#ifglrefractories

Explore tagged Tumblr posts

Text

Basic Oxygen Furnace (BOF) steel making involves blowing oxygen through molten pig iron that is heated to more than 1,600℃ to convert it into steel. Different types of refractories play an important role to maximize furnace life and yield. IFGL Refractories offers specialized BOF refractory solutions for enhanced furnace performance.

#steelmanufacturing#steelindustries#ifglrefractories#refractory solutions#bof refractories#basic oxygen furnace

0 notes

Text

The spirit of unity, compassion and community-building for holistic growth lies at the heart of #IFGLRefractories.

Our recent ‘Blood Donation Camp’ at the KASEZ Health Centre, organised as part of the 60th Foundation Day celebrations for the Kandla Special Economic Zone, received a uniformly positive response from the local people. We thank all the donors who generously contributed to this life-saving cause. Together, let’s keep this positivity going.

0 notes

Text

Record Breaking Performance with IFGL's Purging Refractories at JSW Bellary!

Kudos to JSW Bellary on setting a new record with a remarkable Purging Plug performance of 55 heats at SMS-3 using our top-notch 'Make In India' purging refractories. A single plug lasted for half the campaign life of a 160 MT ladle.

IFGL Refractories is thrilled to have contributed to this success and is excited about the future accomplishments ahead.

0 notes

Text

IFGL's State-of-the-Art Research Centre at Kalunga!

As the pioneer in flow control solutions in India, IFGL Refractories is always on the lookout for opportunities to take refractory technologies to the next level. Our state-of-the-art Research Centre at Kalunga, India underlines an important dimension to our operations, with a focus on basic research in developing indigenous raw materials and new product development in synchronisation with emerging process changes in user industries. With a carefully assembled team of internationally experienced and exposed researchers, the Centre drives the flow of innovation in the field of refractory solutions.

#refractory#ifglrefractories#steelindustries#steelmanufacturing#refractory solutions#refractory companies

0 notes

Text

IFGL Refractories is fueled by the ethos of sharing, both in the present and every day! Our recent celebratory gathering at the Kalunga Shilpanchal Bidyalaya, featuring a heartwarming Sweater Distribution event, marked the beginning of the holiday season. With the presence of our esteemed COO, Mr. Arasu S., and the joyous smiles of the children, the event truly encapsulated the spirit of the festivities.

0 notes

Text

Inspiring young minds is, and will always be, a priority for #IFGLRefractories.

Our Chairman Shishir Kumar Bajoria and MD James McIntosh recently visited the IFGL-supported Kalunga Shilpanchal Bidyalaya, along with other key company dignitaries. With an amazing lineup of cultural activities, sports events, science exhibition, personal interactions, felicitations & more, the day was truly enjoyable and underlined our commitment towards nurturing the leaders of tomorrow.

To know more, visit us: ifglgroup.com

0 notes

Text

IFGL Announces Academic Excellence Reward Scheme For Team-Members’ Wards

IFGL's outstanding initiative to nurture young minds and assist them in their academic pursuits. Through the Academic Excellence Reward Scheme, IFGL acknowledges the academic brilliance of the children/wards of their team-members with merit scholarships. The scheme, for performance in Xth and XIIth standard examinations, underlines IFGL's promise of encouraging education and growing as an extended family.

0 notes

Text

Refractories Solutions Worldwide | IFGL Refractories

With 10 strategically located manufacturing units across Asia, Europe and North America, we deliver specialised refractories and operating systems to clients from 50+ countries. As one of the fastest growing brands in this industry, we are committed to taking the sector forward by setting new benchmarks in metallurgical excellence.

0 notes

Text

Industrial Promotion and Investment Corporation of Odisha Limited

We are proud to announce that the Industrial Promotion and Investment Corporation of Odisha Limited has given approval to IFGL Refractories to set up a new manufacturing facility for Continuous Casting Refractories in Odisha, with an installed capacity of 240,000 pieces per annum.

Odisha has been selected for its mineral wealth, excellent infrastructure, abundance of well-trained people, and future high concentration of steel manufacturing. This ₹150 crore project will have a commercial production target of March 2025 and will be our second manufacturing facility in Odisha and fourth in India. Read the full news… https://shorturl.at/juJT4

#IFGL#IFGLRefractories#GrowthUpdates#IFGLGrowthStory#WeAreIFGL#SteelManufacturing#SteelIndustries#CastingIndustry#Refractory

0 notes

Text

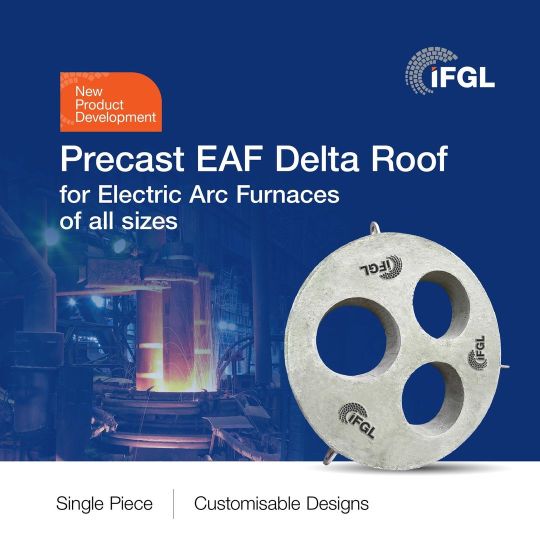

Precast EAF Delta Roof for Electric Arc Furnances of all sizes

IFGLRefractories is constantly looking to push the boundaries of refractory performance, with new products and technologies. We have developed a single-piece Precast #EAF Delta Roof for electric arc furnaces of any size. With easy assembly & installation, and option to create different shapes, the product is designed to meet precise customer requirements.

#IFGL#IFGLRefractories#EAF#ElectricArcFurnace#IndustrialSolutions#SteelManufacturing#SteelIndustries#CastingIndustry#Refractory

0 notes

Text

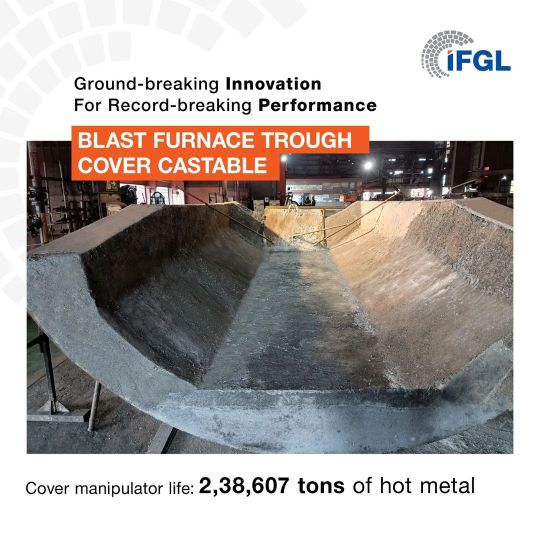

Blast furnace trough cover castable

Through continuous innovation, we push the boundaries of refractory performance, delivering value to our customers worldwide.

Our new alumina-silicon carbide-carbon-spinel trough cover castable (no cement) for blast furnaces was recently used for one of our esteemed customers, to enhance Cover Manipulator life to a record 2,38,607 tons of hot metal. We thank them for their constant support, and promise to keep setting the bar higher.

#IFGL#IFGLRefractories#Refractory#BlastFurnace#Furnace#Innovation#SteelManufacturing#SteelIndustries#CastingIndustry

0 notes

Text

SAIL Bhilai Steel Plant (BSP) for achieving a record-breaking tundish sequence

Congratulations to SAIL Bhilai Steel Plant (BSP) for achieving a record-breaking tundish sequence (at SMS-2 Bloom Caster-5) of 22 heats and a casting duration of 24 hours and 35 minutes, with our specialised tundish refractories.

We are proud to be a part of this achievement and look forward to many more success stories.

0 notes

Text

IFGL Refractories recently participated in a Road Safety Awareness Training programme

IFGLRefractories recently participated in a Road Safety Awareness Training programme, organised by the Traffic Police Department, East Kutch, Gandhidham, at our Kandla facility. We thank PSI Mr. V.P. Ahir for conducting an informative session on road safety for our team-members. To spread safety awareness, ‘No Helmet No Entry’ posters were also put up at Security Gate 1. 50+ IFGL team members, including Mr. Subrata Talukdar (VP), Mr. Jagdish Padhiyar (HR) and Mr. Prashant Ganorkar (Production) took part in the event, and it was a big success.

0 notes