#industrial oils & lubricants

Text

2 notes

·

View notes

Text

Can all contaminants be seen with naked eyes?

As a part 2 of #knowyouroil series, we will discuss about Particle Contamination. Whenever we talk about contamination the first thing that comes to our mind is solid particles that we can see or feel. But what we do not understand is how big a particle can really cause wear and tear to your machines, can all contaminants be seen with naked eyes? Is it too late to wait until then?

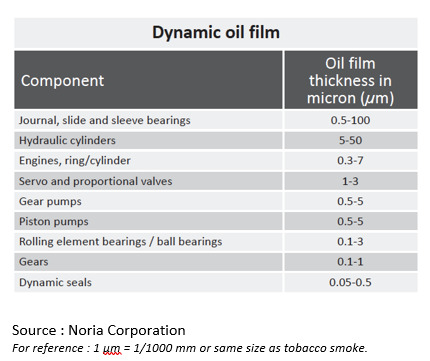

To answer the above questions we must first understand the actual clearance size of the different types of lubrication film formed between rolling and rotating components which is essential for providing proper lubrication. Oil film thickness in machinery is measured in microns (µm), or one-millionth of a meter.

For queries related to Oil Testing, follow:https://www.minimacsystems.com/oil-condition-monitoring-equipment

Below are the finest tolerance found in different types of components.

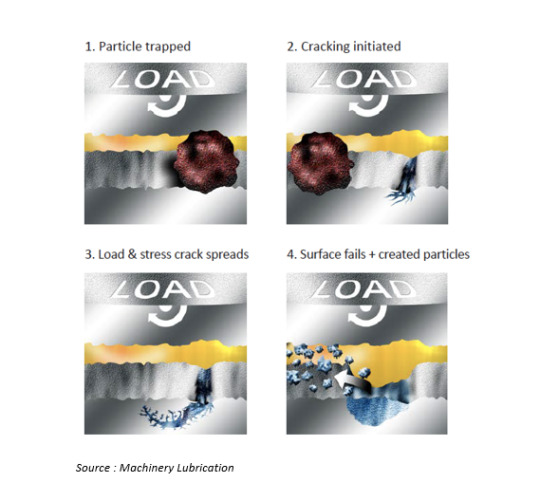

When small particles, which cannot be seen through human eyes, pass through the critical machine parts under load, they create small microtears which get transformed into cracks over a period of time due to continuous stress and strain conditions leading to the more fine generation and hence increase contamination.

The contaminants that are considered to be most damaged are from size 2 to 20 µm and avoiding these are key to keeping your machinery breakdown free.

But it is also important to understand when to call the oil clean and when dirty, as it is understood that changing oil very frequently and maintenance every time is not feasible.

Below chart shows us what particle levels are admissible and what harms our system.

But knowing this is not enough if we don’t know when to get oil sampling and testing done. Below chart provides an estimation for testing and the type of test to be conducted.

Get your machine's oil check today with our technical expert call +91 7030901266. Ask for a brochure today.

We at Minimac System Pvt. Ltd. not only design a maintenance schedule for your lubrication oil but also provide OIL TESTING and FILTRATION services and the filtered oil complies to the ISO standard of Super Clean oil as we stand for MINImum MAChinery Maintenance.

#oil testing#oil industry#Oil Filter#lubrication#lubricating oil#oil contamination#conditionmonitoring

3 notes

·

View notes

Text

Lubricant Oil Manufacturers & Suppliers in India

Indiabizzness shows a variety of listed Indian Industry based petroleum products & lubricant oils from petroleum product manufacturers, lubricant oil manufacturers, lubricant oil dealers, petroleum product dealers, lubricant oil traders & petroleum products exporters who offer best deals at super finest quality & best rates.

Find here best India�s Industry based Petroleum Products & different types of Lubricant Oil and easily contact verified Petroleum Products companies & lubricant oil companies at best prices in India maintaining high quality and best performance. We have a verified list of manufacturers, suppliers, exporters & traders of Petroleum products & lubricant oil from across India at affordable market rates.

Buyers can directly connect via call or SMS at 9811727437 or via email at [email protected] or [email protected]

#Indiabizzness shows a variety of listed Indian Industry based petroleum products & lubricant oils from petroleum product manufacturers#lubricant oil manufacturers#lubricant oil dealers#petroleum product dealers#lubricant oil traders & petroleum products exporters who offer best deals at super finest quality & best rates.#Find here best India�s Industry based Petroleum Products & different types of Lubricant Oil and easily contact verified Petroleum Products#suppliers#exporters & traders of Petroleum products & lubricant oil from across India at affordable market rates.#Buyers can directly connect via call or SMS at 9811727437 or via email at [email protected] or [email protected]#https://www.indiabizzness.com/products/lubricants-oils-and-petroleum-products

2 notes

·

View notes

Text

Manufacturers of high quality industrial and automobile oils and lubricants in India for cars, light commercial, heavy commercial vehicles and various industrial uses. We are ISO 9001-2008 certified Company from TUV NORD, Germany.

#Lubricants#Paras#Palco#Manufacturer of Automotive Oils#Industrial Oils#Automotive Gear Oils#Automotive Greases#Industrial Greases#Car Care products#Speciality Lubricants#Palco lubricants#cars#Automobiles#scooter#Motor Cycle#Bike#Sumo#Oil#Truck#Bus#RTV#Ship#Qualis#Crane#Greases

2 notes

·

View notes

Text

Automobile Oil Manufacturers

Engine |Industrial Oil |Lubricants India

Paras Lubricants Limited was incorporated in 1985 as Private Limited Company and subsequently converted into Public Limited Company in 1995. The Company’s Head Office is in Delhi and Western Office is in Mumbai. The overall marketing, administrative matters and the day-to-day activities of the Company are looked after from these two offices. The Company’s products are marketed under the trade name “PALCO” Lubricants are manufactured at two plants located at Khopoli, (Dist. Raigarh, Maharashtra) and Daman (U.T.).

2 notes

·

View notes

Text

Difference Between Cutting Fluid and Coolant

While cutting fluid is an umbrella term that covers substances used in cooling and lubricating process, coolant on the other hand refers to a specific product within that umbrella term that dissipates heat when your engine is working for a long period of time. So, while all coolants are cutting fluids, not all cutting fluids are coolants. Visit here:

0 notes

Text

Premium Lubricants for Industrial Machinery | TGP India

Explore TGP India's range of high-quality lubricants designed to enhance performance and longevity of industrial machinery. From oils to greases, find the perfect solution for your equipment needs.

0 notes

Text

Enhancing Efficiency and Performance: Shell Lubricants for Machinery and Industries | Caravan Oil Suppliers

Enhancing Efficiency and Performance: Shell Lubricants for Machinery and Industries:

Transmission Oils

The Shell Spirax range of oils

The Shell Spirax range of oils is designed to keep your axles and gearboxes going. Those in the Construction segment, as well as Crusher, Quarry, and Fleet Owners have been very satisfied by using Spirax in their machines. Our oils can be used for

Gearboxes and manual transmissions

Axles

Automatic transmissions

Cone Lubrication (for Crushers)

Slideway Oils

The Shell Tonna range of Slideway oils

The Shell Tonna range of Slideway oils is very useful for CNC Machines and in Steel Industries. The oils are designed to prevent stick-slip and thus reduce the number of rejections. They also have a faster rate of separation from water which allows for reuse.

Contact Details:

Address: 106 Road number 4 2nd phase, Jigani Industrial Area Anekal Taluk Bangalore, Karnataka 562106

Phone Number: 9980005255

Email: [email protected]

0 notes

Text

America Lubricants Market: Charting the Course of Eco-Friendly Lubricants in the Booming Industry

The America lubricants market is expected to reach USD 45.8 billion by 2030, registering a CAGR of 3.0% during the forecast period, as per the new report by Grand View Research, Inc. The growth is attributed to the increase in demand for the automotive and industrial segments within the region. The lubricants market in America is expected to increase significantly, during the forecast period. The region's fast growth in the automotive and industrial end-use categories will bolster the enlargement. The major application markets, which account for more than 90.0% of the market share, are automotive and industrial manufacturing. The need for industrial applications is likely to be the largest contributor, owing to rising disposable incomes and strong employment figures. As a result of the changing pollution standards and the introduction of electric vehicles, the growth within the automobile industry is expected to be restrained. Top producers in the industry at present cater to the high-margin application sectors of aerospace and marine.

The development of better infrastructure and public transportation networks in emerging economies such as Argentina and Brazil has resulted in improving economic situations. Apart from that, people in the U.S. are increasingly choosing personal vehicles. This is likely to drive demand for the high-performance oil used in automobiles within the region during the forecast period.

Companies are strategically divesting assets and investing in upstream facilities, making the industry extremely competitive. Premium lubricants are projected to be the main driver of industry growth in the future. Companies are also seeking strategic alliances and collaborations, in order to enhance their brand image and invest in new product development.

For More Details or Sample Copy please visit link @: America Lubricants Market Report

America Lubricants Market Report Highlights

Automotive segment accounted for 56.0% of revenue share in 2021. The growth is attributed to the increase in demand for passenger vehicles, commercial vehicles, and scooters. Growth in the consumption of personal vehicles is driving demand for the lubricant oil, used for maintaining vehicle

Industrial segment is anticipated to grow at a CAGR of 3.1% from 2022 to 2030 in terms of revenue as there is a rising need for industrial vehicles owing to the infrastructural development, which in turn will drive demand for the product in the region

Motorcycle vehicle type dominated the industry with USD 6.8 billion in 2021. The demand is anticipated to grow with an increase in consumption of the latest type of motorcycle by the young population of the region

Aerospace segment is anticipated to witness a CAGR of 3.8% during the forecast period. The growth is anticipated due to the increase in the use of oil in aircraft. Aerospace lubricants are used to ensure reliability and provide long-lasting lubrication

Companies have integrated throughout the value chain, to gain the competitive advantage

#Lubricants Industry#Industrial Lubricants#Automotive Lubrication#America Lubricants Market#Grease and Oil#Lubrication Technologies#Sustainable Lubricants#Lubricants Innovation#Eco-Friendly Lubrication#Oil and Gas Industry#Lubricants Analysis#Engineering Solutions#Fluid Technology

0 notes

Text

0 notes

Text

Industrial Lubricants - Enhancing Machinery Performance with Mobil Industrial Oils

In the dynamic world of industrial machinery, where efficiency and reliability are paramount, the choice of lubricants plays a crucial role in ensuring optimal performance and longevity. Two prominent players in the industrial lubricants market,

0 notes

Text

"The Automotive Industry Fuels Global Growth in Base Oil Demand: An In-Depth Market Analysis"

Base Oil Market: Exploring Types, Applications, and Geographic Trends – Forecast up to 2028″

Base oil, derived from the refining process of crude oil, plays a pivotal role in the formulation of lubricants. The quality of lubricants hinges on the type and production method of the base oil, making it a critical component, typically comprising 70-97% of lubricant formulations.

The automotive…

View On WordPress

#Base Oils#Hydraulic Oil#Industrial Oil#Lubricants#Lubricants and Greases#Lubrication#Metalworking Fluids#Viscosity Index

0 notes

Text

Lubrication Challenges in Steel Plant

Steel production in India -

India beat Japan in steel production in 2019 and became the world’s second-largest steel producer with 111.2 million tonnes (MT) of steel production. The demand for steel production is estimated to increase in the upcoming years. It is crucial to keep the machinery healthy in order to fulfill these growing steel production demands.

In the journey of fulfilling these demands, there is a factor called “Lubrication” that is often overlooked or taken for granted which ultimately results in disturbance in machine operation and mechanical breakdowns.

Let’s take a dig at such challenges related to lubrication in steel plants.

Steel plants have various components for steel production, finishing, and rolling. Steel production involves an environment consisting of various conditions which contaminate Oil. Some of the most frequently faced challenges are: 1) Heavy Load 2) High Speed 3) Extreme Fluctuating Temperature 4) Dusty Environment These invite both Solid Particle and Moisture contamination in Oil as a result of which Oil loses its properties and mechanical breakdowns happen. Don’t let these challenges be the reason for oil contamination. Adopt the right lubrication management programme. Lubrication in Iron Making is as tough as it sounds!

The Ironmaking group includes plants like raw material blending & blending yard, beneficial plant, sinter plant, coke ovens, and blast furnaces, etc. The equipment, in general, is required to work under high temperature dusty (abrasive) and corrosive environments. For crushing and screening applications, the equipment used is subjected to high impact as well. The speeds are lower. The cost incurred in maintaining them and replacing lubricants frequently is very high. These challenges call for Lubrication Reliability solutions to make sure that equipment is in good shape and Production is not affected by Mechanical Breakdowns. Minimac Systems Pvt. Ltd. helps Steel plants across India from Commissioning to Routined Maintenance in saving cost and increasing efficiency. Explore our range of offerings for the Maintenance of Hydraulic and Rotary equipment in your Plant. Do read our Why do Lubricants lose their Properties?

The steelmaking group includes plant-like LD Furnaces, continuous casters as well as lime plants, etc. The equipment is subjected to a very high temperature, dusty and corrosive environment. This environment opens the gate to all kinds of contaminants, mainly Solid and Moisture in Lubricants making them lose their properties and unfit for equipment. Saving Rotary and Hydraulic Equipment from untimely breakdown is very necessary for continuous production. Lubrication Reliability Practices ensure efficient Operation and also saves cost incurred on maintenance and repairs. Do your remedies to overcome lubrication challenges prove to be ineffective? and reach out to us. for our upcoming webinar on Improve Turbine Reliability Through Lubrication Management.

Originally published at https://minimacsystems.blogspot.com

3 notes

·

View notes

Text

#Air compressors distributors#industrial air compressors#air compressors#piston air compressors#compressors#oil-free compressors#Rotary screw air compressors#oil lubricated air compressors

0 notes

Text

Exploring Mobil Jet Oil II: The Preferred Choice of Lubricant Suppliers in Dubai

High-performance gas turbine engine oil Mobil Jet Oil II has long been a reliable option for the industrial and aviation industries. This cutting-edge lubricant offers outstanding resistance against wear, corrosion, and deposit formation and is especially designed to satisfy the demanding specifications of contemporary gas turbine engines. One of the top manufacturers of premium lubricants in Dubai and the rest of the globe, Mobil Industrial Lubricants, is the source of Mobil Jet Oil II. Mobil Industrial Lubricants has more than a century of expertise and is renowned for its trustworthy and creative solutions that maintain the smooth operation of machines.

0 notes

Text

Definition Of Lubricating Grease

A lubricating grease is meant to reduce the friction between moving engine parts to make sure that there is as little wear and tear as possible. Visit here:

0 notes