#hydraulic cylinders

Text

The Power of Hydraulics: A Comprehensive Guide to Hydraulic Cylinders, Linear Actuators, and Their Applications

Introduction:

The world around us is driven by motion, and hydraulic cylinders play a crucial role in generating that motion. These powerful workhorses are the backbone of countless machines, from construction equipment to factory assembly lines. But how exactly do hydraulic cylinders function, and what makes them so versatile? This comprehensive guide will delve into the fascinating world of…

View On WordPress

#Displacement#Double-Acting Cylinder#Force#Hydraulic cylinders#Hydraulic Fluid#Linear Actuator#Piston#pressure#Rod Seal#Single-Acting Cylinder#Telescopic Cylinder

0 notes

Text

Exploring the Role and Benefits of Nitrogen Gas Bottles

Nitrogen gas bottles play a crucial role in various industries, offering a reliable source of compressed nitrogen gas for a wide range of applications. From industrial processes to automotive maintenance, nitrogen gas bottles are indispensable tools that provide numerous benefits. In this article, we delve into the significance of nitrogen gas bottles, their applications, and the advantages they offer.

Understanding Nitrogen Gas Bottles:

Nitrogen gas bottles, also known as nitrogen cylinders or tanks, are containers specifically designed to store and transport compressed nitrogen gas under high pressure. These bottles are typically made from durable materials such as steel or aluminum and are equipped with valves for safe dispensing of the gas. Nitrogen gas bottles come in various sizes and pressure ratings to accommodate different requirements and applications.

Applications of Nitrogen Gas Bottles:

Nitrogen gas bottles find widespread use across diverse industries due to their versatile properties and applications. Some common uses of nitrogen gas bottles include:

Industrial Applications: In industrial settings, nitrogen gas bottles are utilized for processes such as blanketing, purging, and inerting. Nitrogen gas is often employed to displace oxygen and moisture in storage tanks, pipelines, and reactors, preventing corrosion, oxidation, and contamination of sensitive materials.

Automotive Maintenance: Automotive shops and garages utilize nitrogen gas bottles for tire inflation purposes. Nitrogen-filled tires offer benefits such as improved tire pressure retention, enhanced fuel efficiency, and extended tire life. Nitrogen gas also eliminates the risk of moisture-related tire corrosion.

Food and Beverage Industry: Nitrogen gas bottles play a crucial role in the food and beverage industry for packaging and preservation purposes. Nitrogen gas is used to create a protective atmosphere in food packaging, extending the shelf life of perishable products and preventing spoilage.

Advantages of Nitrogen Gas Bottles:

The use of nitrogen gas bottles offers several advantages, including:

Purity: Nitrogen gas bottles provide a consistent and high-purity nitrogen supply, ensuring reliable performance in various applications.

Safety: Nitrogen gas bottles are designed and manufactured to meet strict safety standards, minimizing the risk of leaks or accidents.

Convenience: Nitrogen gas bottles are portable and easy to transport, allowing for flexibility in deployment across different job sites or facilities.

Conclusion:

Nitrogen gas bottles are indispensable assets in numerous industries, offering a reliable source of compressed nitrogen gas for various applications. Whether it's industrial processes, automotive maintenance, or food packaging, nitrogen gas bottles provide an efficient and cost-effective solution to meet diverse needs. With their versatility, purity, and convenience, nitrogen gas bottles continue to be essential tools for businesses worldwide.

0 notes

Link

Hey there, hydraulic fam! We know keeping your machines running smoothly is key. That's why we're here to talk about the unsung heroes of the hydraulic world: seals! These little guys prevent leaks, contamination, and friction, ensuring your cylinders are working at their best.

At A2Z SEALS, we're all about providing top-notch hydraulic cylinder seals for all your needs. We have a massive stock, from U-cups to rod wipers, so you can find the perfect fit for your machine, no matter what it is.

Worried about worn-out seals killing your machine's performance? Don't sweat it! We can help you get the right seals to keep things running smooth.

#hydraulic cylinder seal#hydraulic cylinder seals#hydraulic cylinder#hydraulic cylinders#hydraulic#hydrauliccylinder#hydrauliccylinders#sealkits#seals#mining#A2ZSeals#sealkit

0 notes

Text

Steel Bar Manufacturers in Delhi, india

Bright Bars and Wires: Cold Drawn Bars, Peeled Bars, Ground Bars, Shaped Profile Bars, CHQ Wires. Shapes Wires & profile, Spring Steel Wires. HB/HHB Wires, Stainless Steel Fine Wires,

Hydraulic Cylinders: Hydraulic Lift Cylinder, Loader Hydraulic Cylinders, Welded Hydraulic Cylinders, Tie Rod Hydraulic Cylinder, Single & Double Acting Hydraulic Cylinder,

Precision Auto Components: Precision Turned Components, Forged Components, Fasteners, Dowel Pins, Spacers, FIP Components, Retainers, Coupling Assembly, Equalizer Shaft and Balancer Shafts, Hydraulic & Pneumatic Parts, Stainless Steel Fittings, Stainless Steel Bars, Aluminium Cup Washers, Aluminium Parts, Sheet Metal Parts, Wheel Nuts& Bolts, Slave Nuts and Bolts, Nozzle Nuts and many more Precision Components as per customer’s drawing.

At JSG we manufactures diversified range of Cold Drawn Bright Steel Bars classified according to various sizes and tolerances, in round, flat, square, hexagonal and octagonal varieties.

For us the quality of Surface Finish, Toughness, Straightness, and Packing are paramount. By way of meeting the customer specific requirements, our bar products offer good formability, machine-ability and weld-ability.

JSG also has offline Ultrasonic Inspection System for detecting the sub surface defects with crack detection in the final process application , we improvise and modernize our processes and product technology continuously.

1 note

·

View note

Text

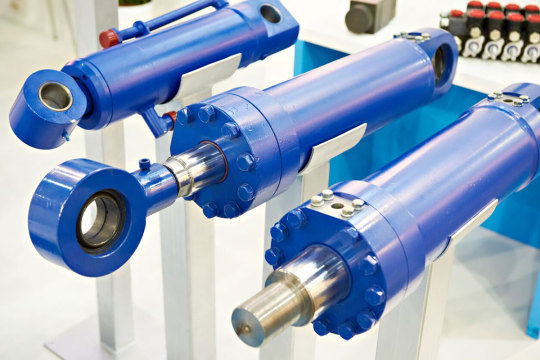

Hydraulic Cylinders 101 A Comprehensive Guide for Beginners

Welcome to our comprehensive guide on hydraulic cylinders! Whether you're new to the world of engineering, construction, or automotive industries, understanding the basics of hydraulic cylinders in Australia is essential.

These powerful devices play a crucial role in various applications, and our guide aims to provide beginners with a clear understanding of their function, operation, and maintenance.

What are Hydraulic Cylinders?

Hydraulic cylinders are mechanical actuators that are used to provide unidirectional force through a unidirectional stroke. In simpler terms, they are devices that convert hydraulic energy into mechanical energy to perform work.

These are commonly found in heavy machinery, construction equipment, agricultural machinery, and even in the automotive industry. For instance, hydraulic cylinders are used in excavators to power the boom and bucket movements, in dump trucks for lifting the bed, and in hydraulic brakes in automobiles.

How Do Hydraulic Cylinders Work?

Hydraulic cylinders operate based on the principles of fluid mechanics and Pascal's law. A hydraulic fluid, typically oil, is used to transmit force within the cylinder. When pressure is applied to the fluid, it exerts force on the piston inside the cylinder, causing it to move in a linear motion.

This movement is then used to perform tasks such as lifting, pushing, or pulling heavy loads. Understanding the role of hydraulic fluid and pressure is crucial to grasping how hydraulic cylinders work.

Types of Hydraulic Cylinders

There are several types of hydraulic cylinders in Australia, each designed for specific applications. These include single-acting cylinders, double-acting cylinders, telescopic cylinders, and differential cylinders.

Single-acting cylinders exert force in one direction while double-acting cylinders can push and pull. Telescopic cylinders have multiple stages that allow for a longer stroke without sacrificing space, and differential cylinders have different piston diameters to provide varying forces. Each type has its unique features and applications, making it important for beginners to understand their differences.

Key Components and Terminology

Hydraulic cylinders consist of various components, including a piston, rod, cylinder barrel, seals, and ports. The piston is responsible for generating the linear motion, while the rod transmits the force to the external load.

Seals prevent fluid leakage, and ports allow for the inlet and outlet of hydraulic fluid. Understanding these components and associated terminology, such as bore size, stroke length, and rod end types, is essential for beginners to communicate effectively within the industry.

Maintenance and Troubleshooting Tips

Proper maintenance is crucial for ensuring the longevity and performance of hydraulic cylinders. Regular inspection of seals, fluid levels, and any signs of wear can prevent potential issues.

Additionally, troubleshooting tips for common problems like leaks, uneven movement, and loss of pressure can help beginners address issues effectively. Following manufacturer guidelines and seeking professional assistance when needed are also key to maintaining hydraulic cylinders.

Conclusion

This guide has provided beginners with a foundational understanding of hydraulic cylinders in Australia, their function, types, components, and maintenance.

By familiarising yourself with these fundamental concepts, individuals can confidently engage with hydraulic systems in various industries. We encourage readers to continue exploring further resources and seeking professional assistance to deepen their knowledge and expertise in the realm of hydraulic cylinders.

Source: Hydraulic Cylinders 101 A Comprehensive Guide for Beginners

0 notes

Text

Hotion Group: Revolutionizing Industrial Processes with Electromagnetic Stirrers and Hydraulic Cylinders

Hotion Group stands as a leader in providing advanced solutions for industrial processes, with its electromagnetic stirrers and hydraulic cylinders representing pinnacle technologies in their respective fields. Whether it's achieving precise mixing and homogenization or delivering power and precision in motion control, Hotion Group's products excel in enhancing efficiency, productivity, and quality across diverse industries. Choose Hotion Group as your partner in industrial innovation, and experience the transformative impact of cutting-edge technologies on your operations.

1 note

·

View note

Text

Fluid Force in Saudi Arabia offers a wide range of high-quality Hydraulic cylinders. Trust us for your hydraulic actuation needs. #FluidForceSA

0 notes

Text

Roemheld Hydraulic Clamps | Omkar Supernational

Our roemheld hydraulic clamps, Germany is a very well known name associated with quality products in the field of workpiece clamping systems and related products.

We can supply all range of products manufactured from Roemheld, Germany.

Workpiece Clamping Elements

Hydraulic Cylinders

1 note

·

View note

Text

Surface Engineering Technology and its significance

Technologies that are intended to transform the properties of metallic or non-metallic constituents, especially on the surface for either decorative or functional resolves are in general called surface engineering. The main motive behind the development of this technology is to reduce or eliminate corrosion, increase wear resistance and lengthen the component life. A precise and well-calculated process makes the surface more visually attractive and enhances the durability of the material. The most common examples of surface engineering is electroplating, applying metal coatings, aluminium anodising, electro polishing and so on.

These processes apart there are some simple but effective methods that are carried out to protect and lengthen the life of metal surfaces. The metal is heated in presence of specific gases which modify the surface structure and to some extent the properties of a substance which results in softening or hardening and a considerable change in composition to produce unique surface properties that are sought after. Methods like galvanizing, tinning, metal spraying and enamelling are also followed to create a comparatively dense layer on the surface of the material thereby protecting the metal against deterioration.

Surface engineering is no doubt that makes use of a variety of surface coating and modification methods in order to produce diverse properties which act as a protective aid to the material. This technology is employed in sectors like the manufacture of advanced engineering tools and products that enhance the ability to add value to products. Surface engineering technology has also found a place in several application sectors like the equipment industry wherein they have created a strong influence in terms of design modifications and cost-effective benefits.

WWG Engineering Pte Ltd was started to basically provide engineering services with a speciality in surface engineering expertise, especially in thermal spray aluminium coating, hard chromeplating and so on. With its exceptional skills in Integrated Engineering Solutions, the company also provides first-class engineering solutions in reference to hydraulic cylinders and other rotating equipment. WWG Engineering Pte Ltd also provides expert services in components refurbishing, repairing and re-manufacturing as well.

#Surface engineering technology#mechanical engineering services#thermal spray aluminium coating#hydraulic cylinders#integrated engineering solutions

0 notes

Text

Smart Cylinders

Position sensing smart hydraulic cylinders are specifically designed for direct stroke measurement. Linear sensors are integrated into the cylinders to provide feedback. Contact us to learn more.

1 note

·

View note

Text

Exploring Leading Hydraulic Cylinder Manufacturers: A Comprehensive Guide

Hydraulic cylinders are crucial components in various industries, powering machinery and equipment with precision and efficiency. When it comes to sourcing high-quality hydraulic cylinders, choosing the right manufacturer is essential. In this article, we delve into some of the leading hydraulic cylinder manufacturers, highlighting their expertise, product range, and industry reputation.

Bosch Rexroth:

Bosch Rexroth stands out as a global leader in hydraulic technology, offering a diverse range of hydraulic cylinders designed for performance and reliability. With a rich history spanning decades, Bosch Rexroth is known for its innovative engineering solutions and commitment to quality. Their hydraulic cylinders cater to diverse applications across industries such as manufacturing, construction, and agriculture.

Parker Hannifin:

Parker Hannifin is another renowned name in the hydraulic cylinder manufacturing industry. With a wide array of cylinder types and configurations, including tie-rod, welded, and telescopic cylinders, Parker Hannifin caters to the unique needs of various sectors. Their cylinders are known for their durability, precision, and efficient performance, making them a preferred choice for demanding applications.

Eaton:

Eaton is a trusted manufacturer of hydraulic components, including cylinders renowned for their robustness and performance. With a focus on innovation and customer satisfaction, Eaton offers a comprehensive range of hydraulic cylinders tailored to meet the evolving needs of different industries. Their cylinders are designed to withstand extreme conditions and deliver consistent results, ensuring reliable operation over the long term.

Hyva:

Hyva is a leading global provider of hydraulic solutions, including hydraulic cylinders renowned for their quality and durability. Specializing in solutions for the commercial vehicle and material handling industries, Hyva offers a wide range of cylinders designed to meet specific customer requirements. With a strong focus on technological advancements and customer service, Hyva continues to be a preferred choice for hydraulic cylinder solutions worldwide.

Conclusion:

Choosing the right hydraulic cylinder manufacturer is crucial for ensuring optimal performance and reliability in various applications. Whether it's Bosch Rexroth, Parker Hannifin, Eaton, or Hyva, each of these manufacturers brings unique expertise and capabilities to the table. By partnering with a trusted manufacturer, businesses can benefit from high-quality hydraulic cylinders tailored to their specific needs, driving efficiency and productivity in their operations.

0 notes

Video

TAFE | Hydraulic Cylinders | Tractors and Farm Equipments

Established in 2009, TAFE Access Limited (TAL) – Hydraulic Cylinder Division came into existence with an aim of becoming one of the top organizations in the field of fluid power in India. Hydraulic cylinders manufactured by TAL are highly-efficient, durable, and have exceptional features. These reasons make hydraulic cylinders by TAL the first choice for people! If you are also looking for hydraulic cylinders with superior quality, now you know what to look for. Find hydraulic cylinders for a wide range of applications with TAL.

0 notes

Text

The Hydraulic System, Mechanics And Its Applications

A typical hydraulic system fundamentally features an incredible ability to apply a considerably monstrous force or torque boost in a comparatively easy way. The main advantage of the process is that the action is affected without the use of any mechanically joined parts like gears, levers or similar attachments, from the point of origin of force generation to the point of impact. These systems are based on the law of Pascal where it is said that when a pressure is applied to a fluid inside a closed container, the resultant will be that the fluid will exert an equally strong pressure in all directions.

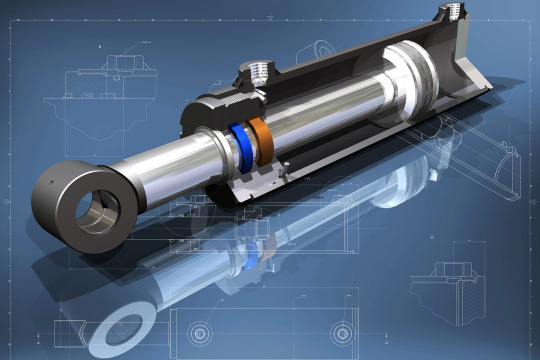

In case of these systems, the usage of a non-compressible fluid is preferred. The most spoken convenience about these systems is that a very large amount of torque and power can be transferred through tubes of considerably small cross sections, where the high power density actuators make use of this and in turn a huge multiplication of forces are obtained as an end result. A linear hydraulic motor or a hydraulic cylinder is in other words an actuator that produces unidirectional force of great volume, through a unidirectional stroke. These hydraulic cylinders get the desired power from the highly pressurised hydraulic fluids, which are commonly oils.

The cylinder is a barrel made of highly resistant material, inside which a piston is enabled to freely move back and forth. The cylinder at one is securely sealed and the other end is where the piston head gets aligned. The piston is packed with sliding rings and seals so that the fluid inside does not spurt out during the pressurising action. In this way the cylinder is mainly divided into 2 parts by the piston that is the piston head part and the bottom chamber or the cap end. The piston head part along with the piston rod is connected to the object or the machine part that pulls or pushes the piston.

Hydraulic machines find application in heavy construction sectors. Here the machines that are used must be of very high torque and power and hence the utility of hydraulic machines are more preferred. The mechanics and the system of functioning happens to be a straightforward process where the fluid is pumped into various hydraulic motors and cylinders throughout the machine, where it gets subjected to different pressures depending on the resistance, the fluid then is regulated by control valves and is distributed through strong and resistant hoses, pipes and tubes. The controlling of the fluid may either be manual or automatic depending on the application and where it is being used. For instance in case of an excavator the cylinders work in accordance to the machines linkages to carry out the desired work.

The same principle of the hydraulic system is made use of in case of fork lifts, elevators, hydraulic cranes, earth moving equipment, and many more sectors where enormous power and torque are mandatory to carry out the job. Most of the hydraulic equipment, since they do not involve many mechanically moving parts that are literally connected to each other, seldom require frequent servicing but all the same due to the fact that they are used in very heavy works especially in earth moving and heavy load lifting, it needs to be supervised and kept well-tuned up always. Although not comprising of complex structures, it has to be serviced and maintained by a skilled and qualified technician so that the machine does not come across any technical faults leading to hampered jobs or work location causalities.

While discussion on this aspect wwg engineering, well-known organization dealing with industrial machinery and services, specialising in hydraulic equipment and allied facilities have been a forerunner in the mentioned sector. Rendering second to none services in and around Singapore since the last two decades, have much more than hydraulic equipment Services, hydraulic cylinder repair and maintenance services, the organization is also proficient in thermal spray coating, rotating equipment servicing and repairs, process piping and plumbing services, chrome plating, gear fabrication, balancing machine servicing and more. With a steadfast mission to offer excellent services in the mentioned sector, wwg engineering has been one of the preferred organizations when it comes to hydraulic machinery, its servicing, repairs, and maintenance.

To Learn About More Details Hydraulic Cylinder Repair Services Kindly Checkout Our Site Today...!

#Hydraulic Equipment Services#Hydraulic Cylinder Singapore#Hydraulic Cylinder Repair Services#Hydraulic Cylinder Specialist#Hydraulic Cylinders

1 note

·

View note

Text

How Hydraulic Cylinders Enhance Performance in Industrial Applications

In the realm of industrial machinery, efficiency and precision are paramount. One crucial component that plays a significant role in achieving these goals is the hydraulic cylinder.

These powerful devices are ubiquitous in a wide range of industrial applications, from manufacturing and construction to agriculture and aerospace.

In this blog post, we'll delve into the fascinating world of hydraulic cylinders in Australia and explore how they enhance performance in various industrial settings, revolutionising the way heavy-duty tasks are accomplished.

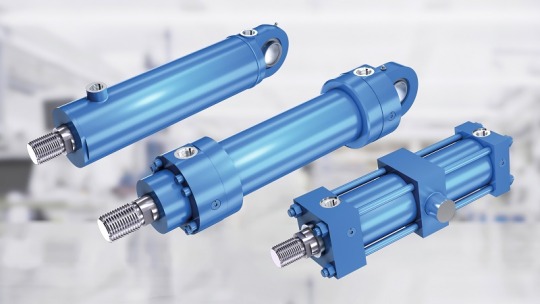

The Anatomy of Hydraulic Cylinders

At the heart of hydraulic systems, hydraulic cylinders are mechanical actuators that generate linear motion through the use of hydraulic fluid.

Comprising a cylindrical barrel, piston, rod, and various seals, these robust devices convert the energy from the pressurised fluid into force and motion, making them indispensable for countless industrial processes.

Precision and Control

One of the most significant advantages of hydraulic cylinders in Australia is the unparalleled precision and control they offer in industrial operations.

Whether it's lifting heavy loads, pushing, pulling, bending, or straightening materials, these cylinders provide smooth and controlled motion, allowing for finesse and accuracy in even the most demanding tasks.

This level of control is crucial in applications where consistency and precision are non-negotiable.

Power and Versatility

The power generated by hydraulic cylinders is truly awe-inspiring. With their ability to exert formidable force, these devices are capable of handling tasks that would be unattainable with other actuation methods.

From heavy lifting and pressing to powering machinery and equipment, their sheer strength makes them indispensable across diverse industrial sectors.

Furthermore, the versatility of these cylinders allows them to adapt to an array of challenging tasks, providing an adaptable and reliable solution in various environments.

Durability and Reliability

In the unforgiving landscape of industrial settings, equipment durability is crucial. Hydraulic cylinders are renowned for their robust construction and ability to withstand harsh conditions.

The materials used in their manufacture, coupled with meticulous engineering, result in devices that can endure high-temperature environments, heavy loads, and frequent operation without succumbing to wear and tear.

This durability translates into enhanced operational reliability, minimising downtime and maintenance costs.

Efficiency and Cost-Effectiveness

Efficiency is a cornerstone of industrial operations, and hydraulic cylinders excel in this regard.

By seamlessly converting hydraulic energy into mechanical force, these devices maximise energy utilisation, resulting in efficient and cost-effective performance.

Their exceptional power-to-size ratio and minimal energy loss during operation make them an economical choice for industrial applications, contributing to overall operational efficiency and reduced energy consumption.

Safety and Operator Well-Being

In industrial environments where heavy machinery and equipment are commonplace, safety is of paramount importance.

Hydraulic cylinders offer inherent safety advantages, such as stable and controlled motion, as well as overload protection features.

This not only safeguards the machinery and materials but also prioritises the well-being of operators and personnel working around these devices, further underscoring their significance in industrial settings.

Customisation and Adaptability

The adaptability of hydraulic cylinders is a key factor in their widespread use across diverse industrial applications.

Their design flexibility allows for customisation to suit specific operational requirements, whether it's modifying stroke length, bore diameter, or mounting options.

This adaptability ensures that the cylinders can seamlessly integrate into existing systems and machinery, enhancing their functionality without the need for costly overhauls.

Environmental Considerations

In an era where environmental sustainability holds increasing importance, hydraulic cylinders are making strides in minimising their ecological impact.

Innovations in seal technologies, fluid selection, and overall system design are driving advancements that reduce hydraulic fluid leakage and consumption, contributing to greener industrial practices.

Future Innovations and Advancements

As technology continues to evolve, so do hydraulic cylinders. Ongoing developments in materials, manufacturing techniques, and integration with smart technologies promise to further enhance the capabilities of these devices in the industrial landscape.

From predictive maintenance and condition monitoring to improved energy efficiency, the future of hydraulic cylinders looks promising, offering even greater potential for performance optimisation in industrial applications.

Conclusion

In conclusion, hydraulic cylinders in Australia stand as fundamental assets in the industrial realm, elevating the performance, safety, and efficiency of a myriad of applications.

Their precision, power, durability, efficiency, and adaptability make them indispensable across manufacturing, construction, agriculture, and beyond.

With an eye to sustainability and ongoing technological progress, these robust devices are not only instrumental today but also hold tremendous promise for the future of industrial machinery and equipment.

Source: How Hydraulic Cylinders Enhance Performance in Industrial Applications

0 notes

Text

Quality Hydraulic Cylinders - Hotion Group

Hotion Group offers quality hydraulic cylinders designed for a wide range of applications in industries such as construction, manufacturing, and agriculture. Our hydraulic cylinders are built to withstand high pressures and harsh environments, ensuring reliable performance and long service life. Explore our selection of hydraulic cylinders and trust Hotion Group for durable and efficient hydraulic solutions.

1 note

·

View note

Note

I remember when GLaDOS woke up, she was making a lot of metal creaking noises, so obviously something needs to be oiled up

Oof ouch her boings......

#i was thinking after a while her neck might get too stiff. that specifically is where a lot of the joints are#like what happens if she can't move....does she have an automatic hydraulic cylinder cleaning process??#or is she just screwed because that's something the scientists used to take care of and now she can't#cuz she's got clunky robot claws and no hands#ah wait I'm stupo does the nuclear reactor factor into any of this whole ordeal#portal#glados

16 notes

·

View notes