#incoloy

Text

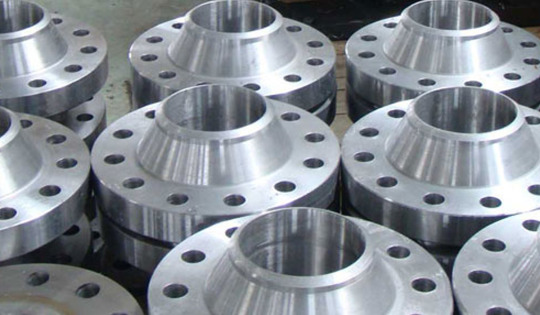

Incoloy 800 Flanges

In high-temperature environments where corrosion resistance and mechanical strength are paramount, the choice of materials for critical components becomes crucial. In such demanding conditions, Incoloy 800 emerges as a reliable solution, particularly for flange applications. In this article, we delve into the characteristics, applications, and advantages of Incoloy 800 flanges, shedding light on why they are favored across various industries.

Understanding Incoloy 800:

Incoloy 800 is a high-strength nickel-iron-chromium alloy renowned for its exceptional resistance to oxidation, carburization, and high-temperature exposure. With its unique composition of nickel, chromium, and iron, coupled with the addition of aluminum and titanium for enhanced strength and stability, Incoloy 800 exhibits remarkable mechanical properties even in the most challenging thermal environments.

The Role of Flanges:

Flanges serve as critical components in piping systems, facilitating connection, disconnection, and maintenance while ensuring leak-proof seals. In high-temperature applications, flanges are subjected to thermal cycling, mechanical stresses, and corrosive agents, demanding materials capable of withstanding such conditions without compromising performance or safety.

Applications:

Incoloy 800 flanges find extensive application across various industries, including:

Petrochemical: Incoloy 800 flanges are used in refinery operations, chemical processing plants, and petrochemical facilities for applications such as furnace components, heat exchangers, and reaction vessels.

Power Generation: Incoloy 800 flanges are employed in power plants for boiler components, steam turbines, and exhaust systems, where they withstand high temperatures and corrosive environments.

Aerospace: Incoloy 800 flanges find application in aircraft engines, exhaust systems, and combustion chambers, where they endure extreme heat and mechanical stresses.

Heat Treatment: Incoloy 800 flanges are utilized in heat treatment furnaces, annealing equipment, and thermal processing systems, where they maintain dimensional stability and mechanical strength at elevated temperatures.

Conclusion:

Incoloy 800 flanges represent a pinnacle of engineering excellence, offering unparalleled resistance to high temperatures, corrosion, and mechanical stresses. Their versatility, reliability, and ease of fabrication make them indispensable across a spectrum of industries, ensuring the integrity and efficiency of critical piping systems in extreme thermal environments. As industries continue to push the boundaries of temperature and performance, the enduring appeal of Incoloy 800 flanges remains steadfast, promising continued innovation and advancement in high-temperature materials engineering.

0 notes

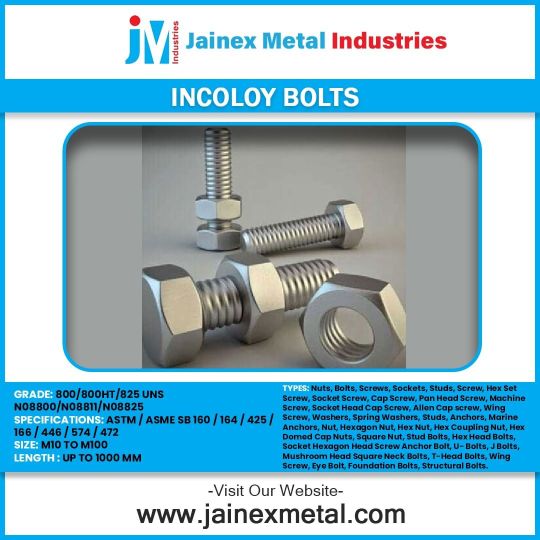

Photo

INCOLOY GRADE ALL TYPES OF BOLTS, NUTS AND WASHER #incoloy #incoloy825 #incoloy800h #incoloy800 #incoloy800ht #alloy825 #hexbolt #hexscrew #hexnut #washer #locknut #springwasher #allencapbolt #allencapscrew #cskscrew #manufacture #exporters #stockists #jainexmetalindustries (at India Mumbai) https://www.instagram.com/p/ClV0SWoynfC/?igshid=NGJjMDIxMWI=

#incoloy#incoloy825#incoloy800h#incoloy800#incoloy800ht#alloy825#hexbolt#hexscrew#hexnut#washer#locknut#springwasher#allencapbolt#allencapscrew#cskscrew#manufacture#exporters#stockists#jainexmetalindustries

0 notes

Text

INCOLOY 800H/N08810 NICKEL ALLOY PIPE/TUBE

Incoloy 800H is a slightly modified version of Incoloy 800 with the 800H grade possessing higher creep and rupture strength. The modification of incoloy alloy 800H pipe is possible because of the closely controlled carbon content and modified heat treatment.

INCOLOY ALLOY 800H PIPE EQUIVALENT SPECIFICATION

Country

Body

Grade

USA

UNS

N08800

France

AFTER

Z8NC 32.21

GB

BS

NA 15

Germany

DIN

1.4876

INCOLOY ALLOY 800H PIPE PHYSICAL PROPERTIES

Properties

Metric Units

Density

7,940 kg /m3 @ 20℃

Melting Range

1357-1385. ℃

Electrical Resistivity

0.989 micro-ohm. m @ 20℃

Specific Heat

460y / kg. ℃@ 20℃

Mean Coefficient of Expansion

14. 4x10 / ℃ @ 20℃

Thermal Conductivity

11. 5W / m. @ 20℃

Curie Temperature

-115℃

Modulus of Elasticity

Tension

196.5 Gpa @ 20℃

Torsion

73.4 Gpa @ 20℃

Poisson's Ratio

0 . 339 @ 20℃

INCOLOY ALLOY 800H PIPE CHEMICAL COMPOSITION

Element

Incoloy 800

Incoloy 800H

Incoloy 800HT

Nicke

30.00-35.00

30.00-35.00

30.00-35.00

Chromium

19.00-23.00

19.00-23.00

19.00-23.00

Iron

39.50 min

39.50 min

39.50 min

Carbon

0.10 max

0.10 max

0.10 max

Aluminum

0.15-0.60

0.15-0.60

0.25-0.60

Titanium

0.15-0.60

0.15-0.60

0.25-0.60

Aluminum + Titanium

0.30-1.20

0.30-1.20

0.30-1.20

ASTM Grain Size

Not Specified

5 or Coarser

INCOLOY ALLOY 800H PIPE MECHANICAL PROPERTIES

Incoloy 800H/N08810 Nickel Alloy Pipe/Tube

Yield Strength

Tensile Strength

Elongation

Mpa

Mpa

%

Incoloy 800, 800H, 800HT

Hot Finished Annealed

170

450

30

Incoloy 800

Cold Worked. Annealed

205

520

30

INCOLOY ALLOY 800H PIPE HIGHLIGHTS

Incoloy 800H(UNS N08810) pipe has a restricted carbon content range of 0.05 to 0.10%, which is in the upper portion of that of Incoloy 800 tube and is annealed at 1149 to 1177℃ (Incoloy 800 is annealed at 983 to 1038℃). These differences impart Incoloy 800H pipe to have higher stress rupture and creep properties than Incoloy 800.

https://www.nickelalloytubes.com/products/incoloy-800h-n08810-nickel-alloy-pipe-tube.html

0 notes

Text

Incoloy 800 Pipes & Tubes are high-performance alloy pipes and tubes made from Incoloy 800, a nickel-iron-chromium alloy. They are available in both seamless and welded forms.

#Incoloy 800 Pipes & Tubes#Incoloy 800 Pipes & Tubes Manufacturers#Incoloy 800 Pipes & Tubes Suppliers

2 notes

·

View notes

Text

Sinopec-approved flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C offers a wide quality extent of Incoloy 800/800H/800HT Flanges, which has presumably the best components like high versatility, outrageous arrangement, strength and that is only the start. Incoloy 800 Slip on Flanges (UNS N08800) is used for process piping, heat exchangers, warming part sheathing, carburizing gear, and nuclear steam-generator tubing. Incoloy 800 Flanges (UNS N08810) has added carbon and reinforcing treatment that considers higher jerk and break properties at 1100 Degree F (800 Degree C).

Incoloy 800 Weld Neck Flanges (UNS N08811) is a nickel-iron-chromium blend, which has a significant part of the comparable characteristics of various people from the 800 composite social occasion. Meanwhile, these Incoloy 800 Outwardly weakened flanges are furthermore being introduced in different sizes and shapes to our clients. We moreover offer these Incoloy 800H Connection Weld Flanges at market driving expenses. Also, similarly as with standard austenitic treated prepares, Incoloy 800 Lap Joint Flanges may be welded using methodologies like MIG, TIG, and shield metal round portion welding. Incoloy 800 Ring Joint Sort Flanges is impenetrable to chloride molecule stress utilization breaking.

The nickel content makes Incoloy 800 Presentation Blind Flanges astoundingly impenetrable to both chloride stress-utilization breaking and to embrittlement from precipitation of sigma stage. Incoloy 800 Spacer Flanges is ordinarily used in electric arrive at warming-part sheathing; steam methane further developing radiators and removed tubing for ethylene; smelling salts refluent coolers, etc. Incoloy 800HT Long Weld Neck Flanges is in like manner used in Compound and Petrochemical dealing.

#Incoloy 800/800HT Flanges Manufacturers in UAE#Incoloy 800/800HT Flanges Suppliers in UAE#Incoloy 800/800HT Flanges Stockists in UAE

2 notes

·

View notes

Text

Incoloy 825 Flanges

Sankalp Alloys Overseas are Manufacturers, Provider, and Exporters of Incoloy 825 Flanges that is Produced using Phenomenal Unrefined parts. Incoloy 825 Flanges are Accessible in various grades and sizes, shapes. we offer these things at additional reasonable costs and these Flanges have a stunning income in the neighborhood as well as the overall market.

INCOLOY 825 ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation: ASTM / ASME B 564 / SB 564

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size: 1/2″NB TO 60″NB

Grades: Incoloy 825 (UNS N08825) Flanges, 2.4858

Pressure: DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

7 notes

·

View notes

Text

Inconel 800HT Flanges

Technolloy Inc. is the Manufacturers, Suppliers, and Exporters of Incoloy 800HT flanges that are conveyed using astonishing and disturbing perspectives. Incoloy 800HT flanges are available in different grades, sizes, and shapes. These Incoloy 800HT flanges are scratched by most saw makers, who, in general, take goliath-contemplated heads for worth and standard.

INCOLOY 800/800H/800HT ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard : ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation : ASTM / ASME B 564 / SB 564

Class : Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size : 1/2″NB TO 60″NB

Grades : Incoloy 800 (UNS N08800) Flanges, 2.4876

Pressure : DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

For more information

Email us [email protected]

Call us :(022) 67437682

Website : https://www.technolloy.com/incoloy-alloy-800-800ht-flanges-manufacturer-exporter-supplier.html

2 notes

·

View notes

Text

Astm B408 Incoloy 800 Round Bars Supplier and Exporter in Saudi arabia | Anand steels

The ASTM B408 Incoloy 800 round bars are high-performance alloy products designed for applications requiring excellent resistance to oxidation and carburization at elevated temperatures. Manufactured to meet stringent industry standards, these bars are ideal for use in chemical processing, power generation, and heat exchangers. Available in various diameters and lengths, the Incoloy 800 round bars are supplied and exported in Saudi Arabia, ensuring reliable quality and timely delivery for diverse industrial needs.

0 notes

Text

Incoloy 800HT Flanges Manufacturers

Incoloy 800, a nickel-iron-chromium alloy, is well-known for its excellent strength and resistance to oxidation, carburization, and other high-temperature corrosion. One of the primary applications of this alloy is in the manufacturing of flanges, essential components in various industrial piping systems. In this article, we delve into the properties, benefits, and applications of Incoloy 800 flanges, as well as highlighting some prominent suppliers in the market.

Properties of Incoloy 800

Incoloy 800 is prized for its remarkable properties that make it suitable for high-temperature applications. These properties include:

High-Temperature Strength: Incoloy 800 retains its strength and stability at elevated temperatures, making it ideal for use in environments where thermal stability is crucial.

Corrosion Resistance: This alloy offers excellent resistance to oxidation, sulfidation, and carburization, providing longevity and reliability in harsh environments.

Metallurgical Stability: Incoloy 800 maintains its microstructure and resists sensitization, thus preventing intergranular corrosion.

Benefits of Using Incoloy 800 Flanges

Using Incoloy 800 flanges in industrial applications comes with several benefits:

Durability: The high strength and corrosion resistance of Incoloy 800 ensure that the flanges have a long service life, reducing maintenance and replacement costs.

Versatility: These flanges can be used in a wide range of temperatures and environments, making them suitable for various industrial applications.

Reliability: The alloy's stability at high temperatures ensures consistent performance, crucial for maintaining the integrity of piping systems.

Applications of Incoloy 800 Flanges

Incoloy 800 flanges find applications in several industries, including:

Chemical Processing: Due to its resistance to corrosive chemicals, Incoloy 800 is used in heat exchangers, process piping, and other components in chemical plants.

Power Generation: The alloy's ability to withstand high temperatures makes it suitable for use in steam generators and other high-temperature components in power plants.

Petrochemical Industry: Incoloy 800 flanges are used in refining processes, where high temperatures and corrosive environments are common.

Heat Treatment Equipment: The alloy's stability and resistance to oxidation make it ideal for use in furnaces and other heat treatment equipment.

Prominent Suppliers of Incoloy 800 Flanges

Several suppliers specialize in providing high-quality Incoloy 800 flanges. Some notable suppliers include:

Special Metals Corporation: A leading manufacturer of nickel alloys, including Incoloy 800, Special Metals offers a range of products for high-temperature and corrosion-resistant applications.

NeoNickel: Known for its extensive inventory and expertise in high-performance alloys, NeoNickel provides Incoloy 800 flanges suitable for various industrial applications.

Rolled Alloys: With a strong focus on quality and customer service, Rolled Alloys offers a comprehensive range of Incoloy 800 products, including flanges, pipes, and fittings.

For More Information:

Visit Our Website - https://technolloy.com/

Call Us –(022)49617682

E-mail - [email protected]

0 notes

Text

Incoloy Alloy 800/800HT/825 Forged Fittings

Introduction

In the world of industrial manufacturing and engineering, materials that can withstand extreme environments are crucial. Incoloy alloys, particularly Incoloy 800, 800HT, and 825, are known for their exceptional performance in high-temperature and corrosive environments. These alloys are widely used in various industries, including chemical processing, power generation, and oil and gas. Forged fittings made from these alloys are essential components in these industries due to their superior mechanical properties and resistance to oxidation and carburization. Ranflex Metals, a leading manufacturer in the field, specializes in producing high-quality Incoloy Alloy 800/800HT/825 forged fittings, ensuring reliability and durability in critical applications.

Understanding Incoloy Alloys

Incoloy 800

Incoloy 800 is an iron-nickel-chromium alloy with excellent resistance to oxidation and carburization at high temperatures. It maintains its structural integrity and strength even when exposed to extreme temperatures, making it ideal for applications such as furnace components, heat exchangers, and petrochemical processing equipment. Its composition typically includes 30-35% nickel, 19-23% chromium, and trace amounts of aluminum and titanium, which enhance its stability and resistance to scaling.

Incoloy 800HT

An enhanced version of Incoloy 800, Incoloy 800HT contains higher levels of carbon, aluminum, and titanium, providing improved creep and stress rupture properties. This makes Incoloy 800HT particularly suitable for applications requiring prolonged exposure to high temperatures. Industries that benefit from this alloy include nuclear power plants, where it is used in steam generators and heat exchangers, and petrochemical processing, where it finds applications in high-temperature reaction vessels and catalytic support grids.

Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This unique composition offers outstanding resistance to both reducing and oxidizing acids, as well as to stress-corrosion cracking. It is extensively used in environments where sulfuric and phosphoric acids are present. Typical applications of Incoloy 825 include chemical processing, pollution control equipment, and oil and gas well piping.

The Role of Forged Fittings

Forged fittings are critical components in piping systems, providing secure and leak-proof connections. The forging process involves shaping metal using compressive forces, resulting in a product with a dense and uniform grain structure. This enhances the mechanical properties of the fittings, making them stronger and more reliable than cast or machined fittings.

Ranflex Metals: Excellence in Forged Fittings

At Ranflex Metals, we pride ourselves on producing top-quality Incoloy Alloy 800/800HT/825 forged fittings. Our state-of-the-art manufacturing facility and stringent quality control measures ensure that each fitting meets the highest standards of performance and durability.

Our Product Range

Elbows: Available in various angles, our Incoloy elbows provide smooth directional flow in piping systems, reducing turbulence and pressure drop.

Tees: Our tees are designed to distribute fluid flow evenly, ensuring efficient operation of your piping network.

Reducers: Used to connect pipes of different diameters, our reducers ensure a seamless and secure transition.

Couplings: Our couplings provide a reliable connection between two pipes, ensuring leak-proof performance.

Quality Assurance

Ranflex Metals is committed to delivering products that meet or exceed customer expectations. Our Incoloy forged fittings undergo rigorous testing, including:

Chemical Analysis: Ensuring the precise composition of the alloy.

Mechanical Testing: Verifying tensile strength, hardness, and impact resistance.

Non-Destructive Testing: Detecting any surface or internal defects to ensure the integrity of the fittings.

Conclusion

Incoloy Alloy 800, 800HT, and 825 forged fittings are indispensable in industries where high-temperature and corrosion-resistant materials are required. Ranflex Metals stands out as a trusted supplier, providing high-quality forged fittings that meet the demanding requirements of various applications. Our commitment to excellence and customer satisfaction makes us a preferred choice for Incoloy forged fittings. When it comes to ensuring the reliability and durability of your piping systems, trust Ranflex Metals to deliver the best.

#Incoloy Forged Fittings#Incoloy Alloy 800/800HT/825 Forged Fittings#ASTM B564 Incoloy Alloy UNS N08800/11/25 Forged Fittings#825 Incoloy Alloy reducer#800 Incoloy elbow#800 stainless steel tee#601 Incoloy Alloy cross#825 Incoloy Alloy stub closes#825 Incoloy Alloy channel twist#800 Incoloy Alloy short range elbow Suppliers India

0 notes

Photo

We are Manufacturers and Exporters of INCOLOY PRECISION TURNED COMPONENTS As Per Customers Drawings and Requirements. #incoloy #incoloy800 #incoloy825 #incoloy800h #machinedcomponents #precisionturnedparts #precisionturnedcomponents #nickelalloys #alloy800 #incoloy800ht #alloy825 #manufacturer #exporters #jainexmetalindustries #machineparts #forgingring #mechanicalseal #mechanicalseals #mechanicalsealsforpump #mechanicalsealsupplier (at India Mumbai) https://www.instagram.com/p/ClVcyn7yqI-/?igshid=NGJjMDIxMWI=

#incoloy#incoloy800#incoloy825#incoloy800h#machinedcomponents#precisionturnedparts#precisionturnedcomponents#nickelalloys#alloy800#incoloy800ht#alloy825#manufacturer#exporters#jainexmetalindustries#machineparts#forgingring#mechanicalseal#mechanicalseals#mechanicalsealsforpump#mechanicalsealsupplier

0 notes

Text

Quality Assurance Manufacturer of Incoloy 825/ DIN 2.4858/ UNS N08825 Round Bars in India with Piyush Steel.

Precision Manufacturer of Incoloy 825/ DIN 2.4858/ UNS N08825 Round Bars in India is our area of expertise at Piyush Steel, and we guarantee that every bar satisfies strict international requirements. Our dedication to excellence guarantees dependability and durability in demanding settings. Our bars provide reliable performance and longevity for a variety of industries, including the oil and gas, maritime, and chemical processing sectors.

Contact Us

0 notes

Text

Incoloy 825 Bars Exporters In India - Chhajed Steel Limited

#Incoloy 825 Bars Manufacturers#Incoloy 825 Bars Suppliers#Incoloy 825 Bars Stockists#Incoloy 825 Bars Exporters#Incoloy 825 Bars Manufacturers In India#Incoloy 825 Bars Suppliers In India#Incoloy 825 Bars Stockists In India#Incoloy 825 Bars Exporters In India

0 notes

Text

ThaiOil-approved flanges in UAE

Being a quality driven firm, Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is offering a quality-upheld group of Incoloy 825 Flanges to the clients. Chromium content in Incoloy 825 Slip on Flanges (UNS N08825) gives assurance from oxidizing conditions, as nitric destructive courses of action, nitrates and oxidizing salts. These Incoloy 825 Scene Blind Flanges sidesteps pressure-disintegration-breaking and has extraordinary weldability by each normal communication.

Incoloy 825 Weld Neck Flanges accepts a basic part in heat exchangers for engineered dealing with, pollution control gear, oil well and gas gathering pipes - even as clad steel pipes - where security from stress breaking or general utilization to an extent of diminishing or oxidizing acids is normal. Meanwhile, these Incoloy 825 Lap Joint Flanges are similarly being introduced in different sizes and shapes to our clients. Between the Molybdenum, Nickel and Titanium, Incoloy UNS N08825 Hung Flanges gives phenomenal insurance from sulfuric and phosphoric acids.

These Incoloy 825 Weld Flanges is by and large used in Air - cooled heat exchangers in oil refineries, Engineered and Food Taking care of. Incoloy 825 Outwardly impeded Flanges is fundamental for totally clean all traces of lubes directly following molding as embrittlement of the composite would occur at high temperatures thusly. These Incoloy 825 Ring Joint Sort Flanges is titanium offset to go against pitting and cover - granular attack after produce, particularly welding, which warmed for the fundamental refinement temperature range (650 Degree C - 760 Degree C).

#Incoloy 825 Flanges Manufacturers in Dubai#Incoloy 825 Flanges Suppliers in Dubai#Incoloy 825 Flanges Stockists in Dubai#Incoloy 825 Flanges Exporters in Dubai#TCO Tengizchevroil Approved Flanges in Oman

2 notes

·

View notes

Text

Its application in a salty environment, nuclear power plants, exhaust systems, disposing of radioactive waste, and other areas is heavily discussed in the market. Because to their high fortitude due to the copper-molybdenum content, Incoloy 825 Sheets & Plates are perfect for businesses. The strategies of opening utilization, stress utilization breaking, intergranular disintegration, and phosphoric and sulfuric destructive pitting are all impermeable. It is not recommended to use Incoloy 825 Sheets and Plates in a machine at the medium where exceptional breakage properties are needed

#Incoloy 825 Sheets & Plates Manufacturers#Incoloy 825 Sheets & Plates Suppliers#Incoloy 825 Sheets & Plates Stockists#Incoloy 825 Sheets & Plates Exporters#Incoloy 825 Sheets & Plates Manufacturers in India

0 notes