pump efficiency chart#heatpumpaus#hot water heat pump#residentialheatpump#heat pumps#energyefficiency

0 notes

Text

Excerpt from this story from Canary Media:

The country that once boasted the world’s first coal-fired power plant is now set to eliminate the highly polluting fossil fuel from its power grid.

In late September, the United Kingdom will shutter the Ratcliffe-on-Soar Power Station, the country’s last operational coal-fired power plant. The closure indicates just how far the U.K. has come in its bid to do away with dirty sources of electricity.

The rapid change was made possible by the U.K.’s embrace of wind power, both on- and offshore. Over the last decade, this form of renewable energy has surged in the U.K., from generating around 8 percent of the country’s electricity in 2013 to 29 percent in 2023. Coal has plummeted over that same time period, falling from 36 percent of power generation to 1 percent last year — and then to a (literally) vanishingly small portion this year.

The country’s grid cleanup comes amid a backdrop of declining electricity demand. The U.K. used 17 percent less electricity in 2023 than it did in 2013, per Ember, as households adopted more efficient appliances, natural gas prices rose, and its economy shifted away from energy-intensive manufacturing jobs. Demand has continued to decline even as the country has started to embrace heat pumps and electric vehicles.

As a result of the U.K.’s rapidly decarbonizing grid and falling electricity demand, emissions from the country’s power sector have taken a nosedive, helping the nation reduce overall emissions to the lowest levels since 1879 — three years before that first coal-fired power station was even built.

Still, planet-warming fossil gas remains the single biggest source of electricity in the U.K. The country has led the way in moving past one form of polluting power, but now it will have to do the same with another if it is to meet its rapidly approaching goal of decarbonizing the grid by 2035.

18 notes

·

View notes

Text

Skills Required for Mechanical Engineering Students

Mechanical engineering encompasses a wide range of skills essential for students pursuing this discipline. Here is a comprehensive list of 20 skills that mechanical engineering students should develop to excel in their studies and future careers.

Technical Skills

1. Computer-Aided Design (CAD)

Proficiency in CAD software such as SolidWorks, AutoCAD, and CATIA is crucial for creating detailed designs and models of mechanical components. This skill aids in visualizing and refining designs before production.

2. Thermodynamics

A solid understanding of thermodynamics is essential for analyzing energy systems, heat transfer, and fluid dynamics. This knowledge is critical for applications such as engines and HVAC systems.

3. Mechanics and Materials Science

Knowledge of mechanics and materials science helps engineers understand how materials behave under various forces and conditions, which is vital for selecting appropriate materials for designs.

4. Programming Skills

Familiarity with programming languages like Python, MATLAB, and C++ is increasingly important for automating tasks, conducting simulations, and analyzing data.

5. Manufacturing Processes

Understanding various manufacturing processes, including machining, welding, and additive manufacturing, is essential for designing components that can be produced efficiently and economically.

6. Finite Element Analysis (FEA)

FEA is a computational technique to predict how objects react to external forces, vibrations, heat, and other physical effects. Proficiency in FEA software is important for validating designs.

7. Fluid Dynamics

Knowledge of fluid dynamics is crucial for designing fluid flow systems, such as pumps, turbines, and HVAC systems. Understanding principles like Bernoulli's equation is essential.

8. Control Systems

Understanding control systems and automation is vital for modern mechanical engineering, especially in robotics and manufacturing processes. This includes knowledge of sensors, actuators, and feedback loops.

9. Technical Drawing

The ability to create and interpret technical drawings is fundamental. This skill ensures that designs are communicated clearly and accurately to manufacturers and other engineers.

10. Project Management

Mechanical engineers often lead projects, requiring skills in project management, including planning, budgeting, and resource allocation. Familiarity with tools like Gantt charts is beneficial.

Soft Skills

11. Problem-Solving Abilities

Strong problem-solving skills enable engineers to tackle complex challenges, identify root causes, and develop effective solutions. This is a core competency in engineering design and troubleshooting.

12. Communication Skills

Effective communication is essential for collaborating with team members and stakeholders. Engineers must convey technical information and ideas, both verbally and in writing.

13. Teamwork and Collaboration

Mechanical engineers often work in multidisciplinary teams, making the ability to collaborate effectively with others crucial for project success.

14. Critical Thinking

Critical thinking skills allow engineers to analyze situations, evaluate options, and make informed decisions. This is vital for optimizing designs and processes.

15. Adaptability

The ability to adapt to new technologies, methods, and challenges is important in a rapidly evolving field like mechanical engineering. Continuous learning is a key aspect of professional growth.

16. Attention to Detail

Attention to detail is crucial in engineering, as small errors can lead to significant problems in design and manufacturing. Engineers must ensure precision in their work.

17. Leadership Skills

Leadership skills are important for guiding teams, making decisions, and managing projects. Effective leaders can inspire and motivate their teams to achieve project goals.

18. Time Management

Effective time management skills help engineers prioritize tasks, meet deadlines, and maintain productivity in fast-paced environments.

19. Negotiation Skills

Negotiation skills are valuable for engineers who need to work with suppliers, clients, and team members to reach agreements that benefit all parties involved.

20. Ethical Judgment

Understanding and adhering to ethical standards in engineering practices is essential. Engineers must consider the societal impacts of their designs and decisions

Conclusion:

In summary, mechanical engineering students must cultivate a diverse skill set that includes both technical and soft skills. Mastery of these skills not only enhances their academic performance but also prepares them for successful careers in various industries Mechanical engineering is a demanding field that requires a blend of technical and soft skills. Also with the help of good college which is The Best Engineering College in Jaipur which is Arya College of Engineering & I.T. develop strong mathematical, analytical, and technical capabilities alongside effective communication, teamwork, and leadership skills, mechanical engineering students can position themselves for success in their careers. These competencies not only enhance their ability to solve complex engineering problems but also prepare them to thrive in collaborative and dynamic work environments.

Source: Click Here

#best btech college in jaipur#top engineering college in jaipur#best btech college in rajasthan#best engineering college in jaipur#best private engineering college in jaipur#best engineering college in rajasthan

0 notes

Text

Sizing a Water Pressure Vessel: Why It Matters and How to Do It Right

Properly sizing a water pressure vessel is critical to the efficiency, longevity, and safety of any plumbing or heating system. Whether for residential, commercial, or industrial applications, getting the size right ensures that the system operates smoothly, minimizes wear and tear, and avoids costly repairs. In this blog, we’ll discuss why sizing matters and provide a step-by-step guide on how to do it correctly.

1. Why Proper Sizing Matters

System Efficiency:

A correctly sized pressure vessel helps maintain consistent water pressure, reducing the frequency of pump cycling. This not only improves the efficiency of the system but also reduces energy consumption and operational costs.

Longevity of Components:

An undersized pressure vessel can lead to excessive wear on pumps, valves, and other components due to frequent cycling. Conversely, an oversized vessel may be unnecessarily costly and take up more space without adding significant benefits.

Preventing System Damage:

Incorrect sizing can result in pressure fluctuations that stress the plumbing system, leading to leaks, ruptures, or even system failure. Proper sizing ensures that the vessel can absorb pressure changes effectively, protecting the entire system.

Safety Concerns:

Over-pressurization can be a safety hazard, potentially leading to bursts or explosions in extreme cases. A correctly sized pressure vessel, paired with appropriate safety devices like pressure relief valves, minimizes these risks.

2. Key Factors to Consider in Sizing

System Capacity and Flow Rate:

The size of the pressure vessel should be matched to the system’s capacity (measured in gallons or liters) and the flow rate (measured in gallons per minute or liters per second). A higher flow rate generally requires a larger vessel to maintain stable pressure.

Pump Cycling Frequency:

The pressure vessel should be large enough to minimize pump cycling. Ideally, the pump should run long enough to fill the vessel and then have a rest period before the next cycle begins. Frequent cycling indicates that the vessel may be too small.

Pressure Range:

Consider the pressure range within which the system operates, typically defined by the cut-in and cut-out pressure settings on the pump. The vessel needs to accommodate the volume of water that corresponds to this pressure range.

Water Demand Patterns:

If the system experiences high or variable water demand, such as in a commercial or industrial setting, a larger vessel may be required to handle peak usage periods without compromising system pressure.

3. Step-by-Step Guide to Sizing a Pressure Vessel

Step 1: Determine the System’s Flow Rate

Calculate the flow rate of your system, which is the amount of water that flows through the system during operation. This is typically measured in gallons per minute (GPM) or liters per second (L/s).

Step 2: Identify the Pump’s Pressure Settings

Note the cut-in (the pressure at which the pump starts) and cut-out (the pressure at which the pump stops) settings on your pump. This pressure range will determine the amount of water the vessel needs to hold to prevent excessive cycling.

Step 3: Calculate the Drawdown Capacity

The drawdown capacity is the amount of water the vessel will supply between the pump turning on and off. This can be calculated using the following formula:

Drawdown Capacity (gallons) = (Flow Rate (GPM) x Run Time (minutes)) / 4

The run time is the desired duration of each pump cycle, typically between 1 to 2 minutes.

Step 4: Select the Appropriate Vessel Size

Based on the drawdown capacity, select a pressure vessel with a volume that can handle this capacity within the specified pressure range. Manufacturers often provide charts or calculators to help match vessel size to system requirements.

Step 5: Account for Future Needs

Consider whether your water usage may increase in the future, such as with home expansions or increased demand in a commercial setting. If growth is anticipated, it might be wise to choose a slightly larger vessel to accommodate these changes.

4. Common Mistakes to Avoid

Ignoring Pressure Range:

Failing to consider the pressure range can lead to selecting a vessel that is either too small or too large for the system’s operational needs.

Overlooking Peak Demand:

Not accounting for peak water usage times can result in pressure drops during high-demand periods, affecting the performance of the system.

Skipping Professional Consultation:

For complex systems or industrial applications, it’s advisable to consult with a professional to ensure accurate sizing and avoid costly mistakes.

Properly sizing a water pressure vessel is crucial for the efficient and safe operation of any water system. By considering factors such as flow rate, pressure settings, and future water demand, you can select a vessel that meets your needs and ensures long-term system reliability. Avoid common mistakes by following a systematic approach, and when in doubt, seek professional advice to make the best decision for your system. For more info contact Wates Pressure Vessel Supplier in UAE or call us at +971 4 2522966.

0 notes

Text

Monel Prices | Pricing | Price | News | Database | Chart | Forecast

Monel prices, a group of nickel alloys primarily composed of nickel and copper, has garnered attention in various industries for its exceptional corrosion resistance and mechanical properties. The price of Monel is influenced by several factors, including raw material costs, market demand, production processes, and geopolitical conditions. Nickel, the primary component of Monel, is a commodity traded on global markets, with its price subject to fluctuations based on supply and demand dynamics. As nickel prices rise or fall, Monel prices tend to follow suit, reflecting the close relationship between these two metals.

The demand for Monel is driven by its use in diverse applications across industries such as marine engineering, chemical processing, oil and gas, aerospace, and even musical instruments. In marine environments, Monel’s resistance to saltwater corrosion makes it a preferred material for shipbuilding and underwater applications. The chemical industry values Monel for its ability to withstand acidic and alkaline environments, making it ideal for valves, pumps, and heat exchangers. In the oil and gas sector, Monel is used in critical components that require high strength and corrosion resistance under extreme conditions. These varied applications ensure a steady demand for Monel, contributing to its price stability.

Production costs are another significant factor influencing Monel prices. The extraction and refining of nickel and copper involve complex and energy-intensive processes, which can be affected by changes in energy prices, labor costs, and technological advancements. Additionally, environmental regulations and policies regarding mining and smelting activities can impact production costs. For instance, stricter environmental standards may increase operational costs, subsequently raising the price of Monel. Technological improvements in extraction and processing, on the other hand, can enhance efficiency and reduce costs, potentially lowering Monel prices.

Get Real Time Prices for Monel: https://www.chemanalyst.com/Pricing-data/monel-1364

Geopolitical conditions also play a crucial role in determining Monel prices. Political instability in key nickel-producing regions can disrupt supply chains, leading to price volatility. Trade policies and tariffs imposed by major economies can influence the cost and availability of raw materials required for Monel production. For example, trade tensions between major nickel-producing countries and consuming countries can result in supply shortages or increased prices for nickel, thereby affecting Monel prices. Moreover, global economic conditions, including inflation rates and currency exchange rates, can have indirect effects on Monel prices by influencing production costs and market demand.

The recycling of nickel and copper also impacts Monel prices. The growing emphasis on sustainability and circular economy practices has led to increased recycling of these metals, providing a secondary source of raw materials. Recycling can help stabilize Monel prices by reducing dependence on primary extraction and mitigating the effects of supply disruptions. However, the availability and efficiency of recycling processes can vary, influencing the overall impact on Monel prices. Innovations in recycling technology and increased investment in recycling infrastructure can enhance the supply of recycled materials, potentially lowering Monel prices over time.

Market speculation and investor behavior are additional factors that can influence Monel prices. Commodity markets are often subject to speculative trading, where investors buy and sell based on anticipated price movements rather than actual supply and demand. Such speculative activities can lead to short-term price volatility, affecting Monel prices. Investors’ perceptions of future market conditions, geopolitical events, and technological advancements can drive speculative behavior, contributing to price fluctuations.

The global supply chain dynamics also affect Monel prices. Disruptions in transportation and logistics can lead to delays in the delivery of raw materials and finished products, impacting production schedules and costs. Events such as natural disasters, pandemics, and strikes can cause significant disruptions in supply chains, leading to price volatility. For instance, the COVID-19 pandemic caused widespread disruptions in global supply chains, affecting the availability of raw materials and leading to increased production costs for many industries, including those using Monel.

Moreover, the competitive landscape within the metals industry can influence Monel prices. The presence of alternative materials that offer similar properties at lower costs can affect demand for Monel. For example, stainless steel and titanium are often considered as alternatives to Monel in certain applications. The availability and pricing of these alternatives can influence buyers’ decisions, potentially impacting Monel prices. Companies producing Monel must continually innovate and improve their processes to maintain a competitive edge and justify the premium associated with Monel alloys.

In conclusion, Monel prices are determined by a complex interplay of factors including raw material costs, market demand, production processes, geopolitical conditions, recycling practices, market speculation, supply chain dynamics, and competition from alternative materials. Understanding these factors is crucial for stakeholders in industries reliant on Monel, as it enables them to anticipate price movements and make informed decisions regarding procurement and production strategies. As the global economy and technological landscape continue to evolve, the factors influencing Monel prices will likely become even more intricate, necessitating continuous monitoring and analysis to navigate the challenges and opportunities in the market.

Get Real Time Prices for Monel: https://www.chemanalyst.com/Pricing-data/monel-1364

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Monel#Monel Price#Monel Prices#Monel Pricing#Monel News#Monel Price Monitor#Monel Database#Monel Price Chart#Monel Price Trend

0 notes

Text

Top Skills for Mechanical Engineers in 2024 - ACEIT

Mechanical engineering encompasses a wide range of skills essential for students pursuing this discipline. Here is a comprehensive list of 20 skills that mechanical engineering students should develop to excel in their studies and future careers.

Technical Skills

1. Computer-Aided Design (CAD)

Proficiency in CAD software such as SolidWorks, AutoCAD, and CATIA is crucial for creating detailed designs and models of mechanical components. This skill aids in visualizing and refining designs before production.

2. Thermodynamics

A solid understanding of thermodynamics is essential for analyzing energy systems, heat transfer, and fluid dynamics. This knowledge is critical for applications such as engines and HVAC systems.

3. Mechanics and Materials Science

Knowledge of mechanics and materials science helps engineers understand how materials behave under various forces and conditions, which is vital for selecting appropriate materials for designs.

4. Programming Skills

Familiarity with programming languages like Python, MATLAB, and C++ is increasingly important for automating tasks, conducting simulations, and analyzing data.

5. Manufacturing Processes

Understanding various manufacturing processes, including machining, welding, and additive manufacturing, is essential for designing components that can be produced efficiently and economically.

6. Finite Element Analysis (FEA)

FEA is a computational technique to predict how objects react to external forces, vibrations, heat, and other physical effects. Proficiency in FEA software is important for validating designs.

7. Fluid Dynamics

Knowledge of fluid dynamics is crucial for designing fluid flow systems, such as pumps, turbines, and HVAC systems. Understanding principles like Bernoulli's equation is essential.

8. Control Systems

Understanding control systems and automation is vital for modern mechanical engineering, especially in robotics and manufacturing processes. This includes knowledge of sensors, actuators, and feedback loops.

9. Technical Drawing

The ability to create and interpret technical drawings is fundamental. This skill ensures that designs are communicated clearly and accurately to manufacturers and other engineers.

10. Project Management

Mechanical engineers often lead projects, requiring skills in project management, including planning, budgeting, and resource allocation. Familiarity with tools like Gantt charts is beneficial.

11. Problem-Solving Abilities

Strong problem-solving skills enable engineers to tackle complex challenges, identify root causes, and develop effective solutions. This is a core competency in engineering design and troubleshooting.

12. Communication Skills

Effective communication is essential for collaborating with team members and stakeholders. Engineers must convey technical information and ideas, both verbally and in writing.

13. Teamwork and Collaboration

Mechanical engineers often work in multidisciplinary teams, making the ability to collaborate effectively with others crucial for project success.

14. Critical Thinking

Critical thinking skills allow engineers to analyze situations, evaluate options, and make informed decisions. This is vital for optimizing designs and processes.

Conclusion:

In summary, mechanical engineering students must cultivate a diverse skill set that includes both technical and soft skills. Mastery of these skills not only enhances their academic performance but also prepares them for successful careers in various industries Mechanical engineering is a demanding field that requires a blend of technical and soft skills. Also with the help of good college which is The Best Engineering College in Jaipur which is Arya College of Engineering & I.T. develop strong mathematical, analytical, and technical capabilities alongside effective communication, teamwork, and leadership skills, mechanical engineering students can position themselves for success in their careers. These competencies not only enhance their ability to solve complex engineering problems but also prepare them to thrive in collaborative and dynamic work environments.

0 notes

Text

A Comprehensive Guide to Choosing the Right Heat Pump Hot Water Heater

In the quest for energy efficiency and cost savings, many homeowners are turning to heat pump hot water heaters as a viable solution. These systems, known for their ability to transfer heat rather than generate it directly, offer significant benefits over traditional water heating methods. However, choosing the right heat pump hot water heater requires careful consideration of several factors. This guide will walk you through the key aspects to consider, helping you make an informed decision for your home.

Understanding How Heat Pump Hot Water Heaters Work

Heat pump hot water heaters operate on the principle of heat transfer, similar to how a refrigerator works but in reverse. They extract heat from the surrounding air and use it to heat water stored in a tank. This process is significantly more energy-efficient compared to conventional electric or gas water heaters, which generate heat through combustion or electrical resistance.

Key Factors to Consider When Choosing a Heat Pump Hot Water Heater

Energy Efficiency

One of the primary reasons for choosing a heat pump hot water heater is its energy efficiency. Look for models with a high Energy Factor (EF) rating, which indicates the unit's efficiency in converting energy into hot water. The higher the EF, the more efficient the system. Additionally, consider units that are ENERGY STAR certified, as they meet strict energy efficiency guidelines set by the U.S. Environmental Protection Agency.

Size and Capacity

Choosing the right size and capacity for your heat pump hot water heater is crucial. The size you need depends on the number of occupants in your home and your daily hot water usage. A unit that's too small will struggle to meet demand, while an oversized unit may lead to unnecessary energy consumption. Most manufacturers provide sizing charts to help you determine the appropriate capacity based on household size and usage patterns.

Installation Location

Heat pump hot water heaters require a specific installation environment to operate efficiently. They work best in areas with moderate to warm temperatures, such as basements, garages, or utility rooms. Ensure that the installation location has adequate space for proper airflow around the unit. Additionally, these systems may generate some noise during operation, so consider placing them in a location where noise won’t be an issue.

Cost and Incentives

While heat pump hot water heaters can be more expensive upfront than traditional systems, their long-term energy savings often justify the initial investment. Calculate the total cost of ownership, including installation, maintenance, and operating costs. Furthermore, check for available incentives and rebates from local utility companies or government programs that can help offset the initial purchase and installation costs.

Climate Considerations

The climate in your region plays a significant role in the performance of a heat pump hot water heater. These systems are most efficient in warmer climates but can still be effective in cooler regions with proper planning and insulation. In colder climates, hybrid models that combine heat pump technology with traditional electric heating elements can provide reliable hot water year-round.

Maintenance Requirements

Like any appliance, heat pump hot water heaters require regular maintenance to ensure optimal performance and longevity. Regularly clean or replace air filters, inspect the condensate drain for clogs, and check the unit’s refrigerant levels. Some models come with smart features that provide maintenance alerts and diagnostic information, making it easier to keep your system in top shape.

Comparing Heat Pump Hot Water Heaters with Other Systems

To fully appreciate the benefits of heat pump hot water heaters, it's helpful to compare them with other types of water heating systems:

Electric Water Heaters

Electric water heaters are less expensive to purchase and install but tend to have higher operating costs due to their lower energy efficiency. They convert electrical energy directly into heat, which is less efficient than the heat transfer process used by heat pumps.

Gas Water Heaters

Gas water heaters heat water quickly and have lower operating costs in areas where natural gas is affordable. However, they are less environmentally friendly due to greenhouse gas emissions and can pose safety risks if not properly maintained.

Solar Water Heaters

Solar water heaters offer exceptional energy savings and environmental benefits but come with high upfront costs and depend on sufficient sunlight for optimal performance. Heat pump hot water heaters can be a more reliable alternative in regions with inconsistent sunlight.

Conclusion

Choosing the right heat pump hot water heater involves evaluating several factors, including energy efficiency, size and capacity, installation location, cost, climate considerations, and maintenance requirements. By carefully considering these aspects, you can select a system that not only meets your household's hot water needs but also provides long-term cost savings and environmental benefits. As you navigate the selection process, remember that investing in a heat pump hot water heater is an investment in your home's energy efficiency and sustainability, making it a smart choice for the future.

Contact Us:

Hot Water Solutions

3d Tait Place, Auckland

Email: [email protected]

Call Us: 0800 HWSOLU (497658)

Google map: https://maps.app.goo.gl/weuxr8LohUEv2ooj6

Social Links:

https://www.facebook.com/Hot-Water-Solutions-100885308035357/

https://www.instagram.com/pete_hotwatersolutions/?hl=en

https://www.youtube.com/@HotWaterSolutions_NZ

0 notes

Text

Double Diaphragm Pumps (DDP) Market Worldwide Industry Analysis, Future Demand and Forecast till 2032

Double Diaphragm Pumps (DDP) Market Size Was Valued at USD 6.04 Billion in 2023 and is Projected to Reach USD 11.29 Billion by 2032, Growing at a CAGR of 7.2% From 2024-2032.

Double diaphragm pumps are characterized by two flexible diaphragms that reciprocate back and forth, creating a temporary chamber, which draws in and then expels fluid through the pump. This design allows the pump to handle a wide range of fluids, from clean, light viscosity to corrosive, abrasive, medium viscosity fluids, and even fluids containing solid particles.

These pumps are used in various industries due to their adaptability and efficiency. Key industries include chemical processing, water and wastewater management, pharmaceuticals, food and beverage, and oil and gas. They are particularly valued in applications where the fluid being pumped is complex, like high viscosity, or contains fragile solids or abrasive particles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/9889

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Double Diaphragm Pumps (DDP) Market include:

Dover Corporation (USA), Flowserve (USA), Idex Corporation (USA), Graco Inc. (USA), Xylem Inc. (USA), Pump Solutions Group (USA), SPX Flow, Inc. (USA), DAYTON (USA), WHITE KNIGHT (USA), EDSON (USA), SOTERA (USA), VERSA-MATIC (USA), SANDPIPER (USA), WARREN-RUPP (USA), STANDARD PUMP (USA), ARO (USA)

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Double Diaphragm Pumps (DDP) Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/9889

Segmentation of Double Diaphragm Pumps (DDP) Market:

By Operation Type

Single Acting

Double Acting Agent

By Mechanism Type

Air Operated Pumps

Electrically Operated Pumps

By End User Industry

Oil & Gas

Food & Beverages

Water & Waste Water

Chemicals & Petrochemicals

Pharmaceuticals

An in-depth study of the Double Diaphragm Pumps (DDP) industry for the years 2024–2032 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Key Benefits of Double Diaphragm Pumps (DDP) Market Research:

Research Report covers the Industry drivers, restraints, opportunities and challenges

Competitive landscape & strategies of leading key players

Potential & niche segments and regional analysis exhibiting promising growth covered in the study

Recent industry trends and market developments

Research provides historical, current, and projected market size & share, in terms of value

Market intelligence to enable effective decision making

Growth opportunities and trend analysis

Covid-19 Impact analysis and analysis to Double Diaphragm Pumps (DDP) market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=9889

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assist our clients grow and have a successful impact on the market. Our team at IMR is ready to assist our clients flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, specialized in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1 773 382 1049

Email: [email protected]

#Double Diaphragm Pumps (DDP)#Double Diaphragm Pumps (DDP) Market#Double Diaphragm Pumps (DDP) Market Size#Double Diaphragm Pumps (DDP) Market Share#Double Diaphragm Pumps (DDP) Market Growth#Double Diaphragm Pumps (DDP) Market Trend#Double Diaphragm Pumps (DDP) Market segment#Double Diaphragm Pumps (DDP) Market Opportunity#Double Diaphragm Pumps (DDP) Market Analysis 2024

0 notes

Text

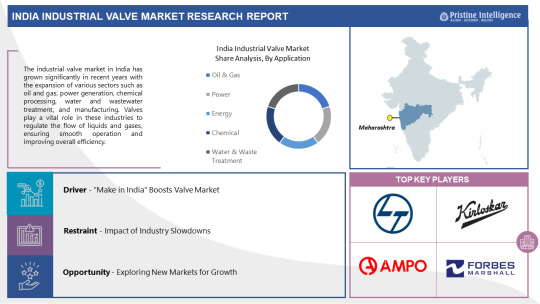

India Industrial Valve Market: Forthcoming Trends and Share Analysis by 2030

India Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

With the growth of several industries, including manufacturing, chemical processing, oil and gas, power production, water and wastewater treatment, and water treatment, the industrial valve market in India has expanded dramatically in recent years. In these sectors, valves are essential for controlling the flow of gases and liquids, guaranteeing efficient functioning.

The demand for industrial valves in India has expanded as a result of the government's ongoing emphasis on infrastructure development and programs like "Make in India". Furthermore, the application of increasingly sophisticated and effective valve technology has been prompted by growing concerns about safety regulations and environmental sustainability. The expansion of the industry has also been aided by the significant presence of major multinational valve manufacturers in India. Nonetheless, there are difficulties in the sector.

Price pressure, fierce competition, and shifting raw material prices are examples of potential barriers. In spite of this, as the country invests in vital infrastructure projects and modernizes its industrial base, the Indian industrial valve market is expected to grow. Manufacturers will probably concentrate on technological development, product customisation, and fostering strong relationships with end users in order to successfully adapt to their changing needs if they want to succeed in this dynamic environment.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the India Industrial Valve Market include:

L&T (India), Kirloskar Brothers Limited (India), Ampo Valves (Spain), Emerson Electric Co. (United States), CRI Pumps (India), VIP Valves Private Limited India (India), Amco Industrial Valves (India), Amtech Valves (India), Hawa Engineers Ltd (India), Novel Valves (India), Forbes Marshall (India), IMI Plc (United Kingdom), Metso Corporation (Finland), The Weir Group Plc (United Kingdom), AVK Holding (Denmark), Avcon Controls Pvt. Ltd. (India), Schlumberger Limited (United States), Crane (United States), Virgo Valves Pvt. Ltd. (India), Oswal Valves Ltd. (India), Weir BDK (India), Hindustan Valves & Engineering Co. (India), Jaiprakash Valves (India) and other major players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query India Industrial Valve Market Report, Visit:

Segmentation of India Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global India Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

India Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#India Industrial Valve#India Industrial Valve Market#India Industrial Valve Market Size#India Industrial Valve Market Share#India Industrial Valve Market Growth#India Industrial Valve Market Trend#India Industrial Valve Market segment#India Industrial Valve Market Opportunity#India Industrial Valve Market Analysis 2023

0 notes

Text

Tips for Optimizing Efficiency in Your Chemical Engineering Lab with the Right Equipment

Chemical engineering is that branch of engineering that touches the lives of all of us. They are the engineering wizards that turn raw materials into useful and valuable products. With the principles of chemistry, math, and physics and the aid of equipment by top chemistry engineering lab equipment manufacturers, they design processes and equipment for making things like chemicals, medicines, fuels, and even food on a large scale.

Chemical engineers figure out how to do it efficiently, safely, and economically. They're like the chefs of the industrial world, creating the instructions for making stuff in factories. Chemical engineering lab equipment manufacturers are proud to be collaborators with chemical engineers worldwide. They are on board as the official chemical engineering lab equipment manufacturers and suppliers to the topmost chemical engineering companies in the world.

Tips for Optimizing Efficiency By Chemical Engineering Lab Equipment Suppliers

Optimizing efficiency in a chemical engineering lab relies on several key factors, including having the right equipment from the best chemical engineering lab equipment manufacturer and employing effective practices. Here are some tips for achieving greater efficiency, along with suitable examples:

Material Compatibility:

Consider the materials you'll be working with and ensure that the equipment is compatible with those substances. Carefully assess the materials that will come into contact with the equipment. Ensure it can handle the corrosiveness, reactivity, and potential chemical interactions with your substances. Consult material compatibility charts and guidelines for reference provided along with the chemical engineering lab equipment list.

Example: When working with highly corrosive chemicals, choose equipment made from corrosion-resistant materials such as PTFE (Teflon), stainless steel, or glass-lined reactors. For handling reactive substances, consider specialized reactors like Hastelloy reactors, designed for chemical resistance.

Harness The Power Of Automation:

Whenever possible, leverage automation and computer-controlled systems to increase precision and reduce human error. Check with chemical engineering lab equipment manufacturers and suppliers of the latest automated equipment that shall significantly enhance efficiency. Here's how automation achieves this:

Precision and Consistency

24/7 Operation

Reduced Human Error

Accurate and real-time data acquisition

Parallel Processing

Task Integration within a single system

Remote Monitoring and Control

Better safety standards with handling of hazardous or toxic materials without direct human contact

Workflow Efficiency

Resource Optimization

Instrument Integration:

Mostly, chemical engineers plan to use multiple instruments in sync. Ensure to source equipment from experienced chemical engineering lab equipment suppliers that are compatible and integrate seamlessly with automated processes.

Example: Gas chromatography-mass spectrometry (GC-MS) systems combine the separation capabilities of GC with mass spectrometry for compound identification. These integrated systems streamline chemical analysis.

Optimizing Energy Use

Modern Chemical engineering labs must strategize and take practical steps to reduce energy consumption while maintaining or improving productivity. Some of these practices are:

Invest in energy-efficient lab equipment and instrumentation, such as energy-efficient refrigeration systems, ovens, and pumps.

Ensure that lab equipment is correctly sized, as it reduces energy waste.

Use smart controls and sensors to implement heating, ventilation, and air conditioning (HVAC) systems with controls and sensors.

LED lighting for less consumption of electricity.

Use automated timers that turn off lighting, fume hoods, and equipment during non-operational hours or when not in use.

It is a great thing to practice periodic energy audits to identify areas of energy inefficiency within the lab.

Avoid energy wastage by optimizing temperature and pressure.

Implement energy management systems for real-time monitoring and control of lab equipment.

Every step must be taken to lower the carbon footprint, and partial reliance on clean energy is the best and proven step for it.

Design or revamp chemical engineering labs with Energy-Efficient Lab Design

Regulatory Compliance & Supplier Reputation

Undoubtedly, chemical engineering labs witness the use of chemical engineering lab equipment at all times. Thus, it is one of the labs where there can be no quality compromise of the equipment. Chemical engineers can optimize the efficiency of their lab operation by selecting equipment that complies with relevant industry regulations and safety standards. With the leading chemical engineering lab equipment suppliers comes the guarantee of certifications and approvals that validate the equipment's suitability for use in the chemical engineering lab.

With chemical engineering lab equipment suppliers and exporters, every aspect of lab equipment comes verified. They have a proven track record of providing equipment that is certified to meet safety and regulatory standards, ensuring compliance.

Setting Up Of Safety Enclosures

These enclosures protect both operators and the surrounding environment during experiments involving hazardous materials or reactions. The following measures are effective steps for lab operations in chemical engineering labs:

Set-up safety enclosures provide a physical barrier between these hazardous materials and laboratory personnel.

Ensure these enclosures have built-in trays, catchment systems, or containment chambers. They help to capture and safely manage any spills, preventing them from spreading into the lab environment.

Check with chemical engineering lab equipment suppliers to install fume hoods. They ensure that the lab air remains clean and safe to breathe.

The Safety enclosures must have transparent windows or panels that allow engineers to observe and manipulate experiments without direct contact with the chemicals.

Safety enclosures, like glove boxes and isolation chambers, must be sourced from top chemical engineering lab equipment manufacturers. They are essential when working with air-sensitive or moisture-sensitive materials.

Provision of emergency shut-off systems for quick deactivation of equipment or experiments in case of emergencies or unexpected events.

Safety enclosures are designed and manufactured to meet strict safety standards and regulations. Using compliant enclosures ensures that the lab adheres to safety guidelines and protocols, which is essential for both research integrity and personnel safety.

Safety enclosures by chemical engineering lab equipment suppliers come in various configurations to accommodate different experimental requirements. Share your lab requirements with them, and the experts will install safety enclosures that sync absolutely with your lab goals.

Many more tips by chemical engineering lab equipment suppliers can help you make informed decisions when selecting equipment for your chemical engineering lab. Following these tips ensures that your choices align with your research goals and contribute to the overall efficiency and productivity of your laboratory operations.

0 notes

Text

Ducted vs Ductless Heat Pump: Which is More Efficient?

In recent years, the shift towards energy-efficient home heating and cooling solutions has been remarkable. Among these, heat pumps have emerged as a frontrunner, especially in the diverse climates we experience. The big question, however, remains: Ducted vs Ductless Heat Pump – which one tops the efficiency charts?

Understanding Heat Pumps

At their core, heat pumps are ingenious devices that transfer heat instead of generating it, making them a highly efficient cornerstone for modern heating and cooling. Whether it’s the nippy winters or the occasional summer heatwave, heat pumps have proven their mettle across various Canadian climates.

Ducted Heat Pumps

Ducted heat pumps are the traditional heavyweights in the HVAC world. They work by distributing conditioned air through a series of ducts and vents.

Ideal Scenarios for Ducted Heat Pumps

Homes with existing ductwork: Retrofitting a ducted system in a house already equipped with ducts is a breeze.

Large homes: For sprawling spaces, ducted systems offer uniform heating and cooling.

Pros and Cons

Efficiency in Energy Use: While ducted systems are efficient, they can lose some heat through the ducts, especially if they aren’t well insulated.

Installation Considerations: Installing ductwork can be invasive and costly, but if you already have it, you’re golden.

Aesthetics and Space Requirements: Ducted systems are almost invisible, with only the vents showing.

Maintenance and Longevity: Regular duct cleaning and maintenance are crucial for efficiency and longevity.

I remember visiting a client’s newly renovated home where they had installed a ducted system. The seamless integration with their modern aesthetics was impressive. However, they did mention the initial hiccups with duct installation in their older home structure.

Ductless Heat Pumps

Ductless heat pumps, commonly known as mini-splits, have been a game-changer in the HVAC industry. These systems consist of an outdoor compressor unit and one or more indoor air-handling units, connected by a conduit.

When to Choose Ductless Heat Pumps

Homes without existing ductwork: Ideal for older homes or additions where installing ducts is impractical.

Zoned heating and cooling needs: Perfect for controlling temperatures in individual rooms.

Pros and Cons

Energy Efficiency and Cost Savings: Ductless systems are highly efficient as they avoid energy losses typically associated with ductwork. They can significantly reduce utility bills.

Installation Ease and Flexibility: These systems can be installed quickly with minimal disruption to your home.

Room-by-Room Control and Comfort: You can heat or cool specific areas as needed, enhancing comfort and efficiency.

Visual Impact and Maintenance Needs: While they are more visible, modern units have sleek designs that blend well with interior decor. Maintenance is generally straightforward and less frequent.

Ducted vs Ductless Heat Pump: Efficiency and Performance

Energy Efficiency Comparison

Ducted Systems: Can lose up to 30% of energy through ductwork, especially if not properly insulated.

Ductless Systems: Higher efficiency as they eliminate duct losses, ideal for targeted heating/cooling.

Performance in Extreme Temperatures

Both systems perform well in various climates, but ductless systems may have an edge in extreme conditions due to their direct air delivery.

Long-Term Cost Implications

While ductless systems may have a higher initial cost, especially for multiple zones, their operational efficiency often leads to lower long-term costs.

Environmental Impact Considerations

Ductless systems, with their reduced energy consumption, have a smaller carbon footprint.

Installation and Maintenance

Overview of Installation Processes

Ducted Systems: Installation can be extensive, requiring ductwork throughout the home.

Ductless Systems: Installation is less invasive, often completed in a day.

Maintenance Requirements and Tips

Regular cleaning and servicing are vital for both systems to ensure efficiency and longevity.

The Importance of Professional Installation and Regular Check-Ups

Professional installation guarantees optimal performance. Regular maintenance can prevent costly repairs down the line.

Cost Analysis of Ducted vs Ductless Heat Pump

Initial Installation Costs

Ducted Systems: More cost-effective if you already have ductwork.

Ductless Systems: Higher initial cost but can be more economical in homes without existing ductwork.

Long-Term Financial Benefits and Potential Savings

The energy efficiency of ductless systems often translates into significant savings over time.

Rebates and Incentives Available in Canada

Various rebates and incentives can offset the initial costs, especially for energy-efficient systems.

Making the Right Choice for Your Home

Factors to Consider

Home Layout: The size and layout of your home can dictate the most suitable system.

Climate: Consider your local climate and how each system performs under those conditions.

Personal Preferences: Aesthetics, noise levels, and individual room control might influence your decision.

Case Studies

Stories from homeowners who have experienced the benefits and challenges of each system can provide valuable insights.

Expert Recommendations for Different Scenarios

Consulting with HVAC professionals can help tailor the choice to your specific needs.

Conclusion

In conclusion, both ducted and ductless heat pumps have their merits. Your choice will depend on various factors, including your home’s existing infrastructure, your heating and cooling needs, and your budget. Consulting with a professional can provide personalized advice tailored to your situation.

10. FAQs

Q: Can ductless heat pumps provide heating and cooling for an entire house?

A: Yes, especially in homes without existing ductwork, they can be an efficient whole-house solution.

Q: Are ducted systems more suitable for larger homes?

A: Generally, yes, due to their ability to distribute air evenly throughout larger spaces.

Q: How often should I service my heat pump?

A: Annual servicing is recommended for both ducted and ductless systems to maintain efficiency and longevity.

0 notes

Text

Reducing The Carbon Footprint Of Your Business Using Technology

The term ‘carbon footprint’ has been in use for some time now, as a handy if reductive way of addressing our contributions to carbon emissions – both personally and in terms of businesses and enterprises. It should come as no surprise that businesses and industries carry a great deal of the weight in terms of national carbon emissions, and that their responsibility to address climate change is far greater than that of the individual.

As a manager or business owner yourself, it would then fall on you to chart a course towards a more sustainable future as a business by reducing the size of this carbon footprint. Not only are there ethical factors at place, but also legal imperatives – to say nothing of consumer demand and the PR positives that can come from directly addressing pollutive practices. But what are some ways in which the modern tech-forward business can adequately address its carbon footprint?

Renewable Energy Sources

One of the major routes by which larger businesses can seek to reduce their carbon footprint is through pivoting away from pollutive energy sources altogether. Renewable sources like solar and wind have been available for decades, and continue to grow as effective alternatives to fossil fuels. This change could be as simple as signing up with an eco-conscious energy supplier that guarantees supply of renewable energy to the grid; alternatively, a business could assemble its own solar arrays to produce its own energy off-grid.

Heating Systems

Energy sources are just one part of the equation, though. Energy efficiency is another vital consideration, particularly with regard to building heating systems. Older heating systems are inefficient at heating water, resulting in energy lost and undue pollution. An efficient combi boiler could be revelatory for the smaller office in terms of carbon emissions. Larger offices and administrative centres, meanwhile, might benefit from newer iterations of air source heat pump technology – which run on electricity as opposed to natural gas.

IoT

IoT, or the Internet of Things, describes a not-so-new form of technology wherein ‘smart’ systems can speak to one another via an internet connection. On the consumer side, the IoT has been somewhat defined by gimmicks: refrigerators that can access social media, and wireless speakers that can play music on command.

However, for businesses IoT devices can be revolutionary in terms of energy efficiency. Interconnected systems can automate the switching on and off of lights, heating systems and even equipment. This allows for the most efficient possible usage of said equipment.

Cloud Computing

Cloud computing is another technological innovation which has been a fixture in modern life. Consumers use cloud computing on a daily basis to store personal files such as photos, in the form of products like iCloud and Dropbox.

Businesses can use cloud computing to host large tranches of their own data, and even live information such as websites and active databases, off-site. This means less energy expended on in-house server arrays. When combined with an eco-conscious cloud computing service, this could dramatically reduce emissions.

Read the full article

0 notes

Text

Why Invest in a Self Contained AC Unit In Vero Beach And Riviera Beach, FL?

Being out on the sea for months on end has a romantic feel. Sadly, the reality is quite different, with boat owners struggling to provide basic comfort inside their boats. The hot and humid weather that is associated with the seaside, as well as the salinity in the air, makes life inside the boat discomfiting until the vessel is fitted with a quality air conditioning system. A small to medium-sized watercraft is ideally fitted with a self contained AC unit in Vero Beach and Riviera Beach, FL, that comes with multiple advantages and is indeed a value addition for marine vessel operators and boat owners.

Sure, the idea of cool air blowing through the cabin when the boat or yacht is operating sounds divine. Unfortunately, a split AC of standard size will take up a lot of space, leaving the rest of the boat cabin look unfurnished. One cannot compromise on this, though, especially when the vessel is being used commercially. Opting for a compact marine AC that functions perfectly is the best possible solution for boats and operators. It is an ideal cooling system for crafts with one to 2 and 3 cabins. Fishing trawlers may find it perfect as long as they have a separate ice box inside meant to hold the fresh catchment.

The unit consists of all essential parts added to a single chassis. The unit can be installed conveniently in the living area, under the bunks, or inside a locker. There are multiple models to choose from, with a few small boat operators settling for cooling-only devices, whereas others opting for the more extensive heating plus cooling units. The end-user would do well to invest in an air conditioning kit that includes the following:-

· Self-Contained Unit

· Water Pump

· Ducting

· Grilles

Finding a good quality AC unit is not troublesome for most marine product dealers who provide a selection of such units. Not much guidance is required to buy a particular unit either as long as the following are considered carefully:-

· Efficiency- It is imperative to check for power usage and associated cooling effect that needs to be balanced to provide value for money. While small to mid-sized boats can function very well by installing a single unit, the bigger watercraft may have a couple of units installed to maximize efficiency instead of looking at other types of cooling devices.

· Size of Boat- Measuring the entire boat will not help. Instead, it is important to think of the area that requires cooling. It is a good idea to ask the manufacturer or dealer for recommendations. Most of them will have a handy chart displaying the right-sized AC unit for a particular size of boat/yacht.

· Installation- The ease of installation is one of the significant advantages of investing in a self-contained unit. There is no need to provide additional support as a majority of units can be plugged in conveniently.

A self-contained AC unit in Vero Beach and Riviera Beach, FL, is considered to be a wise investment as it provides exemplary cooling without compromising other essential factors.

0 notes

Text

The Ultimate Guide to Choosing the Right Backup Generator for Your Home

Introduction: Understanding the Importance of Home Backup Generators

In today's modern world, where electricity is essential for almost every aspect of our lives, power outages can be a major inconvenience and even pose a threat to our safety and security. That's why having a reliable backup generator for your home is crucial. In this guide, we will explore the world of home backup generators and help you choose the right one for your specific needs.

Chapter 1: How Home Backup Generators Work

Before diving into the selection process, it's important to understand how home backup generators work. Home backup generators are connected to your home's electrical system and automatically switch on when a power outage occurs. They are usually fueled by natural gas or propane and can provide power to essential appliances and systems, such as lights, refrigerators, heating or cooling systems, and medical equipment.

To learn more about the technical aspects of home backup generators, you can refer to this detailed article.

Chapter 2: Assessing Your Power Needs

Not all backup generators are created equal, and it's important to choose one that can meet your specific power needs during an outage. Start by making a list of the essential appliances and systems that you cannot afford to lose power to, such as medical devices, sump pumps, or security systems. Calculate the total power consumption of these devices to determine the minimum power capacity you will need in a backup generator.

For a more in-depth guide on assessing your power needs, refer to this helpful resource.

Chapter 3: Selecting the Right Size and Type of Generator

Once you have determined your power needs, it's time to select the right size and type of generator for your home. Backup generators come in various sizes and types, ranging from portable units to whole-house standby generators. Factors to consider include the available space for installation, noise level, fuel type, and budget.

For a comprehensive comparison of different generator sizes and types, refer to this informative comparison chart.

Chapter 4: Installation and Maintenance

Proper installation and regular maintenance are essential for the reliable and efficient operation of your home backup generator. It's crucial to hire a licensed electrician or generator installer to ensure that the generator is installed correctly and complies with all safety codes. Regular maintenance, such as oil changes and battery checks, will help prolong the lifespan of your generator and ensure it's always ready for action.

For a detailed guide on generator installation and maintenance, check out this handy resource.

Conclusion

Investing in a home backup generator is a wise decision that can provide peace of mind knowing that you and your family will not be left in the dark during a power outage. By understanding the technical aspects, assessing your power needs, selecting the right size and type, and ensuring proper installation and maintenance, you can choose the perfect backup generator for your home.

Remember, the power to protect your home and loved ones is in your hands. Choose wisely and stay prepared! Article by None

0 notes

Text

How To Properly Irrigate A Garden In The Heat And Humidity?

Even in most inland climates, there will be times when your garden must contend with hot and humid weather. With temperatures soaring and humidity levels skyrocketing, it’s essential to know how to properly irrigate your garden in such conditions. This blog post will discuss the different methods for watering a garden in hot weather and how to choose the right one for your specific situation. We will also provide tips on how to avoid over-watering and other common irrigation mistakes.

What Is Irrigation?

Irrigation is the process of supplying water to plants. In most cases, the water is delivered through a system of pipes and controllers. This article will provide an overview of irrigation and tips on adequately irrigating a garden in the heat and humidity.

Irrigation is one of the gardeners' essential strategies to ensure successful plant growth. Not only does it help keep plants watered during hot weather, but it also helps reduce the chances of weed growth. It helps maintain healthy foliage in high-humidity areas.

How Much Water Do I Need?

The amount of water your plants require broadly depends on their size and type of soil. However, a general guideline is to give plants about 1 inch (2.5 cm) of water per week during periods of extended hot weather. You may need to water every three or four days during cooler temperatures instead. Check your soil moisture level regularly using a soil moisture meter or digging down a few inches and squeezing the soil between your fingers - if it feels dry, add more water before planting or growing new plants. Refer to this handy chart for more specific information:

In high-humidity areas such as coastal regions or along the Gulf Coast, give your plants 1-3 times more water than usual - about 6-12 inches (15-30 cm) per week during extended hot weather. Again, check your soil moisture regularly using a meter or by digging down a few inches

Types of Irrigation

Irrigation is the water distribution and application process for plants. When done correctly, irrigation can help a garden flourish in the hot, humid conditions that often prevail during summer. Many types of irrigation systems are available to homeowners, from drip tubing to sprinklers. It's essential to choose the right type for your situation. Gardeners should consult with an experienced professional before making any irrigation decisions.

One type of irrigation system used in gardens is surface water runoff (SWR) which generally refers to rainfall or melting snow falling on roofs and ground surfaces and running off into storm drains or streams. This method is free and environmentally friendly, as it avoids the need to dispose of wastewater generated by irrigating a garden. SWR requires good drainage in the area where it will be applied and should be avoided where there is standing water or poor soil drainage.

A more expensive but efficient option is drilled well irrigation (DWI). Drilled wells are dug specifically to deliver water directly to plants via a subterranean network of pipes. This system is often used for extensive commercial gardens because of its greater capacity and efficiency. However, it can be challenging to set up, requires regular maintenance, and may require purchasing specialized equipment such as pressure tanks or pumps.

A third option is using an injection well that taps into underground water sources such as aquifers or reservoirs. Injection wells are not commonly used in residential settings because they can be costly and

How to Properly Irrigate a Garden in the Heat and Humidity

If you live in a hot and humid climate, your garden will likely suffer from water shortages. Proper irrigation is the key to preventing garden soil from becoming parched and dry. Here are five tips for adequately irrigating a garden in the heat and humidity:

1. use rotary sprinklers: Rotary sprinklers are the most efficient garden irrigation system because they distribute water evenly over large areas. This means that less water is required to achieve the desired result.

2. stagger watering times: Watering should be staggered throughout the day, so plants don't receive too much or too little water at once.

3. avoid over-watering: Over-watering can cause plants to become root-bound and stressed, further aggravating water shortages.

4. use mulch: Mulch helps retain moisture and reduces evaporation from the soil surface. It also helps to reduce weed growth, which can be troublesome in a hot and humid climate.

5. Drip irrigation systems are ideal for smaller gardens because they deliver a steady stream of water directly to plant roots without causing drippage or runoff problems.

Conclusion

Gardening in the heat and humidity can be a challenge. However, you can succeed with some preparation and knowledge of how to properly irrigation companies near me. Follow these tips to ensure your garden receives the water it needs 1) Use a rainfall simulator or weather app to simulate expected rainfall patterns for your area. This will help you plan when and where to irrigate most effectively. 2) Ensure drainage is good in all garden areas by grading the soil, adding organic matter, and installing rain gardens, swales, and percolation systems. Watering should only occur where necessary - avoid flooding!

Down To Earth Landscape & Irrigation

2701 Maitland Center Pkwy Suite 200,

Maitland, FL 32751,

United States

+13523857227

0 notes

Text

Rocky mountain power window rebate

ROCKY MOUNTAIN POWER WINDOW REBATE INSTALL

ROCKY MOUNTAIN POWER WINDOW REBATE UPGRADE

ROCKY MOUNTAIN POWER WINDOW REBATE FULL

Have your upgrades installed by a contractor with a valid B.C.

Carefully read the Program Requirements and Additional Terms and Conditions to confirm your eligibility.

Home must be a year-round primary residence that is at least 12 months old.

Use the BC Hydro Home Renovation Rebate program eligibility tool to determine whether your home meets the minimum electricity consumption rates.

When the home is heated with electricity supplied by BC Hydro, the home must meet a minimum electricity consumption.

Homes primarily heated by wood or other solid fossil fuels are able to access heat pump rebates, natural gas fireplace rebates, hot water heater rebates, and EnerGuide Home Evaluation rebates only.

Oil or propane not supplied by FortisBC.

Electricity supplied by FortisBC, BC Hydro, or a municipal utility.

Natural Gas supplied by Pacific Northern Gas.

Natural Gas or piped-propane supplied by FortisBC.

Your home must be primarily heated with:.

You must have a residential utility account with FortisBC, BC Hydro, or a municipal utility.

business license for the trade applicable to the installation work.

Your upgrades must be installed by a licensed contractor with a valid B.C.

ROCKY MOUNTAIN POWER WINDOW REBATE UPGRADE

Important Note: Participants can receive either the Two Upgrade Bonus or the Home Energy Improvement Bonus, but not both.How much will my rebate be for the Home Energy Improvement Bonus?.How does the Home Energy Improvements Bonus Work?.Note: a maximum of one primary heating system and one primary water heater can be counted towards the Home Energy Improvement Bonus.The Home Energy Improvement Bonus can be accessed in addition to rebates for individual upgrades. All three bonus-eligible upgrades must be installed within 18 months of the pre-upgrade EnerGuide Home Evaluation.

ROCKY MOUNTAIN POWER WINDOW REBATE INSTALL

Home Energy Improvement Bonus – install three eligible individual upgrades and receive $20 per percentage reduction in your EnerGuide rating (GJ/year), between your pre- and post-upgrade energy evaluation, to a maximum of $2,000.

The following offers require both a pre- and post-upgrade EnerGuide home evaluation by a program-qualified energy advisor:

Note: a maximum of one primary heating system and one primary water heater can be counted towards the Two Upgrade Bonus.

Does not require an EnerGuide home evaluation. The Two Upgrade Bonus can be accessed in addition to Individual Upgrades rebates. The second bonus-eligible upgrade must be installed within 18 months of the first bonus-eligible upgrade.

Two Upgrade Bonus – receive a $300 rebate for installing two eligible upgrades.

Select municipalities have Municipal Offers that can be accessed in addition to individual rebate.

Natural Gas Combination Heating and Hot Water System Refer to the individual rebate pages for eligibility and application details.

ROCKY MOUNTAIN POWER WINDOW REBATE FULL

For full program details, read the Program Requirements and Additional Terms and Conditions. The Better Homes BC Rebate Chart is a quick at-a-glance chart summarizing all of the rebates currently available through the CleanBC Better Homes and Home Renovation Rebate Programs. See the What Rebates are Available FAQ for information on how invoice date effects associated upgrade requirements and available rebates. The CleanBC Better Homes and Home Renovation Rebate Programs, administered by BC Hydro, FortisBC and the Province of BC, provides rebates for improving your home’s energy efficiency through select upgrades.Įligibility requirements and rebates are based on the date of the invoice.

0 notes