#horizontal milling and boring machine

Explore tagged Tumblr posts

Text

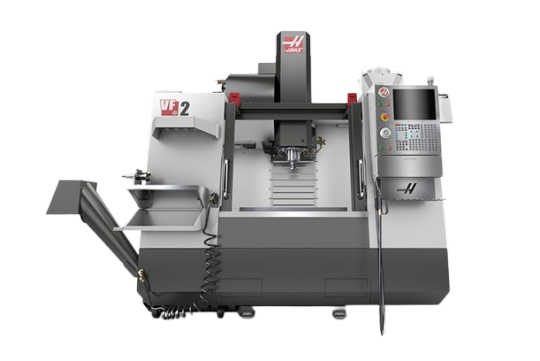

What are the main components of a CNC Vertical Machine? | SBV Engineering Works Coimbatore

Main Components of a CNC Vertical Machine

A CNC Vertical Machine is an advanced manufacturing tool widely used in industries for its precision, efficiency, and versatility. These machines automate complex tasks such as cutting, milling, drilling, and shaping materials, mainly metals and plastics. To understand the functionality and importance of CNC vertical machines, it is crucial to explore their main components.

Machine Frame

The machine frame is the backbone of a CNC vertical machine. Typically made from cast iron or steel, it provides structural integrity and stability to the entire setup. The rigidity of the frame is vital as it minimizes vibrations and ensures precision during machining operations. The frame houses and supports other critical components, such as the spindle, worktable, and guideways.

Spindle

The spindle is one of the most critical components of a CNC vertical machine. It is responsible for holding and rotating the cutting tool at various speeds, depending on the material and operation being performed. Spindles in CNC machines are typically powered by electric motors and can achieve very high rotational speeds, enabling precise and efficient material removal. The quality and performance of the spindle directly impact the machine’s accuracy and surface finish of the workpiece.

Worktable

The worktable, also known as the bed or table, is the platform where the workpiece is securely clamped or fixtured during machining. The worktable moves along the X and Y axes to position the workpiece under the spindle for machining operations. Many CNC vertical machines feature T-slots or grid patterns on the worktable, allowing flexible and secure clamping of various workpieces. The worktable's movement is controlled by precision ball screws and linear guideways, ensuring smooth and accurate positioning.

Control System

The control system is the brain of a CNC vertical machine. It interprets the G-code or machine instructions, which are programmed commands that dictate the movement and operations of the machine. Modern CNC machines utilize advanced computer control systems equipped with user-friendly interfaces, allowing operators to input, modify, and monitor machining parameters easily. The control system coordinates the movement of the spindle, worktable, and other components to execute complex machining tasks with high precision.

Motors and Drives

Motors and drives are essential for the movement of various machine components. Stepper motors or servo motors, coupled with precision ball screws and linear guideways, enable the controlled movement of the spindle, worktable, and other axes. Servo motors, known for their high torque and accuracy, are commonly used in CNC machines. These motors receive signals from the control system and translate them into precise mechanical movements, ensuring accurate positioning and repeatability.

Tool Changer

Many CNC vertical machines are equipped with an automatic tool changer (ATC). The ATC allows the machine to switch between different cutting tools without manual intervention, significantly increasing productivity and reducing downtime. The tool changer typically consists of a carousel or linear magazine that holds multiple tools, and a robotic arm or similar mechanism that exchanges tools as needed during the machining process.

Coolant System

The coolant system plays a crucial role in maintaining the temperature of the cutting tools and workpiece. During machining, cutting tools generate significant heat due to friction. The coolant system delivers a steady flow of coolant, usually a mixture of water and soluble oil, to the cutting zone. This not only reduces heat but also lubricates the cutting process, prolonging tool life and ensuring a better surface finish.

Enclosure

The enclosure, or machine cabinet, serves multiple purposes. It contains the machining area, protecting the operator from flying debris, coolant splash, and noise. The enclosure also helps in containing the coolant within the machine, reducing wastage and maintaining a cleaner work environment. Many CNC machines feature transparent panels in the enclosure, allowing operators to monitor the machining process safely.

Sensors and Feedback Systems

Modern CNC vertical machines are equipped with various sensors and feedback systems that enhance accuracy and reliability. These sensors monitor parameters such as tool position, spindle speed, temperature, and vibration. Feedback systems provide real-time data to the control system, enabling dynamic adjustments to optimize machining performance and prevent errors.

conclusion

CNC vertical machines are sophisticated tools composed of several integral components working in harmony. Each component plays a vital role in ensuring precision, efficiency, and productivity in modern manufacturing processes. Understanding these components provides insight into the complex yet fascinating world of CNC machining.

See more: https://www.sbvengineering.com/

#cncmachine#cncturningmachinejobwork#cnccompany#cncmachinejobwork#cncverticalmachining#cncmachineshop#horizontal milling and boring machine#commercial

0 notes

Text

Discover why CNC horizontal boring mills are a top choice in modern manufacturing. Learn how they offer precision, productivity, and versatility in machining.

0 notes

Text

0 notes

Text

Chicago’s Best Boring Mill Machining: Precision Engineering at Its Finest

Across Chicago’s dynamic industries — from manufacturing to energy — success depends not just on production but on precision and lasting quality. It is only possible when the production remains stable. Project uncertainties, increased manufacturing expenditures, and serious safety hazards are some of the problems that may arise when the machine parts get damaged or are ill-aligned. Businesses from different industries select services like part rebuilding and boring mill machining in Chicago to avoid the aforementioned problems.

Boring Mill Machining: A Potent Answer To Industrial Wear and Tear

Industrial machine components worsen with time. This interrupts the production process. Nevertheless, replacing worn-out parts or machinery isn't always the solution, as it can be exceedingly costly. However, employing broken and worn machinery for production might not be safe. Moreover, it may result in the creation of defective items, leading to rework and waste, as well as irregular product output due to unplanned downtime. Boring Mill and rebuilding service provide the perfect solution for this.

Industrial facilities in Chicago opt for boring mill machining in Chicago. It is a specialized process that accurately widens and refines holes in metal parts using large, computer-controlled machines. Available in horizontal and vertical models, it helps achieve just the right surface smoothness or texture, tailored to the part's specification. An expert places the boring tool into the existing hole in the workpiece (which remains stationary), which rotates and scrapes the unwanted portions on the inner wall of the hole, thus modifying the existing one.

Boring mill machining and part rebuilding machining, powering Chicago's Manufacturing Industries

Chicago is home to numerous industries, and boring mill machining and part rebuilding machining in Chicago play a crucial part in keeping the machine working in pristine condition. While different automotive companies use the services to revamp engine components and frames, construction and manufacturing units use them to keep their machines running smoothly. Similarly, energy and utilities use them to restore large valves, and turbine oil & gas facilities use them to manufacture valves and pumps that withstand high pressures and corrosive environments.

Marvel Machining Company: Transforming Chicago’s Manufacturing Scene

Marvel Machining is devoted to surpassing your expectations with its high-quality precision-machined products. It has led the way in providing all-inclusive machining services that increase productivity, accuracy, and financial savings. Situated in Bensenville, IL, it combines the latest technology with extensive expertise to deliver top-tier precision machining services to oil and gas facilities, food manufacturing plants, and other industrial plants. The company offers rapid response, perfect for small-batch production, high-precision prototypes, and emergency rebuild services. Its proficient engineers furnish high-accuracy machining using CNC boring mills and vertical turret lathes and can tackle tough projects with utmost precision. Being a long-established business, it offers the ultimate solution for people looking for high-quality boring mill and part rebuilding machining in Chicago.

Summing Up

Businesses looking for precision in Chicago rely on the true potential of boring mill machining. They act as catalysts for the smooth running of machines, safe operation, and productive units. And there is no better option than Marvel Machining Company, the expert in boring milling and part rebuilding machining in Chicago.

0 notes

Text

Optimizing Large Component Machining with Vertical Turning Lathes

In today’s fast-paced manufacturing world, handling large and heavy components efficiently is a common challenge. When precision meets weight, traditional horizontal machining solutions often fall short. That’s where Vertical Turning Lathes (VTLs) come into play, offering a high-performance solution for industries that deal with bulkier parts. Let’s dive into how these machines—alongside Vertical Turret Lathes and 5-axis turnmill centers—optimize production, and why WIDMA is a name you should know.

Why Vertical Turning Lathes Are a Game-Changer

Imagine trying to machine a massive pump housing or a large motor body on a traditional lathe. Balancing the component, ensuring accuracy, and maintaining safety becomes cumbersome. A Vertical Turning Lathe solves this by positioning the workpiece vertically—letting gravity do part of the job.

Key Benefits of Vertical Turning Lathes

Gravity-Assisted Work Holding: The vertical orientation naturally stabilizes heavy parts.

Improved Chip Disposal: Gravity aids in removing chips, preventing re-cutting and tool damage.

High Metal Removal Rates: Perfect for roughing operations on large workpieces.

Compact Footprint: Despite their capacity, VTLs take up less floor space than their horizontal counterparts.

Whether you're machining cast iron, steel, or composite materials, VTLs handle the job with remarkable consistency.

Vertical Turret Lathes: A Step Further in Automation

Now take a VTL and add a rotating tool turret—that’s your Vertical Turret Lathe. These machines increase machining flexibility by allowing multiple operations like drilling, boring, and tapping without needing to switch stations.

Advantages of Vertical Turret Lathes

Multiple Tools in One Setup: Reduces cycle time and manual intervention.

Higher Throughput: Especially useful in production environments with repetitive parts.

Consistency and Precision: Automated tool changes mean fewer errors and better repeatability.

For manufacturers aiming to scale efficiently while maintaining accuracy, a Vertical Turret Lathe offers an ideal middle ground between manual machining and full automation.

Embracing the Future with 5-Axis Turnmill Centers

When part complexity reaches another level—say intricate valve components or aerospace parts—you’ll want the flexibility of a 5-axis turnmill center. These machines combine turning and milling in one setup, drastically reducing lead times and setup errors.

Why 5-Axis Turnmills Make Sense

Complex Geometries, Single Setup: Eliminate multiple clamping and repositioning.

Higher Precision: Fewer setups mean fewer chances for dimensional errors.

Time-Saving: Multiple operations executed simultaneously or sequentially in a single go.

Integrating a 5-axis turnmill machine is like hiring a master machinist with five hands. It’s precise, efficient, and incredibly adaptable.

Why WIDMA Stands Out in Advanced Machining

With decades of industry expertise, WIDMA understands the evolving needs of precision machining. Their range of Vertical Turning Lathes, Vertical Turret Lathes, and 5-axis turnmill centers is engineered for industries that can’t compromise on performance.

What Makes WIDMA the Preferred Choice?

CNC-Driven Precision: All machines are designed with state-of-the-art CNC technology.

Industry-Specific Customization: Machines tailored for automotive, aerospace, energy, and general engineering applications.

Plug-and-Play Simplicity: Easy integration into existing production lines with minimal learning curve.

Proven Track Record: Trusted by global OEMs and Tier-1 suppliers.

WIDMA’s VTLs, such as the VT850, are particularly known for their ability to handle large components with exceptional stability and reliability. Their 5-axis VU-1150 turnmill lathe has even redefined how valve bodies are machined, reducing multiple setups into just two.

Conclusion: Smarter Machining Starts with Smarter Machines

Large component machining doesn’t have to be a bottleneck. By leveraging advanced solutions like Vertical Turning Lathes, Vertical Turret Lathes, and 5-axis turnmill centers, manufacturers can achieve higher throughput, tighter tolerances, and more reliable production.

And if you're looking for a partner who understands the nuances of heavy-duty precision machining, WIDMA is ready to deliver. With innovative technologies and a commitment to quality, WIDMA is shaping the future of large component manufacturing—one precise cut at a time.

0 notes

Text

Upgrade your workshop with SPM & Heavy Machines from Yash Machine Tools! Our Vertical Turning Lathes, Horizontal Milling Boring Machines, and Vertical Machining Centers are built for high precision, strength, and reliability. Designed to meet international standards, these vibration-free, noise-free machines ensure smooth handling and multi-tasking efficiency. Get the best in special-purpose machining with our imported range of heavy machines, tailored to your industry needs.

For more details, visit - https://www.yashmachine.com/product/spm-heavy-machine

#YashMachihneTools#heavymachines#VerticalTurningLathe#HorizontalMilingBoringMachine#VerticalMachiningCenter

0 notes

Text

Horizontal Milling Machines: The Key to Efficient and Precise Manufacturing

In the competitive world of manufacturing, efficiency, precision, and speed are crucial. Horizontal milling machines have become essential tools in achieving these goals, particularly for high-volume production and larger workpieces. These machines offer distinct advantages, making them an ideal choice for industries such as automotive, aerospace, and heavy equipment manufacturing.

At Phillips Corporation Middle East, we provide top-quality horizontal milling machines designed to improve productivity while maintaining exceptional levels of precision. Let’s dive deeper into why horizontal milling machines are an essential addition to modern manufacturing setups.

What Are Horizontal Milling Machines?

Horizontal milling machines are advanced CNC (Computer Numerical Control) tools that use a horizontal spindle to cut materials. The workpiece is typically placed on a horizontal surface, and the cutter moves along multiple axes to remove material, creating the desired shape. Unlike vertical mills, which have a spindle positioned vertically, horizontal mills utilize a horizontally oriented spindle, offering unique benefits for certain machining tasks.

These machines are especially well-suited for larger, heavier workpieces and high-volume production. They also allow for improved chip removal and greater stability, leading to better performance during longer machining cycles.

Key Benefits of Horizontal Milling Machines

Increased Stability and Efficiency

Horizontal milling machines offer enhanced stability compared to vertical mills. The horizontal spindle position provides better support, making them ideal for heavy-duty tasks and larger workpieces. Additionally, horizontal milling machines can be equipped with multiple cutting tools, reducing the need for tool changes and improving efficiency during long production runs.

Superior Chip Removal

One of the standout features of horizontal milling machines is their superior chip removal capability. The horizontal orientation allows gravity to assist in the removal of chips, preventing them from accumulating and interfering with the cutting process. This improves the overall machining quality and ensures that the tool operates at optimal efficiency, even in heavy-duty applications.

Versatility in Operations

Horizontal milling machines are versatile and can perform a wide range of operations, including slotting, boring, drilling, and tapping. This versatility allows manufacturers to use horizontal mills for various tasks, whether it's creating complex geometries or performing basic tasks on large workpieces. They are also compatible with various materials, including metals, plastics, and composites, providing manufacturers with the flexibility to work on diverse projects.

Better Tooling and Automation

Horizontal milling machines can support automatic tool changers (ATC) that make production processes more efficient. An ATC allows the machine to automatically switch between different cutting tools without operator intervention, reducing downtime and increasing productivity. These automated systems are perfect for tasks requiring multiple tools, further enhancing the machine's capabilities in high-volume manufacturing.

Higher Precision for Large Workpieces

Horizontal milling machines excel in machining large parts that require high precision. Their rigid design and horizontal cutting orientation make them ideal for maintaining tight tolerances, especially when working with large and heavy components. This makes horizontal mills an excellent choice for industries like aerospace, automotive, and heavy machinery, where precision is critical for safety and performance.

Types of Horizontal Milling Machines

At Phillips Corporation Middle East, we offer a wide range of horizontal milling machines to meet various manufacturing needs. Some of the most common types include:

Universal Horizontal Milling Machines: These machines are versatile and can be used for a wide range of operations. They feature a table that can be adjusted to different angles, allowing the machine to perform more complex tasks.

Ram-Type Horizontal Milling Machines: This type of machine features a horizontal spindle that is mounted on a movable ram. These machines are suitable for operations that require high flexibility and the ability to handle larger workpieces.

Plain Horizontal Milling Machines: These are designed for simpler tasks and are often used in high-volume production. They are typically equipped with a single spindle and are ideal for cutting large parts with straightforward geometries.

Bed-Type Horizontal Milling Machines: Bed-type mills are designed for heavy-duty operations and are suitable for large, complex components. The workpiece is mounted on a bed that moves along the X, Y, and Z axes, providing increased stability and support during machining.

How to Choose the Right Horizontal Milling Machine

Selecting the right horizontal milling machine for your business depends on several factors:

Workpiece Size and Complexity: If you work with large, heavy workpieces, a bed-type or ram-type horizontal mill may be the best option. For smaller, more intricate parts, a universal or plain horizontal milling machine may suffice.

Production Volume: For high-volume production, choosing a machine with automated features such as an automatic tool changer can significantly improve efficiency.

Material Compatibility: Ensure that the milling machine can handle the materials you plan to work with. Horizontal mills are compatible with a wide range of materials, including tough metals and composites.

Precision Requirements: For industries like aerospace or automotive, where tight tolerances are crucial, opt for a machine known for its precision and stability during long machining cycles.

Why Choose Phillips Corporation Middle East for Your Horizontal Milling Machines?

At Phillips Corporation Middle East, we pride ourselves on offering premium horizontal milling machines that help businesses improve their manufacturing processes. Our machines are built for reliability, efficiency, and precision, ensuring that you can meet the demands of even the most challenging projects.

We offer a comprehensive range of machines tailored to your specific needs, from simple milling operations to complex multi-axis machining tasks. Additionally, our team of experts provides full support, training, and after-sales service, ensuring that your investment continues to deliver outstanding results.

Get Started with Phillips Corporation Middle East Today!

Are you ready to enhance your manufacturing capabilities with a top-quality horizontal milling machine? Contact Phillips Corporation Middle East today to learn more about our machines and how they can transform your production processes. Our team is ready to help you find the perfect solution for your business.

0 notes

Text

The Most Valuable Equipment You Can Find at Machine Shop Auctions

Machine shop auctions often provide a unique opportunity to acquire valuable equipment at a fraction of the cost of new machines. The most valuable equipment at these auctions includes high-quality, durable machines that offer excellent long-term value. Key items that are highly sought after include:

CNC Machines : Computer Numerical Control (CNC) machines are incredibly valuable due to their precision, versatility, and automation capabilities. These machines can perform tasks such as drilling, milling, and turning with high accuracy, which significantly enhances productivity in manufacturing environments.

They are expensive when bought new, but at auctions, you can find them for a fraction of the price. Well-maintained CNC machines can last for many years, making them a worthwhile investment.

Lathes : Lathes are essential for shaping and machining materials like metal, wood, and plastic. These machines are versatile and can be used for a wide variety of tasks, such as turning, facing, and boring.

There are several types of lathes, including engine lathes, turret lathes, and CNC lathes. Depending on their condition, lathes can offer significant value, especially when you find a high-quality, well-maintained unit at an auction.

Milling Machines : Milling machines are indispensable in machine shops, used for drilling, cutting, and shaping materials. These machines are capable of creating precise cuts and are available in both vertical and horizontal configurations.

Milling machines are highly valuable due to their broad applications in industries such as aerospace, automotive, and manufacturing. Purchasing a well-maintained milling machine at an auction can be an excellent investment.

Surface Grinders : Surface grinders are used to achieve a smooth, flat finish on metal surfaces, making them an essential tool for many industries. High-precision surface grinders, when found at auctions, are highly valuable due to their ability to improve the quality of parts. These machines are known for their durability and can continue to perform reliably for years when properly maintained.

Welding Equipment : Industrial welding machines, including TIG, MIG, and stick welders, are also highly valuable at machine shop auctions. These machines are used in manufacturing, construction, and repair work, making them indispensable in various industries.

A good-quality welding machine from a reputable brand can be found at auction prices much lower than new equipment, providing a great return on investment.

In summary, machine shop auctions present an opportunity to find valuable equipment such as CNC machines, lathes, milling machines, surface grinders, and welding equipment. These machines, when properly maintained, can serve for many years, offering exceptional value to businesses looking to expand their capabilities without the high costs of new machinery.

0 notes

Text

Metal Machining & Cylindrical Grinding: Precision at Its Finest

Metal machining and cylindrical grinding are essential processes in modern engineering, enabling the manufacturing of components with unparalleled precision and durability. These processes play a pivotal role in various industries, such as aerospace, automotive, power generation, and heavy machinery. From crafting new parts to repairing damaged ones, machining and grinding ensure components meet the most stringent requirements for size, finish, and functionality. At WWG Engineering, the Machining Workshop is the hub where these crucial operations take place, powered by state-of-the-art equipment and skilled professionals.

The Machining Workshop at WWG Engineering

The Machining Workshop at WWG Engineering was established with very specific objectives:

To manufacture new components and fabricate parts through machining and grinding.

To perform pre-machining and undercutting, preparing surfaces for Surface Engineering processes in both repair and new manufacturing.

To provide final machine turning, facing, and grinding finishing for Thermal Spray Coated, Cold Spray Coated, or Welded surfaces.

This well-equipped workshop allows WWG Engineering to offer comprehensive surface and cylindrical grinding capabilities. These capabilities enable the company to grind various materials on both external and internal faces, ensuring polished and finished components that meet the highest tolerances and form integrity. Whether it is for new manufacturing or repairing existing parts, the workshop stands as a center of precision and excellence in the field of metalworking.

Precision Metal Machining

Metal machining involves removing material from a work piece to achieve the desired shape, size, and finish. The process utilizes a wide range of tools, including lathes, milling machines, and horizontal boring machines, each selected based on the specific requirements of the job. At WWG Engineering, machining operations range from simple tasks such as threading to the creation of complex shapes like tapers and spheres.

One of the major strengths of WWG Engineering lies in its versatility. Whether a client needs small or large components, the workshop is equipped to handle it. The lathe machines in the workshop can accommodate work pieces from short to 10 meters long, offering flexibility for various machining needs. With its expertise in machining, WWG Engineering ensures that every project, from small parts to larger industrial components, is completed with precision and efficiency.

The Art of Cylindrical Grinding

Cylindrical grinding is a specialized form of grinding used to shape the exterior or interior of a workpiece, ensuring that it meets exact dimensional specifications. WWG Engineering offers both small and large cylindrical grinding machines, enabling the handling of a wide variety of work piece sizes. Whether grinding small shafts or large crankshafts, the team is experienced in producing highly polished, finished components to the tightest tolerances.

The process involves rotating the work piece around a central axis while it is ground with an abrasive wheel. This ensures even material removal and a smooth surface finish. Cylindrical grinding is commonly used to achieve fine tolerances, often in conjunction with other machining processes such as turning and milling. WWG Engineering excels in this field, offering grinding services that guarantee dimensional accuracy, surface finish, and form integrity.

Surface Engineering and Finishing

Metal surfaces often undergo additional treatments after machining or grinding to improve their durability, resistance to wear, or appearance. At WWG Engineering, surface engineering involves processes such as thermal spray coating, cold spray coating, and welding. After these treatments, the surfaces often require final finishing, which includes machine turning, facing, and cylindrical grinding.

The final finishing process is critical to ensuring that coated surfaces meet the exact specifications required for their intended applications. For instance, thermal spray-coated parts often need to be ground and polished to achieve a smooth, durable finish. WWG Engineering’s expertise in combining machining and grinding with advanced surface engineering technologies allows them to deliver high-quality, long-lasting components that meet the most demanding industry standards.

Comprehensive Machine Capability

WWG Engineering's workshop is equipped with a comprehensive range of machines, enabling it to undertake a variety of precision machining services. The available equipment includes:

Small, medium, and large lathe machines, capable of handling short to 10-meter-long work pieces.

Small and large cylindrical grinding machines, for external and internal grinding of different-sized components.

Small and large crankshaft grinding machines, for precision grinding of crankshafts.

Milling machines and other specialized tools for creating complex shapes and machining precise components.

Horizontal boring machines, used for machining large parts that require deep holes or large-diameter bores.

Polishing machines, used to achieve high-quality surface finishes after machining and grinding.

This extensive range of equipment allows WWG Engineering to provide efficient, effective solutions for various machining and grinding challenges. Whether it is manufacturing new components or repairing worn-out parts, the workshop’s capability ensures that all work is done to exacting standards, ensuring client satisfaction.

Expertise and Experience

WWG Engineering’s reputation in the field of metal machining and cylindrical grinding stems from its experience, expertise, and commitment to delivering high-quality results. The company has built a strong team of skilled machinists and engineers who work together to ensure that every project is completed with precision. From initial design to final finishing, the team’s attention to detail and focus on quality ensures that components meet the highest standards.

With advanced technologies and a deep understanding of machining and grinding processes, WWG Engineering continues to be a trusted partner for industries that require precision-engineered components. Whether you need simple machining tasks or complex grinding services, WWG Engineering is equipped to provide solutions tailored to your exact needs.

Conclusion

Metal machining and cylindrical grinding are critical processes that ensure the precision, functionality, and longevity of industrial components. At WWG Engineering, the Machining Workshop stands as a testament to the company’s commitment to delivering high-quality, reliable machining and grinding services. With a comprehensive range of machines and equipment, as well as a team of skilled professionals, WWG Engineering continues to push the boundaries of precision engineering, delivering solutions that meet the most demanding industry standards.

#Surface Engineering Technology#Engineering Service Company#Engineering Service Provider#Engineering Solutions#Cylindrical Grinding Machine#Metal Machining Services in Singapore

0 notes

Text

Applications of CNC Machines | SBV Engineering Works Coimbatore

CNC machines are integral to various industries, including:

Aerospace: Manufacturing high-precision components for aircraft engines and structural parts.

Automotive: Producing engine components, transmission parts, and custom modifications.

Medical: Creating surgical instruments, prosthetics, and implants with exacting standards.

Electronics: Fabricating circuit boards and enclosures for electronic devices.

Furniture: Designing intricate patterns and shapes in wood and other materials.

Our machines are:

CNC Vertical Machine

CNC Turning Machine

VMC Machine

Horizontal Boring Machine

Radial Drilling Machine

See more about our machines and services: https://www.sbvengineering.com/

#cncmachine#cncturningmachinejobwork#cnccompany#cncmachinejobwork#cncverticalmachining#horizontal milling and boring machine#cncmachineshop

0 notes

Text

Get CNC Horizontal Boring Mills from Karam Boring, Batala

Karam Boring is a CNC Horizontal Boring Mill manufacturer based in Batala, Punjab, offering both standard and tailor-made solutions for diverse industries. Our machines are built for strength, efficiency, and flawless accuracy. We understand the complexities of modern manufacturing and design our boring mills to meet those demands. Each CNC Horizontal Boring Mill is engineered for heavy-duty performance and long-term durability. If you’re looking for custom boring machines with dependable support, Karam Boring is your answer.

0 notes

Text

0 notes

Text

How Advanced Machining Technologies Are Transforming Manufacturing

Precision, speed, and adaptability—these aren't just buzzwords in manufacturing anymore. They're the foundation of any shop floor that aims to stay competitive. Whether you're dealing with complex aerospace components or high-volume automotive parts, your machinery needs to keep up. And that’s where technologies like deep hole drilling, Turn-mill centers, Horizontal Machining Centers, and BTA machines step in.

Let’s break down how these tools are making a real difference.

Deep Hole Drilling—Where Standard Drills Fall Short

Ever tried to drill a hole ten times deeper than its diameter using a standard machine? Chances are, you ended up with a misaligned mess. That's why deep hole drilling has become a go-to in industries like oil and gas, defense, and medical devices.

These machines are engineered to handle extreme depth-to-diameter ratios, often exceeding 20:1. With internal coolant systems and special tools, they maintain accuracy and finish, even at depths traditional drills can’t reach. It’s the difference between a usable part and scrap.

Why Turn-Mill Centers Are the Shop Floor's Swiss Army Knife

Imagine being able to turn, mill, drill, and tap—all on a single setup. That’s what Turn-mill centers bring to the table. You’re not just saving space; you're eliminating error-prone part transfers and drastically cutting down setup time.

These machines are particularly valuable in small-batch production where flexibility matters. Got a complex part with multiple features on different faces? A turn-mill center lets you finish it in one go. It's smart machining without the juggling act.

Horizontal Machining Centers—Built for Speed and Stability

If you’re pushing out large volumes and need consistency, a Horizontal Machining Center (HMC) is hard to beat. The horizontal orientation makes chip removal more efficient—crucial when machining tough materials like titanium or Inconel.

Plus, with their larger tool magazines and multi-pallet setups, HMCs thrive in lights-out manufacturing. You load them up, walk away, and come back to finished parts. It’s no wonder they’re a favorite in automotive and heavy engineering.

BTA Machines—For When You Need to Go Really Deep

BTA (Boring and Trepanning Association) machines are the heavy hitters of deep hole drilling. They handle larger diameters and longer depths than conventional drills, making them essential for applications like heat exchangers, hydraulic cylinders, and gun barrels.

What makes them special? A centralized coolant supply that flushes chips out as drilling happens—keeping the tool cool and the hole clean. If your part specs demand big, precise bores, a BTA machine is your best bet.

Why WIDMA Is a Trusted Name in Machining

If you’re in the market for high-performance machining tools, WIDMA is a name worth knowing. As a part of Kennametal India, they combine decades of experience with cutting-edge tech. Whether you're looking for a deep hole drilling solution or a multi-tasking turn-mill center, WIDMA’s lineup covers it all.

But it's not just about machines. It’s about partnerships. WIDMA works closely with manufacturers to tailor machines to specific needs—because no two production lines are exactly alike.

Wrapping Up

Precision machining isn’t a luxury anymore—it’s a necessity. With tools like deep hole drills, turn-mill centers, horizontal machining centers, and BTA machines, manufacturers can hit tighter tolerances, improve throughput, and reduce waste. And if you're looking for a reliable partner in this journey, WIDMA is well-equipped to guide you every step of the way.

0 notes

Text

[ad_1] Have you ever ever been midway by means of a venture and wished you had a software that would end it rapidly and exactly? Say howdy to the horizontal boring mill, which goes to be your new greatest buddy on this planet of machining. These highly effective gadgets are the unsung heroes of latest manufacturing; they're subtly altering the way in which we handle difficult and large workpieces. However what precisely is a horizontal boring mill? This monumental system is made to bore holes and perform quite a few different machining duties with unmatched precision and effectiveness. A horizontal boring mill’s spindle is positioned horizontally, in distinction to its vertical counterpart’s, which allows it to simply deal with massive workpieces. This multipurpose software can deal with practically any process you throw at it, from boring and threading to drilling and milling. Now, you is perhaps pondering, “Why ought to I care a few horizontal boring mill?” Effectively, stick round, as a result of I’m about to dive into the highest fifteen advantages of utilizing this powerhouse software. The benefits of using a horizontal boring mill will astound you and fully change the way in which you use, no matter how large or little your manufacturing enterprise is. Now let’s get began! 1. Precision Galore First off, let’s discuss precision. With a horizontal boring mill, you’re not simply getting shut; you’re hitting the bullseye each single time. These machines are designed to supply unparalleled accuracy, making certain that your components are made to actual specs. Say goodbye to the frustration of components not becoming collectively good. Whether or not you’re drilling, milling, or boring, the extent of precision is off the charts. 2. Versatility to the Max Horizontal boring mills are just like the Swiss Military knives of the machining world. They'll deal with quite a lot of duties, from drilling holes and slicing threads to milling surfaces and boring massive items. You possibly can change between duties with out lacking a beat, making it a one-stop-shop for all of your machining wants. No extra hopping from machine to machine, squandering precious time and vitality. 3. Heavy-Responsibility Efficiency Bought an enormous job? No drawback! These machines are constructed powerful and might deal with massive, heavy workpieces with ease. The strong development means they will function at excessive speeds with out compromising on stability or accuracy. It’s like having a workhorse that by no means tires. So, convey on the heavy metallic—your horizontal boring mill can take it. 4. Time is Cash On the earth of machining, time is cash, and horizontal boring mills prevent loads of each. The power to carry out a number of operations in a single setup means you spend much less time repositioning and recalibrating. Plus, with quicker processing speeds, you’re churning out components at a file tempo. Extra components in much less time equals more cash in your pocket. Basic math, proper? 5. Person-Pleasant Interface Now, don’t let the scale and complexity idiot you. These machines are surprisingly user-friendly. Trendy horizontal boring mills include intuitive controls and interfaces that make them straightforward to function, even for newcomers. It’s like driving a motorcycle—when you get the hold of it, you’re good to go. Plus, with automated options, you may set it and overlook it, letting the machine do the heavy lifting. 6. Consistency You Can Rely On Consistency is essential in manufacturing, and horizontal boring mills ship. With their superior know-how, these machines be certain that every half is an identical to the final. No extra worrying about variations that may throw off your total meeting. You get the identical high-quality outcomes each single time, constructing belief and reliability in your merchandise. 7. Flexibility in Setup Whether or not you’re engaged on a small batch or a big manufacturing run, horizontal boring mills supply the pliability you want.

You possibly can simply alter the machine to accommodate totally different sizes and varieties of workpieces. This adaptability makes it an excellent funding for retailers of all sizes, offering the flexibility to deal with any job that comes your manner. 8. Lowered Labor Prices Right here’s a profit that’ll make any enterprise proprietor smile: decreased labor prices. With a horizontal boring mill, you want fewer arms on deck. The machine’s effectivity and automation imply one operator can oversee a number of machines, slicing down on labor bills. It’s a win-win—you get monetary savings, and your group can give attention to extra crucial duties. 9. Improved Security Security first, people! Horizontal boring mills are designed with security in thoughts. Options like enclosed work areas, automated controls, and emergency cease buttons scale back the chance of accidents. Plus, with fewer guide changes wanted, there’s much less probability for human error. It’s peace of thoughts figuring out that you simply’re working in a safer setting. 10. Lengthy-Time period Sturdiness These machines are constructed to final. Investing in a horizontal boring mill is like placing cash within the financial institution. With correct upkeep, they’ll serve you nicely for years, offering dependable and constant efficiency. It’s a long-term funding that pays off in spades, saving you from frequent replacements and downtime. 11. Enhanced High quality Management High quality management is a breeze with a horizontal boring mill. The precision and consistency imply you may keep tight tolerances, making certain that every half meets your excessive requirements. It’s simpler to catch and proper errors early within the course of, lowering waste and rework. Your prospects will discover the distinction, too, appreciating the superior high quality of your merchandise. 12. Aggressive Edge Final however not least, let’s speak about staying forward of the sport. In at this time’s aggressive market, having the appropriate instruments could make all of the distinction. A horizontal boring mill offers you an edge by rising your manufacturing capability, enhancing high quality, and lowering prices. You’ll be capable of tackle extra complicated and profitable jobs, positioning your online business as a pacesetter within the business. 13. Price-Efficient Upkeep Sustaining a horizontal boring mill gained’t break the financial institution. These machines are designed with sturdiness and ease of upkeep in thoughts. Common repairs is simple, and components are available. This implies much less downtime and extra time spent doing what you do greatest—creating top-notch merchandise. 14. Excessive Return on Funding Let’s discuss dollars and cents. The preliminary value of a horizontal boring mill might sound steep, however if you issue within the elevated manufacturing pace, improved high quality, and decreased labor prices, it’s clear that this machine is a great funding. Over time, the return on funding is important, making it a savvy alternative for any critical machining enterprise. 15. Adaptability to Technological Advances Final however undoubtedly not least, horizontal boring mills are adaptable to technological advances. As new software program and machining strategies emerge, these machines will be upgraded and modified to include the most recent tech. This implies your funding stays related and aggressive, holding you on the slicing fringe of the business. Conclusion So, there you've it—fifteen stable the reason why a horizontal boring mill is a game-changer. From precision and flexibility to value financial savings and security, these machines supply a bunch of advantages that may rework your operations. In case you’re critical about stepping up your machining sport, it’s time to think about including considered one of these powerhouses to your lineup. You gained’t remorse it! [ad_2] Supply hyperlink

0 notes

Text

0 notes

Text

Vertical Machining Center - Ray Mechatronics

Explore the next wave in vertical machining centers at Ray Mechatronics, featuring Awea's New Generation technology. These machines redefine precision with advanced CNC control systems, ensuring exacting control over multiple axes for intricate operations. With intelligent software, high-speed spindles, and automatic tool changers, Awea's vertical milling machines promise seamless and efficient performance.

Awea, a Taiwan Stock Exchange-certified powerhouse, has expanded beyond its bridge machine roots to offer a comprehensive lineup, including vertical machining centers, horizontal boring mills, high-speed machines, and large 5-axis machines. Extend your company's productivity horizon with Awea's cutting-edge solutions, now making waves in markets across India, North America, South Korea, Spain, Italy, Germany, and beyond. Elevate your machining capabilities with Awea's certified excellence.

0 notes