#lime particle sizes

Explore tagged Tumblr posts

Link

3 notes

·

View notes

Text

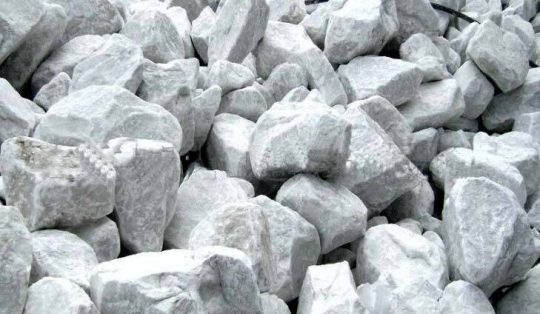

Export Quality Limestone from Rajasthan

Rajasthan, a state rich in natural resources, has emerged as a global hub for limestone mining and processing. Its limestone is not just abundant but also of export quality — ideal for steel, construction, chemical, and agriculture industries. But what truly makes Rajasthan's limestone stand out in the international market?

This blog explores what sets export quality limestone from Rajasthan apart, the role of leading lime manufacturers in India, and how lime suppliers in Jodhpur contribute to the global supply chain.

1. Geological Superiority of Rajasthan’s Limestone

Rajasthan has vast reserves of high-grade limestone with high calcium content and low impurities. These characteristics make the limestone ideal for applications such as cement manufacturing, steel production, water treatment, and soil neutralization.

The mineralogical structure found in districts like Jodhpur, Nagaur, and Udaipur provides consistent quality, essential for export standards.

2. Advanced Mining and Processing Infrastructure

The state has heavily invested in mechanized mining and advanced crushing, screening, and grinding technology. This ensures:

Uniform particle size

Reduced contamination

Higher purity levels

Consistency in bulk supply

Best Lime Manufacturers in India have set up processing plants near mining areas to reduce lead time and maintain quality control.

3. Strict Adherence to Global Export Standards

Exporters from Rajasthan ensure compliance with international quality standards like ASTM, BIS, and EN. Parameters such as calcium oxide (CaO) levels, silica content, and moisture levels are regularly tested.

Moreover, certifications like ISO and CE among Rajasthan-based lime manufacturers in India boost the credibility of their products in global markets.

4. Customization in Lime Products

Export clients often require customized grades of limestone or lime products (quick lime, hydrated lime, calcined lime). The best lime manufacturers in India, especially in Rajasthan, offer:

Tailor-made mesh sizes

Specific chemical compositions

Packaging for sea transport

Bulk and container shipment flexibility

Such adaptability makes lime suppliers in Jodhpur reliable partners for international businesses.

5. Strategic Location and Seamless Export Logistics

Rajasthan's proximity to ports like Kandla, Mundra, and Mumbai enables smooth exports. Moreover, strong rail and road connectivity from industrial hubs like Jodhpur, Nagaur, and Kota ensures timely delivery to ports.

With dedicated warehousing and logistics partners, most lime manufacturers in India from Rajasthan offer end-to-end export handling services.

6. Government Policies Encouraging Exports

Rajasthan’s state policies promote mineral-based industries. Ease of obtaining mining leases, environmental clearances, and subsidies on exports have made it easier for lime suppliers in Jodhpur to expand their international footprint.

Additionally, initiatives like the Rajasthan Investment Promotion Scheme (RIPS) further support mineral exporters with tax benefits and incentives.

7. Sustainable Mining and Eco-Friendly Practices

Many reputed lime manufacturers in India adopt sustainable practices:

Controlled blasting to reduce environmental impact

Water recycling and dust suppression systems

Renewable energy integration in processing plants

Zero-waste management systems for lime kilns

This commitment to sustainability also attracts global clients prioritizing eco-conscious sourcing.

8. Versatile Applications Across Industries

The high-quality limestone from Rajasthan caters to various industries:

Steel Industry: Used as flux in blast furnaces

Cement Industry: Base material for clinker production

Chemical Industry: Essential in calcium-based compounds

Water Treatment: Lime stabilizes pH in wastewater

Agriculture: Improves soil quality by reducing acidity

Because of this versatility, Rajasthan’s limestone sees constant global demand, making lime suppliers in Jodhpur essential to many industries.

9. Trusted Brands and Long-Term Exporters

Some of the top lime manufacturers in India headquartered in Rajasthan have been exporting lime products for decades. Their international client base spans the Middle East, Southeast Asia, Africa, and Europe.

Their reputation is built on:

High-quality products

On-time shipments

Transparent communication

Technical support

These long-standing relationships reinforce Rajasthan’s global dominance in lime exports.

10. Competitive Pricing and Bulk Supply Capabilities

Despite its superior quality, Rajasthan’s limestone remains cost-effective due to:

Low extraction costs

Availability in large volumes

Proximity to processing hubs

This allows lime suppliers in Jodhpur to offer competitive pricing without compromising quality—making them the preferred choice in both domestic and international markets.

Final Thoughts

Rajasthan's export quality limestone stands tall on the pillars of geological richness, modern processing, sustainability, and international trust. From Jodhpur’s robust lime supply chain to cutting-edge manufacturing facilities, the region exemplifies excellence in mineral exports.

If you're seeking reliable lime manufacturers in India or exploring partnerships with lime suppliers in Jodhpur, Rajasthan is undoubtedly your best bet for premium, export-ready limestone products.

0 notes

Text

Can Calcium Carbonate Powder Replace Traditional Fillers in Modern Manufacturing?

In the ever-evolving world of manufacturing, companies constantly seek materials that enhance product performance while remaining cost-effective. As industries adapt to environmental concerns and shifting economic factors that influence the use of Calcium Carbonate Powder emerges as a strong contender against traditional fillers. Could this mineral truly redefine how we approach industrial fillers?

Understanding Traditional Fillers in Manufacturing

Traditional fillers like talc, kaolin clay, silica, and carbon black have been extensively used for decades. They serve crucial roles in altering material properties, reducing costs, and enhancing processing capabilities. However, these fillers come with their own limitations—rising costs, limited reserves, and growing environmental concerns, which drive industries to explore alternative solutions.

What is Calcium Carbonate Powder?

At its core, calcium carbonate powder is a naturally occurring mineral composed of calcium, carbon, and oxygen. Found in abundance in limestone, marble, and chalk deposits, it is processed into a fine, white powder that can be incorporated into various manufacturing processes.

Historical Use of Calcium Carbonate

Calcium carbonate isn’t new to the scene. It has long been used in construction (cement, lime), agriculture (soil treatment), and food industries (as a dietary supplement). But its role in modern manufacturing as a primary filler has only recently gained momentum.

How Calcium Carbonate Powder Differs from Traditional Fillers

Unlike many traditional fillers, calcium carbonate powder offers a unique combination of affordability, performance, and versatility. Its low abrasiveness, high whiteness, and excellent dispersion qualities make it ideal for a wide range of applications, setting it apart from its more expensive or environmentally challenging counterparts.

The Growing Demand for Sustainable Alternatives

Today’s manufacturers face mounting pressure to adopt greener, more sustainable practices. Traditional fillers, often requiring energy-intensive mining and processing, contribute significantly to environmental degradation. Calcium carbonate powder, being widely available and requiring relatively lower processing energy, presents an eco-friendlier choice.

Key Industries Using Calcium Carbonate Powder

Plastics Industry

In the plastics sector, calcium carbonate powder is increasingly favored as a filler. It enhances rigidity, improves dimensional stability, and reduces production costs, all while maintaining the desired mechanical properties of the plastic products.

Rubber Industry

Rubber manufacturers benefit from the inclusion of calcium carbonate powder by improving the stiffness and durability of rubber products. Its fine particle size allows for uniform dispersion, leading to superior product consistency.

Paints and Coatings Industry

Calcium carbonate powder acts as a functional extender pigment, contributing to better opacity, surface gloss, and paint durability. It also helps in reducing the reliance on more expensive titanium dioxide.

Paper Industry

One of the oldest applications, calcium carbonate powder, helps improve brightness, opacity, and smoothness of paper, while also enhancing printability and reducing production costs.

Advantages of Using Calcium Carbonate Powder

Cost Efficiency

Perhaps one of the most attractive aspects for manufacturers is its affordability. Calcium carbonate powder reduces the need for more costly raw materials without compromising product performance.

Improved Product Properties

Products filled with calcium carbonate often exhibit improved physical properties—enhanced strength, better processing behavior, and improved thermal stability, making them more desirable in competitive markets.

Environmental Benefits

Compared to some traditional fillers, calcium carbonate powder offers lower carbon footprint production. Its wide availability also means reduced environmental impact from mining operations.

Challenges and Limitations

While calcium carbonate powder offers numerous benefits, it isn’t a perfect solution for every application. Issues like compatibility with certain polymers, moisture sensitivity, and limitations in ultra-high-performance materials still require careful consideration.

Technological Innovations Boosting Its Adoption

Advances in surface modification technology, nano-calcium carbonate production, and enhanced dispersion methods have significantly improved its application range, addressing many of its earlier limitations and making it viable even in more demanding manufacturing processes.

Comparing Performance with Traditional Fillers

When directly compared, calcium carbonate powder often matches or exceeds traditional fillers in applications that prioritize cost, sustainability, and moderate performance requirements. However, in extremely high-performance products where specialized properties are critical, traditional fillers may still hold an edge.

Economic Implications for Manufacturers

For industries battling shrinking profit margins and rising raw material costs, calcium carbonate powder provides a lifeline. Its integration can dramatically cut production costs while maintaining, or even improving, product quality, leading to stronger market competitiveness.

Sudarshan Group’s Role in Supplying High-Quality Calcium Carbonate Powder

As a trusted name in the industry, Sudarshan Group has been at the forefront of delivering premium quality calcium carbonate powder to manufacturers across sectors. With stringent quality control, advanced processing facilities, and a commitment to sustainability, Sudarshan Group ensures that industries receive consistent, high-purity material tailored to their unique manufacturing needs.

Future Trends and Market Predictions

The global demand for calcium carbonate powder is projected to rise steadily as industries worldwide lean into sustainable, cost-effective manufacturing solutions. Innovations in processing and application technology are expected to widen its adoption even further, potentially positioning it as a dominant filler across multiple industries.

Conclusion

The manufacturing landscape is shifting, and calcium carbonate powder stands poised to take center stage. While it may not completely replace every traditional filler, its growing versatility, affordability, and environmental advantages make it a highly attractive option for many industries. Companies like Sudarshan Group are ensuring that this transition is smooth, providing top-quality materials that meet the evolving needs of modern manufacturers.

FAQs

Q1: Is calcium carbonate powder safe for all manufacturing processes? Yes, but manufacturers must consider compatibility with specific materials and processing conditions to optimize performance.

Q2: Can calcium carbonate powder fully replace titanium dioxide in paints? Not entirely. While it can significantly reduce the need for titanium dioxide, certain high-opacity requirements still necessitate some titanium dioxide usage.

Q3: Does calcium carbonate powder affect the recyclability of plastics? Generally, it does not negatively impact recyclability and can sometimes improve certain recycling processes by enhancing thermal properties.

Q4: What are the main environmental benefits of using calcium carbonate powder? Lower energy consumption during processing, abundant natural reserves, and reduced environmental footprint compared to some traditional fillers.

Q5: Why is Sudarshan Group considered a reliable supplier of calcium carbonate powder? Due to their strict quality control, advanced manufacturing techniques, and strong focus on customer-specific solutions, Sudarshan Group ensures high-quality, consistent products for various industries.

0 notes

Text

A Complete Guide to Ground Calcium Carbonate Grades for Industrial Use

Ground Calcium Carbonate (GCC) is a naturally occurring mineral that plays a critical role across a wide range of industrial applications. From plastics and paints to paper and rubber, GCC is used as a filler, extender, and performance enhancer. However, not all calcium carbonate is the same—different grades are formulated to meet the specific needs of various industries. This article provides a comprehensive overview of the different grades of Ground Calcium Carbonate, their properties, applications, and the importance of choosing a reliable Ground Calcium Carbonate Manufacturer in India.

What is Ground Calcium Carbonate?

Ground Calcium Carbonate is produced by grinding natural limestone or marble into fine powder. It retains the crystalline structure of the raw material and does not involve chemical processing, unlike precipitated calcium carbonate (PCC). The particle size, purity, brightness, and surface treatment of GCC can vary depending on its intended use, which leads to the development of different "grades."

Why Grades Matter in Ground Calcium Carbonate

The performance of GCC in industrial processes depends largely on the grade used. Factors that define GCC grades include:

Particle size distribution (PSD)

Purity (CaCO₃ content)

Brightness and whiteness

Oil absorption

Surface coating (coated or uncoated)

Using the correct grade ensures optimal performance, better efficiency, and reduced production costs.

Key Grades of Ground Calcium Carbonate and Their Applications

1. Fine Grade GCC

Description: Fine grade GCC typically has particle sizes below 10 microns. It offers high whiteness and good dispersion, making it ideal for applications requiring smooth surfaces and strong reinforcement.

Applications:

Plastics (PVC pipes, profiles, sheets)

Masterbatches and compounds

Rubber industry

Paints and coatings

Benefits:

Enhances mechanical strength

Improves surface finish

Reduces polymer consumption

A reliable Ground Calcium Carbonate Manufacturer in India can provide customized fine-grade GCC tailored for polymer processing applications.

2. Ultra-Fine Grade GCC

Description: Ultra-fine GCC has particles as small as 1 micron or less. This grade is used in high-performance applications where maximum smoothness, brightness, and opacity are critical.

Applications:

High-gloss paints and automotive coatings

Coated paper and printing paper

Thermoplastics and engineering plastics

Sealants and adhesives

Benefits:

Excellent dispersion and flowability

Higher opacity and brightness

Superior printability in paper applications

Manufacturers using ultra-fine GCC often rely on advanced grinding and classification technologies, which top-tier Ground Calcium Carbonate Manufacturers in India are equipped with.

3. Coarse Grade GCC

Description: Coarse grade GCC features larger particles (above 20 microns). It is used in applications where filler function is more about volume and weight than fine texture.

Applications:

Construction materials

Concrete and cement additives

Animal feed and agricultural lime

Benefits:

Economical filler

Improves bulk and reduces shrinkage

pH neutralizing effect in agriculture

This grade is particularly cost-effective and widely used in the building sector.

4. Coated GCC (Surface-Treated)

Description: This grade involves the surface modification of GCC particles with stearic acid or other hydrophobic agents. Coated GCC is primarily used in non-polar polymers where dispersion and adhesion are vital.

Applications:

Polypropylene (PP), polyethylene (PE), and other thermoplastics

Wire and cable insulation

High-performance rubber compounds

Benefits:

Improved compatibility with polymers

Better dispersion in plastic matrices

Enhanced mechanical properties

Working with an experienced Ground Calcium Carbonate Manufacturer in India is essential when sourcing coated grades, as coating consistency directly affects product quality.

5. High-Brightness GCC

Description: This grade has very high whiteness and brightness (typically over 96%) and is used in visual or print-sensitive products.

Applications:

Writing and printing paper

High-end decorative paints

Cosmetic and pharmaceutical applications (non-industrial grade)

Benefits:

Vibrant finish in coatings and paints

Sharp and clear print quality in paper

Enhanced product appearance

For industries that depend on visual quality, sourcing this grade from a reputable Ground Calcium Carbonate Manufacturer in India is critical to maintaining brand standards.

Choosing a Ground Calcium Carbonate Manufacturer in India

India has become a hub for high-quality GCC production, supported by vast limestone reserves and modern processing facilities. However, the supplier you choose plays a crucial role in the performance and consistency of your end product.

What to Look For:

Consistent Quality Control

Advanced Grinding & Coating Technology

Tailored Particle Size Distribution

Technical Support for Product Development

Compliance with International Standards

A top-tier Ground Calcium Carbonate Manufacturer in India will offer not only superior raw material but also end-to-end support, helping industries meet performance, cost, and sustainability goals.

Conclusion

Ground Calcium Carbonate is an indispensable material in modern manufacturing. With multiple grades available, it’s crucial for businesses to understand which type best suits their needs. Whether it’s fine-grade for plastics, ultra-fine for paints, or high-brightness for paper, each GCC grade serves a unique purpose.

Partnering with a reputable Ground Calcium Carbonate Manufacturer in India ensures access to reliable quality, customized solutions, and expert guidance—empowering industries to improve their products and optimize production costs.

0 notes

Text

On the global bundling market, quality, affordability, PP bag manufacturer in Rajkot and natural impact play a key role in selecting the correct structure. One product that stands tall in all three markets is the PP woven pack. Abbreviated as Polypropylene woven sacks, these bags have become the backbone of mass bundling for corporate entities like agribusiness, development, chemicals, and retail.

PP woven bags are renowned for their strength, flexibility, and durability, making them amongst the leading commonly used bundling solutions across the globe. This article explores what PP woven bags are, how they're fabricated, how they're applied, types, advantages, and why they're such a standard alternative across so many industries.PP bags for rice

What Are PP Woven Bags?

PP woven sacks consist of polypropylene, a type of plastic polymer that's woven into texture to create solid, flexible packs. The phrase "woven" refers to the process of interlap polypropylene strips in a crisscross pattern, creating a texture that's extreme and light.

Due to their woven construction, these bags are ideal for hauling inundating and bulk materials. They are widely used in both developed and developing countries and are commonly found in packaging uses for grains, fertilizers, cement, sand, animal feed, and more.

Manufacturing Process

The production of PP woven bags involves a few steps:

Extrusion

Raw polypropylene beads are melted and pushed out into flat, slender strips or tapes.

2. Stretching

The discarded tapes are stretched to adapt the particles and enhance strength.

3. Weaving

The stretched tapes are woven into texture using circular or level looms. This determines the base woven fabric.

4. Cover

Certain PP woven packs are coated with a thin film PP bags for rice of polypropylene or BOPP (Biaxially Oriented Polypropylene) to make them moisture-resistant and suitable for quality printing.

5. Cutting and Stitching

The woven fabric is cut to needed sizes and sewed in packs. Additions such as gussets, liners, or handles may be added at this point.

6. Printing

The packs may be printed using flexographic or rotogravure printing, particularly in case they are laminated with BOPP film.

Types of PP Woven Bags

PP woven sacks are available in a variety of shapes based on their usage:

Unlaminated PP Woven Bags

These are basic packs used for dry goods such as rice, wheat, beats, and sand. They are ventilated and cost-effective.

2. Covered PP Woven Bags

Laminated with a thin plastic film, these bags are water- and dust-proof, thus suitable for flour, sugar, and chemical powder.

3. BOPP Covered Bags

These high-end bags are ideal for purchaser commodities such as branded creature nourish, rice, and fertilizers. They support multicolor, high-resolution printing.

4. PP Woven Packs with Liner

These have a secondary polyethylene liner interior for water protection. Often used for chemical and fine powders.

5. Gusseted Bags

Having side tucks, these bags expand to hold more volume and are easier to stack.

6. Valve Bags

Primarily used in the cement industry, these bags contain a self-closing valve for high-speed filling and tight packaging.

Uses of PP Woven Bags

Agriculture

Used for compressing grains, seeds, fertilizers, and animal bolster. These bags keep the material away from moisture, pests, and sunlight.

2. Building

Suitable for the transportation of sand, cement, stone, and lime. PPwoven bags are robust enough to withstand unsavory usage on construction sites.

3. Chemical Industry

Used for packaging tars, powders, and minerals because of their chemical resistance and suitability for lining.

4. Retail Packing

With attractive BOPP prints, these packs are used for products such as pet nutrition, sugar, and branded rural items.

5. Waste Collection

PP woven bags are commonly used to collect mechanical waste, scrap, or recyclables because of their strength and capacity.

Advantages of PP Woven Bags

a. High Strength-to-Weight Ratio

These bags are strong enough to transport heavy loads but remain light in weight, decreasing the cost of transportation.

b. Resistance to Dampness and Chemicals

With discretionary cover or lining, they stand up to dampness and numerous chemicals, securing the substance effectively.

c. Customizable

Sizes, colors, printing, and highlights like handles or zippers can be customized based on application.

d. Cost-Effective

PP woven packs are among the foremost economical bulk bundling choices available.

e. Reusable and Recyclable

They can be reused several times and are completely recyclable, making them an eco-friendly elective to single-use plastic or paper.

Environmental Impact

While polypropylene may be a plastic shape, PP woven bags can be part of a sustainable bundling configuration in case used and recycled responsibly. Unlike one-time use plastic, these packs are designed to be reused multiple times. Also, several manufacturers today use recycled PP granules in production to minimize environmental impact.

Moreover, some companies are researching biodegradable laminations and coatings to further enhance upgrade eco-friendliness. If properly arranged, PP woven sacks leave a lower carbon footprint than paper sacks or jute sacks in many mechanical uses.

Limitations and Challenges

Even with their advantages, PP woven packs also have some limitations:

Not biodegradable â they need to be properly recycled.

Sun introduction weakens the fabric â unless UV-treated.

Not suitable for bundling liquids â unless modified or lined.

Needs mechanical installation for repeated use â not always available in rural regions.

But most of these issues are being addressed through material and reusing facility advancements.

Future Outlook

The need for solid, light, and low-cost bundling is expected to emerge in the next a long time, specifically in making economies. Through advances in sophisticated printing, mechanized stowing systems, and recycled materials, PP woven sacks are moving forward to achieve sophisticated levels.

Markets are also expanding for premium woven packs with retail branding, particularly in pet supply and nourishment categories. In addition, global trends towards sustainable bundling are encouraging manufacturers to adopt environmentally friendly processes in production and disposal.

Conclusion

PP woven bags have won their place as the leading down to earth and reliable packaging option available today. PP fibc bags They are robust, light in weight, adaptable, and by default more insightful than many options when reused and reutilized correctly.

FAQ: PP Woven Bags

Q1: Are PP woven packs waterproof?

A: Unlaminated PP woven packs are not waterproof. While in any case covered forms with PP or BOPP film provide excellent water resistance, for complete waterproofing a polyethylene liner can be included interior the bag.

Q2: How much weight can a PP woven sack hold?

A: Depending on the measure of the bag and the quality of the texture, they can haul loads ranging from 5 kg to more than 100 kg. Typical grain and cement packs commonly weigh 25â50 kg.

Q3: Are PP woven packs environmentally friendly?

A: Yes. Although made of plastic, PP woven packs are reusable and can be recycled, thus making them a more sustainable option than many other one-time bundling products.

0 notes

Text

Critical application of fertilizer screener machines in organic fertilizer production lines

In organic fertilizer production, screener machines play a vital role. They effectively separate raw materials by particle size, ensuring final product quality and consistency. Here are their specific applications in organic fertilizer production lines:

1. Raw Material Screening

Production materials like livestock manure and crop straw often contain various-sized particles. Screening machines grade these materials, removing large impurities and incompletely decomposed substances to ensure smooth subsequent processing.

2. Finished Product Grading

After production completion, screener machines categorize finished fertilizers into different particle size groups according to market demands. This meets diverse customer needs and enhances market competitiveness.

3. Efficiency Improvement

These machines enable continuous, high-efficiency production. Their automated operation reduces manual labor, lowers work intensity, while boosting productivity and product quality.

4. Environmental Benefits

Screening processes effectively reduce dust and noise pollution, improving working conditions. Precise separation also improves fertilizer utilization rates and minimizes waste, delivering clear environmental advantages.

5. Easy Maintenance

Modern fertilizer screener machines feature simple structures and user-friendly maintenance. For example, rotary drum screens use modular mesh components that are quick and easy to replace, reducing maintenance costs.

6. Material Adaptability

These machines handle various materials including damp or clog-prone substances. Rotary drum screens work particularly well with moisture-rich materials like fertilizers, coal, coke, and lime.

In summary, fertilizer screener machines boost production efficiency and product quality while delivering environmental and economic benefits. With technological advancements, their performance and functionality keep improving, providing strong support for organic fertilizer industry development.

0 notes

Text

Importance of Slaked Lime in the Paper and Sugar Industry

Slaked lime, also known as calcium hydroxide [Ca(OH)₂], is one of those humble yet highly essential materials that quietly power some of our biggest industries. You may not think twice about how that crisp sheet of paper or sweet spoonful of sugar came to be, but behind the scenes, slaked lime plays a crucial role in both. In this blog, we'll explore how this compound is used in the paper and sugar industries, and why it’s so important.

What is Slaked Lime?

Before diving into its industrial uses, let’s understand what slaked lime actually is. When water is added to quicklime (calcium oxide), a chemical reaction takes place, forming slaked lime. This process is called slaking, and the result is a soft white powder or a suspension in water known as lime milk.

This compound is known for its strong alkaline nature, low cost, and versatility, making it invaluable across various sectors. Among its many uses, the paper and sugar industries rely heavily on slaked lime for processing and refining.

Slaked Lime in the Paper Industry

The paper you use every day—whether it's in a notebook, a newspaper, or a packaging box—owes a lot to slaked lime. Here's how:

1. Pulping Process

In the paper industry, slaked lime is primarily used during the chemical pulping process. This is where wood chips are broken down into pulp using chemicals. In the Kraft process, a widely used method, slaked lime helps regenerate caustic soda (NaOH) from sodium carbonate during the chemical recovery cycle. This step is vital for making the process more sustainable and cost-effective, as it allows chemicals to be reused instead of discarded.

2. pH Control

Slaked lime is also used to regulate the pH of the pulp and wastewater during paper production. Maintaining the right pH ensures the pulp has the desired texture and strength while also keeping the machinery from corroding.

3. Bleaching and De-Inking

In recycling paper, slaked lime helps in the de-inking process—removing old ink from paper fibers. It is also used in bleaching to make the paper appear whiter and cleaner, especially for writing or printing purposes.

Slaked Lime in the Sugar Industry

If you enjoy a cup of tea or coffee with sugar, you might be surprised to learn that slaked lime played a role in its production.

1. Juice Purification

When sugarcane or sugar beets are crushed, the juice extracted is dark, murky, and full of impurities. To clean this juice, slaked lime is added in a process called liming. The lime reacts with impurities like organic acids, phosphates, and proteins, helping to coagulate and remove them.

2. Carbonation

In the next step, carbon dioxide is bubbled through the limed juice in a process called carbonation. This causes the formation of calcium carbonate, which further helps in settling out remaining impurities. The result is a clear juice that is then boiled and crystallized to make sugar.

3. pH Stabilization

Slaked lime also helps in maintaining an optimal alkaline environment, which prevents the sugar from degrading during processing. This ensures the sugar remains stable, with the right sweetness and shelf life.

Why the Quality of Slaked Lime Matters

In both industries, the quality of slaked lime used significantly affects the efficiency of the production process. Low-grade lime can result in poor chemical reactions, high impurity levels, or even damage to equipment. That’s why it’s crucial to work with reliable slaked lime manufacturers and choose a trusted slaked lime supplier who can provide a consistent and pure product.

Choosing the Right Slaked Lime Supplier

When selecting a slaked lime supplier, industries look for:

High purity levels (typically above 90% Ca(OH)₂)

Fine particle size for better reactivity

Moisture content control

Reliable delivery and technical support

Established slaked lime manufacturers ensure that their product meets industry-specific standards, whether it’s for food-grade sugar processing or high-performance paper production.

Conclusion

From clearing sugarcane juice to purifying pulp in paper mills, slaked lime is truly an unsung hero of modern manufacturing. Its ability to purify, stabilize, and optimize various processes makes it indispensable in the paper and sugar industries.

As industries continue to modernize, the demand for high-quality slaked lime will only grow. If you're in these sectors, choosing the right slaked lime supplier is not just a matter of cost, but of quality, efficiency, and environmental sustainability. So the next time you pour sugar into your coffee or jot down a note, take a moment to appreciate the vital role of slaked lime in your everyday life.

Also Read: Role of Hydrated Lime in Soil Stabilization and Masonry Work

0 notes

Text

Quality Control and Testing Standards for Soil Stabilisation in Queensland

Ensuring Long-Term Success Through Rigorous Testing and Monitoring

The Foundation of Success: Why Quality Control Matters in Queensland

In Queensland's diverse landscape—from the expansive clays of Brisbane to the tropical conditions of Cairns—soil stabilisation projects face unique environmental challenges that demand rigorous quality control. The state's variable climate, ranging from coastal salt exposure to inland temperature extremes, means that a standardized approach to testing isn't enough. Comprehensive quality control ensures project longevity, safety compliance, and cost-effectiveness. Without proper testing protocols, even well-designed stabilisation projects can fail prematurely, leading to expensive reconstruction, safety hazards, and damaged reputations. Queensland's soil stabilisation industry operates under strict regulatory frameworks, including AS 1289 series standards and Queensland Department of Transport and Main Roads specifications, making quality control not just good practice but a legal requirement.

Pre-Construction Testing: Setting the Foundation Right

Before any stabilisation work begins, thorough soil characterisation forms the backbone of project success. Comprehensive site investigation includes particle size distribution testing, Atterberg limits assessment for plasticity determination, and pH analysis to ensure chemical compatibility between soil and stabilising agents. California Bearing Ratio (CBR) testing under various moisture conditions reveals the soil's load-bearing capacity, while unconfined compressive strength testing provides baseline performance metrics. Material compatibility testing is crucial for Queensland's varied soil types, requiring cement consumption tests to determine optimal binder content and lime modification assessments for reactive clay soils. These pre-construction evaluations prevent costly mid-project discoveries and ensure the chosen stabilisation method matches the specific soil conditions encountered across Queensland's diverse geological zones.

Real-Time Construction Monitoring: Maintaining Standards in the Field

During construction, systematic field testing maintains quality consistency and prevents deviations that could compromise long-term performance. Daily quality checks include in-situ density testing using nuclear density gauges, moisture content verification to ensure optimal compaction conditions, and visual inspection of mixing uniformity. Progressive strength monitoring through field CBR testing and unconfined compressive strength assessment of field-mixed samples provides immediate feedback on stabilisation effectiveness. Temperature monitoring becomes particularly important in Queensland's climate, as chemical reactions between soil and stabilising agents are temperature-dependent. Equipment calibration and maintenance ensure testing accuracy, with daily calibration checks for nuclear density gauges and regular certification of laboratory equipment being non-negotiable requirements for reliable results.

Laboratory Analysis and Advanced Testing Techniques

Laboratory testing provides the scientific foundation for field decisions through comprehensive mix design verification and strength development analysis. Compressive strength testing at 7, 14, and 28-day intervals tracks the stabilisation process, while environmental resistance testing evaluates freeze-thaw resistance for Southern Queensland highlands and sulfate resistance for areas with high groundwater sulfate content. Modern projects increasingly employ advanced non-destructive testing methods, including ground-penetrating radar for subsurface evaluation, spectral analysis for elastic modulus determination, and infrared thermography for moisture content mapping. These sophisticated techniques provide detailed insights without compromising the stabilised material, enabling continuous monitoring throughout the project lifecycle and early identification of potential issues before they become costly problems.

Regional Adaptations and Performance Standards

Queensland's extensive geography requires testing protocols that account for regional variations and specific environmental challenges. Coastal environments demand salt exposure testing and chloride resistance evaluation, while tropical North Queensland requires high-temperature compressive strength testing and moisture susceptibility assessment under humid conditions. Inland and western Queensland's arid conditions necessitate shrinkage crack resistance testing and water retention capacity evaluation. Minimum performance requirements typically include unconfined compressive strength of 1.5-4.0 MPa depending on application, CBR values of minimum 80% for heavy traffic applications, and maximum allowable strength loss of 20% after durability testing. Statistical quality control methods using control charts and trend analysis ensure consistent performance and early problem identification across all regional conditions.

Future-Proofing Through Documentation and Emerging Technologies

Comprehensive documentation and record-keeping ensure project accountability while supporting future maintenance and expansion decisions. Complete chain of custody records, photographic evidence of testing procedures, weather condition logs, and equipment calibration certificates create an audit trail that protects all stakeholders. Digital data management through cloud-based storage and real-time reporting systems enhances accessibility and stakeholder communication. The industry continues evolving with emerging technologies, including automated testing equipment with IoT connectivity, artificial intelligence for pattern recognition in test results, and drone-based monitoring systems. These innovations promise greater efficiency and accuracy while maintaining the fundamental principle that thorough testing and quality control represent investments in long-term project success. By embracing comprehensive quality control measures adapted to Queensland's unique conditions, soil stabilisation projects can achieve optimal performance, regulatory compliance, and extended service life in one of Australia's most challenging and diverse environments.

0 notes

Text

How Cement Testing Labs Support Regulatory Compliance in the Construction Sector?

In the construction sector, the integrity and safety of structures depend heavily on the quality of materials used—especially cement. As the primary binding agent in concrete, cement must meet strict standards to ensure durability, strength, and safety. This is where a Cement Testing Lab plays a pivotal role. These specialized laboratories ensure that cement meets national and international regulatory standards, reducing the risk of structural failure and helping construction companies stay compliant with building codes.

In this blog, we will explore how cement testing labs support regulatory compliance, the types of tests conducted, and why choosing the right lab is essential for any construction project.

Why Regulatory Compliance Matters in Construction

Regulatory compliance in construction isn't just a formality—it's essential for:

Public Safety: Non-compliant structures can result in accidents, injuries, and even fatalities.

Structural Integrity: Compliance ensures that buildings withstand environmental stressors like earthquakes, wind, and load pressure.

Legal Requirements: Failing to comply with regulations can lead to legal action, project shutdowns, and financial penalties.

Insurance and Liability: Compliance is often a prerequisite for insurance coverage and reduces liability for engineers, builders, and developers.

Given the importance of cement in foundational construction, verifying its quality through lab testing is non-negotiable.

What is a Cement Testing Lab?

A Cement Testing Lab is a facility equipped with instruments and skilled technicians to evaluate the physical and chemical properties of cement. These labs follow specific procedures in line with international standards like:

ASTM (American Society for Testing and Materials)

BS EN (British/European Standards)

IS (Indian Standards)

ISO (International Organization for Standardization)

Cement testing labs provide third-party verification, ensuring that the cement used complies with regulatory specifications and project requirements.

How Cement Testing Labs Ensure Compliance

1. Verification Against Standards

The most direct way cement testing labs support regulatory compliance is by conducting tests to verify that cement meets standard specifications. These include:

ASTM C150 – for portland cement

EN 197-1 – for common cements in the EU

IS 12269 – for 53-grade cement in India

Testing labs issue certificates and detailed reports confirming whether the sample meets these benchmarks, offering documented proof of compliance.

2. Comprehensive Testing Services

Cement testing labs perform a wide range of tests that are crucial for regulatory approval. These include:

a. Compressive Strength Test

Measures the strength of cement after curing. Regulatory bodies require minimum strength levels after 3, 7, and 28 days of curing.

b. Fineness Test

Determines particle size, which affects the rate of hydration and strength development. Regulatory standards set maximum limits for retained particles.

c. Setting Time Test

Assesses how long it takes for cement to set. This affects workability and project timelines, and standards define both initial and final setting times.

d. Soundness Test

Ensures that cement does not expand after setting, which can lead to cracks and structural weaknesses.

e. Chemical Composition Test

Analyzes levels of lime, silica, alumina, and iron oxide to ensure the chemical makeup supports strength and durability.

By conducting these tests, labs ensure that cement batches are fully compliant with building codes and quality regulations.

Regulatory Bodies That Rely on Cement Testing

Several national and local regulatory authorities require testing certificates before project approvals:

Municipalities and Urban Planning Departments

Ministries of Infrastructure and Public Works

Building and Construction Authorities

Environmental Protection Agencies

For instance, in the UAE, organizations like the Dubai Municipality, ADQCC (Abu Dhabi Quality and Conformity Council), and ESMA (Emirates Authority for Standardization and Metrology) mandate compliance testing of cement and concrete.

Cement testing labs provide the compliance documents necessary to meet these authorities' requirements and ensure a project's approval and smooth execution.

Benefits of Using Accredited Cement Testing Labs

To meet regulatory demands effectively, it’s important to work with ISO/IEC 17025 accredited cement testing labs. These labs are recognized for their competence and impartiality in testing.

1. Accurate Results

ISO-accredited labs use calibrated equipment and trained professionals to produce precise test results that regulators trust.

2. Traceability

Reports issued by certified labs are traceable and auditable, which is essential in case of future inspections or disputes.

3. International Recognition

Accredited labs follow global testing methods, making it easier to comply with regulations across borders—particularly useful for export-oriented construction projects.

Ensuring Compliance Throughout the Construction Lifecycle

a. Pre-Construction Phase

Cement samples are tested before construction begins to ensure compatibility with design requirements and local regulations.

b. During Construction

Batch testing is conducted during construction to ensure consistency in cement quality and to prevent using contaminated or degraded material.

c. Post-Construction Audits

Regulators may request compliance documentation even after project completion. Reports from a cement testing lab serve as proof that proper materials were used.

Real-World Impact: Preventing Failures

A cement testing lab's role goes beyond paperwork. In regions where cement testing is ignored or done improperly, issues such as:

Structural cracks

Foundation failures

Water seepage

Premature wear and tear

are common. These lead to high costs for remediation, legal liability, and potentially life-threatening situations.

Proper testing minimizes these risks, ensuring that construction companies deliver safe, durable, and compliant structures.

Choosing the Right Cement Testing Lab

When selecting a cement testing lab, consider:

Accreditation (ISO/IEC 17025 or national equivalents)

Turnaround Time for Test Results

Range of Tests Offered

Experience in Regulatory Testing

Digital Reporting and Documentation Support

A well-equipped lab with an established reputation provides peace of mind and regulatory assurance for your construction project.

Conclusion

The construction industry is governed by strict regulations to ensure safety, reliability, and performance. Cement Testing Labs are essential in helping construction companies comply with these standards. From verifying compressive strength to analyzing chemical composition, these labs play a key role in ensuring that only compliant, high-quality cement is used in infrastructure development.

For developers, contractors, and engineers, partnering with a trusted cement testing lab is a smart investment. It not only ensures regulatory compliance but also protects your projects from costly failures and liabilities. As the construction sector continues to grow and evolve, the role of cement testing labs in maintaining quality and compliance becomes more critical than ever.

0 notes

Text

Crushing It Right: Why CRAFTSMEN CRUSHER is the Top Lime Stone Crusher Provider

Crushing It Right: Why CRAFTSMEN CRUSHER is the Top Lime Stone Crusher Provider

In the high-stakes business of construction and mining, selecting the best lime stone crusher can break or make your operations. At CRAFTSMEN CRUSHER, we engineer crushing machines that not only satisfy the industry's most stringent challenges but outperform expectations in performance, durability, and efficiency.

Precision-Driven Crushing for Every Project

Our dedication to engineering excellence is embodied in each and every lime stone crushing plant that we construct. Whether you crush raw material for infrastructure development or cement manufacturing, our crushers are designed to perform consistently on any job site.

With affordable lime stone crusher machine price options and higher output quality, CRAFTSMEN CRUSHER makes sure that you receive long-term value. With high-capacity production and power-saving designs, each machine is built to be reliable.

Designed for Flexibility: Portable and Mobile Options

We offer both mobile lime stone crusher and portable lime stone crusher models, allowing contractors to change sites more easily without having to give up crushing force. These versatile units are designed for jobs on site and isolated quarry sites, where mobility is as important as performance.

Whether you require a limestone crusher in a transient operation or a fixed quarry crusher plant, CRAFTSMEN CRUSHER provides durable, plug-and-play equipment that holds up to pressure.

Relied Upon Throughout India's Industrial Heartland

Being a leading manufacturer of lime stone crushers, we are honored to be in a position to supply machinery to big mining and construction projects. Be it a lime stone crusher for Indian Rajasthan highway project or a cement plant crusher for Gujarat, our machinery is relied upon by industry giants across the country.

Customers rely on our lime stone jaw crusher systems for efficient reduction of materials. Created for demanding use, these equipment are characterized by low wear, maintenance ease, and excellent durability.

Industry-Proven Crushing Equipment for All Needs

Our selection of crushers is applicable for primary and secondary crusher stages, providing optimized particle size and reliable material flow. Each CRAFTSMEN CRUSHER is designed to integrate into your line seamlessly, whether a stone crusher in a mining process or as part of a granite and lime stone crushing operation.

With the latest hydraulic stone crushing machine technology, our machines provide unparalleled force control and lower downtime. Our machines are also suitable for aggregate crusher operations where dust suppression and consistent output are essential.

Why CRAFTSMEN CRUSHER Stands Out

We are a heavy-duty stone crusher supplier who will never compromise on quality, safety, or service.

If you are looking for top-of-the-line lime stone crusher with superior backing and innovation supporting it, the search is over with CRAFTSMEN CRUSHER.

Feel power, precision, and performance — the CRAFTSMEN way.

Conclusion: Opt for Unmatched Crushing Power with CRAFTSMEN CRUSHER

In the industrial age of today, reliability and efficiency are not niceties—they're necessities. That's why selecting the optimal lime stone crusher is important. At CRAFTSMEN CRUSHER, we don't merely build machines — we provide comprehensive crushing solutions that fit your site, your material, and your objectives.

Whether you require a mobile lime stone crusher for in-house operations or a heavy-duty stone crusher for high volume production, we have machines that run longer, crush tougher, and save you more. With superior features, reasonable prices, and consistent performance across India and overseas, CRAFTSMEN CRUSHER

is the partner industries choose.

Choose CRAFTSMEN CRUSHER — where innovation meets rock-solid results.

0 notes

Text

Super Lubricating Abilities for The Steel Industry

Lubrication is a crucial element required for any moving machine and its parts. Without lubricants, the life-expectancy and efficient functioning of any rotating equipment is greatly reduced. Productivity is delayed due to premature bearing failures, increased use of energy, and machine downtime. This leads to further losses of production which calls for new and improved lubrication solutions.

When lubricants are used in machines, their main functions are to:

Transport contaminated particles to filters and maintain cleanliness

Create a film between metal surfaces to reduce friction

Protect metal parts from corrosion

Cool surfaces by dissipating heat

The steel manufacturing industry involves processes that are exposed to high temperatures, extreme loads, and corrosive and humid environments. These factors influence the way lubricants work on machines, creating more demand for super lubricating abilities.

Molygraph’s speciality lubricants have, therefore, been developed to offer several benefits to clients. Our diverse and complete range of lubricant solutions helps in managing critical steel manufacturing processes. The cost of maintenance is reduced as productivity is improved through quality lubrication. Our products are environment-friendly, making them a safe and protective fit for operators.

Molygraph’s Customised Range of Speciality Lubricants

We have developed three versatile lubrication applications for the steel industry, namely:

Integrated Steel Plant

Steel Pelletizing Plant

Sponge Iron Plant

1. Integrated Steel Plant

Our lubrication products cover a wide range of areas at integrated steel plants. We aim to help reduce costs by enhancing productivity regardless of any extreme environmental conditions. From ironmaking to finished products, lubrication solutions are, thus, developed to meet all requirements at Integrated Steel Plants.

The application components shown below are based on the areas our products can be used.

Raw Material Preparations: Storage

Raw Material Processing: Coke Oven Plant, Lime Plant, Sinter Plant

Pig Iron Production: Blast Furnace

Caster: Continuous Caster

Hot Rolling Mill: Work/Back-Up Roll Bearings, Chokes Window Liner, Rolling Mill Drive Shaft Gear Couplings, and Re-Heating Furnace Table Roll Bearing

Cold Rolling Mill: Work/Back-Up Roll Bearings, Roll Chokes Liner, Rolling Mill Drive Shaft, Gear Couplings, Pickling Line, Squeezer Roll Bearing, Water Rinse Tank Bearing, Wringer Roll Bearing, Arb Blower Fan Bearing

Bar and Rod Mill: Reheating Furnace Withdrawal/Roll Table Bearing, Work/Back-Up Roll Bearing, Roll Chokes Liner, and Rolling Mill Drive Shaft Gear Couplings

2. Steel Pelletizing Plant

The process of pelletizing iron involves converting iron ore fines into uniformly sized iron pellets. These pellets are then charged directly into the blast furnace. Our lubricating range of products is designed to meet the challenging and demanding processes involved in the Steel Pelletizing Plant.

The application components involved in the following processes are:

Grinding Mill: Ball Mill Girth Gear, Ball Mill Girth Gear Pinion Bearing

Mixture Machine: Mixture Machine Bearing, Mixture Machine Gear

Balling Disc: Balling Disc Girth Gear, Balling Disc Bearing

Travelling Guide: TG Plumber Block Bearing

Kiln: Kiln Girth Gear – Spray System, Support Roller Bearing/Kiln, Thrust Bearing/Bucket, Elevator Bearing, Sliding Surface of Track

3. Sponge Iron Plant

Sponge iron is produced from the direct reduction of iron ore, and it can be further processed into wrought iron. It is useful as feedstock for speciality steel manufacturers. The lubricants in this process are required to be thermally and mechanically stable. It should also be able to resist water washouts.

Our range of lubricants covers the entire spectrum of applications including Kiln & Cooler Slip Seal, Kiln & Cooler Girth Gear, Support Roller Bearing, Vibrator Screen Bearing, Id/Fd Fan Bearing, and so much more. You can know more about the Sponge Iron Plant on our website.

Are you prepared to take your steel manufacturing processes to the next level? We have a Field Engineering Services Team ready to support, guide you and provide end-to-end lubrication education. Get the best deals in lubrication for steel with Molygraph.

#polyurea grease manufacturers#grease oil manufacturers#steel lubricants#steel industry lubricants#grease for stainless steel

0 notes

Link

1 note

·

View note

Text

Why Rajasthan Leads India’s Limestone Supply Chain | Top Lime Manufacturers in India

Rajasthan, India’s largest state by area, is not only known for its palaces and desert landscapes but also for its immense mineral wealth—especially limestone. With vast reserves and a well-established network of mining, processing, and logistics infrastructure, Rajasthan has emerged as the undisputed leader in India’s limestone supply chain. This dominance is further cemented by the presence of some of the best lime manufacturers in India, particularly concentrated in regions like Jodhpur, Nagaur, and Gotan.

In this blog, we will explore the geographical, economic, and industrial factors that make Rajasthan the core of India’s limestone economy. We will also highlight key lime manufacturers in India and how lime suppliers in Jodhpur are setting new standards in the industry.

1. Abundant Geological Reserves of Limestone

One of the primary reasons Rajasthan leads India’s limestone supply is its abundant and high-purity limestone reserves. The state accounts for nearly 90% of the country's limestone production, making it a key source for sectors like steel, cement, metallurgy, water treatment, and construction.

Regions such as Jodhpur, Udaipur, Chittorgarh, and Nagaur are rich in high-grade limestone deposits, including both sedimentary and metamorphic types. These raw materials are ideal for producing a wide range of lime-based products like quicklime, hydrated lime, and calcined lime powder.

2. Strategic Location and Transportation Infrastructure

Rajasthan’s central location and proximity to major industrial states like Gujarat, Maharashtra, Madhya Pradesh, and Punjab offer a logistic advantage for lime manufacturers in India. With well-connected road, rail, and dry port facilities, transporting limestone and processed lime products across India becomes highly efficient.

Major highways like the NH62 and NH48 pass through key limestone-producing districts, allowing lime suppliers in Jodhpur and surrounding regions to deliver bulk consignments quickly to customers in cement, steel, chemical, and power industries.

3. Presence of Top Lime Manufacturers in India

Rajasthan, and especially Jodhpur, is home to some of the best lime manufacturers in India. These manufacturers produce high-quality lime products including quicklime lumps, hydrated lime powder, and calcined lime.

Leading companies such as Rajasthan Lime, one of the oldest lime businesses in India, have set benchmarks in quality, delivery timelines, and industry certifications. These lime suppliers in Jodhpur cater to a broad client base ranging from steel giants to copper processors and even export markets in Africa and the Middle East.

4. Technological Advancements in Lime Manufacturing

Over the years, lime manufacturers in Rajasthan have embraced advanced technologies for mining, crushing, and lime calcination. Automated kilns, environment-friendly processes, and laboratory-backed quality testing are now standard across the region.

These innovations allow lime manufacturers in India, especially those based in Jodhpur, to meet stringent quality requirements of industries like food processing, pharmaceuticals, and wastewater treatment—further reinforcing Rajasthan's leadership in the limestone value chain.

5. Skilled Workforce and Traditional Expertise

The lime industry in Rajasthan is backed by decades of traditional expertise and a skilled workforce. The people of Rajasthan, particularly those in the Marwar belt, have been involved in lime production and stonework for generations.

This blend of heritage knowledge with modern manufacturing techniques allows best lime manufacturers in India to deliver products with consistent chemical composition, particle size distribution, and reactivity.

6. Government Policies and Industry Support

The Rajasthan government actively supports mining and mineral-based industries through favorable policies, subsidies, and mining lease reforms. The Rajasthan State Industrial Development and Investment Corporation (RIICO) also plays a crucial role in developing industrial zones near limestone belts.

Additionally, environmental clearances and renewable energy adoption (such as solar kilns) are encouraged, helping lime suppliers in Jodhpur maintain both cost-efficiency and sustainability.

7. Industrial Demand for Lime Products

Limestone and lime-based products are essential raw materials for several core industries. Rajasthan caters to:

Steel and metallurgical industries needing quicklime for fluxing

Water treatment plants using hydrated lime for pH regulation

Construction and cement industries requiring high-calcium limestone

Copper and chemical units needing fine calcined lime powder

This increasing industrial demand ensures continuous production and supply across the state, solidifying its place in India’s lime ecosystem.

8. Export Capability and Global Reach

Several lime manufacturers in India based in Rajasthan also cater to international clients. With ports in Gujarat just a few hundred kilometers away, lime products can be exported to countries like Bangladesh, UAE, Oman, and Kenya.

Jodhpur-based lime suppliers especially focus on premium-grade lime that meets international standards like ASTM and EN norms—contributing to India’s growing reputation in global lime exports.

9. Sustainability and Circular Economy Practices

The best lime manufacturers in India, particularly in Rajasthan, are increasingly moving towards sustainable practices. These include:

Using solar dryers and energy-efficient kilns

Recycling kiln dust

Capturing CO₂ for reuse in chemical processes

Reusing limestone waste for road construction or agriculture

Such measures not only reduce the environmental footprint but also enhance cost-efficiency for manufacturers and customers.

10. Rajasthan's Limestone Belt and Future Growth

The future of the limestone supply chain in India is tightly linked to Rajasthan’s performance. The state is expected to maintain its leadership due to upcoming smart industrial clusters, digitized mining operations, and private investments in high-capacity lime plants.

With global demand rising and the government pushing for infrastructure and green steel, lime suppliers in Jodhpur and nearby districts are poised for rapid growth.

Conclusion

From abundant reserves and modern infrastructure to technological innovation and export readiness, Rajasthan truly stands out as the leader in India’s limestone supply chain. The presence of some of the best lime manufacturers in India, especially in Jodhpur, further strengthens this leadership position.

Whether you're in the steel, copper, water treatment, or cement industry, partnering with top lime suppliers in Jodhpur ensures consistent quality, timely delivery, and cost-effectiveness.

If you are looking for reliable and quality-focused lime manufacturers in India, Rajasthan should be your first destination.

0 notes

Text

Fly ash is a fine, powdery material that is a byproduct of burning pulverized coal in thermal power plants. It consists mainly of silica, alumina, iron oxide, and calcium oxide. This byproduct, when properly processed and utilized, can significantly improve concrete strength, durability, and sustainability.

Composition and Types of Fly Ash

Fly ash is classified into two main types based on its chemical composition:

Class F Fly Ash

Derived from bituminous and anthracite coal.

Contains low calcium content (<10‰).

Possesses pozzolanic properties, requiring a cementing agent such as lime or Portland cement.

Ideal for high-performance concrete applications.

Class C Fly Ash

Produced from lignite and sub-bituminous coal.

Has a higher calcium content (>10‰).

Can act as a self-cementing material without the need for additional binders.

Used in road construction, structural concrete, and soil stabilization.

Production and Processing of Fly Ash

Fly ash is collected from electrostatic precipitators or baghouses in power plants before the gases are released into the atmosphere. It is then processed to remove impurities and ensure consistency in particle size and chemical composition.

Read more

0 notes

Text

How Calcium Carbonate Is Extracted and Processed

Calcium carbonate is one of the most widely used minerals across the globe. It is a crucial raw material in industries such as construction, paper, plastics, paints, pharmaceuticals, and agriculture. Found naturally in limestone, chalk, and marble, calcium carbonate (CaCO₃) is prized for its whiteness, purity, and versatility. But how does it go from natural deposits to a fine, industrial-grade powder?

This article provides a comprehensive look into how calcium carbonate is extracted and processed—from quarry to final product. We’ll also highlight why working with a trusted Calcium Carbonate Manufacturer in India can ensure superior quality, cost efficiency, and supply chain reliability.

What Is Calcium Carbonate?

Calcium carbonate is a chemical compound made up of calcium, carbon, and oxygen. It naturally occurs in rocks such as limestone, marble, and chalk, and is also found in the shells of marine organisms and eggs. It is available in two primary forms:

Ground Calcium Carbonate (GCC): Produced by mechanical grinding of natural limestone or marble.

Precipitated Calcium Carbonate (PCC): Produced through a chemical precipitation process involving carbon dioxide and lime.

This article focuses on the extraction and processing of Ground Calcium Carbonate (GCC).

Step-by-Step: How Calcium Carbonate Is Extracted and Processed

1. Mining and Quarrying

The process begins with the identification of high-purity limestone or marble deposits. In India, states like Rajasthan, Gujarat, and Himachal Pradesh are known for their vast reserves of quality limestone.

The mining process includes:

Surveying and Mapping: Geologists assess the quality, thickness, and distribution of the deposit.

Overburden Removal: The top layer of soil and rock is removed to access the limestone.

Extraction: Limestone is extracted using drills, explosives, or mechanized equipment like excavators and bulldozers.

The extracted rocks are then transported to the processing plant for further refinement.

2. Primary Crushing

At the plant, the raw limestone is passed through crushers (usually jaw or cone crushers) that reduce large chunks into smaller, manageable pieces. This step is essential to prepare the material for grinding.

3. Grinding and Pulverization

The crushed limestone is fed into grinding machines such as ball mills, vertical roller mills, or Raymond mills. The goal here is to reduce the limestone into a fine powder.

The degree of fineness depends on the intended application:

Coarse particles (100-200 mesh) for agriculture and construction

Fine particles (300-500 mesh) for plastics, paints, and coatings

Ultra-fine particles (800 mesh or more) for specialty industries like cosmetics or pharmaceuticals

4. Air Classification

Once ground, the powder is passed through classifiers or sieves that separate particles based on size. Air classifiers are often used to ensure a uniform particle distribution. Finer grades may go through multiple stages of classification.

5. Surface Treatment (Optional)

In some industries—particularly plastics, rubber, and coatings—the calcium carbonate may undergo surface modification. This involves coating the particles with fatty acids like stearic acid to enhance compatibility with organic compounds and improve dispersion.

6. Quality Control and Testing

Before packaging, calcium carbonate undergoes stringent quality control tests, including:

Whiteness and brightness index

Particle size distribution (PSD)

Moisture content

Chemical purity (CaCO₃ content)

Specific gravity and oil absorption

These parameters ensure that the product meets industry-specific requirements.

7. Packaging and Distribution

Once the product passes quality checks, it is packed in moisture-proof bags or bulk containers (such as jumbo bags or tankers) depending on the client's requirements. It is then shipped locally or exported to global markets.

Applications of Calcium Carbonate

The versatility of calcium carbonate makes it essential in various industries:

Construction

Used as a key ingredient in cement, concrete, and mortar. It also serves as a base material in roads and as a filler in asphalt.

Paper and Pulp

Calcium carbonate is used as a filler and coating agent to enhance paper brightness, smoothness, and printability.

Plastic and Rubber

Acts as a functional filler to improve mechanical strength, reduce material costs, and increase thermal conductivity.

Paints and Coatings

Used as an extender and pigment, it improves opacity, brightness, and weather resistance.

Agriculture

Used to neutralize acidic soils and provide essential nutrients like calcium and magnesium.

Pharmaceuticals and Food

High-purity grades are used as dietary calcium supplements and food additives (E170).

Why Choose a Calcium Carbonate Manufacturer in India?

India is one of the largest producers of calcium carbonate in the world. Partnering with a reliable Calcium Carbonate Manufacturer in India offers several advantages:

1. Abundant and High-Quality Resources

India has vast limestone deposits known for their high purity, making it easier to produce premium-grade calcium carbonate at scale.

2. Cost-Efficient Production

Lower labor and production costs allow Indian manufacturers to offer highly competitive pricing without compromising on quality.

3. Technological Expertise

Modern Indian manufacturers use advanced machinery and quality control systems, ensuring consistent product specifications across batches.

4. Export Capabilities

Many Indian suppliers are well-established exporters, capable of meeting international demand with proper documentation, timely delivery, and global logistics support.

5. Customization and Technical Support

Top-tier manufacturers offer tailored solutions such as custom particle sizes, surface-treated grades, and technical consultations for specific industrial applications.

Conclusion

The production of calcium carbonate—from natural limestone to industrial-grade powder—is a well-defined, precision-driven process involving extraction, grinding, classification, and testing. Its widespread use across diverse industries makes it one of the most important industrial minerals today.

Choosing the right Calcium Carbonate Manufacturer in India is key to ensuring consistent quality, cost savings, and reliable supply. Whether you're in construction, plastics, pharmaceuticals, or agriculture, sourcing calcium carbonate from a trusted Indian manufacturer can significantly enhance your product performance and operational efficiency.

0 notes

Text

January 6 - Blog #3

The Pantheon is a testament to human ingenuity. Make an argument for the Pantheon to be included as the 8th Wonder of the World. Discuss both the feat of engineering and the design intentions of the structure.

According to National Geographic, the 7 wonders of the world are the “grandest physical achievements of nature and human behavior,” but only one is still standing today. The Pantheon exceeds this statement as it is still in great health today even through natural disasters and multiple leaders. The impact it had on the area around it is clear as roads and passageways were created just to reach the structure for building and visiting which in itself tells how infrastructure was shaped by it. Most importantly, it is an engineering icon as there is not another building in the world that is a circular room with a dome that isn’t reinforced with metal rebar internally as it is free standing, much less one with the hole in it. This is due to the ingenuity of using new concrete mixtures of rock, cement, and ash with lime clasts which becomes stronger and more compact when water is mixed in or seeps into the small spaces between particles. This also shows they knew that the pressures and weight are not strong in the center of the dome but instead outward which allows for a beautiful node into the sky without any barriers. Because the sun can enter the building uninterrupted, it is a sundial where the main ray of light shines on specifically parts of the floor and doorway like on April 21 annually, when Rome was founded. To create this tall structure, simple machines like pulleys were used, wood scaffolding for support was built to hold it up while in various stages, and human hands did most of the heavy lifting. Another reason it is likely successful in being a reliable reference for time is because the building is a perfect sphere with a “perfect number” of coffers that was planned and executed with no mistakes. While it is in the middle of a busy plaza that is stimulating, it clashes with its surroundings and the grandness of its ornate carvings and a darker color which makes it stand out even better. In my opinion, this structure over-covers the vertruvian triad of firmness, utility and beauty which is said are the 3 things to make a well designed building that seems to accurately apply to current times. The Pantheon should be the 8th wonder because of simplicity that lets the behind the scenes stories shine, the authenticity, and sheer size of aspects that are one piece.

0 notes