#is it a photosensitivity thing or like a bandwidth thing?

Text

If I got paid for my role as a Professional Crastinator, I'd be making bank, because I have never done a damn thing when I'm supposed to in my entire life.

STORY UPDATES COMING EVENTUALLY I GUESS I DON'T FUCKING KNOW (╯°□°)╯︵ ┻━┻

#ramblings#i don't even know what to tag this#i'm just being generally useless again#i thought i was going to have an update out yesterday but then my brain was like#hey laura hey what about we don't do that#so then i didn't#and i played mobile games and listened to creepypastas on yt all night#and you know what#it was a good fucking time#but it didn't get me closer to getting over this hump i'm in storytelling wise#and i see all the stuff down the road from this part of the story#and it's good#it's good shit#i'm so looking forward to it#but i just gotta get through this one part#and i don't wanna#oh uh#gif warning#why do we warn for gifs btw?#is it a photosensitivity thing or like a bandwidth thing?#i do it because my usage of gifs will go unchecked if i don't remind myself not to do what i usually do#and spam that shit everywhere#you know what i could have written all of this in the main body of this post#but i didn't#because fuck you that's why#i'm sorry i didn't mean that#i love you#if you're reading my mental breakdown in the tags#i love the shit out of you#because you could have just kept scrolling

14 notes

·

View notes

Note

if computers wanted to communicate with us, how would they do that?

i’ll humor this once since people tell me to quit being an asshole all the time

computers, even the huge neural networks at google or the supercomputers at oak ridge, have no semblance of what we consider “consciousness” in terms of existentialism or the human condition or whatever

it’s true that our brains, much like computers, operate via exchanging electrical signals between huge networks of uniform, similar logic units (neurons) over structured and organized connections joining them (synapses). there are multiple such systems in our brain (lobes, etc) that work more-or-less independently but communicate through more sophisticated pathways (neurotransmitters, corpus callosum) which allows for the nuanced behavior you see in mammals (i.e. i see a banana: photons bouncing off the banana interact with the rods and cones in my eyes, translating the wavelength & intensity of the banana’s light to structured signals that travel down my optical nerve, and are processed by my occipital lobe, which then works with my hippocampus [through the aforementioned higher-order channels]. the processed signal is matched with an extant representation of “bananas” in my memory and the conclusion “this thing in front of me is a banana, banana is food”. since food is very important to us, this will prompt information exchange with the part of my brain responsible for digestion/consumption to ascertain whether or not i should eat the banana, which would involve communicating with motor nerves, and so on, and so on)

i have absolutely no idea how brains work

a computer, let’s say a fruit picking robot, might follow a similar sequence of events and decisions. light bouncing off the fruit would hit & interact with a photosensitive sensor surface (analog: rods/cones in eyeball) whereupon a small voltage (characteristic of the implicated photons’ wavelength (color) and intensity (# of photons interacting temporally)) is generated via the photoelectric effect(analog: electrical signal traveling from optic nerve to brain). that signal represents a single pixel’s information and it, along with 2,073,599 similar ones (assuming 1080p sensor*) simultaneously travel down a network of circuity that serializes and organizes them (analog: occipital lobe) and they eventually end up at some analog-to-digital converter that turns the color information into 1s and 0s. the ADC would write those 1′s and 0′s to a block of SRAM (analog: short term memory) which provides a temporary, expensive, capacity-limited but high bandwidth medium for the OCR-like software running on the main processor to make a determination if the image captured contains fruit that should be picked or not

even though the human brains and computers share functionally similar fundamental operational building blocks (neurons/transistors), have those similar building blocks connected in such a way that allows for consistent, logical responses given consistent stimuli (synapses/bitwise logic), have multiple independent systems built from such media that communicate with one another (ocipital lobe + corpus callosum, etc/analog-to-digital converter writing to RAM via DMA which is later read by CPU) to give rise to very nuanced and sophisticated behaviors (human peeling and eating banana because he saw it and was hungry/robot banana picker manipulating solenoids and actuators to grab banana based on pixel analysis whose confidence value exceeded some threshold) they are not at all the same

there is a reason that things like asimo the robot aren’t at all what you see in a movie like i-robot. so far, i have explained why computers and brains are similar as to establish why you would ask me this question in the first place: your understanding of the “mammal eating banana/robot picking banana” scenario might not be as fleshed-out as mine but you still see the same thing at the end of the day; computers resembling conscious beings. your question is reasonable. now let’s look at where things diverge

central processing units are the most intricate and complicated parts of most computers. the newest, top of line i7 contains between 1 and 2 billion transistors. the human brain, on the other hand, contains somewhere between 21-26 billion neurons. that’s two whole orders of magnitude! that is hugely significant. but don’t be shortsighted, mislead: it’s not that we are just supercomputers. even CPUs from the 70s that contain mere thousands of transistors, ones simple enough that you can see each individual transistor with a microscope, are still able to solve hundreds, perhaps thousands of complicated arithmetic problems with zero mistakes in the time it takes you to take a sip of coffee -- our brains and our computers compromise two entirely different categories of problem-solving engines

why is this?

computers operate entirely on one fundamental premise: 1s and 0s represented by periods of high or low voltages (respectively) in some conductor. just those two and nothing else. the 1s and 0s are mere representations of reality, they are necessarily imprecise and inaccurate understandings of events and media and stimuli coming from reality. for example, take a perfectly shot 8K image of the david in rome, presented on a perfectly calibrated state-of-the-art 8K LCD display. this image is just a large list of ordered pixels which each contain 1s and 0s describing the intensity of colors of that pixel

this super state-of-the-art image still pales in comparison to what you’d see if you were actually standing in front of the david and seeing it yourself -- the light reflecting off the statue hasn’t passed through a dirty enumeration/digitization process that strips it of the important nuances like hue/chromacity/etc.** and boils it down to 24 bits -- twenty-four ones or zeroes -- that represent the perceived red, blue, and green values needed to later represent the image on a screen

audio is similar -- even with the highest end headphones and playback equipment, wave files will never match what you would hear at a live rendition of the same songs. the implicated information simply cannot be losslessly translated to ones and zeroes, making the eventual rebroadcast necessarily flawed

our brains have a more sophisticated approach

afaik (and again i need to restate i’m not a neuroscientist or biologist or anything similar) the electrical signals fired between synapses aren’t at all like the transistor-to-transistor logic*** present in a CMOS circuit. it’s not a square wave; not a timed, sequenced transmission of two voltages. it’s some complicated analog signal that contains much more information than possible with a similar transmission of 1s and 0s. it isn’t half-duplex, either, i don’t think: electrical signals are generated and perceived on both ends of the synapse, and there are feedback responses that aren’t present in computers. we are much better at keeping our perceptions of reality accurate and precise because the form the physical media embodying these representations takes is sophisticated enough to capture all -- or most -- of the nuances present in reality

there is a term describing a phenomena decievingly similar to the one described above that i’m very hesitant to reveal, it will probably lead to misconceptions. the term is sampling and it refers to taking a continuous signal (like light waves or sound waves) and turning it into a discrete one. continuous signals contain an infinite amount of information, which is to say that one could keep zooming in and zooming in on a continuous signal and keep finding newly-visible modulations and evidence that there “is still more” to the signal****. it’s infinite. a discrete signal -- like a square wave representing 1s and 0s -- contains a finite amount of information. going from continuous -> discrete always implicates a loss of quality, or a loss of information formerly present in the continuous signal and now missing from the discrete one

sampling, as described above, is sort of an analog to the differences between how computers process reality and our brains process reality. our brains do indeed “sample” reality and turn an infinite amount of information to a finite amount, but it does so in a way that is more complex than just “associating binary numbers describing equidistant timewise signal magnitudes with a perceived signal”. this isn’t an “analog vs. digital” thing, the mechanisms and sequences of chemical/electrical exchanges go far beyond “sampling analog signal and re-creating it with bits”. it’s not well understood by emeritus professors at jon hopkins. it’s not well understood by me either

what really breaks this analogy is neurotransmitters. chemicals that do something or other, i don’t understand what exactly, with neurons. seratonin, norephedrine, all those. iirc there’s something like six or eight that all have heavily contextual and relative impacts. contextual meaning that seratonin in one part of the brain can cause a completely different category of behavior than a similar amount somewhere else, and relative meaning that even if we know that increased levels of serotonin in a certain part of the brain is associated with a “happy” feeling, that such an association may be dependent on other concentrations being present in other parts of the brain

it’s all very relative and all very contextual, unlike computers. signals in computers have objective meanings and are (hopefully) heavily uncoupled with systems they weren’t created to drive. the PC register in your CPU, actualized in 32 or 64 very fast SRAM cells, will never fluctuate based on the signals traveling through the USB controller on your motherboard, for example. this is why computers are so, so, so much better suited to solve math problems: there is an ALU built for the sole purpose of adding/subtracting/multiplying/bitwise logic’ing binary numbers. these binary numbers represent real numbers, and luckily in this case, binary numbers can represent real numbers with 100% accuracy. since the signals traveling through the ALU have categorically nothing to do with anything but the input values, there’s nothing to impeded computation and it happens very quickly. there’s also nothing to “screw up” the actual sequences occurring during computation, which is why your computer never gets such problems wrong like you might on a math test in school*****

our brains are not so brutalistically decoupled. the ~25 billion neurons in your brain are connected in a way that doesn’t look anything like the conductive pathways lithographically printed onto a silicon die. in graph theory terms, the neural maps in our brains look much more like a complete graph:

as opposed to what a computer’s transistor connectivity map might look like: a minimally spanning tree:

the result of this higher rate of connectivity in our brain, connectivity between things that might have very little to do with one another, is existential phenomena and noumenona -- specifically emergent phenomena

if there’s one thing i want you to take home from this outrageously long wall of text is the concept of emergent phenomena

emergent phenomena is, and i’m paraphrasing here, when higher-level, more sophisticated, architecturally complex phenomena arise from a configuration of consistently acting phenomena of lesser complexity and sophistication. emergence is seen in modern computers -- the cold exacting logic of 1s and 0s zipping through a processor, addressed lists of instructions describing arithmatical steps to be performed on a number of registers -- can give rise to something like a film being played on a monitor. a calculator performs nearly the same set of actions a CPU does, but with a calculator it’s numbers in, numbers out: no significant change in complexity. but a CPU driving a video card that reads in bits of an MPEG file and running them through a digital signal processing chip to very quickly (as in the film is presented 60 frames per second) extract pixel information suitable for a monitor? that is emergent as hell

human brains though! jesus christ. they display titanically, astonishingly more significant incidences of emergence, and -- according to my completely uninformed and laymen understanding of the brain -- this is due to the much more liberal neural connectivity in the brain opposed to on the silicon

we have electrical signals zipping to and from neurons in the brain. we have a handful of neurotransmitters that do this and that, here and there. and what do we get?

we get things like emotions, curiosity, ability to learn, ability to synthesize information based on prior knowledge. we’re able to do things like put money into a roth IRA, money that could buy food or something a much more simplistic, “robotic” creature would prefer, because we have a complex knowledge of the fact that we’ll need money when we grow old and can no longer work, and we have a concept of what an IRA is and why today’s money will multiply over the years. hell, we are able to analyze and ascertain how liable the investment firms in place today are to actually produce that money in the future, and we’re able to make an informed decision on whether or not to invest in an IRA based on how trustworthy we deem such institutions

we’re able to take our greasy ape brains and contort them to understand -- and master! -- the physical world around us, the parts that do not at all make sense to a mammalian brain primarily concerned with food, fucking, and shelter.

we built computers. we sat down and, through some amazing process, were able to teach ourselves how to think in the totally unnatural terms of electrical circuity, binary logic, etc. and make a computer. that’s nothing short of incredible

i’ll leave you with one final idea: the halting problem. the halting problem is very simply stated and understood, but implicates huge amounts when you start poking beneath the surface, which is now you, the reader’s, task. i’ll start you off

the halting problem proves, through universally valid and completely comprehensive mathematical proofs, that a computer cannot look at a program and an input to that program, and tell if the program will eventually complete****** given the input. it can’t tell if it’ll run into an infinite loop, which is loosely to say that you can’t write a program that will fix any bugs in another program

mathematically it’s impossible. it’s impossible to the same degree of certainty that exceeding the speed of light is impossible. to the same degree of certainty that gravity will exert forces of energies according to their proximity. impossible in the most absolute and severe way mankind can define

but you know what can solve these bugs? humans. humans and their brains.

wild.

----- annotations -----

* i’ve heavily simplified how image sensors work for the sake of brevity. image sensors are incredibly complicated even compared to other electronics and you’d need a physics, chemistry, and electrical engineering degree to properly understand how a digital image sensor works.

** hue/luminance/chromacity are indeed digitally enumerable. i do not know the exact information excluded by quanitization so i cheated. if you send me an ask being pedantic about YCbCr encoding i’m going to be snarky

*** i used the term TTL logic here because it provides an intended idea of the logic behind transistors talking to transistors. TTL is defined as a very specific standard and methodology no longer used today. i am aware. don’t be pedantic

**** continuous signals (nor much of anything) is “infinite” when modeled in terms of quantum physics. do not send me anything containing the words “planck length” or “superstrings”. you aren’t clever and you don’t understand quantum physics because nobody understands quantum physics.

***** our brains aren’t built to process math. math involves absolute, discrete values through which absolute, discrete answers result after comprehensively defined steps. our heavily-interconnected brains do much better at problems like “do i want to fuck or eat this bear” and “what is best way to utilize fire to kill the fucker stealing melons”, problems that have fuzzy starting premises and many (perhaps infinite) answers.

****** this is actually more amazing than you’d think at first glance because the kind of bugs the halting problem precludes solving don’t categorically involve completely unknown, outside stimulus. a program that spins until you click the mouse is obviously not determinable because the bug-solving software couldn’t have any idea of when someone will click the mouse. the debugging program can’t even spot infinite loop conditions when the target program appears deterministic and uncoupled from outside interrupts/events. that’s crazy.

401 notes

·

View notes

Text

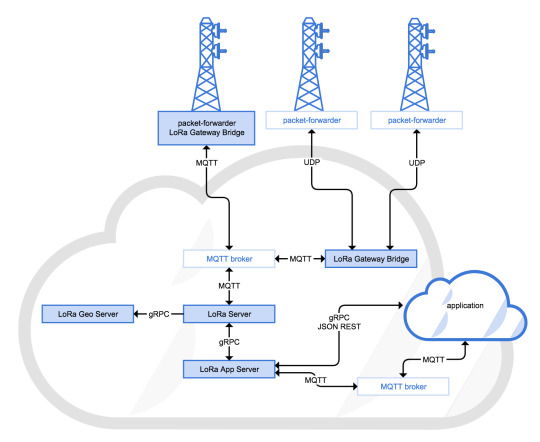

How does LoRa sensor works

Those sensors which are based on LoRa technology is known as a LoRa sensor. LoRa sensors have capabilities for geolocation, allows for low power consumption and long-range transmissions (typically more than 10 km). Hence, we can use these via timestamps from various gateways to triangulate positions of devices. LoRa sensors allow for long-range connectivity between devices to allow for an effective Internet of Things (IoT) implementation. This has applications across multiple industries.

How Does LoRa Sensor Send and Receive data

A LoRa network uses LoRaWAN protocol for sending and receiving data from LoRa sensors. LoRaWAN is a cloud-based media access control (MAC) layer protocol but acts mainly as a network layer protocol. We use LoRaWAN for managing communication between LoRa gateways and LoRa devices (nodes). It functions as a routing protocol and the LoRa Alliance maintains it. The first version of LoRaWAN was released in the year 2015.

LoRaWAN defines the system architecture and the communication protocol for the LoRa network. It allows for a secure and reliable long-range communication link. LoRaWAN also manages data rates, communication frequencies, and power optimization for all LoRa devices.

LoRa nodes in a LoRa network are based on asynchronous communication, and they start transmitting when they have data available to send. This enables a LoRa network to trade off sensitivity for data rate with a fixed channel bandwidth. It mainly involves selecting the amount of used spread (which is a selectable parameter between 7 and12). This spreading factor determines the sensitivity of a LoRa node and determines its data rate.

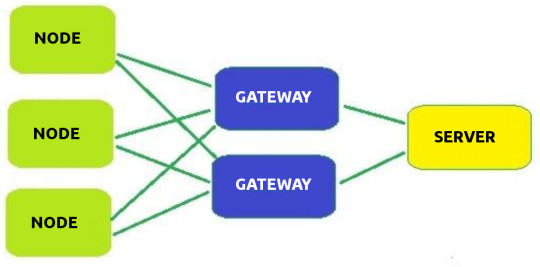

Data transmitted by a LoRa node is received by multiple LoRa gateways, which forward the received data packets to a centralized network server (IoT server). The IoT server filters out the duplicate packets, manages the network and performs security checks. The server then sends this data to the application modules, control panels, or connected smart devices. This way LoRaWAN protocol shows high reliability and accuracy for the moderate load.

Additionally, LoRa uses Forward Error Correction coding. This improves the LoRa network's resilience against any kind of high interference. The high range of a LoRa network is characterized by very high wireless link budgets, which are around 155 dB to 170 dB.

How to make LoRa Sensors?

We typically integrate LoRa sensors into IoT networks. The sensors which we mostly use with LoRa technology are,

DHT11

It is a basic temperature and humidity sensor.

Ultrasonic Sensor

We use this sensor for checking if there is an object in front of it.

Photosensitive sensor

We use this sensor for monitoring the ambient light.

Flame sensor

It detects the presence of fire or a flame.

Relay

We use this for controlling the power of a device.

Buzzer

We use this for alarming or warning nearby individuals.

LED

These are for showing the progress or status of any process.

A collection of these sensors when combined with a GPS module via a microcontroller (usually Arduino or Raspberry Pi), forms a LoRa Sensor.

How to use LoRa sensors?

For using a LoRa sensor, we have to set up an effective LoRa Network. A typical LoRa network includes the following,

1. LoRa Node

A LoRa sensor, when embedded with wireless connectivity and LoRa protocol, then it forms a LoRa Node. A LoRa node collects the required sensor data and sends it over to the LoRa Gateway.

2. LoRa Gateway (LG01)

A gateway is generally a device which we use for connecting various types of Network. LG01 is a LoRa Gateway which we use for bridging the LoRa wireless network and IP network. Its main features are,

a. It is the central point for forming a LoRa network.

b. Receives data from LoRa device (Node) in LoRa Network via LoRa wireless and sends it to IoT server in the IP network via

Wi-Fi

Ethernet

3G/4G etc.

c. Receives command from the IoT Server and sends it to LoRa device (Node).

3.IoT server

An IoT server is basically a cloud server that allows connectivity between various devices. It receives and stores data from multiple devices and allows access across multiple platforms. In the case of a LoRa network, the IoT server receives data from the LoRa Gateway and then stores it accordingly. This data can is then accessible from any smart device (A computer, laptop, mobile phone, or tablet, whichever is convenient).

When we want to scale the performance of LoRa sensors up or down or if we want to increase or decrease the range of their measurements, then the IoT server also allows for that. In this case, we send the commands from the control panel (any smart device) to the IoT server. The IoT server sends the command to the LoRa gateway, which in turn sends it to the Lora Node (device). The command is interpreted at the LoRa node, and the LoRa sensors follow it accordingly.

So, this is how we set up LoRa sensors within a LoRa network. A LoRa network can accommodate as many LoRa sensors as required.

Why Use LoRa Sensors?

LoRa technology, compared to other disruptive technologies, is not a promise of the future but is available today throughout the world. There are 600 known cases of deployment of LoRa technology in citywide IoT implementations, and this number is growing steadily. According to an estimate, more than 105 million LoRa devices are deployed around the world. LoRa sensors combined with the LoRaWAN protocol are helping in creating a smart world. Analysts predict that by 2023, around 43% of all IoT implementations will incorporate LoRa technology. Hence, LoRa technology is realizing the potential for IoT applications.

LoRa Technology Fills a Technological Gap

LoRa technology is revolutionizing IoT by using very little power and enabling data communication over a long-range. LoRaWAN fills the technology gap of Wi-Fi/BLE and cellular-based networks, which require either high power or high bandwidth and have the inability to penetrate shielded indoor environments or have a limited range. Hence, LoRa technology is efficient for usage in any indoor or rural settings.

2. LoRa Technology Complements Other Technologies

LoRa technology operates in the unlicensed band like Wi-Fi and is very secure from end devices to the IoT server like Cellular. This makes it suitable for both indoor and outdoor use. LoRaWAN protocol offers a flexible, economical, and efficient connectivity solution that is ideal for IoT applications, whether installed in private, public, or hybrid networks. LoRa sensor data can fuel analytics platforms that use machine learning and artificial intelligence. These technologies need data diversity, which is accommodated by LoRa sensors at a very low cost and power consumption.

3. Global Network Availability

LoRa devices (nodes) operate on the LoRaWAN protocol, which is an open standard. It is backed by the LoRa Alliance, a nonprofit association that is promoting worldwide adoption of LoRa technology. The ecosystem of LoRa alliance has over 500 members, which include 100 public network operators with service offerings in more than 58 countries. LoRaWAN based networks are globally accessible and are available in more than 100 countries. Therefore, this existing and established infrastructure makes it more efficient and easier to immediately deploy LoRa based solutions.

4. A Rapidly Growing Ecosystem

The ecosystem supporting LoRaWAN and LoRa includes a wide range of hardware manufacturers, service providers, network operators, software designers, universities, and industry associations. These play an integral role in creating devices, applications, and networks. The ecosystem is growing rapidly, and entities are adopting LoRa technology across multiple segments.

What are some prospective applications of LoRa Sensor ?

LoRa Sensors offer a wide range of possibilities that we can use for applications across multiple sectors. Some of the prospective applications of LoRa sensors are,

Smart Agriculture

IoT is widely being used in agriculture from measuring environmental conditions that affect crop production to tracking the health indicators of livestock. This allows for the minimum strain on the environment, maximization of yield, and minimization of expenses. LoRa devices (nodes) and LoRaWAN protocol can significantly improve the effectiveness of such networks. Some case studies have shown that the use of LoRa sensors has reduced the water consumption of commercial farms up to 50%. LoRa sensors have long-range connectivity and consume low power. Hence, they are able to send data from agriculture farms to the Cloud Server. The data is processed and analyzed there for improving operations.

2. Smart Cities

We can make municipal operations more efficient with the long-range and low power LoRa sensor. These sensors provide secure and GPS-free geolocation capacities. If city services such as parking, lighting, and waste removal are connected together, then cities can optimize the use of personnel and utilities for saving money and time.

3. Smart Healthcare

The low cost and low power consumption of LoRa sensors make them suitable for healthcare applications, which are critical and require reliability. IoT solutions based on LoRa sensors and gateways can help in monitoring high-risk patients around the clock. Therefore, this will help in ensuring that the medical safety and health of critical patients is never overlooked.

4. Smart Industrial Control

Operations in the industry can benefit from the LoRa sensors, which have continuous monitoring functions. Due to long-range and low power consumption of LoRa devices (nodes), we frequently use them in manufacturing industries and plants. They can also relay important data via LoRaWAN protocol to the concerned network. This can allow for analysis of data and subsequent optimization of business operations.

5. Smart Utilities

Conventional utility operations use subjective measurement by field technicians, and hence, they are labor-intensive. On top of that, meters are often located indoors, underground, or dense urban environments. This makes it difficult for most wireless technologies to reach them. So, using LoRa sensors and LoRaWAN protocol will allow metering and utility companies to collect data remotely. Therefore, it will also help them in streamlining the operations by using their personnel more efficiently.

6. Smart Supply Chain & Logistics

LoRa sensors make it affordable and easier for logistics and supply chain to track high valued assets that are in transit. The long-range and low power consumption of LoRa sensors makes it easier for GPS-free geolocation of vehicles and cargos. Hence, we can easily monitor any kind of assets within harsh environments and large geographic regions.

7. Alzheimer Patient Tracking

LoRa technology wearable tracking devices can alert caregivers when an Alzheimer patient leaves a designated safe zone. This will help in ensuring round the clock safety in the absence of physical supervision.

8. Smart Homes & Buildings

LoRa sensors can send data even from within buildings constructed from dense materials, and they consume low power. This makes LoRa sensors ideal for manufacturing smart home and building devices. Additionally, long-range capabilities of LoRa sensors and LoRaWAN protocol allow them to track assets that may stray away from home. LoRa sensors in smart home and building applications can optimize utility usage, detect danger, and improve the safety & convenience of daily life.

9. Smart Refrigeration Solutions

LoRa technology can help in smart refrigeration solutions, which can help in tracking food temperatures for the food retail industry. Global developments in established supermarket chains can save a lot of money every year. LoRa sensors can also help restaurants in reducing food waste and optimize the operational costs of food management.

If you are working on an IoT based solution and want to use LoRa technology but are worried about the complexity of the process, then you can rely on MOKO Smart. We offer state of the art LoRa sensors, which you can use as per your needs. Additionally, we offer hardware designing, prototyping, product assembling, RF debugging, and LoRaWAN embedding services. So, you will get professional-grade LoRa modules for your IoT based solution. Feel free to contact us if you want to inquire about a quote or ask any questions.

0 notes

Text

Applications and Benefits of LED Lighting in Food Safety

As the old adage goes, “Cleanliness is next to godliness.” However, in the United States, the food and beverage industry is tightly controlled by the U.S. Department of Agriculture (USDA) and the Food and Drug Administration (FDA). In other countries around the world, similar regulatory agencies regulate the food and beverage industry.

To ensure sanitary conditions are always maintained, all appliances and equipment used in food and beverage facilities – including lighting – must adhere to strict manufacturing standards set by the National Sanitation Foundation (NSF International). Food and beverage plants require lighting fixtures that must function optimally under hygienic and even hazardous conditions.

The compliance standards that apply to a specific food and beverage facility and the lighting fixtures used usually depend on the specific facility. Food production facilities, food processing facilities, food storage facilities, and food preparation facilities all require different types of lighting fixtures.

These plants have different lighting needs from industrial spaces like warehouses and manufacturing plants. For example, the lighting fixtures used in food processing areas must be able to withstand airborne dust, water, steam, grime, oils, mists, effluents, and other contaminants.

The Stringent Standards in the Food and Beverage Industry

NSF International has set strict standards that are based on a location’s condition and the extent of contact with food procedures. The NSF standard that relates to food and beverage lighting products is referred to as NSF/ANSI Standard 2, or just NSF 2.

It categorizes food facilities into 3 zonal groups: Food Zones, Non-Food Zones, and Splash Zones. Each zone represents specific surroundings which include locations where there isn’t any direct contact with food produce (like food storage areas), locations where there is direct contact with food, and wet-processing locations, those that need high pressure wash downs.

NSF International also requires that food and beverage plants use light fixtures with IP65 or IP66 Ingress Protection ratings. The luminaires must also have UL damp location or UL wet location ratings. Vapor-tight lighting fixtures must be used in hazardous locations (for instance, Class 1 Division 1 and Class 1 Division 2). The fixtures should also be cleanroom-rated.

Some food and beverage plants normally use the lighting fixtures that are found in other industrial settings. However, the fixtures used in these spaces must perform optimally under sanitary and even dangerous conditions. The types of lighting products used and the compliance standards that are applicable usually depend on the environment of a particular area – because food plants usually house different environments under one roof.

A food facility might have locations for processing, staging, warehousing, cold or dry storage, distribution, offices, restrooms, lobbies, hallways, cleanrooms, and a lot more. Each of these has its own lighting requirements.

Lighting products never come into direct contact with food, so only the NSF regulations for Splash Zones and Non-Food Zones usually apply to them. LED lighting manufacturers who would like to obtain NSF-2 certification for their lighting products must make sure that the products’ design, their materials, and the manufacturing processes used comply with the NSF standards for the relevant zone.

Some food plants, such as grain processing facilities, have areas with flammable gases or dust that can cause dangerous situations. In these locations, lighting products should fall under Class 2 Division 1 or 2 and group G.

LED Technology Meets All Stringent Standards of the Food Industry

Light-emitting diodes have unique properties that make them highly suitable for different operations in the food industry. They include:

A long life expectancy

Mechanical robustness

High emissions of monochromatic light

Low radiant heat emissions

Flexibility

Because of the way they are constructed, they may decrease degradation and thermal damage in foods and are suitable for cold storage applications. Recent research has shown that LEDs can preserve or even improve the nutritive quality of food in the postharvest stage and reduce fungal infections.

LED lights can be used together with photocatalysts or photosensitizes to inactivate pathogenic bacteria in food. Ultraviolet LEDs – which were introduced to the market not very long ago – can efficiently inactivate pathogens and preserve the freshness of food in postharvest stages.

High intensity discharge lights (such as high pressure sodium, metal halide, and xenon lamps) and fluorescent lamps have been popular lighting sources in food production and preservation facilities. However, these lighting systems have broad spectral power distribution and give off a lot of heat.

To control the temperature in various applications, such as food processing plants and food storage facilities, more energy is needed to remove the excess heat they produce. In addition, low pressure mercury lamps and fluorescent lights contain mercury and must be handled with utmost care to prevent damage and leakage of the toxic metal.

Light-emitting diodes are solid state lighting devices that produce light with wavelengths of narrow bandwidths, low thermal output, and high photoelectric efficiency. They are portable and compact and can be easily incorporated into electronic systems. As we earlier mentioned, LEDs have unique properties that make for the convenient manipulation of the luminous intensity, temporal settings, and spectral characteristics of the light produced.

In the 1970s, when LEDs were still in the early stages of development, they had very low power and were mostly used as indicator lamps. But as LED technology rapidly developed, new semiconductor materials were integrated, optics were improved, and enhanced techniques of thermal dissipation were implemented. Because of this, LEDs became universal and are widely used in different applications.

LEDs have low radiant heat emissions and their efficiency improves at lower temperatures, which makes them perfect for food storage facilities. Because food safety is a major concern in the food industry at all stages (production, processing, storage, and preparation), LEDs are used in these applications to ensure that food is not contaminated and is safe for consumption.

Thanks to their long life expectancy and their compactness and robustness, LEDs are a very economical technology to adopt. And as the technology continues to advance, LEDs become more efficient and cheaper. It is expected that more companies in the food and beverage industry will convert to LED because of the benefits it offers to food and also for compliance purposes.

Complying with Food Safety Standards

The great thing about LEDs is that they comply with the strict requirements that are set by the U.S. Department of Agriculture and The Food and Drug Administration. The FDA defines adequate lighting in food manufacturing facilities as.

540 lux in areas where food employees work with food equipment or utensils and safety is paramount

215 lux in locations where packaged food is sold or provided for consumption and in self-service areas

108 lux at 30 inches above the floor in dry storage areas and walk-in refrigeration areas

Meat, poultry, and dairy processing plants that want to comply with the USDA regulations for inspections must follow specific illumination criteria. The lighting guidelines stipulate:

30 foot candles in all locations where dairy products are cleaned, produced, or packaged

30 foot candles in all locations where utensils are washed, produced, or packaged

50 foot candles in all locations where products can get contaminated. Additionally, the luminaires should be protected from breakage

50 to 200 foot candles for inspection stations (the foot candles required depend on the specific inspection area)

The Illuminating Engineering Society of North America (IESNA) has specific illumination levels for different food processing areas. For example, the illumination levels for food examination areas range between 30 to 1,000 foot candles, depending on the intricacy of the process. Locations for color grading must have a minimum of 150 foot candles, while packing areas need a minimum of 30 foot candles.

These are some of the requirements that businesses must observe if they want to adhere to the Food and Drug Administration’s Current Good Manufacturing Practices. The guidelines also stipulate that lights in facilities where food is present must be coated, shielded, covered, or provide shatterproof protection.

The Application of LEDs in Food Safety

The food industry depends on powerful lighting systems to enhance productivity and safety in the workplace. Food processing, manufacturing, and retail establishments are shifting from traditional lighting systems (such as high intensity discharge lights and fluorescent lamps) to light emitting diode products. This is because LED technology is able to meet the strict food safety guidelines set by the regulatory bodies in place.

According to research, by 2020, the adoption of LED technology in the food industry will reach $80 billion annually. The food plants that are currently leading in the adoption of LED technology are food processing and manufacturing facilities, because LEDs provide solutions to the complex and challenging working conditions in these environments.

The successful application of LEDs in food processing and manufacturing facilities usually depends on the types of fixtures used. Explosion proof LED lights must be used in facilities that deal with explosive dust and gases. The units must comply with the guidelines set by the National Electric Code. In case of an explosion, explosion proof LEDs contain the activity and ensure it does not spread.

Operators inspecting storage tanks and confined spaces should use LED drop lights as these units are designed for tasks that require portable lighting. These LED fixtures are usually shatterproof, shock-resistant, and devoid of glass. They have hooks located at their tops that enable people to easily latch them on various structures for support.

Businesses can use LED dock lights to meet the needs of hectic delivery bays when receiving products. Hinges or extendable arms can be attached to the units to create versatile lighting options for workers.

Supermarkets and restaurants normally use LED lights to adhere to Hazard Analysis and Critical Control Points (HACCP) guidelines. Most of the time, these units are found in the backend. Since LEDs are solid state lighting devices, they contain no fragile parts, which means glass and toxic chemicals cannot make their way into food.

They also have a very low heat output, which ensures that cooking processes are not affected by high temperature levels. This feature is very critical in baking stations as a minor change in temperature can quickly melt icing, cake batters, and chocolate.

3 Benefits LED Lighting Offers Food Facilities

Energy Efficiency

The major reason LEDs are so popular is because they offer significant energy savings compared to conventional lighting technologies. Before LEDs were introduced to the market, metal halides and fluorescent lamps were used in many food and beverage plants. However, these lights are not energy-efficient, waste a lot of energy as heat, take a long time to warm up and cool down, and lose their brightness extremely fast.

LEDs can reduce energy consumption by as much as 75%. If they are paired with lighting controls, the energy savings can be as much as 90%. They have a high lumen output and do not need a lot of watts to produce adequate light. For instance, a 400W metal halide bulb usually consumes about 470 watts. A 150W LED bulb can easily replace this traditional bulb and offer better light because of its higher lumen output and Color Rendering Index.

Food plants that switch to LED don’t just save money on their monthly electric bills, they also save money during the conversion project as many utility companies and government programs offer rebates for installing energy-efficient lighting. Government programs are a big motivator in converting to LED technology. Most food manufacturers make the switch because of the rebates and incentives offered. The added benefit is that they also get better lighting and create a safer working environment for their employees.

Less Downtime and Reduced Labor Costs

While energy efficiency and compliance are the top motivators for converting to LED lighting, the real value of LEDs comes from their lower ownership costs. Most businesses don’t think of getting ROI on their lighting, but LEDs usually pay for themselves in less than 2 years.

While their upfront costs may be a bit higher than for metal halides and fluorescent lamps, the cost of ownership is considerably lower. LEDs last 10 times longer than traditional lighting technologies, meaning they have to be replaced less often. Their long lifespan lowers both downtime and labor costs.

Metal halide and fluorescent lamps have a very steep degradation curve. After one year, they may only produce 60% of their initial light output, and after 2 years they may only produce 40%. These lighting systems have no return on investment because they have to be replaced every now and then. You may pay $60 for the light bulb, $80 for the electrician, and $200 for the lift used to install the bulbs. The costs add up quickly.

But LEDs only lose about 2% of their original light output every two years. It takes approximately 10 years for the light to degrade 20%. In food processing facilities, LED bulbs can easily last 5 years and still offer sufficient illumination. The same cannot be said for metal halide and fluorescent bulbs which only offer adequate light for less than one year. When converting to LED lighting, the return on interest is more important than the initial cost of the product.

LEDs Have Excellent Color Rendition, Which Is Vital For Food Safety

LEDs don’t just provide high-quality light, they also render colors very well, thanks to their high Color Rendering Index (CRI). Color Rendering Index is a measurement that ranges from 0 to 100 which measures how precisely a light source renders colors when compared to the perfect light source, the sun.

The sun has a Color Rendering Index of 100, which means it renders the whole color spectrum perfectly. High-quality LED lights have a color rendering index of 70 and above. Those with a Color Rendering Index of 80 and above render colors very well.

The United States Department of Agriculture and the Food Drug Administration specify lighting requirements for food and beverage plants. The USDA requires food inspection areas to have a CRI of 85 and general food processing areas to meet a CRI of 70.

In the food and beverage industry, accurate color rendering is crucial for assuring product quality. It is also important for compliance because it is one of the things that are examined by food safety inspectors. In order to comply with the stringent standards that are set by the regulatory agencies, many food processing plants are making the switch from metal halide lamps to LEDs.

In days gone by, the Color Rendering Index for food inspection areas was in the high 70s. It was later changed to 80, then 83 and now it’s 85. If any changes are made in the near future, chances are that the number will be higher because a high CRI helps food inspectors to make very accurate assessments.

Forward-thinking LED manufacturers are now manufacturing LEDs with a CRI of 85 and above. They are not aiming for the current industry standards because history has shown that the standards will change, so they most definitely will.

Thinking of Switching to LED Lighting To Enhance Food Safety? Talk to Us!

At The Lighting Center, we don’t just meet your lighting needs, we also offer retrofits, replacements, upgrade parts, and industrial-grade power accessories. Our lighting experts can create any lighting plan or design to fit the unique requirements of your food facility.

Our commitment to quality, dependability, and honesty has made our company a leader in the lighting industry. Contact us today to get more information on our customized options for your specific industry needs.

from TheLightingCenter.com https://www.thelightingcenter.com/applications-and-benefits-of-led-lighting-in-food-safety/

from The Lighting Center https://thelightingcenter.tumblr.com/post/179929159001

0 notes

Text

Applications and Benefits of LED Lighting in Food Safety

As the old adage goes, “Cleanliness is next to godliness.” However, in the United States, the food and beverage industry is tightly controlled by the U.S. Department of Agriculture (USDA) and the Food and Drug Administration (FDA). In other countries around the world, similar regulatory agencies regulate the food and beverage industry.

To ensure sanitary conditions are always maintained, all appliances and equipment used in food and beverage facilities – including lighting – must adhere to strict manufacturing standards set by the National Sanitation Foundation (NSF International). Food and beverage plants require lighting fixtures that must function optimally under hygienic and even hazardous conditions.

The compliance standards that apply to a specific food and beverage facility and the lighting fixtures used usually depend on the specific facility. Food production facilities, food processing facilities, food storage facilities, and food preparation facilities all require different types of lighting fixtures.

These plants have different lighting needs from industrial spaces like warehouses and manufacturing plants. For example, the lighting fixtures used in food processing areas must be able to withstand airborne dust, water, steam, grime, oils, mists, effluents, and other contaminants.

The Stringent Standards in the Food and Beverage Industry

NSF International has set strict standards that are based on a location’s condition and the extent of contact with food procedures. The NSF standard that relates to food and beverage lighting products is referred to as NSF/ANSI Standard 2, or just NSF 2.

It categorizes food facilities into 3 zonal groups: Food Zones, Non-Food Zones, and Splash Zones. Each zone represents specific surroundings which include locations where there isn’t any direct contact with food produce (like food storage areas), locations where there is direct contact with food, and wet-processing locations, those that need high pressure wash downs.

NSF International also requires that food and beverage plants use light fixtures with IP65 or IP66 Ingress Protection ratings. The luminaires must also have UL damp location or UL wet location ratings. Vapor-tight lighting fixtures must be used in hazardous locations (for instance, Class 1 Division 1 and Class 1 Division 2). The fixtures should also be cleanroom-rated.

Some food and beverage plants normally use the lighting fixtures that are found in other industrial settings. However, the fixtures used in these spaces must perform optimally under sanitary and even dangerous conditions. The types of lighting products used and the compliance standards that are applicable usually depend on the environment of a particular area – because food plants usually house different environments under one roof.

A food facility might have locations for processing, staging, warehousing, cold or dry storage, distribution, offices, restrooms, lobbies, hallways, cleanrooms, and a lot more. Each of these has its own lighting requirements.

Lighting products never come into direct contact with food, so only the NSF regulations for Splash Zones and Non-Food Zones usually apply to them. LED lighting manufacturers who would like to obtain NSF-2 certification for their lighting products must make sure that the products’ design, their materials, and the manufacturing processes used comply with the NSF standards for the relevant zone.

Some food plants, such as grain processing facilities, have areas with flammable gases or dust that can cause dangerous situations. In these locations, lighting products should fall under Class 2 Division 1 or 2 and group G.

LED Technology Meets All Stringent Standards of the Food Industry

Light-emitting diodes have unique properties that make them highly suitable for different operations in the food industry. They include:

A long life expectancy

Mechanical robustness

High emissions of monochromatic light

Low radiant heat emissions

Flexibility

Because of the way they are constructed, they may decrease degradation and thermal damage in foods and are suitable for cold storage applications. Recent research has shown that LEDs can preserve or even improve the nutritive quality of food in the postharvest stage and reduce fungal infections.

LED lights can be used together with photocatalysts or photosensitizes to inactivate pathogenic bacteria in food. Ultraviolet LEDs – which were introduced to the market not very long ago – can efficiently inactivate pathogens and preserve the freshness of food in postharvest stages.

High intensity discharge lights (such as high pressure sodium, metal halide, and xenon lamps) and fluorescent lamps have been popular lighting sources in food production and preservation facilities. However, these lighting systems have broad spectral power distribution and give off a lot of heat.

To control the temperature in various applications, such as food processing plants and food storage facilities, more energy is needed to remove the excess heat they produce. In addition, low pressure mercury lamps and fluorescent lights contain mercury and must be handled with utmost care to prevent damage and leakage of the toxic metal.

Light-emitting diodes are solid state lighting devices that produce light with wavelengths of narrow bandwidths, low thermal output, and high photoelectric efficiency. They are portable and compact and can be easily incorporated into electronic systems. As we earlier mentioned, LEDs have unique properties that make for the convenient manipulation of the luminous intensity, temporal settings, and spectral characteristics of the light produced.

In the 1970s, when LEDs were still in the early stages of development, they had very low power and were mostly used as indicator lamps. But as LED technology rapidly developed, new semiconductor materials were integrated, optics were improved, and enhanced techniques of thermal dissipation were implemented. Because of this, LEDs became universal and are widely used in different applications.

LEDs have low radiant heat emissions and their efficiency improves at lower temperatures, which makes them perfect for food storage facilities. Because food safety is a major concern in the food industry at all stages (production, processing, storage, and preparation), LEDs are used in these applications to ensure that food is not contaminated and is safe for consumption.

Thanks to their long life expectancy and their compactness and robustness, LEDs are a very economical technology to adopt. And as the technology continues to advance, LEDs become more efficient and cheaper. It is expected that more companies in the food and beverage industry will convert to LED because of the benefits it offers to food and also for compliance purposes.

Complying with Food Safety Standards

The great thing about LEDs is that they comply with the strict requirements that are set by the U.S. Department of Agriculture and The Food and Drug Administration. The FDA defines adequate lighting in food manufacturing facilities as.

540 lux in areas where food employees work with food equipment or utensils and safety is paramount

215 lux in locations where packaged food is sold or provided for consumption and in self-service areas

108 lux at 30 inches above the floor in dry storage areas and walk-in refrigeration areas

Meat, poultry, and dairy processing plants that want to comply with the USDA regulations for inspections must follow specific illumination criteria. The lighting guidelines stipulate:

30 foot candles in all locations where dairy products are cleaned, produced, or packaged

30 foot candles in all locations where utensils are washed, produced, or packaged

50 foot candles in all locations where products can get contaminated. Additionally, the luminaires should be protected from breakage

50 to 200 foot candles for inspection stations (the foot candles required depend on the specific inspection area)

The Illuminating Engineering Society of North America (IESNA) has specific illumination levels for different food processing areas. For example, the illumination levels for food examination areas range between 30 to 1,000 foot candles, depending on the intricacy of the process. Locations for color grading must have a minimum of 150 foot candles, while packing areas need a minimum of 30 foot candles.

These are some of the requirements that businesses must observe if they want to adhere to the Food and Drug Administration’s Current Good Manufacturing Practices. The guidelines also stipulate that lights in facilities where food is present must be coated, shielded, covered, or provide shatterproof protection.

The Application of LEDs in Food Safety

The food industry depends on powerful lighting systems to enhance productivity and safety in the workplace. Food processing, manufacturing, and retail establishments are shifting from traditional lighting systems (such as high intensity discharge lights and fluorescent lamps) to light emitting diode products. This is because LED technology is able to meet the strict food safety guidelines set by the regulatory bodies in place.

According to research, by 2020, the adoption of LED technology in the food industry will reach $80 billion annually. The food plants that are currently leading in the adoption of LED technology are food processing and manufacturing facilities, because LEDs provide solutions to the complex and challenging working conditions in these environments.

The successful application of LEDs in food processing and manufacturing facilities usually depends on the types of fixtures used. Explosion proof LED lights must be used in facilities that deal with explosive dust and gases. The units must comply with the guidelines set by the National Electric Code. In case of an explosion, explosion proof LEDs contain the activity and ensure it does not spread.

Operators inspecting storage tanks and confined spaces should use LED drop lights as these units are designed for tasks that require portable lighting. These LED fixtures are usually shatterproof, shock-resistant, and devoid of glass. They have hooks located at their tops that enable people to easily latch them on various structures for support.

Businesses can use LED dock lights to meet the needs of hectic delivery bays when receiving products. Hinges or extendable arms can be attached to the units to create versatile lighting options for workers.

Supermarkets and restaurants normally use LED lights to adhere to Hazard Analysis and Critical Control Points (HACCP) guidelines. Most of the time, these units are found in the backend. Since LEDs are solid state lighting devices, they contain no fragile parts, which means glass and toxic chemicals cannot make their way into food.

They also have a very low heat output, which ensures that cooking processes are not affected by high temperature levels. This feature is very critical in baking stations as a minor change in temperature can quickly melt icing, cake batters, and chocolate.

3 Benefits LED Lighting Offers Food Facilities

Energy Efficiency

The major reason LEDs are so popular is because they offer significant energy savings compared to conventional lighting technologies. Before LEDs were introduced to the market, metal halides and fluorescent lamps were used in many food and beverage plants. However, these lights are not energy-efficient, waste a lot of energy as heat, take a long time to warm up and cool down, and lose their brightness extremely fast.

LEDs can reduce energy consumption by as much as 75%. If they are paired with lighting controls, the energy savings can be as much as 90%. They have a high lumen output and do not need a lot of watts to produce adequate light. For instance, a 400W metal halide bulb usually consumes about 470 watts. A 150W LED bulb can easily replace this traditional bulb and offer better light because of its higher lumen output and Color Rendering Index.

Food plants that switch to LED don’t just save money on their monthly electric bills, they also save money during the conversion project as many utility companies and government programs offer rebates for installing energy-efficient lighting. Government programs are a big motivator in converting to LED technology. Most food manufacturers make the switch because of the rebates and incentives offered. The added benefit is that they also get better lighting and create a safer working environment for their employees.

Less Downtime and Reduced Labor Costs

While energy efficiency and compliance are the top motivators for converting to LED lighting, the real value of LEDs comes from their lower ownership costs. Most businesses don’t think of getting ROI on their lighting, but LEDs usually pay for themselves in less than 2 years.

While their upfront costs may be a bit higher than for metal halides and fluorescent lamps, the cost of ownership is considerably lower. LEDs last 10 times longer than traditional lighting technologies, meaning they have to be replaced less often. Their long lifespan lowers both downtime and labor costs.

Metal halide and fluorescent lamps have a very steep degradation curve. After one year, they may only produce 60% of their initial light output, and after 2 years they may only produce 40%. These lighting systems have no return on investment because they have to be replaced every now and then. You may pay $60 for the light bulb, $80 for the electrician, and $200 for the lift used to install the bulbs. The costs add up quickly.

But LEDs only lose about 2% of their original light output every two years. It takes approximately 10 years for the light to degrade 20%. In food processing facilities, LED bulbs can easily last 5 years and still offer sufficient illumination. The same cannot be said for metal halide and fluorescent bulbs which only offer adequate light for less than one year. When converting to LED lighting, the return on interest is more important than the initial cost of the product.

LEDs Have Excellent Color Rendition, Which Is Vital For Food Safety

LEDs don’t just provide high-quality light, they also render colors very well, thanks to their high Color Rendering Index (CRI). Color Rendering Index is a measurement that ranges from 0 to 100 which measures how precisely a light source renders colors when compared to the perfect light source, the sun.

The sun has a Color Rendering Index of 100, which means it renders the whole color spectrum perfectly. High-quality LED lights have a color rendering index of 70 and above. Those with a Color Rendering Index of 80 and above render colors very well.

The United States Department of Agriculture and the Food Drug Administration specify lighting requirements for food and beverage plants. The USDA requires food inspection areas to have a CRI of 85 and general food processing areas to meet a CRI of 70.

In the food and beverage industry, accurate color rendering is crucial for assuring product quality. It is also important for compliance because it is one of the things that are examined by food safety inspectors. In order to comply with the stringent standards that are set by the regulatory agencies, many food processing plants are making the switch from metal halide lamps to LEDs.

In days gone by, the Color Rendering Index for food inspection areas was in the high 70s. It was later changed to 80, then 83 and now it’s 85. If any changes are made in the near future, chances are that the number will be higher because a high CRI helps food inspectors to make very accurate assessments.

Forward-thinking LED manufacturers are now manufacturing LEDs with a CRI of 85 and above. They are not aiming for the current industry standards because history has shown that the standards will change, so they most definitely will.

Thinking of Switching to LED Lighting To Enhance Food Safety? Talk to Us!

At The Lighting Center, we don’t just meet your lighting needs, we also offer retrofits, replacements, upgrade parts, and industrial-grade power accessories. Our lighting experts can create any lighting plan or design to fit the unique requirements of your food facility.

Our commitment to quality, dependability, and honesty has made our company a leader in the lighting industry. Contact us today to get more information on our customized options for your specific industry needs.

from TheLightingCenter.com https://www.thelightingcenter.com/applications-and-benefits-of-led-lighting-in-food-safety/

0 notes

Text

Applications and Benefits of LED Lighting in Food Safety

As the old adage goes, “Cleanliness is next to godliness.” However, in the United States, the food and beverage industry is tightly controlled by the U.S. Department of Agriculture (USDA) and the Food and Drug Administration (FDA). In other countries around the world, similar regulatory agencies regulate the food and beverage industry.

To ensure sanitary conditions are always maintained, all appliances and equipment used in food and beverage facilities – including lighting – must adhere to strict manufacturing standards set by the National Sanitation Foundation (NSF International). Food and beverage plants require lighting fixtures that must function optimally under hygienic and even hazardous conditions.

The compliance standards that apply to a specific food and beverage facility and the lighting fixtures used usually depend on the specific facility. Food production facilities, food processing facilities, food storage facilities, and food preparation facilities all require different types of lighting fixtures.

These plants have different lighting needs from industrial spaces like warehouses and manufacturing plants. For example, the lighting fixtures used in food processing areas must be able to withstand airborne dust, water, steam, grime, oils, mists, effluents, and other contaminants.

The Stringent Standards in the Food and Beverage Industry

NSF International has set strict standards that are based on a location’s condition and the extent of contact with food procedures. The NSF standard that relates to food and beverage lighting products is referred to as NSF/ANSI Standard 2, or just NSF 2.

It categorizes food facilities into 3 zonal groups: Food Zones, Non-Food Zones, and Splash Zones. Each zone represents specific surroundings which include locations where there isn’t any direct contact with food produce (like food storage areas), locations where there is direct contact with food, and wet-processing locations, those that need high pressure wash downs.

NSF International also requires that food and beverage plants use light fixtures with IP65 or IP66 Ingress Protection ratings. The luminaires must also have UL damp location or UL wet location ratings. Vapor-tight lighting fixtures must be used in hazardous locations (for instance, Class 1 Division 1 and Class 1 Division 2). The fixtures should also be cleanroom-rated.

Some food and beverage plants normally use the lighting fixtures that are found in other industrial settings. However, the fixtures used in these spaces must perform optimally under sanitary and even dangerous conditions. The types of lighting products used and the compliance standards that are applicable usually depend on the environment of a particular area – because food plants usually house different environments under one roof.

A food facility might have locations for processing, staging, warehousing, cold or dry storage, distribution, offices, restrooms, lobbies, hallways, cleanrooms, and a lot more. Each of these has its own lighting requirements.

Lighting products never come into direct contact with food, so only the NSF regulations for Splash Zones and Non-Food Zones usually apply to them. LED lighting manufacturers who would like to obtain NSF-2 certification for their lighting products must make sure that the products’ design, their materials, and the manufacturing processes used comply with the NSF standards for the relevant zone.

Some food plants, such as grain processing facilities, have areas with flammable gases or dust that can cause dangerous situations. In these locations, lighting products should fall under Class 2 Division 1 or 2 and group G.

LED Technology Meets All Stringent Standards of the Food Industry

Light-emitting diodes have unique properties that make them highly suitable for different operations in the food industry. They include:

A long life expectancy

Mechanical robustness

High emissions of monochromatic light

Low radiant heat emissions

Flexibility

Because of the way they are constructed, they may decrease degradation and thermal damage in foods and are suitable for cold storage applications. Recent research has shown that LEDs can preserve or even improve the nutritive quality of food in the postharvest stage and reduce fungal infections.

LED lights can be used together with photocatalysts or photosensitizes to inactivate pathogenic bacteria in food. Ultraviolet LEDs – which were introduced to the market not very long ago – can efficiently inactivate pathogens and preserve the freshness of food in postharvest stages.

High intensity discharge lights (such as high pressure sodium, metal halide, and xenon lamps) and fluorescent lamps have been popular lighting sources in food production and preservation facilities. However, these lighting systems have broad spectral power distribution and give off a lot of heat.

To control the temperature in various applications, such as food processing plants and food storage facilities, more energy is needed to remove the excess heat they produce. In addition, low pressure mercury lamps and fluorescent lights contain mercury and must be handled with utmost care to prevent damage and leakage of the toxic metal.

Light-emitting diodes are solid state lighting devices that produce light with wavelengths of narrow bandwidths, low thermal output, and high photoelectric efficiency. They are portable and compact and can be easily incorporated into electronic systems. As we earlier mentioned, LEDs have unique properties that make for the convenient manipulation of the luminous intensity, temporal settings, and spectral characteristics of the light produced.

In the 1970s, when LEDs were still in the early stages of development, they had very low power and were mostly used as indicator lamps. But as LED technology rapidly developed, new semiconductor materials were integrated, optics were improved, and enhanced techniques of thermal dissipation were implemented. Because of this, LEDs became universal and are widely used in different applications.

LEDs have low radiant heat emissions and their efficiency improves at lower temperatures, which makes them perfect for food storage facilities. Because food safety is a major concern in the food industry at all stages (production, processing, storage, and preparation), LEDs are used in these applications to ensure that food is not contaminated and is safe for consumption.

Thanks to their long life expectancy and their compactness and robustness, LEDs are a very economical technology to adopt. And as the technology continues to advance, LEDs become more efficient and cheaper. It is expected that more companies in the food and beverage industry will convert to LED because of the benefits it offers to food and also for compliance purposes.

Complying with Food Safety Standards

The great thing about LEDs is that they comply with the strict requirements that are set by the U.S. Department of Agriculture and The Food and Drug Administration. The FDA defines adequate lighting in food manufacturing facilities as.

540 lux in areas where food employees work with food equipment or utensils and safety is paramount

215 lux in locations where packaged food is sold or provided for consumption and in self-service areas

108 lux at 30 inches above the floor in dry storage areas and walk-in refrigeration areas

Meat, poultry, and dairy processing plants that want to comply with the USDA regulations for inspections must follow specific illumination criteria. The lighting guidelines stipulate:

30 foot candles in all locations where dairy products are cleaned, produced, or packaged

30 foot candles in all locations where utensils are washed, produced, or packaged

50 foot candles in all locations where products can get contaminated. Additionally, the luminaires should be protected from breakage

50 to 200 foot candles for inspection stations (the foot candles required depend on the specific inspection area)

The Illuminating Engineering Society of North America (IESNA) has specific illumination levels for different food processing areas. For example, the illumination levels for food examination areas range between 30 to 1,000 foot candles, depending on the intricacy of the process. Locations for color grading must have a minimum of 150 foot candles, while packing areas need a minimum of 30 foot candles.

These are some of the requirements that businesses must observe if they want to adhere to the Food and Drug Administration’s Current Good Manufacturing Practices. The guidelines also stipulate that lights in facilities where food is present must be coated, shielded, covered, or provide shatterproof protection.

The Application of LEDs in Food Safety

The food industry depends on powerful lighting systems to enhance productivity and safety in the workplace. Food processing, manufacturing, and retail establishments are shifting from traditional lighting systems (such as high intensity discharge lights and fluorescent lamps) to light emitting diode products. This is because LED technology is able to meet the strict food safety guidelines set by the regulatory bodies in place.

According to research, by 2020, the adoption of LED technology in the food industry will reach $80 billion annually. The food plants that are currently leading in the adoption of LED technology are food processing and manufacturing facilities, because LEDs provide solutions to the complex and challenging working conditions in these environments.

The successful application of LEDs in food processing and manufacturing facilities usually depends on the types of fixtures used. Explosion proof LED lights must be used in facilities that deal with explosive dust and gases. The units must comply with the guidelines set by the National Electric Code. In case of an explosion, explosion proof LEDs contain the activity and ensure it does not spread.

Operators inspecting storage tanks and confined spaces should use LED drop lights as these units are designed for tasks that require portable lighting. These LED fixtures are usually shatterproof, shock-resistant, and devoid of glass. They have hooks located at their tops that enable people to easily latch them on various structures for support.

Businesses can use LED dock lights to meet the needs of hectic delivery bays when receiving products. Hinges or extendable arms can be attached to the units to create versatile lighting options for workers.

Supermarkets and restaurants normally use LED lights to adhere to Hazard Analysis and Critical Control Points (HACCP) guidelines. Most of the time, these units are found in the backend. Since LEDs are solid state lighting devices, they contain no fragile parts, which means glass and toxic chemicals cannot make their way into food.

They also have a very low heat output, which ensures that cooking processes are not affected by high temperature levels. This feature is very critical in baking stations as a minor change in temperature can quickly melt icing, cake batters, and chocolate.

3 Benefits LED Lighting Offers Food Facilities

Energy Efficiency

The major reason LEDs are so popular is because they offer significant energy savings compared to conventional lighting technologies. Before LEDs were introduced to the market, metal halides and fluorescent lamps were used in many food and beverage plants. However, these lights are not energy-efficient, waste a lot of energy as heat, take a long time to warm up and cool down, and lose their brightness extremely fast.

LEDs can reduce energy consumption by as much as 75%. If they are paired with lighting controls, the energy savings can be as much as 90%. They have a high lumen output and do not need a lot of watts to produce adequate light. For instance, a 400W metal halide bulb usually consumes about 470 watts. A 150W LED bulb can easily replace this traditional bulb and offer better light because of its higher lumen output and Color Rendering Index.

Food plants that switch to LED don’t just save money on their monthly electric bills, they also save money during the conversion project as many utility companies and government programs offer rebates for installing energy-efficient lighting. Government programs are a big motivator in converting to LED technology. Most food manufacturers make the switch because of the rebates and incentives offered. The added benefit is that they also get better lighting and create a safer working environment for their employees.

Less Downtime and Reduced Labor Costs

While energy efficiency and compliance are the top motivators for converting to LED lighting, the real value of LEDs comes from their lower ownership costs. Most businesses don’t think of getting ROI on their lighting, but LEDs usually pay for themselves in less than 2 years.

While their upfront costs may be a bit higher than for metal halides and fluorescent lamps, the cost of ownership is considerably lower. LEDs last 10 times longer than traditional lighting technologies, meaning they have to be replaced less often. Their long lifespan lowers both downtime and labor costs.

Metal halide and fluorescent lamps have a very steep degradation curve. After one year, they may only produce 60% of their initial light output, and after 2 years they may only produce 40%. These lighting systems have no return on investment because they have to be replaced every now and then. You may pay $60 for the light bulb, $80 for the electrician, and $200 for the lift used to install the bulbs. The costs add up quickly.

But LEDs only lose about 2% of their original light output every two years. It takes approximately 10 years for the light to degrade 20%. In food processing facilities, LED bulbs can easily last 5 years and still offer sufficient illumination. The same cannot be said for metal halide and fluorescent bulbs which only offer adequate light for less than one year. When converting to LED lighting, the return on interest is more important than the initial cost of the product.

LEDs Have Excellent Color Rendition, Which Is Vital For Food Safety