#icsockets

Explore tagged Tumblr posts

Text

A Comprehensive Guide to IC Sockets: Applications, Types, and Selection

IC sockets play a crucial role in modern electronics by providing a secure yet removable connection between integrated circuits (ICs) and printed circuit boards (PCBs). These components allow for easy installation, replacement, and testing of ICs without the need for direct soldering, making them invaluable in various industries. If you’re looking for high-quality custom IC sockets, explore our collection of IC Sockets.

What is an IC Socket?

An IC socket is an electrical connector designed to house an integrated circuit, ensuring a reliable yet removable connection to a PCB. They are commonly used in applications where ICs need to be replaced, tested, or upgraded without causing damage to the board or the chip itself.

IC sockets come in different configurations, including DIP (Dual In-line Package), PGA (Pin Grid Array), LGA (Land Grid Array), and BGA (Ball Grid Array), to accommodate different types of ICs.

Applications of IC Sockets

1. Electronics Testing and Prototyping

IC sockets allow engineers to test and validate new integrated circuit sockets without permanent soldering, making them essential for prototyping and debugging.

2. Space and Aerospace Industry

High-performance custom IC sockets are used in satellites, rovers, and other space applications where extreme temperature resistance and durability are critical.

3. Automotive Electronics

IC sockets facilitate the testing, debugging, and replacement of electronic control units (ECUs) in modern vehicles. High-speed GHz sockets are used for applications requiring rapid data transmission.

4. Medical Devices

In medical equipment, IC sockets ensure that life-saving devices remain operational with quick and easy IC replacements, reducing downtime.

5. Consumer Electronics

Many household electronics, such as televisions, gaming consoles, and home automation systems, use IC sockets to extend the lifespan of their internal components.

How to Choose the Right IC Socket

Selecting the right IC socket depends on various factors, including:

Bandwidth and Signal Integrity: High-frequency applications require sockets with minimal signal loss.

Durability and Lifespan: Ensure the socket can withstand multiple insertions and removals.

Temperature Resistance: Essential for high-performance and industrial applications.

Size and Compatibility: Choose a socket that matches your IC’s pin configuration.

Ease of Use: Some sockets come with a locking mechanism for secure placement.

Explore a wide range of integrated circuit sockets tailored to different needs.

Types of IC Sockets

1. Spring Pin Sockets

Designed for endurance and wide temperature range testing, these sockets support multiple IC package types like BGA, QFN, and SOIC.

2. Silver Button Sockets

Ideal for high-speed applications, these sockets provide excellent signal transmission in the GHz range.

3. Elastomer Sockets

Featuring embedded wire elastomers, these sockets are great for ensuring strong electrical contact in prototype applications.

4. Zero Insertion Force (ZIF) Sockets

These sockets allow for the effortless insertion and removal of ICs, making them suitable for frequently swapped chips.

How to Use an IC Socket

Align the Socket: Position the socket on the designated PCB area.

Secure the Socket: Solder or mount the socket properly to ensure stability.

Insert the IC: Place the IC into the socket, ensuring correct orientation.

Test and Replace as Needed: IC sockets enable easy swapping and testing without permanent alterations.

For a detailed guide on choosing and using custom IC sockets, visit our dedicated IC Sockets page.

IC Socket Pricing Factors

The cost of IC sockets varies based on several factors:

Material: Metal sockets are more expensive than plastic ones.

Pin Pitch: Smaller pitches require more precision, increasing costs.

Contact Technology: Advanced designs for high bandwidth applications tend to be pricier.

Customization: Custom IC sockets designed for specific applications may have higher costs.

Conclusion

IC sockets are essential for a range of industries, from electronics testing to automotive and space applications. By choosing the right integrated circuit sockets, you can enhance your product’s reliability, ease of maintenance, and overall performance.

0 notes

Text

The Importance of IC Sockets in Semiconductor Testing Industry — MiniATE

In the intricate world of electronics, integrated circuits (ICs) are essential for creating functional and efficient devices. At the heart of their operation lies a crucial component: the IC socket. These sockets serve as a bridge between the ICs and the circuit board, providing both connectivity and protection.

IC sockets are designed to hold integrated circuits securely, allowing for easy insertion and removal without damaging the IC itself. This is particularly important for prototyping and testing applications, where frequent changes to the circuitry are necessary. Sockets enable engineers to swap out ICs, making it easier to upgrade or replace components as technology evolves.

One of the primary advantages of using IC sockets is that they prevent physical damage to the IC pins. Without a socket, repeated soldering and desoldering can lead to wear and tear, ultimately compromising the functionality of the IC. Moreover, IC sockets facilitate better heat dissipation, ensuring that the IC operates within its optimal temperature range, which is crucial for maintaining performance.

Types of IC Sockets

IC sockets come in various types, each designed for specific applications and requirements:

DIP (Dual In-line Package) Sockets: These are among the most common types and are used for through-hole mounting. They typically have two parallel rows of pins and are widely used in both consumer and industrial electronics.

SOP (Small Outline Package) Sockets: These sockets are used for surface-mounted devices and are ideal for applications where space is a constraint.

QFP (Quad Flat Package) Sockets: Designed for high-density applications, these sockets accommodate ICs with pins on all four sides, allowing for increased functionality without expanding the footprint.

BGA (Ball Grid Array) Sockets: These sockets are used for high-performance applications and feature a grid of solder balls on the bottom of the IC, providing excellent electrical connectivity.

LGA (Land Grid Array) Sockets: Similar to BGA, but instead of solder balls, they use flat pads for connection, making them suitable for high-frequency applications.

The Importance of Quality in IC Sockets

The performance of an IC socket directly affects the reliability of the entire electronic system. Poor-quality sockets can lead to intermittent connections, increased resistance, and ultimately, device failure. Therefore, choosing the right supplier for IC sockets is paramount.

An IC socket is a device that provides a reliable interface for connecting integrated circuits to PCBs. These sockets allow for easy installation and removal of ICs without soldering, which is particularly useful in prototyping and testing applications. By providing a secure connection, IC sockets help prevent damage to the delicate pins of ICs, which can be susceptible to bending or breaking during insertion and removal.

One of the prominent manufacturers in the IC socket industry is Yamaichi Electronics. Established in Japan, Yamaichi has built a reputation for producing high-quality semiconductor sockets that cater to various applications. Their products are engineered for durability, ensuring they withstand the rigors of both prototyping and long-term usage.

Benefits of Using IC Sockets

Ease of Use: IC sockets simplify the process of inserting and removing ICs, which is especially beneficial in environments where components need to be frequently changed or updated. This ease of use can significantly reduce labor costs in manufacturing and prototyping.

Protecting ICs: Sockets provide a protective layer for the IC pins, minimizing the risk of damage during handling. This feature is crucial in applications where high precision and reliability are required, such as in medical devices and aerospace technology.

Testing and Prototyping: During the development phase, engineers often need to test various ICs. Using sockets allows for quick swaps between different components, accelerating the prototyping process and facilitating design iterations.

Reduced Repair Costs: In the event of a failure, replacing an IC socket is often less expensive than repairing a soldered connection on a PCB. This characteristic can lead to significant cost savings over the product’s lifecycle.

Types of IC Sockets

IC sockets come in various types, each designed to meet specific requirements. Here are some common categories:

Dual In-line Package (DIP) Sockets: These sockets accommodate ICs with two rows of pins and are widely used in traditional electronic circuits. They are known for their ease of use and are compatible with many standard ICs.

Surface Mount Device (SMD) Sockets: Designed for surface-mounted ICs, these sockets offer a low-profile solution for modern electronics. They are available in various sizes and configurations, allowing for flexibility in design.

Ball Grid Array (BGA) Sockets: BGA sockets are essential for connecting high-density ICs. They feature an array of solder balls on the underside of the IC, which connect to corresponding pads on the PCB. BGA sockets facilitate better thermal and electrical performance, making them ideal for advanced applications.

Chip-on-Board (COB) Sockets: In this design, the IC is directly mounted onto the PCB, which can lead to space savings. COB sockets are used in applications where size is critical, such as in mobile devices.

Future Trends in IC Socket Technology

As the semiconductor industry continues to evolve, so will the demands placed on IC sockets. Emerging trends, such as the increasing adoption of miniaturized components and the push for higher performance, will influence the design and functionality of IC sockets.

Miniaturization: As devices become smaller and more compact, IC sockets will need to follow suit. Manufacturers will likely develop sockets that occupy less space while maintaining robust performance.

Increased Integration: The trend towards integrating more functionalities into single ICs will require sockets that can support higher pin counts and more complex configurations.

Smart Manufacturing: The rise of smart manufacturing and automation will also impact IC socket production. Companies will invest in advanced manufacturing technologies, such as 3D printing and automated assembly processes, to improve efficiency and reduce lead times.

Enhanced Reliability: With the increasing reliance on electronic devices in critical applications, there will be a greater emphasis on the reliability of IC sockets. Manufacturers will focus on developing sockets that can withstand harsh conditions and provide consistent performance over time.

Read the full article to know more about icsockets

0 notes

Text

https://miniate.com/a-comprehensive-guide-to-ic-sockets-applications-types-and-selection/

A Comprehensive Guide to IC Sockets: Applications, Types, and Selection IC sockets play a crucial role in modern electronics by providing a secure yet removable connection between integrated circuits (ICs) and printed circuit boards (PCBs). These components allow for easy installation, replacement, and testing of ICs without the need for direct soldering, making them invaluable in various industries. If you’re looking for high-quality custom IC sockets, explore our collection of IC Sockets. https://miniate.com/a-comprehensive-guide-to-ic-sockets-applications-types-and-selection/

0 notes

Text

The Essential Guide to IC Sockets and Semiconductor Socket

In the world of electronics and semiconductor testing, IC sockets and semiconductor sockets play a crucial role in connecting integrated circuits (ICs) and other semiconductor devices to test equipment or circuit boards. While these two types of sockets serve similar purposes, they have key differences in their design, applications, and usage across industries. Understanding these distinctions can help engineers, manufacturers, and product developers make informed decisions when selecting the right socket for their needs.

This guide delves into the specifics of and semiconductor sockets, highlighting their applications, key features, and relevant examples to enhance your decision-making process.

What Are IC Sockets?

IC sockets are connectors that facilitate the insertion and removal of integrated circuits (ICs) from printed circuit boards (PCBs) without the need for soldering. This capability allows for secure yet temporary connections, making it easier to replace chips during testing, debugging, or product development.

Common Types of IC Sockets:

DIP (Dual In-line Package) Sockets — Used for through-hole ICs, commonly found in consumer electronics and prototyping.

PGA (Pin Grid Array) Sockets — Designed for microprocessors, used in computers and industrial controllers.

LGA (Land Grid Array) Sockets — Found in high-performance CPUs, such as those used in data centers and gaming PCs.

ZIF (Zero Insertion Force) Sockets — Allow chips to be inserted and removed with minimal force, ideal for programming and testing.

Industry Applications of IC Sockets:

Consumer Electronics — Used in laptops, gaming consoles, and home automation devices.

Automotive Electronics — Found in engine control units (ECUs) and infotainment systems.

Embedded Systems — Used in industrial automation, robotics, and IoT devices.

Semiconductor Testing & Prototyping — Enables rapid evaluation of IC performance in R&D environments.

Example Product:

The Yamaichi IC Sockets are widely used for IC programming and testing, offering high durability and reliability in development labs.

What Are Semiconductor Sockets?

A semiconductor socket is a broader category that includes IC sockets but extends to other semiconductor devices such as transistors, diodes, and power modules. These sockets are engineered for high-performance applications, especially in automated testing (ATE), burn-in testing, and validation of semiconductor chips before they are deployed in real-world environments.

Key Features of Semiconductor Sockets:

Support for advanced semiconductor packaging, including BGA (Ball Grid Array) and QFP (Quad Flat Package).

Designed to handle high-frequency, high-temperature, and high-power applications.

Can be used in wafer-level testing before ICs are packaged.

Industry Applications of Semiconductor Sockets:

Semiconductor Manufacturing & Testing — Used in wafer probing and final product validation.

Telecommunications — Found in RF and microwave components for 5G technology.

Medical Devices — Used in diagnostic imaging and wearable health monitors.

Aerospace & Defense — Enables testing of mission-critical chips in satellites and avionics.

Example Product:

The Yamaichi Test Sockets are a popular choice in semiconductor testing, providing robust connectivity for BGA and QFN devices in high-frequency applications.

Why Choosing the Right Socket Matters

Selecting the correct socket for an application is critical because it affects:

Device longevity and reliability — Ensuring the right connection and thermal management prevents failures.

Testing accuracy — Especially in semiconductor production, where precision is key.

Cost efficiency — Avoiding unnecessary replacement costs and improving manufacturing yield.

Future Trends in IC and Semiconductor Sockets

With miniaturization, 5G, AI, and IoT driving the semiconductor industry forward, socket technology is evolving to meet new challenges.

Innovations include:

Advanced materials for better heat dissipation and signal integrity.

Automated and AI-driven testing to speed up chip validation.

Universal sockets capable of accommodating multiple chip designs for flexible manufacturing.

IC sockets and semiconductor sockets are essential components in modern electronics and semiconductor manufacturing. While IC sockets are more focused on prototyping and chip replacement, semiconductor sockets serve advanced testing and validation purposes in high-performance industries like telecommunications, aerospace, and medical technology.

Understanding these differences helps engineers and manufacturers optimize their design, testing, and production processes, ensuring reliability and efficiency in the ever-evolving semiconductor industry. Whether developing a consumer gadget, an industrial control system, or a next-gen AI chip, choosing the right socket can make all the difference.

Would you like to explore more about selecting the best socket for your application? Reach out to a trusted IC socket and semiconductor socket distributor for expert guidance!

0 notes

Text

The Essential Guide to IC Sockets and Semiconductor Sockets: Applications and Industry Insights In the world of electronics and semiconductor testing, IC sockets and semiconductor sockets play a crucial role in connecting integrated circuits (ICs) and other semiconductor devices to test equipment or circuit boards. While these two types of sockets serve similar purposes, they have key differences in their design, applications, and usage across industries. Understanding these distinctions can help engineers, manufacturers, and product developers make informed decisions when selecting the right socket for their needs. https://abouttheblogs.com/the-essential-guide-to-ic-sockets-and-semiconductor-sockets-applications-and-industry-insights/

0 notes

Text

Optimizing Semiconductor Testing with BGA Sockets

BGA sockets are essential components in semiconductor testing, providing a non-destructive way to evaluate high-density integrated circuits (ICs) without soldering. These sockets enable secure connections, efficient thermal management, and high-speed signal integrity, making them indispensable in industries like consumer electronics, automotive, telecommunications, and medical devices. MiniATE specializes in precision-engineered BGA sockets, offering customized solutions to meet stringent industry requirements. By collaborating with leading manufacturers, MiniATE ensures durable, high-performance sockets that streamline semiconductor testing. Whether for functional validation or burn-in testing, MiniATE’s expertise helps companies optimize their testing processes with reliable, high-quality BGA socket solutions.

Introduction

In the ever-evolving semiconductor industry, ensuring the reliability and efficiency of integrated circuits (ICs) is crucial. Ball Grid Array (BGA) sockets play a vital role in this process, offering a secure and efficient way to test high-density IC packages without permanent soldering. At MiniATE, we specialize in providing advanced BGA socket solutions that cater to the rigorous demands of semiconductor manufacturers.

This article explores the functionality of BGA sockets, their importance in semiconductor testing, the industries that rely on them, and how MiniATE’s expertise and collaborations help companies acquire high-quality testing solutions.

What Are BGA Sockets and How Do They Work?

BGA sockets are specialized connectors designed to interface with BGA-packaged ICs. Unlike traditional ICs that have pins, BGA packages feature an array of solder balls on their underside, enabling higher pin density and improved electrical performance. BGA sockets facilitate:

Secure Testing Without Soldering — Allowing ICs to be tested and reused without damage.

High-Density Connections — Enabling reliable electrical contact for complex semiconductor applications.

Efficient Thermal Management — Ensuring proper heat dissipation during high-temperature testing.

With the growing complexity of semiconductor devices, high-quality BGA sockets are essential for efficient functional and burn-in testing.

MiniATE’s Role in Semiconductor Testing Solutions

MiniATE is at the forefront of providing precision-engineered BGA sockets for semiconductor testing. Through strategic collaborations with leading manufacturers, we help companies acquire customized socket solutions tailored to their specific testing needs. Our expertise ensures:

High-Performance Materials — Enhancing socket durability and electrical integrity.

Precision Engineering — Accommodating fine-pitch ICs with accuracy.

Customizable Designs — Offering tailored solutions for unique testing environments.

Long-Term Reliability — Meeting stringent industry quality standards.

By working with MiniATE, semiconductor companies can streamline their testing processes and improve the reliability of their ICs.

Who Needs BGA Sockets? Industries and Applications

BGA sockets are widely used in various industries where advanced electronics are crucial. Some of the key sectors that rely on BGA testing solutions include:

1. Consumer Electronics

Companies manufacturing smartphones, tablets, and wearables use BGA sockets for testing compact and high-performance ICs.

2. Automotive Industry

With the rise of Advanced Driver-Assistance Systems (ADAS) and electric vehicles, BGA sockets are critical in testing automotive-grade semiconductors for safety and performance.

3. Telecommunications

Network equipment providers and communication device manufacturers use BGA sockets to validate high-speed processors and memory chips.

4. Medical Devices

Medical technology companies rely on BGA sockets to test ICs used in diagnostic equipment and wearable health monitors, ensuring accuracy and longevity.

These industries demand high-quality and reliable testing solutions, making MiniATE’s BGA sockets an indispensable part of the semiconductor supply chain.

Are BGA Sockets a Type of IC Socket?

Yes, BGA sockets fall under the broader category of IC sockets. However, while all BGA sockets are IC sockets, not all IC sockets are designed for BGA packages. BGA sockets are specialized to handle the solder ball array design of BGA chips, ensuring:

Proper alignment for accurate testing.

Robust electrical connectivity with minimal signal loss.

Compatibility with fine-pitch semiconductor designs.

For semiconductor manufacturers working with high-density BGA packages, selecting the right BGA socket is crucial for achieving optimal testing efficiency.

FAQs:

1. What are the main benefits of using BGA sockets in semiconductor testing?

Enables non-destructive testing.

Provides easy insertion and removal for repeated use.

Ensures high-speed signal integrity with minimal resistance.

2. Does MiniATE offer custom BGA socket solutions?

Yes, we provide fully customizable BGA sockets tailored to unique semiconductor testing requirements.

3. What should I consider when selecting a BGA socket?

Pitch size (spacing between solder balls)

Operating temperature range

Contact resistance and electrical performance

Cycle durability (how many times the IC can be inserted/removed)

4. How does MiniATE ensure the quality of its BGA sockets?

MiniATE works with reputed IC socket principals who use rigorous quality control, including:

High-precision manufacturing techniques.

Use of premium materials for durability and performance.

Compliance with global semiconductor testing standards.

5. What is the lead time for a MiniATE custom BGA socket?

Lead times vary depending on design complexity. Contact our team for a consultation and project timeline estimate.

BGA sockets play a critical role in semiconductor testing, enabling manufacturers to validate high-performance ICs with precision and efficiency. MiniATE’s expertise in providing advanced BGA sockets ensures that semiconductor companies receive top-tier testing solutions tailored to their needs.

If you’re looking for reliable BGA sockets to enhance your semiconductor testing process, contact MiniATE today for expert guidance and customized solutions.

0 notes

Text

Optimizing Semiconductor Testing with BGA Sockets BGA sockets are essential components in semiconductor testing, providing a non-destructive way to evaluate high-density integrated circuits (ICs) without soldering. These sockets enable secure connections, efficient thermal management, and high-speed signal integrity, making them indispensable in industries like consumer electronics, automotive, https://miniate.com/optimizing-semiconductor-testing-with-bga-sockets/

0 notes

Text

Materials Used in the Manufacturing of IC Sockets for Inspection

Summary

By selecting the right materials, manufacturers can ensure that their IC sockets are not only durable and reliable but also capable of supporting the cutting-edge technologies of tomorrow. As new materials and innovations continue to emerge, the future of IC socket manufacturing promises even greater efficiency and performance for testing and inspection applications.

Introduction

Integrated Circuit (IC) sockets are vital components in the electronics industry, enabling quick and easy testing and inspection of ICs. These sockets facilitate the evaluation of the functionality and performance of ICs without the need to permanently attach them to a circuit board.

The materials used to manufacture these sockets are crucial for their durability, functionality, and reliability during testing. In recent years, semiconductor packages like BGA and QFP have become more compact.

Importance of Material Selection for IC Sockets

The materials used for IC sockets must meet several key requirements to ensure reliable performance during inspection:

Thermal Resistance: IC sockets must be able to withstand high temperatures as they are often subjected to heat during testing. This is especially important when dealing with ICs that operate at elevated temperatures or undergo thermal cycling during the inspection process.

Mechanical Strength: The materials must be robust enough to handle the mechanical stresses of frequent insertion and removal of ICs. This includes maintaining their structural integrity over repeated usage.

Electrical Insulation: As IC sockets often handle high-frequency signals, the materials must be excellent electrical insulators to prevent unintended electrical conduction or short circuits.

Dimensional Stability: The socket must retain its precise shape and alignment even after repeated exposure to heat and mechanical stresses. Any deformation could result in poor connectivity and unreliable testing results.

Machinability: The material must be easy to machine into precise socket designs that accommodate different types of ICs, from simple through-hole packages to more complex BGA sockets (Ball Grid Array) and LGA sockets (Land Grid Array).

Common Materials Used in IC Socket Manufacturing

Several materials are commonly used in the production of IC sockets, each offering specific advantages suited for inspection and testing applications. Below are the most widely used materials:

1. Engineering Plastics

Engineering plastics are among the most common materials used for IC sockets, particularly for high-performance applications. These materials offer a good balance of thermal stability, mechanical strength, and electrical insulation properties.

Polyetheretherketone (PEEK): PEEK is a high-performance thermoplastic known for its excellent thermal resistance, mechanical strength, and chemical stability. It can withstand temperatures up to 250°C, making it ideal for high-temperature inspection applications. PEEK is often used in high-reliability sectors, such as aerospace and semiconductor testing.

Polyetherimide (PEI): PEI is another engineering plastic widely used for IC sockets. It has strong dimensional stability and is capable of withstanding moderate to high temperatures (up to 170°C). PEI is also known for its electrical insulation properties, making it a preferred choice for sockets used in testing ICs with high-frequency signals.

Polyimide (PI): Polyimide is renowned for its exceptional thermal stability, withstanding temperatures as high as 300°C without significant degradation. It is commonly used in advanced testing scenarios, where both high thermal performance and excellent electrical properties are required.

2. Ceramic-Filled Composites

Ceramic-filled composites are often chosen for their enhanced thermal conductivity and dimensional stability. These materials combine the benefits of polymers with ceramic fillers, offering improved mechanical properties and the ability to handle heat better than standard engineering plastics.

3. Metals and Metal Alloys

While the body of the IC socket is generally made from plastics or composites, metal contacts are essential for ensuring good electrical conductivity. These metal components are typically used in the pins or contact areas of the socket.

Beryllium Copper: This alloy is widely used for socket contacts due to its excellent electrical conductivity, high strength, and good corrosion resistance. Beryllium copper allows for the creation of thin, resilient contact points that maintain reliable electrical connections over time.

Phosphor Bronze: Phosphor bronze is another metal alloy used for contact pins. It is known for its durability and ability to retain spring-like properties, ensuring proper engagement with the IC leads.

Read the full article to know more about icsockets

0 notes

Text

https://miniate.com/materials-used-in-the-manufacturing-of-ic-sockets-for-inspection/

Materials Used in the Manufacturing of IC Sockets for Inspection By selecting the right materials, manufacturers can ensure that their IC sockets are not only durable and reliable but also capable of supporting the cutting-edge technologies of tomorrow. As new materials and innovations continue to emerge, the future of IC socket manufacturing promises even greater efficiency and performance for testing and inspection applications.

0 notes

Text

https://miniate.com/the-importance-of-ic-sockets-in-semiconductor-testing-industry/

The Importance of IC Sockets in Semiconductor Testing Industry In the intricate world of electronics, integrated circuits (ICs) are essential for creating functional and efficient devices. At the heart of their operation lies a crucial component: the IC socket. These sockets serve as a bridge between the ICs and the circuit board, providing both connectivity and protection.

0 notes

Text

Comparing Test Socket Types: Fastlock, Screwlock, QFP and BGA for Semiconductor Testing — MiniATE

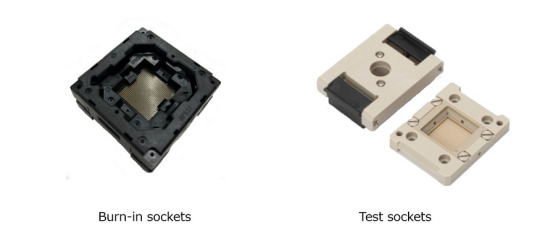

In the fast-paced semiconductor manufacturing industry, it’s essential to ensure that integrated circuits (ICs) meet rigorous performance and reliability standards. A critical component in this testing process is the test socket, which ensures a stable electrical connection between the device under test (DUT) and the testing platform.

Fastlock Test Sockets, Screwlock Test Sockets, QFP (Quad Flat Package), and BGA (Ball Grid Array) test sockets are some of the most commonly used in various testing environments, such as Automated Test Equipment (ATE), bench testing, and validation platforms.

Each of these sockets offers unique features and is tailored for different applications. This article delves into the characteristics, benefits, and ideal applications of these socket types.

1. Fastlock Test Socket: Quick, Secure, and Reliable

The Fastlock Test Socket is designed for quick, efficient, and secure connections. It utilizes a spring mechanism that allows the socket to engage and disengage easily with minimal effort. Fastlock sockets are typically used in situations where fast and repeatable testing cycles are needed, making them ideal for high-volume testing in Automated Test Equipment (ATE) environments.

Key Features

Benefits

Drawbacks

Applications

2. Screwlock Test Socket: Stable and Secure for Sensitive Devices

The Screwlock Test Socket offers a secure connection via screws that tightly fasten the IC into the socket. This socket type is particularly suitable for devices that require a stable connection, especially in high-precision testing scenarios.

3. QFP Test Socket: Ideal for Flat-Pack ICs

The QFP (Quad Flat Package) test socket is designed specifically for ICs packaged in the QFP format, which is one of the most commonly used surface-mount IC packages. QFP test sockets are characterized by the fact that the IC’s leads are on all four sides, and they are usually soldered directly to the PCB.

Key Features

Surface-mount connection: Designed for ICs with leads on all four sides (QFPs).

Reliable contact: Uses spring contacts or pogo pins to connect the leads to the test system, ensuring a reliable electrical connection.

High pin count: Suitable for ICs with a large number of pins.

ATE and Bench Testing: Widely used in Automated Test Equipment environments and bench testing setups for devices with QFP packaging.

Prototyping: Ideal for testing during early-stage design and validation of QFP-based ICs.

Read the full article to know more about Semiconductorsockets

0 notes

Text

https://miniate.com/comparing-test-socket-types-fastlock-screwlock-qfp-and-bga-for-semiconductor-testing/

Comparing Test Socket Types: Fastlock, Screwlock, QFP and BGA for Semiconductor Testing Fastlock Test Sockets, Screwlock Test Sockets, QFP (Quad Flat Package), and BGA (Ball Grid Array) test sockets are some of the most commonly used in various testing environments, such as Automated Test Equipment (ATE), bench testing, and validation platforms.

0 notes

Text

Revolutionizing Connections with Production Sockets

This adaptability is particularly valuable in the fast-paced electronics industry, where constant technological advancements necessitate frequent product updates to remain competitive.

Additionally, IC sockets can accommodate a variety of IC package types and sizes, ensuring compatibility across a wide range of electronic devices.

As a leading distributor of two types of production sockets in India- PLCC (Plastic Leaded Chip Carrier) and QFP (Quad Flat Package)-we prioritize quality in every IC socket we supply.

Read the full article to know more about icsockets

0 notes