#industrial ceramic coating services

Text

Shaping the Future of Car Detailing: Innovations and Technologies

youtube

In the exploration of "Shaping the Future of Auto Detailing: Innovations and Technologies," we delve into the revolutionary changes sweeping through the car detailing industry that combines artistry with science. The car detailing industry is rapidly evolving, transcending from traditional hand-polishing to advanced techniques like nano-coatings and AI diagnostics. This transformation emphasizes not only aesthetic enhancement but also vehicle longevity and eco-friendliness. In this blog, we explore how AI, sustainable practices, and awareness of chemical use are reshaping the car wash sector into a more advanced and environmentally conscious service.

The Evolution of Car Detailing

"The Evolution of Car Detailing Services" traces the journey from simple washes to high-tech care. Discover how traditional waxing has given way to nano-technology and eco-friendly products, revolutionizing how we maintain our vehicles. This exploration delves into the advancements in materials and methods, highlighting how modern detailing not only enhances a car's appearance but also extends its life and respects the environment, marking a new era in automotive care where innovation meets tradition in the pursuit of perfection.

youtube

Breakthrough Technologies Reshaping Detailing

In today's modern era, the Auto detailing industry is diving into simple yet innovative tools and methods that are changing the way cars are cared for. Learn about cool new gadgets that make cleaning easier and faster and intelligent products that keep your car looking newer for longer. This easy-to-understand blog is perfect for anyone curious about how technology is making car detailing services more compelling and exciting than ever!

Sustainability in Car Detailing

Sustainability in auto detailing is about eco-friendly practices to keep cars clean and protected. It involves using biodegradable cleaners, water-saving techniques, and reusable cloths. These methods not only ensure a sparkling vehicle but also protect the environment. By minimizing chemical runoff and conserving water, sustainable car detailing contributes to a healthier planet. It's a responsible approach that combines car care with environmental awareness.

youtube

Automation and Digitization in Detailing

Automation and digitization in detailing revolutionize how we care for vehicles. By integrating advanced technology, tasks like cleaning, polishing, and waxing become more precise and efficient. Automation speeds up processes, ensuring consistent quality, while digitization offers enhanced control and monitoring, allowing for customized detailing on a granular level. This technological approach not only elevates the standard of car care but also streamlines operations, making detailing quicker and more effective, and opening doors to innovative car maintenance techniques.

Advanced Protective Coatings and Films

Technology has transformed the car wash sector, marking a new phase of heightened efficiency and superior performance. At the forefront of these developments is the adoption of Artificial Intelligence (AI). Moreover, the trend towards automation is increasingly evident, with advanced touchless and soft-touch technologies ensuring meticulous cleaning while reducing the risk of damage to vehicles. Also, in the installation of paint protection film, the industry has come up with AI pre-cut technology. You can also customize the pre-cut pattern according to car body kits, panels, shapes, and edges. Such advanced automation enhances the customer experience by delivering speedy and effective service, and it also significantly reduces labor expenses, a critical factor in a sector often characterized by slim profit margins.

youtube

Future Trends and Predictions

In the future, the car wash business is going to change a lot. One significant change is using intelligent sensors for predictive maintenance. These sensors can tell when a machine might break down before it happens. This will help car washes work better and their machines last longer. Also, mobile apps and online services will become more critical. They'll make it easier for people to book and pay for car washes whenever they want. As more businesses start using digital technology, the car wash industry is also getting ready to use these new ways of working.

Conclusion

In conclusion, the future of car detailing is bright and brimming with innovation. As we've explored, advancements in technology like predictive maintenance and the integration of digital platforms are transforming the industry. These changes promise not only enhanced efficiency and precision in car care but also a more personalized and convenient experience for consumers. The adoption of these technologies signals a shift towards a more sustainable, reliable, and user-friendly approach to car detailing services.

Source: https://thedetailingmafia.blogspot.com/2024/01/shaping-future-of-car-detailing.html

#Car Detailing#Car Detailing Services#car detailing industry#paint protection film#ceramic coating#car ppf#ceramic car coating#ceramic coating near me#the detailing mafia#Youtube

0 notes

Text

youtube

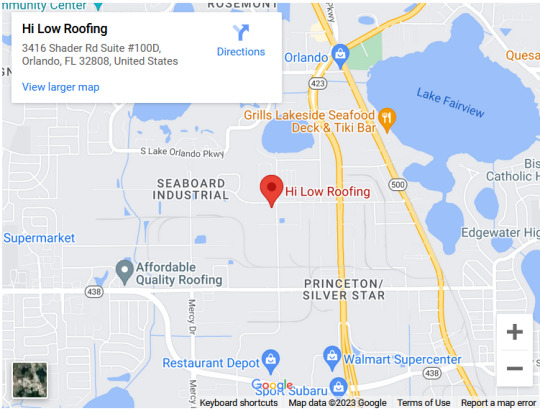

Business Name:

Hi Low Roofing

Street Address 1:

3416 Shader Rd

Street Address 2:

Suite #100D

City:

Orlando

State:

Florida (FL)

Zip Code:

32808

Country:

United States

Business Phone:

(407) 988-0054

Business Email:

[email protected]

Website:

https://hilowroofing.com/

Facebook:

https://www.facebook.com/HiLowRoof

Instagram:

https://www.instagram.com/hilowroofing/

Twitter:

https://twitter.com/hilowroofing

YouTube:

https://www.youtube.com/channel/UCiyw18kgm50KNxp03u4b2uw

Tumblr:

https://www.tumblr.com/hilowroofing-orlando

Business Description:

From new construction to roofing repairs to preventative maintenance, all your roofing problems in Orlando can be resolved by Hi Low Roofing. We are a team of professional roofers that can handle roof repair and replacements on residential roofs, commercial roofs, or specialty roofs. We are one of the top roofing companies in the greater Orlando area, and we have experience working with a wide variety of products, including composition shingles, asphalt shingles, metal roofs, tile roofs, PVC, and TPO. We can also work with flat roofs, roof coating, PVC, and single ply roofing, and there are many more options available. Be sure to consider us when you’re choosing a roofer for your next roofing repair or roof replacement in Orlando, FL.

Google My Business CID URL:

https://www.google.com/maps?cid=4395002910487231597

Business Hours:

Sunday Closed

Monday 8:00am-5:00pm

Tuesday 8:00am-5:00pm

Wednesday 8:00am-5:00pm

Thursday 8:00am-5:00pm

Friday 8:00am-5:00pm

Saturday Closed

Payment Methods:

Cash, Debit Card, Visa, Master, Amex, Discover

Services:

Shingle Roofing ,Tile Roofing ,Metal Roofing ,TPO Roofing ,Modified Bitumen Roofing ,Roof Coating ,Roof inspection ,Roof installation ,Roof repair ,Attic venting ,Gutter installation ,Gutter repairs ,Roof damage repair ,Skylight installation ,Skylight repair ,Roof repair for storm & wind damage ,All Types Of Roofing ,Commercial Reroof ,Commercial Shingles ,Free Quote Roofing ,Free Roofing Assessment ,General Contracting ,Installing New Roofs ,Minor Repair ,Modified Bitumen Roofing ,New Construction Building ,New Construction Project ,New Construction Roofing ,Prime Roofing ,Remove Shingles ,Replacement Roofing Problems ,Residential And Commercial Roofing ,Residential Shingle Roofing ,Roof Leaks ,Roofing Created ,Roofing Design ,Roofing Jobs ,Roofing Metal Roofing ,Roofing Options ,Roofing Projects ,Roofing Specialists ,Roofing Tile Roofing ,Shingle Roofing Tile ,Small Roofing Repairs ,Temporary Labor ,Tile Roofing Metal ,Tpo Roofing ,Cement Roofing ,Ceramic Tile ,Chimney Caps ,Clay Roof ,Commercial Flat Roofing ,Commercial Shingle Roofing ,Complete Roofing Installations ,Concrete Tile Roofs ,Drip Edges ,Energy Efficient Roofing ,Flat Roofing Systems ,Free Roofing Quote ,Full Roof Replacement ,Leaking Roof ,Metal Sheet Roof ,Minor Roof ,New Roof Replacement ,Periodic Maintenance ,Residential Flat Roof ,Residential Roof Replacement Services ,Residential Roofers ,Residential Roofing Systems ,Residential, Commercial, And Industrial Roofing ,Resin Coating ,Roof Coating Applying ,Roof Membrane ,Roof Sealer ,Roofing And Siding ,Roofing Modified ,Roofing Repair Work ,Roofing Solutions ,Shingle Roof Maintenance ,Siding Panels ,Slate Shingle ,Sloped Roofs ,Structural Engineering ,Water Damage

Keywords:

Shingle Roofing ,Tile Roofing ,Metal Roofing ,TPO Roofing ,Modified Bitumen Roofing ,Roof Coating ,Roof inspection ,Roof installation ,Roof repair ,Attic venting ,Gutter installation ,Gutter repairs ,Roof damage repair ,Skylight installation ,Skylight repair ,Roof repair for storm & wind damage ,All Types Of Roofing ,Commercial Reroof ,Commercial Shingles ,Free Quote Roofing ,Free Roofing Assessment ,General Contracting ,Installing New Roofs ,Minor Repair ,Modified Bitumen Roofing ,New Construction Building ,New Construction Project ,New Construction Roofing ,Prime Roofing ,Remove Shingles ,Replacement Roofing Problems ,Residential And Commercial Roofing ,Residential Shingle Roofing ,Roof Leaks ,Roofing Created ,Roofing Design ,Roofing Jobs ,Roofing Metal Roofing ,Roofing Options ,Roofing Projects ,Roofing Specialists ,Roofing Tile Roofing ,Shingle Roofing Tile ,Small Roofing Repairs ,Temporary Labor ,Tile Roofing Metal ,Tpo Roofing ,Cement Roofing ,Ceramic Tile ,Chimney Caps ,Clay Roof ,Commercial Flat Roofing ,Commercial Shingle Roofing ,Complete Roofing Installations ,Concrete Tile Roofs ,Drip Edges ,Energy Efficient Roofing ,Flat Roofing Systems ,Free Roofing Quote ,Full Roof Replacement ,Leaking Roof ,Metal Sheet Roof ,Minor Roof ,New Roof Replacement ,Periodic Maintenance ,Residential Flat Roof ,Residential Roof Replacement Services ,Residential Roofers ,Residential Roofing Systems ,Residential, Commercial, And Industrial Roofing ,Resin Coating ,Roof Coating Applying ,Roof Membrane ,Roof Sealer ,Roofing And Siding ,Roofing Modified ,Roofing Repair Work ,Roofing Solutions ,Shingle Roof Maintenance ,Siding Panels ,Slate Shingle ,Sloped Roofs ,Structural Engineering ,Water Damage

Owner Name, Email, and Contact Number:

Ben Benkiran, [email protected], (407) 988-0054

Location:

Service Areas:

2 notes

·

View notes

Text

ClearBra® Inc Window Tint - Clear Protection Film

Welcome to the ClearBra® Inc Window Tint - Clear Protection Film Utah. We are a leading St. George car detailing service company. Clearbra® Paint Protection Window tint Paint Correction Ceramic Coatings. The “Original” ClearBra® is the leader in paint protection film. We are the leading window tinting service in Saint George. Our headquarter is in Salt Lake City Utah. With over 28 years and over 30,000 vehicles covered in the industry, we can customize our film to cover any car with a professional installation. We also carry thousands of custom-cut kits in our database for the do-it-yourselfer. If you would like to protect the painted surface of your Car, Truck, Van, SUV, Boat, or Motorcycle from road debris, The Original ClearBra® has the solution for you. The Original CLEARBRA® can provide protection to cover the hood, fenders, mirrors, full front bumper, rocker panels, rear trunk, roof & a-pillars, headlights, window tinting and much more. There are a lot of options when it comes to a vehicle, such as headlight washers on bumpers, sport packages with different lower spoilers and exact coverage just to name a few. With our professional custom installations we use raw materials instead of pre-cut kits. We hand lay raw material onto total panels, which allows us to wrap the panel’s edges to produce truly stunning results with no visible edges or seams.

#window tinting service in st. george#st. george window tinting service#automotive window tinting service st. george#car protection st george#car detailing in st. george#saint george window tinting service#paint protection film st george#car detailing service in saint george#window tinting service in saint george#automotive window tinting service saint george#car protection saint george#car detailing in saint george#window tinting service near me in saint george#paint protection film saint george#paint protection film in Saint George#Car Protection#Car Detailing#Window Tinting#Window tinting st George#Clear Bra#Clear Auto Protection#clear film#car detailing service in st. george

2 notes

·

View notes

Text

Transform Your Car: The Essentials of Denting and Painting in Borivali

Maintaining the aesthetic appeal of your car isn’t just about appearances; it’s about preserving its value and ensuring longevity on the road. In bustling Borivali, where vehicle owners take pride in their rides, the need for reliable car denting and painting services is paramount. Whether it's due to a minor mishap or simply the wear and tear of daily commutes, addressing dents and scratches promptly is crucial for the overall health and appeal of your vehicle.

Understanding Car Denting:

Car dents can occur from various incidents, such as minor collisions, parking mishaps, or even from stray shopping carts. Despite their often superficial appearance, dents can compromise the structural integrity of your vehicle if left untreated. Professional car denting services in Borivali, like those offered at reputable establishments such as 3M Car Care Studio, employ skilled technicians equipped with advanced tools to effectively repair dents without compromising the original paint or finish of your car.

Techniques such as paintless dent repair (PDR) are commonly used for minor dents where the paint hasn't been damaged. This method preserves the original factory finish of your car, making it an environmentally friendly and cost-effective solution. For more severe dents or those involving paint damage, conventional dent repair methods are employed, ensuring a seamless finish that restores your car’s appearance to its former glory.

The Importance of Quality Painting Services:

When scratches, chips, or larger areas of paint damage occur on your car, professional painting services become essential. In Borivali, where the climate and road conditions can challenge the exterior of vehicles, opting for high-quality paint services ensures protection against corrosion and maintains your car’s visual appeal.

At 3M Car Care Studio and similar facilities in Borivali, expert painters use state-of-the-art color-matching technology and premium paint products to achieve flawless results. Whether it’s a full-body repaint or a touch-up to address localized damage, their meticulous approach ensures that the new coat blends seamlessly with the existing paint, leaving no trace of the previous imperfections.

Choosing the Right Service Provider

When selecting a car denting and painting service provider in Borivali, it’s crucial to consider factors beyond just affordability. Look for establishments like 3M Car Care Studio that prioritize quality craftsmanship, use trusted products, and offer warranties on their work. Reading customer reviews and testimonials can also provide valuable insights into the reliability and satisfaction level of past clients.

Additionally, inquire about the technology and techniques employed by the service provider. Modern facilities that utilize advanced equipment and environmentally friendly practices not only deliver superior results but also contribute to sustainable automotive maintenance.

Maintaining Your Investment

Beyond immediate repairs, regular maintenance plays a significant role in preserving the value of your vehicle. In Borivali, where the weather and road conditions vary, scheduling periodic inspections and protective treatments can safeguard your car against potential damage. Services such as rust protection, ceramic coating, and paint sealants are highly recommended to prolong the lifespan of your car’s exterior and maintain its showroom shine.

Conclusion

In conclusion, whether you’re dealing with a minor dent or in need of a comprehensive paint restoration, prioritizing professional car denting and painting services in Borivali is essential for both the aesthetic and functional integrity of your car. By choosing a reputable provider like 3M Car Care Studio, you ensure that your car receives the attention it deserves from skilled technicians using industry-leading techniques and materials.

To schedule your car’s denting and painting service or to learn more about our offerings, contact us at 3M Car Care Studio today. Our team is dedicated to providing exceptional service and ensuring your complete satisfaction with every visit.

Transform your car and maintain its allure—because, at 3M Car Care Studio, we understand that your car isn’t just a vehicle; it’s a reflection of your pride and style.

0 notes

Text

BEST CERAMIC COATING FOR BOATS AND YACHT - SEA SHIELD COATING

YOUR ATTENTION PLEASE : Boat detailers and yacht owners. Sea-Shield provides elite protective and restoration solutions – both products and services – for the mega-yacht and boating industry. We supply an entire system of restoration, protection, and maintenance products that produce unbelievable results for your watercraft - you'll simply be amazed!

SERVING THE MAJOR BOATING MARKETS IN THE (U.S.A), CARIBBEAN, MEXICO AND EUROPE

FOR THE RIGHT PROJECT WE WILL TRAVEL WITH A SEA-SHIELD TEAM TO GET YOUR BOAT OR YACHT SEA-SHIELD

#yacht product#boating product#boat#boating#yacht#usa#caribbean sea#mexico#mexico city#europe#watercraft

0 notes

Text

Mastering the Art of Silicon Carbide Nozzles: Engineering Marvels for Extreme Environments

In the ever-evolving landscape of high-temperature applications and extreme environments, silicon carbide (SiC) nozzles have emerged as true engineering marvels, offering unparalleled performance and durability. These exceptional components have revolutionized various industries, from aerospace and defense to manufacturing and energy production, enabling unprecedented advancements and pushing the boundaries of what is possible. This comprehensive guide delves into the intricacies of silicon carbide nozzles, exploring their unique properties, applications, and the cutting-edge technologies that make them an indispensable asset in extreme environments.

The Extraordinary Properties of Silicon Carbide

Silicon carbide, a remarkable ceramic compound composed of silicon and carbon, is renowned for its exceptional thermal, mechanical, and chemical properties. With a melting point exceeding 2700ᄚC (4892ᄚF), SiC boasts outstanding thermal stability, enabling it to withstand extreme temperatures without compromising its structural integrity. Its hardness, second only to diamond, translates into exceptional wear resistance, making it an ideal material for applications involving abrasive environments or high-velocity particle flows.

Moreover, silicon carbide exhibits remarkable chemical inertness, resisting corrosion and oxidation even in the most demanding conditions. This characteristic ensures prolonged service life and minimizes maintenance requirements, contributing to cost-effectiveness and operational efficiency. The unique combination of these properties makes SiC an ideal choice for high-temperature nozzle applications, where performance and reliability are paramount.

Precision Engineering: Crafting Perfection

The design and manufacturing of silicon carbide nozzles are intricate processes that demand precision engineering and cutting-edge technologies. These nozzles are typically manufactured through advanced techniques such as chemical vapor deposition (CVD), reaction bonding, or hot isostatic pressing (HIP), ensuring consistent quality and performance.

Intricate geometries and complex internal channels are meticulously crafted to optimize fluid dynamics, ensuring precise control over flow patterns and minimizing turbulence. Advanced computational fluid dynamics (CFD) simulations are employed to analyze and refine nozzle designs, enabling engineers to achieve optimal performance tailored to specific application requirements.

Furthermore, advanced surface treatments and coatings can be applied to silicon carbide nozzles, enhancing their performance and tailoring them to specific operating conditions. These coatings may include erosion-resistant materials, thermal barrier coatings, or specialized coatings designed to improve chemical resistance or thermal management.

Applications Pushing the Boundaries

Silicon carbide nozzles have found widespread applications across diverse industries, enabling unprecedented advancements and pushing the boundaries of what is possible in high-temperature environments. Here are some of the most prominent applications:

Aerospace and Defense:

Rocket nozzles: SiC nozzles are instrumental in solid rocket motors and liquid rocket engines, withstanding the extreme temperatures and erosive conditions during rocket firing. Their exceptional thermal stability and wear resistance ensure reliable performance and extended service life, making them a critical component in space exploration and defense applications.

Plasma spray nozzles: Used in plasma spray systems for thermal barrier coatings, these nozzles endure the high-temperature plasma jet without degradation, enabling the deposition of advanced protective coatings on critical components.

Manufacturing:

Sand blasting nozzles: The hardness and wear resistance of SiC make it ideal for sandblasting applications, ensuring prolonged service life and consistent performance. These nozzles enable efficient surface preparation and finishing processes in various manufacturing industries.

Cutting nozzles: SiC nozzles are employed in high-temperature cutting processes like oxy-fuel cutting and plasma cutting, enabling precise and efficient material processing. Their ability to withstand extreme temperatures and abrasive environments ensures accurate cuts and extended tool life.

Energy Production:

Furnace components: Silicon carbide is utilized to manufacture burner nozzles, thermocouple protection tubes, and other high-temperature furnace components, ensuring reliable operation and extended service life in demanding environments.

Gasification processes: SiC nozzles find applications in gasification systems, facilitating the conversion of solid or liquid feedstocks into syngas under extreme conditions. Their chemical inertness and thermal stability make them ideal for handling corrosive and high-temperature gases.

Research and Development:

High-temperature testing: SiC nozzles play a crucial role in research and development efforts involving high-temperature environments, enabling scientists and engineers to push the boundaries of material science and engineering. Their exceptional performance allows for accurate data collection and reliable testing under extreme conditions.

Advancements and Future Prospects

The field of silicon carbide nozzles is continuously evolving, driven by advancements in material science, manufacturing techniques, and application-specific requirements. Ongoing research efforts are focused on optimizing nozzle designs for improved flow dynamics, enhanced thermal management, and increased durability.

The integration of additive manufacturing technologies, such as 3D printing, is paving the way for innovative nozzle designs with complex geometries and internal structures tailored to specific applications. This synergy between cutting-edge manufacturing techniques and material science promises to unlock new potentials, driving efficiency, precision, and cost-effectiveness in various industries.

Furthermore, the development of new coating materials and surface treatments holds the promise of further enhancing the performance and lifespan of SiC nozzles. Researchers are exploring advanced coating systems that can provide additional protection against erosion, corrosion, and thermal degradation, extending the operational envelope of these nozzles in even more extreme environments.

As computational power and simulation capabilities continue to advance, the use of sophisticated computational fluid dynamics (CFD) simulations will become increasingly prevalent in the design and optimization of silicon carbide nozzles. These simulations will enable engineers to accurately predict fluid flow patterns, thermal gradients, and potential areas of wear or erosion, allowing for proactive design improvements and optimizations.

Leveraging Synergies for Groundbreaking Innovations

The future of silicon carbide nozzles lies in the seamless integration of cutting-edge technologies and multidisciplinary collaborations. By fostering synergies between material science, computational modeling, advanced manufacturing techniques, and application-specific expertise, engineers and researchers can unlock groundbreaking innovations in nozzle design and performance.

One exciting area of exploration is the development of hybrid nozzle systems, combining the exceptional properties of silicon carbide with other advanced materials or composites. These hybrid designs could leverage the strengths of multiple materials to create nozzles with tailored properties, such as enhanced thermal management, improved erosion resistance, or optimized fluid dynamics.

Additionally, the integration of smart sensing technologies and real-time monitoring systems could revolutionize the way silicon carbide nozzles are utilized and maintained. Embedded sensors could provide valuable data on operating conditions, wear rates, and potential failure points, enabling predictive maintenance strategies and proactive interventions to maximize service life and minimize downtime.

Conclusion: Mastering the Art of Extreme Engineering

Silicon carbide nozzles have proven to be true engineering marvels, enabling unprecedented performance and reliability in high-temperature and extreme environments. Their exceptional thermal stability, wear resistance, and chemical inertness make them indispensable components in applications ranging from aerospace and defense to manufacturing and energy production.

As technology continues to advance, the demand for silicon carbide nozzles is expected to grow, driving further innovation and advancements in material science and manufacturing techniques. By harnessing the extraordinary properties of these exceptional components, industries can push the boundaries of what is possible, enabling new frontiers in innovation and technological progress.

Through precision engineering, cutting-edge manufacturing processes, and continuous research and development, silicon carbide nozzles will continue to redefine the limits of what is achievable in extreme environments, empowering engineers and scientists to tackle ever-more challenging applications and unlocking new realms of possibility.

By mastering the art of silicon carbide nozzle design and manufacturing, visionary engineers and researchers will shape the future of extreme engineering, propelling humanity's ability to explore, create, and push the boundaries of what was once deemed impossible.

0 notes

Text

Thermal Barrier Coatings Market Opportunities and Forecast By 2028

This Thermal Barrier Coatings market report has been prepared by considering several fragments of the present and upcoming market scenario. The market insights gained through this market research analysis report facilitates more clear understanding of the market landscape, issues that may interrupt in the future, and ways to position definite brand excellently. It consists of most-detailed market segmentation, thorough analysis of major market players, trends in consumer and supply chain dynamics, and insights about new geographical markets. The market insights covered in Thermal Barrier Coatings report simplifies managing marketing of goods and services effectively.

Thermal barrier coatings market size is expected to grow at a compound annual growth rate of 7.43% for the forecast period of 2021 to 2028.

Download Sample PDF Copy of this Report to understand structure of the complete report @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-thermal-barrier-coatings-market

Market Overview:

Thermal barrier coating is largely used to protect the metal structural component from severe elevated temperatures. They resourcefully manage the heat exhaust and usually have four layers metallic bond coat, ceramic top coat, metal substrate and oxide developed thermally. They are also used in the automotive industry to decrease the heat from the exhaust system. Polymers, zirconia, aluminates and resins are used to produce thermal barrier coatings.

Some of the major players operating in the Thermal Barrier Coatings market are A&A Thermal Spray Coatings, Praxair S.T. Technology, Inc., Höganäs AB, ASB Industries, Inc., Zircotec, Flame Spray Coating Company, Integrated Global Services, Inc., Thermion, Metallisation Limited, Metallizing Equipment Co. Pvt. Ltd., Honeywell International Inc., Metallic Bonds, Ltd., Chromalloy Gas Turbine LLC, KOBE STEEL, LTD., DW Pearce Enterprises Ltd., Starshield Technologies Private Limited, TST Engineered Coating Solutions, The Fisher Borton Group, TWI Ltd and CTS, Inc., among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.among others.

Global Thermal Barrier Coatings Market Scope

Thermal barrier coatings market is segmented on the basis of product type, technology, coating combination, and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

On the basis of product type, the thermal barrier coatings market is segmented into metal, ceramic, intermetallic and others.

On the basis of technology, the thermal barrier coatings market is segmented into High-velocity oxy-fuel (HVOF), vapour deposition, air plasma and others.

Based on coating combination, the thermal barrier coatings market is segmented into ceramic YSZ, aluminum oxide, mcraiy and mullite-based.

The application segment for thermal barrier coatings market is segmented into stationary power plants, aerospace, automotive and others.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-thermal-barrier-coatings-market

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Thermal Barrier Coatings Market Landscape

Part 04: Global Thermal Barrier Coatings Market Sizing

Part 05: Global Thermal Barrier Coatings Market Segmentation By Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Browse Trending Reports:

Global Fishing Wader Market – Industry Trends and Forecast to 2030https://www.databridgemarketresearch.com/reports/global-fishing-wader-market

Global Avermactin Market - Industry Trends and Forecast to 2028https://www.databridgemarketresearch.com/reports/global-avermactin-market

Global Agriculture Chemical Packaging Market – Industry Trends and Forecast to 2028https://www.databridgemarketresearch.com/reports/global-agriculture-chemical-packaging-market

Global Smart Buildings Wi-Sun Technology Market – Industry Trends and Forecast to 2028https://www.databridgemarketresearch.com/reports/global-smart-buildings-wi-sun-technology-market

About Data Bridge Market Research:

An absolute way to predict what the future holds is to understand the current trend! Data Bridge Market Research presented itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are committed to uncovering the best market opportunities and nurturing effective information for your business to thrive in the marketplace. Data Bridge strives to provide appropriate solutions to complex business challenges and initiates an effortless decision-making process. Data Bridge is a set of pure wisdom and experience that was formulated and framed in 2015 in Pune.

Data Bridge Market Research has more than 500 analysts working in different industries. We have served more than 40% of the Fortune 500 companies globally and have a network of more than 5,000 clients worldwide. Data Bridge is an expert in creating satisfied customers who trust our services and trust our hard work with certainty. We are pleased with our glorious 99.9% customer satisfaction rating.

Contact Us: -

Data Bridge Market Research

Email: – [email protected]

#Thermal Barrier Coatings Market#Thermal Barrier Coatings Market Growth#Thermal Barrier Coatings Market Demand

0 notes

Text

Battery Material Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The global battery materials market size reached USD 54.1 billion in 2022 and is set to total USD 57.9 billion by 2023. Global battery material sales are projected to increase at 5.9% CAGR during the assessment period, taking the overall market valuation to around USD 102.8 billion by 2033.

Introduction to the Battery Material Market

The battery material market encompasses the production, distribution, and utilization of materials used in the manufacturing of batteries for various applications, including consumer electronics, electric vehicles (EVs), energy storage systems, and renewable energy integration. Battery materials play a crucial role in determining the performance, energy density, lifespan, and safety of batteries, influencing their adoption and effectiveness in different sectors.

Key Materials and Functionality

The battery material market includes several key materials:

Cathode Materials: Cathode materials, such as lithium cobalt oxide (LCO), lithium iron phosphate (LFP), and nickel manganese cobalt (NMC), play a critical role in determining the energy density, voltage, and cycling stability of lithium-ion batteries (LIBs) used in EVs, portable electronics, and grid-scale energy storage systems.

Anode Materials: Anode materials, including graphite, silicon, and lithium titanate (LTO), store and release lithium ions during charge and discharge cycles, influencing the capacity, charging rate, and lifespan of LIBs. Advanced anode materials, such as silicon-graphite composites and silicon-based nanostructures, offer higher energy storage capacity but face challenges related to volume expansion and cycling stability.

Electrolyte Materials: Electrolyte materials, such as lithium salts (e.g., lithium hexafluorophosphate), solvents, and additives, facilitate the transport of lithium ions between the cathode and anode in LIBs, enabling electrochemical reactions and ion conduction. Solid-state electrolytes, polymer electrolytes, and ceramic electrolytes offer advantages in terms of safety, stability, and energy density compared to liquid electrolytes.

Separator Materials: Separator materials, typically made of porous polymeric membranes or ceramic-coated films, prevent direct contact between the cathode and anode in LIBs, preventing short circuits while allowing the passage of lithium ions. Advanced separator materials with enhanced thermal stability, mechanical strength, and ion conductivity contribute to improved battery safety and performance.

Trends: Identify and analyze trends relevant to the market you're researching. This could include shifts in consumer behavior, industry regulations, technological advancements, or changes in market demand. Look at both short-term and long-term trends to provide a comprehensive view.

Technological Developments: Highlight the latest technological innovations impacting the market. This might involve advancements in automation, artificial intelligence, IoT (Internet of Things), blockchain, or any other relevant technologies. Discuss how these developments are shaping the industry landscape and driving change.

Analysis: Conduct a thorough analysis of the market, including SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis, Porter's Five Forces analysis, and any other relevant analytical frameworks. Assess market dynamics, competitive landscape, and barriers to entry. Provide insights into market segmentation, customer demographics, and buying behavior.

Growth Drivers: Identify the primary drivers fueling market growth. This could include factors such as increasing demand for certain products or services, expansion into new geographic regions, rising disposable income levels, technological advancements driving innovation, or favorable regulatory policies. Quantify the impact of these drivers on market growth wherever possible.

Receive the FREE Sample Report of Battery Material Market Research Insights @ https://stringentdatalytics.com/sample-request/battery-material-market/14599/

Market Segmentations:

Global Battery Material Market: By Company

Celgard

Umicore

GS Yuasa Corp

Panasonic Corporation

Envia System

Duracell International

GP Batteries international

Toda Kogyo

Global Battery Material Market: By Type

Lead-Acid

Lithium-Ion

Global Battery Material Market: By Application

Automotive

EVs

Portable Devices

Industrial

Regional Analysis of Global Battery Material Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Battery Material market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Battery Material Market Research Report @ https://stringentdatalytics.com/purchase/battery-material-market/14599/?license=single

Challenges: Identify and discuss the challenges that the market is currently facing. These challenges could include regulatory hurdles, economic instability, supply chain disruptions, intense competition, changing consumer preferences, or technological limitations. Provide insights into how these challenges are impacting the industry and potentially hindering growth or innovation.

Future Outlook: Offer a forward-looking perspective on the market's trajectory. Based on the analysis conducted earlier, forecast the future direction of the market. Consider factors such as emerging technologies, shifting consumer behaviors, regulatory changes, and global economic trends. Discuss potential opportunities that may arise in the future and how stakeholders can capitalize on them. Additionally, highlight potential threats or disruptions that could impact the market landscape.

Mitigation Strategies: Suggest mitigation strategies to address the challenges identified and capitalize on future opportunities. This could involve recommendations for businesses to adapt their strategies, invest in R&D, forge strategic partnerships, or diversify their product/service offerings. Provide actionable insights that stakeholders can use to navigate uncertainties and position themselves for success in the evolving market environment.

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

The Ultimate Guide to Premier Car Detailing Services in Beverly Hills

Are you seeking to restore that showroom shine to your beloved automobile? Look no further than Clean Image, your premier Car detailing Services in Beverly Hills. With a passion for perfection and an unwavering commitment to excellence, we are dedicated to providing your vehicle with the ultimate pampering experience it deserves. From meticulous exterior treatments to luxurious interior rejuvenation, our skilled professionals will leave your car looking and feeling brand new. Let's delve into the car detailing world and discover how Clean Image can transform your ride into a masterpiece on wheels.

Why Choose a Clean Image for Car Detailing in Beverly Hills?

Nothing short of perfection will suffice when entrusting your vehicle to a car detailing company. At Clean Image, we understand the profound connection between car owners and their vehicles. That's precisely why we strive to surpass expectations and provide results that are nothing short of exceptional. Here's why you should choose Clean Image for all your car detailing needs in Beverly Hills:

1. Unparalleled Expertise: With years of experience in the industry, our team consists of seasoned professionals with a wealth of knowledge and expertise in car detailing techniques.

2. State-of-the-Art Facilities: Our Beverly Hills facility, equipped with cutting-edge tools and premium products, provides the perfect environment for delivering superior results.

3. Customized Solutions: We recognize that every vehicle is unique, so we tailor our services to meet your car's specific needs. Whether it's a luxury sedan, sports car, or SUV, we have the skills and resources to handle it carefully.

4. Attention to Detail: We take pride in our meticulous attention to detail at Clean Image. From meticulously cleaning every nook and cranny to eliminating stubborn stains and blemishes, we leave no stone unturned in our quest for perfection.

Our Comprehensive Range of Car Detailing Services

At Clean Image, we offer a comprehensive range of car detailing services designed to cater to all your vehicle's needs. Take a peek at what's in store for you:

1. Exterior Detailing: Our exterior detailing services are designed to restore your car's paintwork to its former glory. From hand washing and waxing to paint correction and ceramic coating, we use advanced techniques to enhance your car's shine and protect it from the elements.

2. Interior Detailing: Treat your car to a spa day with our luxurious interior detailing services. From deep cleaning and vacuuming to leather conditioning and odour removal, we'll leave your car's interior looking and feeling as good as new.

3. Paint Protection Film (PPF): Our premium paint protection film shields your car from chips, scratches, and environmental damage. Our PPF installation services provide an invisible layer of protection that preserves your car's paintwork without compromising its aesthetics.

4. Wheel and Tire Care: Give your wheels the attention they deserve with our wheel and tire care services. From thorough cleaning and polishing to dressing and rim protection, we'll ensure your wheels look their best.

5. Mobile Detailing: Can't make it to our facility? No problem! Our mobile detailing services bring the expertise of Clean Image directly to your doorstep. Whether you're at home or work, we'll come to you and give your car the VIP treatment it deserves.

Experience the Clean Image Difference Today

Ready to experience the ultimate in Car detailing services in Beverly Hills Contact Clean Image today at 877-215-1644 or visit our conveniently located facility at 301 S Shamrock Ave, Monrovia, CA 91016, United States. Let us show you why we're the preferred choice for car owners who demand nothing but the best. Revitalize your ride with Clean Image and make every drive a journey in luxury and style.

#auto detailing#car detailing company#mobile car detailing#interior car detailing#professional mobile car detailing#car detailing

0 notes

Text

How much is the investment for car detailing?

Embarking on the journey to preserve your vehicle’s allure and performance often involves considering the investment required for professional car detailing. This intricate process goes beyond the standard car wash, encompassing services like paint correction, protection, and interior rejuvenation. Join us as we unravel Importance of car detailing for vehicle maintenance and shed light on why it…

View On WordPress

#Car Detailing#car detailing business#Car Detailing Franchise#car detailing industry#Car Detailing Services#Car wash#ceramic coating#detailing business#paint protection film#professional detailing

0 notes

Text

Anti-Icing Coating Market Outlook to 2031

The Insight Partners recently announced the release of the market research titled Anti-Icing Coating Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the Anti-Icing Coating market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Anti-Icing Coating Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Anti-Icing Coating market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Anti-Icing Coating market research has all that you need.

What are Key Offerings Under this Anti-Icing Coating Market Research?

Global Anti-Icing Coating market summary, current and future Anti-Icing Coating market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Anti-Icing Coating Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Anti-Icing Coating Market?

Anti-Icing Coating market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Anti-Icing Coating market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Anti-Icing Coating market share.

Report Attributes

Details

Segmental Coverage

Substrate

Metals

Glass

Concrete and Ceramics

End Use Industry

Automotive and Transportation

Renewable Energy

Communication Equipment

Construction

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

AerospaceandAdvancedCompositesGmbH

CG2NanocoatingsInc.

CytonixLLC

Fraunhofer-Gesellschaft

HelicityTechnologies

KissPolymersLLC

NEICorporation

NeverWet

Oceanit

OpusMaterialsTechnologies

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Anti-Icing Coating market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Anti-Icing Coating market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Provinyl: Leading Car Paint Protection Gold Coast Provider

In the dynamic and fast-paced environment of Gold Coast, maintaining the pristine condition of your vehicle's exterior can be a challenge. However, Provinyl has emerged as a trusted leader for car owners seeking top-tier car paint protection Gold Coast services. As specialists in automotive protection solutions, Provinyl ensures that your vehicle remains as stunning as the day it left the showroom.

Expert Solutions for Car Paint Protection Gold Coast Needs

Provinyl’s expertise in car paint protection Gold Coast solutions lies in their innovative and customizable approach. Every vehicle is unique, and Provinyl tailors their services to meet each client's specific needs. Whether a sleek sedan or a robust SUV, their protection strategies are designed to maximize your car’s lifespan while preserving its brilliance.

High-Quality Protection Films for Ultimate Coverage

Provinyl utilizes cutting-edge paint protection films that offer exceptional durability against harsh elements, scratches, and road debris. Their self-healing technology ensures that minor abrasions disappear, maintaining a flawless finish. For the best car paint protection Gold Coast customers trust, Provinyl’s protective films are an optimal choice, blending seamlessly with your car's existing color.

Advanced Ceramic Coating Technology

Beyond films, Provinyl provides industry-leading ceramic coating services. These advanced coatings create a transparent, hydrophobic layer over your car's paint, repelling water and contaminants. This added layer reinforces the vehicle’s defense against harmful UV rays, oxidation, and corrosion. For comprehensive car paint protection Gold Coast, Provinyl’s ceramic coating gives your car a durable shield with a brilliant shine.

Long-Term Value for Your Investment

Investing in Provinyl's car paint protection Gold Coast services is a long-term decision that offers immense value. Not only does it enhance the aesthetic appeal of your vehicle, but it also preserves its resale value by preventing damage from external factors. With Provinyl, you can confidently protect your vehicle against the wear and tear of daily driving.

Customized Solutions for Every Vehicle Owner

Whether you’re a car enthusiast seeking to preserve a classic or simply want to maintain the new car look, Provinyl offers tailored solutions to suit your preferences. Their team of experts is dedicated to providing unparalleled customer satisfaction, ensuring your car paint protection Gold Coast experience is second to none.

Regarding car paint protection Gold Coast services, Provinyl stands out as the region's premier provider. Their comprehensive protection solutions, combined with a client-centered approach, guarantee that your vehicle will remain pristine, no matter where the road takes you. Trust Provinyl for the ultimate car paint protection Gold Coast has to offer and enjoy the confidence that comes with a beautifully protected vehicle.

#car paint protection gold coast#car wrapping#car paint protection in gold coast#best car paint protection#car paint protection#paint protection film#car paint protection near me#best car paint protection gold coast#car wraps near me#car wraps gold coast

0 notes

Text

Global Top 5 Companies Accounted for 80% of total Dish Washing Capsules & Tablets for Auto Dish Washers market (QYResearch, 2021)

Dishwasher detergent is a detergent made for washing dishes in a dishwasher. In this report, we study the dishwasher capsules & tablets.

Dishwasher tablets were designed to tackle hard water, remove stains, and dissolve grease and fat found in protein-based foods — so it shouldn't be a surprise that they can be used to clean things beyond the dishwasher.

Capsules are a special way mixed salt, rinse and detergent, exposed in a special shell. The shell is PVA, PVA is a water-soluble, shelf-stable, synthetic polymer. Creating a dishwasher pod's outside coating out of this polymer allows the user to store and use these convenient pods knowing that they'll only dissolve when they contact water.

Capsules unlike tablets, are coated with a soluble coating, which implies the gradual introduction of the components of the product into the washing process.The shape of the components of the capsule differs from the shape of the components of the tablet, which again provides the best phased dissolution throughout the washing cycle.

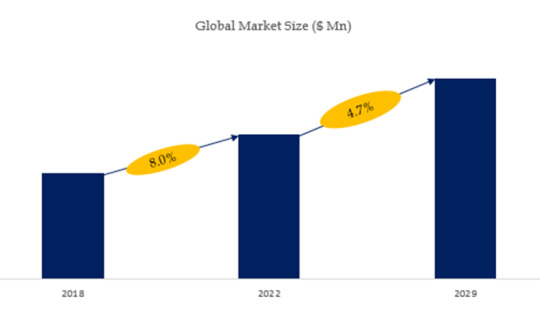

According to the new market research report “Global Dish Washing Capsules & Tablets for Auto Dish Washers Market Report 2023-2029”, published by QYResearch, the global Dish Washing Capsules & Tablets for Auto Dish Washers market size is projected to reach USD 5.16 billion by 2029, at a CAGR of 4.7% during the forecast period.

Figure. Global Dish Washing Capsules & Tablets for Auto Dish Washers Market Size (US$ Million), 2018-2029

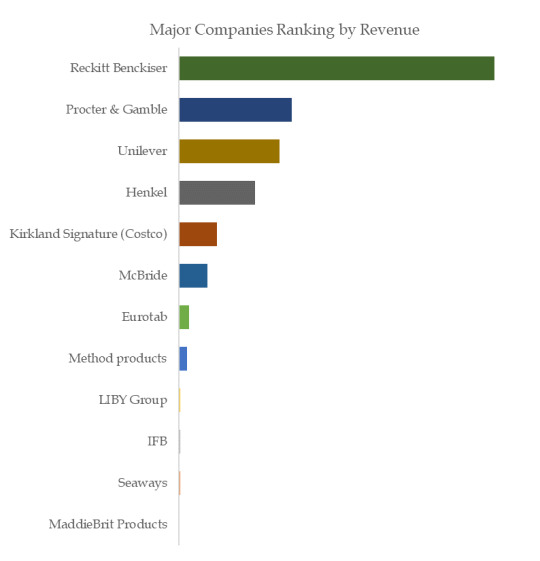

Figure. Global Dish Washing Capsules & Tablets for Auto Dish Washers Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Dish Washing Capsules & Tablets for Auto Dish Washers include Reckitt Benckiser, Procter & Gamble, Unilever, Henkel, Kirkland Signature (Costco), McBride, Eurotab, Method products, LIBY Group, IFB, etc. In 2022, the global top five players had a share approximately 80.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

iPAC Auto Spa / Ceramic Coating / Paint Correction / EV High Voltage Battery Specialist

Address: 1139 W State St Ontario, CA 91762

Phone: (909) 321-4588

Website: https://ipacautomotive.com

Business Email: [email protected]

Hours: Mon - Sun: 9 AM - 6 PM

Social:

https://www.facebook.com/IPACAutomotive

https://www.instagram.com/iPACautospa/

https://www.youtube.com/@iPACautomotive

https://www.tiktok.com/@iPACautomotive

iPAC Auto Spa, a premier shop in the automotive industry for over a decade, specializes in servicing high-end vehicles, particularly Exotics, and German Motorsports. Our small, expert team focuses on quality over quantity, treating each vehicle as an investment. We're not just about service, we're about creating value for those who appreciate the finer things in life. Full Service Automotive Aesthetics and Performance shop in Ontario California. We use the latest technology to preserve and protect your vehicle’s paint for years to come. We specialize in Ceramic Coating and Paint Correction Services. Whether you need Auto Detailing, Ceramic Coating, Ceramic Paint Protection, Paint Correction, Paint Protection Films, Vinyl Wrap, Window Tinting, Vehicle Performance Upgrades, Electric Vehicle Tesla High Voltage Battery Diagnostics, and Maintenance we have you covered. Tesla care with a focus on battery repair, replacement, upgrade services, including programming. Our highly skilled technicians possess extensive knowledge and hands-on experience in dealing with Tesla battery systems

1 note

·

View note

Text

Unveiling the Marvels of Silicon Carbide Nozzles: Engineering Excellence for Extreme Environments

In the ever-evolving landscape of high-temperature applications and extreme environments, silicon carbide (SiC) nozzles have emerged as true engineering marvels, offering unparalleled performance and durability. These exceptional components have revolutionized various industries, from aerospace and defense to manufacturing and energy production, enabling unprecedented advancements and pushing the boundaries of what is possible. This comprehensive guide delves into the intricacies of silicon carbide nozzles, exploring their unique properties, applications, and the cutting-edge technologies that make them an indispensable asset in extreme environments.

The Extraordinary Properties of Silicon Carbide

Silicon carbide, a remarkable ceramic compound composed of silicon and carbon, is renowned for its exceptional thermal, mechanical, and chemical properties. With a melting point exceeding 2700ᄚC (4892ᄚF), SiC boasts outstanding thermal stability, enabling it to withstand extreme temperatures without compromising its structural integrity. Its hardness, second only to diamond, translates into exceptional wear resistance, making it an ideal material for applications involving abrasive environments or high-velocity particle flows.

Moreover, silicon carbide exhibits remarkable chemical inertness, resisting corrosion and oxidation even in the most demanding conditions. This characteristic ensures prolonged service life and minimizes maintenance requirements, contributing to cost-effectiveness and operational efficiency. The unique combination of these properties makes SiC an ideal choice for high-temperature nozzle applications, where performance and reliability are paramount.

Precision Engineering: Crafting Perfection

The design and manufacturing of silicon carbide nozzles are intricate processes that demand precision engineering and cutting-edge technologies. These nozzles are typically manufactured through advanced techniques such as chemical vapor deposition (CVD), reaction bonding, or hot isostatic pressing (HIP), ensuring consistent quality and performance.

Intricate geometries and complex internal channels are meticulously crafted to optimize fluid dynamics, ensuring precise control over flow patterns and minimizing turbulence. Advanced computational fluid dynamics (CFD) simulations are employed to analyze and refine nozzle designs, enabling engineers to achieve optimal performance tailored to specific application requirements.

Furthermore, advanced surface treatments and coatings can be applied to silicon carbide nozzles, enhancing their performance and tailoring them to specific operating conditions. These coatings may include erosion-resistant materials, thermal barrier coatings, or specialized coatings designed to improve chemical resistance or thermal management.

Applications Pushing the Boundaries

Silicon carbide nozzles have found widespread applications across diverse industries, enabling unprecedented advancements and pushing the boundaries of what is possible in high-temperature environments. Here are some of the most prominent applications:

Aerospace and Defense:

Rocket nozzles: SiC nozzles are instrumental in solid rocket motors and liquid rocket engines, withstanding the extreme temperatures and erosive conditions during rocket firing. Their exceptional thermal stability and wear resistance ensure reliable performance and extended service life, making them a critical component in space exploration and defense applications.

Plasma spray nozzles: Used in plasma spray systems for thermal barrier coatings, these nozzles endure the high-temperature plasma jet without degradation, enabling the deposition of advanced protective coatings on critical components.

Manufacturing:

Sand blasting nozzles: The hardness and wear resistance of SiC make it ideal for sandblasting applications, ensuring prolonged service life and consistent performance. These nozzles enable efficient surface preparation and finishing processes in various manufacturing industries.

Cutting nozzles: SiC nozzles are employed in high-temperature cutting processes like oxy-fuel cutting and plasma cutting, enabling precise and efficient material processing. Their ability to withstand extreme temperatures and abrasive environments ensures accurate cuts and extended tool life.

Energy Production:

Furnace components: Silicon carbide is utilized to manufacture burner nozzles, thermocouple protection tubes, and other high-temperature furnace components, ensuring reliable operation and extended service life in demanding environments.

Gasification processes: SiC nozzles find applications in gasification systems, facilitating the conversion of solid or liquid feedstocks into syngas under extreme conditions. Their chemical inertness and thermal stability make them ideal for handling corrosive and high-temperature gases.

Research and Development:

High-temperature testing: SiC nozzles play a crucial role in research and development efforts involving high-temperature environments, enabling scientists and engineers to push the boundaries of material science and engineering. Their exceptional performance allows for accurate data collection and reliable testing under extreme conditions.

Advancements and Future Prospects

The field of silicon carbide nozzles is continuously evolving, driven by advancements in material science, manufacturing techniques, and application-specific requirements. Ongoing research efforts are focused on optimizing nozzle designs for improved flow dynamics, enhanced thermal management, and increased durability.

The integration of additive manufacturing technologies, such as 3D printing, is paving the way for innovative nozzle designs with complex geometries and internal structures tailored to specific applications. This synergy between cutting-edge manufacturing techniques and material science promises to unlock new potentials, driving efficiency, precision, and cost-effectiveness in various industries.

Furthermore, the development of new coating materials and surface treatments holds the promise of further enhancing the performance and lifespan of SiC nozzles. Researchers are exploring advanced coating systems that can provide additional protection against erosion, corrosion, and thermal degradation, extending the operational envelope of these nozzles in even more extreme environments.

As computational power and simulation capabilities continue to advance, the use of sophisticated computational fluid dynamics (CFD) simulations will become increasingly prevalent in the design and optimization of silicon carbide nozzles. These simulations will enable engineers to accurately predict fluid flow patterns, thermal gradients, and potential areas of wear or erosion, allowing for proactive design improvements and optimizations.

Conclusion: Engineering Excellence for Extreme Environments

Silicon carbide nozzle has proven to be true engineering marvels, enabling unprecedented performance and reliability in high-temperature and extreme environments. Their exceptional thermal stability, wear resistance, and chemical inertness make them indispensable components in applications ranging from aerospace and defense to manufacturing and energy production.

As technology continues to advance, the demand for silicon carbide nozzles is expected to grow, driving further innovation and advancements in material science and manufacturing techniques. By harnessing the extraordinary properties of these exceptional components, industries can push the boundaries of what is possible, enabling new frontiers in innovation and technological progress.

Through precision engineering, cutting-edge manufacturing processes, and continuous research and development, silicon carbide nozzles will continue to redefine the limits of what is achievable in extreme environments, empowering engineers and scientists to tackle ever-more challenging applications and unlocking new realms of possibility.

0 notes

Text

Revitalize Your Ride: Car Paint Restoration in Auckland

Introduction:

In the bustling city of Auckland, where vehicles weave through traffic like colorful streaks, maintaining the aesthetic appeal of your car becomes paramount. However, with the constant exposure to harsh weather conditions, road debris, and UV radiation, your car's paint can lose its luster over time. Fear not, for in Auckland, there exists a sanctuary for automotive aesthetics – car paint restoration services. These services offer a rejuvenating touch to your vehicle, breathing new life into its appearance. Let's delve into the world of car paint restoration in Auckland and explore how it can revitalize your ride.

Understanding Car Paint Restoration:

Car Paint Restoration Auckland is more than just a cosmetic enhancement; it's a meticulous process aimed at returning your vehicle's paintwork to its former glory. Whether your car's paint has faded, suffered from scratches and swirl marks, or succumbed to oxidation, restoration specialists employ various techniques to address these issues. From compounding and polishing to paint correction and ceramic coating, these experts possess the knowledge and tools to transform your car's exterior.

The Importance of Professional Restoration:

While DIY solutions may seem tempting, entrusting your car to professionals ensures a superior outcome. Professional restoration services in Auckland boast skilled technicians with years of experience and access to industry-leading products. Moreover, these specialists possess an eye for detail, allowing them to identify underlying issues and tailor their approach accordingly. By opting for professional restoration, you not only enhance your car's appearance but also safeguard its resale value and protect it from future damage.

The Process Unveiled:

Car paint restoration typically begins with a thorough assessment of your vehicle's paintwork. Specialists inspect the surface for imperfections such as scratches, swirl marks, and paint oxidation. Based on their findings, they formulate a tailored restoration plan to address these issues effectively.

One of the primary techniques employed in car paint restoration is compounding. This process involves the application of a compound – a mildly abrasive substance – to the car's surface, which helps remove surface imperfections and restore shine. Following compounding, polishing is performed to further refine the paintwork and enhance its glossiness.

For more severe imperfections, such as deep scratches or paint swirls, paint correction may be necessary. During this process, technicians utilize advanced polishing techniques and specialized equipment to level the paint surface and eliminate defects.

Once the desired level of correction is achieved, a protective coating is applied to the paintwork. Ceramic coatings, known for their durability and hydrophobic properties, form a protective barrier against environmental contaminants, UV radiation, and water spots, thus prolonging the lifespan of your car's paint.

Benefits Beyond Aesthetics:

Beyond enhancing your car's aesthetic appeal, paint restoration offers a myriad of benefits. Firstly, it serves as a form of preventative maintenance, protecting your car's paint from further deterioration. By addressing existing imperfections promptly, you prevent them from worsening over time, thereby preserving the integrity of your vehicle's exterior.

Moreover, car paint restoration can significantly enhance resale value. A well-maintained exterior not only attracts potential buyers but also commands a higher price in the market. Whether you're looking to sell your car or simply maintain its value, investing in paint restoration proves to be a wise decision.

Environmental Considerations:

In today's environmentally conscious society, sustainable practices have become increasingly important. Fortunately, many car paint restoration services in Auckland prioritize eco-friendly solutions. From water-based products to energy-efficient equipment, these businesses strive to minimize their environmental footprint while delivering exceptional results. By choosing eco-friendly restoration services, you contribute to the preservation of the environment while rejuvenating your vehicle.

Conclusion:

In Auckland, where cars are not just a means of transportation but a reflection of one's identity, maintaining impeccable aesthetics is paramount. Car paint restoration services offer a gateway to preserving and enhancing your vehicle's appearance, transforming it into a true automotive masterpiece. By entrusting your car to skilled professionals, you embark on a journey of revitalization, where scratches vanish, swirl marks disappear, and faded paint regains its brilliance. So, why settle for a lackluster exterior when you can revitalize your ride and stand out on the streets of Auckland? Choose car paint restoration and let your vehicle shine like never before.

0 notes