#paperboard converting

Explore tagged Tumblr posts

Text

Notebooks

June 11, 2025

Three-piece bradel binding with cloth on the spine and paper on the front and back.

Fathers day gifts for my dad and stepdad.

Materials: covers - 2 mm grey board spine stiffener - paperboard spine covering material - suede bookcloth in blue and green front and back covering material - marbled jute fiber paper vinyl - siser easyweed white vinyl

endpapers - bronze and blue cardstock with pearlescent finish endbands - paper rolled over twine bookmarks - 1/8" gold ribbon textblock paper - 20lb printer paper, bright white, 8.5x14

Typeset: Individual page layouts were made in Microsoft Word, thoroughly abusing the table function beyond its intention, then converted into PNGs and combined in Scribus. The font is Coelocanth.

dimensions: 4.25"x7"

4 notes

·

View notes

Text

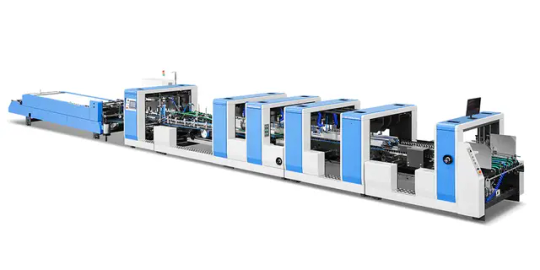

Full Servo Lock Bottom Folder Gluer Machine: Efficiency Meets Precision in Packaging

The Full Servo Lock Bottom Folder Gluer Machine is an advanced solution for modern packaging needs, offering high-speed, precision-driven performance for converting paperboard into lock-bottom cartons. Designed with cutting-edge servo motor technology, this machine ensures superior accuracy and consistency, significantly reducing human error and material waste during production.

0 notes

Text

Leading Paper Core Manufacturers for Industrial Applications

In today’s fast-paced industrial environment, packaging is no longer just about containment—it plays a critical role in storage, logistics, product safety, and sustainability. Among the many packaging components used in various industries, paper cores have become essential due to their strength, flexibility, and environmental benefits.

As one of the top paper core manufacturers in India, Ompackaging specializes in delivering robust and sustainable packaging solutions tailored for industrial use. From textile mills to film converters, and from paper roll handling to adhesive tapes, paper cores are used widely across sectors. This blog explores the role of paper cores, the rise of innovative solutions in the industry, and why Ompackaging is a preferred partner for industrial packaging needs.

Understanding Paper Cores in Industrial Packaging

What Are Paper Cores?

Paper cores are cylindrical structures made from layers of paperboard or fiberboard that are spiral- or convolute-wound. They are widely used to support and protect products that are wound around them, such as plastic films, textiles, paper, foil, and more.

Key Benefits:

High strength-to-weight ratio

Cost-effective and recyclable

Customizable diameter, thickness, and length

Suitable for high-speed winding/unwinding machinery

Paper cores are perfect for a variety of industrial applications because of these advantages.

Industries That Rely on Paper Core Manufacturers

1. Textile and Yarn Industry

Yarns, threads, and fabrics are wound and stored in paper cores in textile mills. Their structural strength ensures they maintain form even under high-speed operations and pressure.

2. Paper & Film Conversion

Converters use paper cores to roll and unwind paper, plastic films, and laminates. The precision in core dimensions is critical to avoid misalignment and wastage.

3. Adhesive Tape & Labels

In the adhesive tape industry, consistent internal diameters ensure tapes are wound evenly. Paper cores offer the perfect balance between rigidity and flexibility.

4. Packaging and Shipping

Paper cores are also used in structural packaging and shipping solutions to support loads, brace containers, or form the internal structure of fiber drums.

What Sets Top Paper Core Manufacturers Apart?

Not all paper core manufacturers are created equal. Leading players like Ompackaging differentiate themselves through:

1. Material Quality

High-grade paperboard and adhesives ensure the strength and consistency of each core.

2. Custom Engineering

Manufacturers like Ompackaging offer customization for:

Core ID (Inner Diameter)

Wall thickness

Length

Coatings and finishes (e.g., waterproof, anti-slip)

3. Sustainability Focus

With growing awareness around sustainability, top paper core manufacturers emphasize recyclable and biodegradable materials.

4. End-to-End Service

From design consultation to on-time delivery, experienced manufacturers ensure a hassle-free experience for industrial clients.

Ompackaging: A Trusted Leader in Paper Core Manufacturing

About Ompackaging

Ompackaging is a trusted name in India’s industrial packaging sector. As one of the most reputed paper core manufacturers and fiber drum manufacturers, the company has built a reputation for quality, innovation, and sustainability.

Why Choose Ompackaging?

Advanced Manufacturing Capabilities: Fully automated production lines with strict QC.

Diverse Applications: Serving paper, textiles, packaging, films, and adhesive industries.

Eco-Friendly Practices: Sourcing renewable materials and minimizing waste.

Quick Turnaround: Fast lead times for both custom and bulk orders.

Paper Cores and Fiber Drum Integration

One of the unique strengths of Ompackaging lies in their dual role as both paper core manufacturers and fiber drum manufacturers. This allows them to integrate their paper cores into the structural framework of fiber drums—especially square and round drums used in industrial packaging.

This synergy results in:

Greater structural integrity

Better load distribution

Customizable packaging solutions

Sustainability in Paper Core Manufacturing

Reducing Environmental Impact

As sustainability becomes a non-negotiable standard, paper core manufacturers are shifting to:

Recycled paperboard inputs

Water-based adhesives

Cleaner production methods

Ompackaging leads this shift by offering:

100% recyclable products

Minimal plastic usage

Compliance with ISO and other environmental standards

This is in line with the objectives of companies looking for environmentally friendly packaging options without sacrificing quality.

Quality Assurance: How Ompackaging Maintains Excellence

Testing & Inspection

Each paper core undergoes:

Compression strength tests

Dimensional checks

Surface smoothness inspection

Moisture resistance testing (for specialty applications)

Certifications

Ompackaging adheres to all major packaging standards required by industries such as food, pharmaceuticals, and logistics.

Customization: Tailored Solutions for Every Industry

Ompackaging understands that no two applications are identical. They offer:

Common cores: For typical uses such as paper rolls and tapes

Heavy-duty cores: For industrial films, textiles, and metals

Precision cores: For printing and converting machines

Optional coatings, printing, and color-coding make the cores user-friendly and compatible with modern systems.

Client-Centric Approach

From inquiry to delivery, Ompackaging follows a structured process:

Requirement Assessment

Sample Approval

Order Confirmation

Production and Testing

Packaging and Dispatch

With decades of expertise, their team supports clients at every stage with technical consultation and responsive service.

Looking Ahead: The Future of Paper Core Manufacturing

Innovation in Materials

Biodegradable coatings, smart sensors for inventory tracking, and flame-resistant liners are being explored to meet evolving industrial demands.

Automation & AI

Digital tools will optimize sizing, material usage, and quality control—resulting in lower costs and better efficiency.

Global Supply Chain Integration

Indian paper core manufacturers like Ompackaging are increasingly exporting globally, offering world-class products at competitive pricing

0 notes

Text

Boost Your Packaging Efficiency with Folding Carton Software by Samadhan

In today’s competitive packaging industry, operational efficiency is no longer optional—it’s essential. The folding carton sector, known for its precision, customizability, and scale, demands cutting-edge solutions that reduce waste, optimize productivity, and deliver high-quality products with shorter turnaround times. This is where specialized folding carton software becomes a game-changer.

Industry Challenges Facing Folding Carton Manufacturers

Packaging businesses are under pressure to deliver customized, short-run, and high-speed packaging options without sacrificing quality or profits. However, manufacturers often struggle with:

Inefficient manual workflows

Inaccurate job costing and estimates

High material waste

Poor integration between departments

Limited visibility into production metrics

According to a recent Smithers Pira report, the global folding carton market is expected to exceed $170 billion by 2027, growing at a CAGR of 4.7%. As demand surges, manufacturers must scale operations without compromising accuracy or delivery timelines. Investing in robust, industry-specific ERP systems becomes vital for long-term growth and sustainability.

The Role of Folding Carton Software in Modern Packaging

Folding carton software is specifically designed to streamline production, inventory, costing, and sales in packaging environments. Unlike generic ERPs, it understands the unique dynamics of the industry—whether it’s die layouts, reel sizes, run lengths, or carton grammage.

Here’s what leading-edge folding carton software enables:

1. Accurate Quotation and Estimation

One of the most error-prone aspects of the business is job costing. Carton ERP solutions ensure accuracy by factoring in:

Material cost per sq. meter or ton

Machine setup and production time

Labor rates and packaging materials

Overhead distribution

This real-time data allows sales teams to provide profitable quotes quickly, increasing win rates while protecting margins.

2. End-to-End Production Visibility

A digital-first folding carton solution provides a single window view of each job—right from order intake to dispatch. Supervisors can track:

Real-time production status

Machine utilization metrics

Downtime analysis

Inventory levels across substrates

This enhanced transparency enables informed decision-making and proactive bottleneck resolution.

3. Waste Reduction and Material Optimization

Folding carton operations often involve high material usage and waste. With integrated software, manufacturers can:

Generate optimal cutting layouts

Reduce print overruns and rejections

Manage scrap and leftover roll tracking

According to an internal survey by Samadhan, packaging units using specialized carton ERP solutions have seen up to 18% reduction in raw material waste, leading to significant cost savings.

4. Seamless Departmental Coordination

Many packaging plants still rely on fragmented tools and spreadsheets. As a result, Sales, Planning, Production, and Accounts often work in silos. Carton ERP bridges these gaps by offering:

Unified dashboards

Inter-departmental workflows

Alerts and auto-reminders

Centralized data repository

This seamless integration boosts turnaround speed and ensures each department works in sync with business priorities.

Real-World Success Story: How a Mid-Sized Packaging Firm Transformed Operations

A mid-sized packaging firm based in Gujarat faced challenges in meeting client timelines due to production delays and estimation errors. After implementing a folding carton ERP solution tailored to their needs, they achieved:

25% faster order-to-dispatch cycles

40% fewer estimation disputes with clients

30% better machine uptime

Significant reduction in paperboard inventory holding

This case highlights how smart software can translate into measurable business outcomes—even for medium-scale converters.

Choosing the Right Folding Carton ERP Solution

Before adopting a new software platform, manufacturers should evaluate:

Industry Fit: Is it designed specifically for folding carton processes?

Scalability: Can it support business growth and complex multi-location operations?

Integration: Does it work with your existing tools like CRM, finance, or logistics platforms?

Support and Customization: Does the vendor offer flexible support and tailored features?

One platform that checks these boxes is Samadhan’s solution—built to meet the evolving needs of folding carton manufacturers with precision, flexibility, and reliability.

Boost Your Packaging Efficiency with Folding Carton Software by Samadhan

This purpose-built solution integrates every department—estimations, inventory, procurement, quality control, and dispatch—into a single source of truth. Its modular design lets businesses adopt features progressively while keeping implementation costs in check.

From centralized data access to AI-powered job costing and material optimization, the software empowers plant managers to make smart, data-driven decisions that align with market demand and production efficiency.

Why Carton ERP is the Future of Packaging

The folding carton segment is undergoing rapid digital transformation. To stay ahead of competitors, packaging businesses must embrace tools that:

Automate workflows

Offer actionable insights

Reduce dependency on tribal knowledge

Improve cross-departmental communication

Folding carton ERP software is no longer a luxury; it’s a strategic investment that defines business scalability and profitability.

Conclusion: Drive Competitive Edge Through Technology

In a fast-evolving packaging landscape, efficiency isn’t about cutting corners—it’s about doing more with less through intelligent automation and insight-driven management. Carton ERP systems like the one from Samadhan are revolutionizing how packaging companies operate—giving them the clarity, control, and consistency they need to succeed.

If you're ready to eliminate guesswork, increase profits, and build smarter production lines, it's time to explore what tailored ERP software can do for your business.

Ready to transform your packaging process? Discover how Samadhan’s advanced folding carton ERP solution can streamline operations, reduce costs, and empower your team to deliver excellence at every stage. Contact the Samadhan team today for a personalized demo.

0 notes

Text

The Value of Custom Rigid Boxes for Lasting Impressions

Custom rigid boxes are the highest choice for businesses looking for premium packaging solutions. These durable, high-quality boxes offer more than just protection. Custom rigid boxes improve the whole product's appearance. For Brands, the packaging is an essential touchpoint that shapes customer observations. High-end packaging reflects a brand's potential to perfect, while rigid box packaging adds elegance with its sleek design and best feel. Whether for extra fashion, electronics, or gifts, rigid apparel boxes convert a simple product into a memorable experience, leaving a long-lasting impression on customers.

Luxury Custom Rigid Boxes for High-End Products

Rigid boxes are luxury packaging solutions made from thick, sturdy paperboard. Unlike folding cartons, Rigid packaging boxes maintain shape, providing greater structural veracity. They are often wrapped in attractive paper or specialty textures, enhancing their visual demand. Custom Rigid Boxes Common-use materials include Corrugated, Kraft, and cardboard, all special for strength and customizability. These boxes are Perfect for high-end items, providing unmatched protection and a premium feel. Rigid Boxes Wholesale strong build and stylish design flexibility make them excellent for showcasing and protecting valuable products, setting brands apart with a refined, polished look.

Boost Your Business with Premium Rigid Packaging

The charm of rigid packaging boxes lies in their numerous benefits. Their robust construction provides outstanding product protection, minimizing damage during shipment. Custom Rigid Boxes' lavish feel enhances the brand image, making products look more valuable. Customizability is a significant advantage; brands can select unique sizes, shapes, and finishes to match their persona. Rigid box packaging enhances the unwrapping experience, turning a bare purchase into a memorable event. By committing to premium packaging, brands foster stronger customer relationships and stand out in a competitive market.

Rigid Box Packaging for Timeless Elegance and Modern Flair

Rigid boxes come in numerous designs, each addressing different packaging requirements. Two-piece rigid boxes with a cover and foundation offer timeless elegance. Magnetic closure rigid box packaging adds a chic, modern flair, enhancing the unwrapping experience. Rigid drawer boxes slide open effortlessly, ideal for jewelry or tech devices. Collapsible custom rigid boxes provide convenient storage without sacrificing quality. For style brands, rigid apparel boxes deliver a refined, upscale appearance. Each variation combines durability with aesthetics, giving brands flexible options to align their product and market placement perfectly.

Cross-Industry Excellence with Custom Rigid Apparel Boxes

Rigid boxes are used across multiple industries, showcasing their flexibility. Luxury fashion brands use rigid apparel boxes to boost clothing display. Electronics companies depend on them for durable, elegant packaging. Jewelry and cosmetics brands appreciate their premium feel and protective features. Custom Rigid gift boxes are ideal for special events, adding a hint of class to any present. They're also well-known for corporate gifts and marketing items, leaving a lasting impression on clients. This versatility makes custom rigid boxes a go-to option for brands seeking to improve their packaging.

Customization Options for Rigid Box Packaging

Rigid packaging boxes are where customization truly excels. Brands can adjust the size, shape, and style of custom rigid boxes to fit their vision. Printing techniques like embossing, debossing, and foil stamping add dimension and elegance. Finishing options, including matte, gloss, and velvety coatings, boost tactile appeal. Inside, inserts, partitions, and padding add security and display value. These options let brands design rigid boxes wholesale that protect products and tell a narrative, leaving a lasting impression and strengthening brand identity through every element.

Rigid Boxes Wholesale For Cost-Effective Solutions

Ordering rigid boxes in bulk offers substantial cost savings. Large-scale purchasing reduces individual costs, making high-quality packaging more attainable. Rigid boxes wholesale is a wise investment for businesses growing, reducing expenses while preserving a luxurious feel. Wholesale suppliers of custom rigid boxes often offer customization services, guaranteeing brands get precisely what they need without exceeding the budget. Finding a trustworthy supplier of custom product packaging ensures steady quality and prompt delivery, allowing brands to fulfill demand and maintain their improved image without sacrificing packaging standards.

Transform Your Brand Image with Premium Custom Rigid Gift Boxes

Rigid boxes assist in establishing a robust label identity. Their lavish appearance instantly boosts item perception, distinguishing labels from rivals. Custom Rigid boxes' upscale wrapping enhances the buyer experience, transforming acquisitions into occasions. Custom Rigid Gift boxes' sturdiness and premium aesthetics convey excellence and attention, strengthening label confidence. For enterprises aiming to leave a perpetual impression, rigid boxes wholesale are a tactical selection—blending elegance, essence, and narrative to craft a compelling, unified label display.

Beyond Packaging with Custom Rigid Boxes as a Strategic Investment

Custom rigid boxes are more than wrapping. They are a label investment. They provide opulence, safeguarding, and limitless personalization opportunities, boosting item worth and buyer experience. From apparel to gadgets, Custom rigid boxes serve varied sectors, assisting labels in gaining recognition and forming enduring bonds. Investing in custom product packaging isn't just about appearance; it's about displaying label principles and crafting unforgettable experiences. Custom rigid boxes are the ultimate choice for enterprises prepared to enhance their packaging strategy.

#custom rigid boxes#rigid apparel boxes#rigid boxes wholesale#rigid box packaging#custom rigid gift boxes#Custom Product Packaging#Custom packaging boxes#packaging boxes wholesale#Printed Rigid Packaging Boxes#Product Rigid Packaging#Rigid Packaging#Luxury Rigid Boxes

0 notes

Text

VK Global Digital's new Faridabad plant

In 2018, the leading Faridabad-based textbook publisher, VK Global Publications, got into printing and carton production by acquiring an existing plant in Manesar that had gone into NCLAT insolvency proceedings. The plant, which has extensive book and packaging printing, binding, and converting equipment, along with luxury hard box-making capacity, was renamed VK Global Digital.

The publishing group has taken about five years to learn the commercial print and carton packaging business. The carton and luxury box-making businesses were stabilized and rationalized by producing premium cartons using VK Global’s proprietary metallic hologram and Fresnel lens effects for brand protection and security.

A new Bobst diecutter and a new Bobst folder-gluer were added to the Manesar plant. However, to expand the plant with new printing, postpress, and converting equipment, it was decided to build a purpose-built factory with space for future expansion in Faridabad. Not far from the headquarters building of the publishing house, the elegant purpose-built factory, along with several additional investments in equipment, is humming.

Ambitious from the blueprint stage, the modern work and production spaces are within the elegant 250,000-square-foot load-bearing factory building. On most of the two acres alongside the building is a hydroponic greenhouse where the first horticultural crop of lettuce and kale was just maturing in mid-January.

Apart from the double-height 100,000-square-foot production space and meeting rooms on the ground floor, the 50,000-square-foot mezzanine contains prepress and open-plan management spaces. Another 100,000-square-foot load-bearing floor is not yet populated.

On one side of the ground floor are the sheetfed multicolor presses for printing cartons. Before the plant was complete, a new Heidelberg 6-color plus coater UV press was installed in February-March 2024. The 6-color coater UV press from Manesar was moved subsequently so that no customer deliveries were disrupted.

In the converting section, alongside the multiple die-cutters and folder-gluers, a new Masterwork autoplaten foil stamping machine critical for incorporating the metallic brand security features was installed. The Mecchi equipment for producing two-piece luxury boxes for electronic, personal care, and confectionery products was brought from the Manesar plant and installed in a dedicated area.

By August 2024, all the equipment from Manesar was moved, installed, and recommissioned. Although not without challenges, the entire closely managed process meant the transition to full production was practically seamless – with few or no hitches in the timely shipment of cartons.

In the double-height pressroom, there are 10 Heidelberg presses, including two 6-color coater UV presses for cartons and two 8-color perfectors for commercial and book printing. Apart from improvement in workflow and material movement in the continuous single–level space, the new converting equipment has smoothened and increased production.

Premium visual effects and brand authentication and protection

All the products produced by VK Global – books, monocartons, or luxury boxes tend – to be in the premium category for its select customers. The quality and consistency of design, paper and printing, embellishment, and brand security stand out. The company’s rich experience in security and embellishment using its holographic technology and expertise is formidable. The company uses its own manufactured transfer films to transfer a combination of metallics with holographic diffraction and optically active surface patterns and Fresnel lens effects for application on paper, PET, and BOPP.

The metallic effects are transferred onto paperboard and carton substrates from recyclable films that the company produces for in-house use and also exports. After use, the brand-secure cartons can be pulped along with other paperboard cartons.

Hence, the company is a global pioneer and exporter in creating completely recyclable book covers, cartons, or blister packs integrated with Fresnel lenses and other holography patterns. VK Global’s transfer films have been validated under EU EN 13430 certification, which classifies the products as bio-degradable. In the case of monocartons and other packaging materials such as blister packs, these effects can authenticate consumer products – easily differentiating them from counterfeit packaging and products.

Technology absorption, process, OEE, and human resource optimization

Educated in computer science, Jain, apart from his exploration of the production processes, is one of the few young printers or print businessmen who have taken an interest in the digitally enabled concepts necessary to drive efficiency in printing and packaging businesses today. For instance, he has understood many of the Heidelberg Prinect prepress, workflow, and production monitoring features that are talked about but rarely implemented. This is usually because of the large gap between the educated management and inadequately skilled personnel on the shop floor.

He sees the benefits of investing in an expert printer from Heidelberg to train his team in a sustained three-week program. “This may sound expensive, but it’s trivial compared to the cost of the presses and their complexity. To achieve efficiencies that are closer to the capacity of the individual presses and the entire workflow will require continuous training and skilling,” he says. Moreover, he suggests there are several challenges in the hypercompetitive carton business, and while efficiencies and quality need to improve, so must profitability to sustain the viability of continuous investments in human resources.

Jain has implemented the processes and calculations of overall equipment effectiveness (OEE) using the Heidelberg Prinect spectrum of digital tools. He uses the Prinect imaging engine in prepress, its scheduling features for production, and its ability to produce pallet tags for production tracking and operational material movement.

The entire project of VK Global Digital reflects a perspective of individuals actively finding out, understanding, and implementing what is already well-established and available in the technology that has been paid for. The attitude of breaking down the business challenges and the production processes is the most exciting thing about the new plant and the persistence of the next-generation management. It is heartening to witness a young technocrat aligning technology, production processes, and human resources with his aspiration to excellence without compromise.

0 notes

Text

Biggest duplex paper board export in South Africa to whom?

Identifying the Biggest duplex paper board export in South Africa would typically require access to detailed trade statistics and import data, which can vary over time and depend on specific market conditions. However, there are several key factors and entities that often play significant roles in importing paper and paperboard products into South Africa:

Large Packaging Companies: Major packaging companies in South Africa that specialize in producing various types of packaging materials, including duplex paper board, are likely significant importers. These companies often import raw materials to meet their production needs.

Paper Merchants and Distributors: Companies engaged in the wholesale and distribution of paper products, including duplex paper board, may also be major importers. They supply to a wide range of industries and clients across South Africa.

Printing and Packaging Industry: The printing and packaging industry in South Africa, which includes converters and manufacturers producing printed packaging materials, relies heavily on imported duplex paper board to meet quality and performance standards.

Retail Chains and Consumer Goods Manufacturers: Large retail chains and consumer goods manufacturers that require packaging solutions for their products may import duplex paper board directly or through suppliers to ensure consistent supply and quality.

Trade and Distribution Channels: Importers and agents specializing in paper and paperboard products, including duplex board, play a crucial role in facilitating imports from various international suppliers and markets.

To pinpoint the single biggest importer of duplex paper board in South Africa, one would typically need access to specific import data from sources such as customs authorities, industry reports, or trade associations specializing in paper and packaging. These sources can provide insights into the volumes, origins, and destinations of duplex paper board imports, helping to identify the leading entities within the market.

0 notes

Text

Recycled-Content Corrugated Boxes: A Sustainable Solution

In an era marked by growing environmental awareness and concerns over climate change, businesses across industries are increasingly prioritizing sustainability in their operations. Packaging, in particular, has come under scrutiny due to its significant environmental impact, prompting a shift towards more eco-friendly alternatives. Recycled-content corrugated boxes have emerged as a sustainable packaging solution that addresses both environmental concerns and the need for functional, reliable packaging.

Corrugated boxes, commonly used for shipping, storage, and product display, are made from a combination of paper-based materials, including linerboard and corrugated medium. Traditionally, these materials were sourced primarily from virgin fibers, leading to deforestation, habitat destruction, and increased carbon emissions. However, recycled-content corrugated boxes offer a more sustainable alternative by utilizing recycled paper fibers as the primary raw material.

The production of recycled-content corrugated boxes begins with the collection and processing of post-consumer and post-industrial paper waste. This waste material, which includes cardboard boxes, newspapers, magazines, and office paper, undergoes a thorough sorting, cleaning, and pulping process to remove contaminants and convert it into pulp. The pulp is then used to manufacture new paperboard, which serves as the basis for corrugated box production.

One of the key benefits of recycled-content corrugated boxes is their ability to reduce the demand for virgin fiber and minimize the environmental impact of paper production. By diverting paper waste from landfills and incinerators, recycled-content boxes help conserve natural resources, reduce energy consumption, and mitigate greenhouse gas emissions. Additionally, recycling paper fibers requires less water and chemical inputs compared to virgin fiber production, further enhancing the sustainability credentials of corrugated boxes made from recycled content.

Moreover, recycled-content corrugated boxes are just as durable, functional, and versatile as their virgin fiber counterparts. They provide excellent protection for goods during shipping and handling, thanks to the cushioning properties of the corrugated structure. Additionally, recycled-content boxes can be customized to meet specific packaging requirements, including size, strength, and printability, making them suitable for a wide range of applications across various industries.

Another significant advantage of recycled-content corrugated boxes is their recyclability. Unlike some packaging materials that end up in landfills or oceans, corrugated boxes are highly recyclable and can be easily collected, sorted, and processed into new paper products. By closing the loop and promoting a circular economy, recycled-content corrugated boxes contribute to the conservation of resources, reduction of waste, and preservation of ecosystems.

In addition to their environmental benefits, recycled-content corrugated boxes offer economic advantages for businesses. By choosing recycled packaging materials, companies can reduce their reliance on virgin fiber, which is subject to price fluctuations and supply chain disruptions. Moreover, many consumers today prefer products packaged in sustainable materials and are willing to pay a premium for eco-friendly packaging, providing businesses with a competitive edge in the market.

Despite their numerous advantages, the widespread adoption of recycled-content corrugated boxes still faces some challenges. These include concerns over contamination of recycled fibers, quality consistency, and cost competitiveness. Visit webpage however, ongoing innovations in recycling technologies, process optimization, and material sourcing are helping to overcome these challenges and drive the adoption of recycled-content corrugated boxes across industries.

In conclusion, recycled-content corrugated boxes represent a sustainable packaging solution that offers environmental, economic, and functional benefits for businesses and consumers alike. By embracing recycled materials in packaging design and production, companies can reduce their environmental footprint, enhance brand reputation, and contribute to a more sustainable future. As the demand for eco-friendly packaging continues to grow, recycled-content corrugated boxes are poised to play a crucial role in shaping the future of packaging and advancing the transition towards a circular economy.

0 notes

Text

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution (from incineration) and water pollution (from landfilling).

Recycling is a key component of modern waste reduction and is the third component of the "Reduce, Reuse, and Recycle" waste hierarchy. It promotes environmental sustainability by removing raw material input and redirecting waste output in the economic system. There are some ISO standards related to recycling, such as ISO 15270:2008 for plastics waste and ISO 14001:2015 for environmental management control of recycling practice.

Recyclable materials include many kinds of glass, paper, cardboard, metal, plastic, tires, textiles, batteries, and electronics. The composting and other reuse of biodegradable waste—such as food and garden waste—is also a form of recycling. Materials for recycling are either delivered to a household recycling center or picked up from curbside bins, then sorted, cleaned, and reprocessed into new materials for manufacturing new products.

In ideal implementations, recycling a material produces a fresh supply of the same material—for example, used office paper would be converted into new office paper, and used polystyrene foam into new polystyrene. Some types of materials, such as metal cans, can be remanufactured repeatedly without losing their purity. With other materials, this is often difficult or too expensive (compared with producing the same product from raw materials or other sources), so "recycling" of many products and materials involves their reuse in producing different materials (for example, paperboard). Another form of recycling is the salvage of constituent materials from complex products, due to either their intrinsic value (such as lead from car batteries and gold from printed circuit boards), or their hazardous nature (e.g. removal and reuse of mercury from thermometers and thermostats).

1 note

·

View note

Text

Best Exporter and Manufacturer of Coated Paper in India

Coated Paper is made up of materials like clay, calcium carbonate, or other chemical compounds resulting in a smoother, glossier surface and improved print quality. What makes it suitable for applications like printing, publishing, advertising, and packaging industries? One key aspect is its versatility and ability to enhance visual content resulting in eye-catching results.

Many trusted organizations distribute Coated paper across the country, but RP Paper Impex, as a main Coated Manufacturer and Exporter in India, excels in delivering the best quality paper products at an inexpensive rate.

Reputable Coated Paper Manufacturer and Exporter in India | RP Paper Implex

With 25 years of experience in the paper industry, our firm holds certifications which include ISO, ROHS, FSC, and REACH. We adhere strictly to national and global standards for quality, safety, and environmental considerations in paper manufacturing, we prioritize supplying high-quality products to our clients.

Moreover, we deal with leading publishers, printers, multinational groups, continuous stationery producers, authorities businesses, academic, workout ebook manufacturers, paper converters, banks, and education boards, shipping groups, pharma agencies, and several FMCG companies. Our dedication is to emerge as a leading coated Paper Exporter in India, offering optimal solutions to meet our customers' needs.

Following rigorous quality control standards

Dedicated to encouraging a healthy lifestyle and sustainability

Customized solutions

Conduct multiple quality-control tests

Own Warehouse

Skilled Workforce

100% Top-Quality Coated Paper Available at an Affordable Price by Our Company

RP Paper Implex mainly focuses on delivering top-quality Coated paper with robust tensile strength for handling and transportation durability· Our papers come in various thicknesses and weights, ensuring strength and stability· We prioritize environmental friendliness through a strategic approach of Reuse, Recycle, and Reduce· Some of our manufactured products include:

Uncoated Paper

Copy Paper

Coated Paper

Paperboard

Thermal Paper POS Rolls

Corrugation Liner

Corrugation Liner

Ruled/ Lined Paper/ Exercise Book

Paper for Bags & Wraps

Greaseproof Paper

Why Our Coated Paper Company Is the Right Choice for Manufacturing Services?

RP Paper Impex is a leading manufacturer of high-quality Coated Paper in India, prioritizing ecological and sustainable products· Our dedicated team of innovative creators, designers, and quality inspectors ensures top-notch manufacturing· We distribute our products with commitment, aiming to serve our valued clients within specified delivery deadlines through our dedicated customer service unit·

Advanced Production Facilities

Utilization of Premium Raw Materials

Focus on Sustainable Product Development

Adherence to Standards and Regulations

Ethical and Sustainable Practices

Adaptability and Flexibility

Competitive Pricing

Assurance of Quality

Robust Supply Chain

Contact Details:

Name: RP Paper Impex

Address: Jawaharpur Industrial Area, Derabassi, Mohali, Punjab, India – 140507

Mobile: +91-8699497616, +91-7508128805

Email: [email protected], [email protected]

0 notes

Text

Flexible Industrial Packaging Market Size by Research Nester Reveals the Market to Grow with a CAGR of 4.79% During 2024-2036

Research Nester’s recent market research analysis on “Flexible Industrial Packaging Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global flexible industrial packaging market in terms of market segmentation by type, pouches size, filling process, application, layer, material, end user, and by region.

Growing Use of Flexible Packaging in Food Industry to Promote Global Market Share of Flexible Industrial Packaging

The global flexible industrial packaging market is estimated to grow majorly on account of the rising use of flexible packaging in the food and beverage sector. Flexible packaging techniques keep food fresh and flavorful. All solid and liquid food products can be safely packaged in these functional packaging choices. Flexible packaging serves several functions and provides an environmentally friendly alternative for culinary items. The demand for flexible packaging in the United States will climb 3.2% every year until 2021. Furthermore, food markets for converted flexible packaging accounted for 71% of overall demand in 2016 and increased to USD 15.5 billion in 2021. In addition to this, items with high liquid content, such as soups, are moving away from rigid packaging and into flexible packaging, such as pouches.

Request Report Sample@

Some of the major growth factors and challenges that are associated with the growth of the global flexible industrial packaging market are:

Growth Drivers:

Growing E-Commerce Sector

Rising Need for Attractive Packaging

Challenges:

Recycling plastic packaging waste is a difficult operation that necessitates cutting-edge infrastructure, and the whole process takes a lot of time and also requires professional expertise. This could stifle expansion in the flexible packaging business. Because of the waste produced by enterprises in this sector, the flexible packaging industry has received criticism from governmental organizations, consumers, and environmental groups. The majority of the materials utilized are frequently non-recyclable.

By material, the global flexible industrial packaging market is segmented into plastic, aluminum foil and paperboard. The plastic category is expected to generate the most market revenue of USD 91.7 billion by 2036, with a CAGR of 4.42%. In 2023, the plastic segment's market revenue was USD 53 billion. Because the materials are lightweight and flexible contribute to the segment’s growth. They may be easily molded into various shapes and sizes to meet the unique packaging requirements of various items.

By region, the market in North America, amongst the market in all the other regions, is projected to hold a market revenue of USD 30.6 billion by the end of 2036. The market revenue in the region was USD 17.8 billion in 2023, and the market is projected to grow at a CAGR of 4.33% over the forecasted period. The growth of the market can be attributed majorly to the growing use of flexible packaging in personal care products. According to the International Trade Administration of the United States Department of Commerce, the personal care and cosmetics sector in Canada will generate around USD 1.24 billion in revenue by 2021. Revenue in the industry is predicted to expand at a 1.45% annual rate, reaching USD 1.8 billion by 2024.

Access our detailed report at:

0 notes

Text

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution (from incineration) and water pollution (from landfilling).

Recycling is a key component of modern waste reduction and is the third component of the "Reduce, Reuse, and Recycle" waste hierarchy. It promotes environmental sustainability by removing raw material input and redirecting waste output in the economic system. There are some ISO standards related to recycling, such as ISO 15270:2008 for plastics waste and ISO 14001:2015 for environmental management control of recycling practice.

Recyclable materials include many kinds of glass, paper, cardboard, metal, plastic, tires, textiles, batteries, and electronics. The composting and other reuse of biodegradable waste—such as food and garden waste—is also a form of recycling. Materials for recycling are either delivered to a household recycling center or picked up from curbside bins, then sorted, cleaned, and reprocessed into new materials for manufacturing new products.

In ideal implementations, recycling a material produces a fresh supply of the same material—for example, used office paper would be converted into new office paper, and used polystyrene foam into new polystyrene. Some types of materials, such as metal cans, can be remanufactured repeatedly without losing their purity. With other materials, this is often difficult or too expensive (compared with producing the same product from raw materials or other sources), so "recycling" of many products and materials involves their reuse in producing different materials (for example, paperboard). Another form of recycling is the salvage of constituent materials from complex products, due to either their intrinsic value (such as lead from car batteries and gold from printed circuit boards), or their hazardous nature (e.g. removal and reuse of mercury from thermometers and thermostats).

1 note

·

View note

Text

Corrugated Packaging Boxes And Carton In Delhi

Custom printed packaging materials elevate your brand's packaging with our customizable and high-quality packaging materials.

Custom Packaging involves printing on a base material such as paper, plastic, fabric, paperboard, etc. and then converting the material into the required packaging product which is like a papers bag or Boxes. You can get custom packing tapes, customs bags, custom sticker printing and much more from papers gallery. Corrugated from Papers Gallery is made from premium materials that are crafted to endure the rigours of shipping and handling. They can be personalised with your company's logo or other design elements and come in a range of sizes.

Our corrugated boxes are not only strong and dependable, but also environmentally beneficial. For companies aiming to lessen their carbon footprint, they are an environmentally friendly option because they are made from recycled materials. We can work with you to select the ideal box for your unique needs and provide a wide range of customization possibilities. Ultimately,

we have the response to all of your questions, including "custom box printing services," "custom box printing near me," "corrugated box printing services," "custom carton box printing," and "e-commerce product packaging boxes printing."

Trusted by 1 Million+ businesses including small-medium businesses and large enterprises.

100% replacement on orders if unsatisfied

Dynamic ordering with online papers gallery and more locations across the country.

Dropship and deliver to customers, clients, communities across the globe. International and country-wide deliveries with express options.

Contact us for sampling charges. whats app/call: +91- 9996444060 Minimum order quantity per size : 500 Pieces for Rigid Boxes.

0 notes

Text

Corrugated Packaging Boxes And Carton In Delhi

Custom printed packaging materials elevate your brand’s packaging with our customizable and high-quality packaging materials. Custom Packaging involves printing on a base material such as paper, plastic, fabric, paperboard, etc. and then converting the material into the required packaging product which is like a papers bag or Boxes. You can get custom packing tapes, customs bags, custom sticker…

View On WordPress

#Designer paper bags#Flip Top Boxes#Industrial Paper#Luxury Packaging Boxes#Packaging Boxes#Paper Boxes#Paper Carry Bags#sale Gift Boxes

0 notes

Text

Antimicrobial Packaging In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Antimicrobial Packaging Market Research, 2031

The global antimicrobial packaging market size was valued at $10.3 billion in 2021, and is projected to reach $17.9 billion by 2031, growing at a CAGR of 5.6% from 2022 to 2031.Antimicrobial packaging is specifically designed packaging medium which helps in eliminating the possibility of growth of bacteria & germs. By inhibiting the pathogenic growth, it extends the shelf life of the product.

There is a rise in the demand for packaged food, owing to the surge in disposable income of people worldwide. This boosts the product demand in the antimicrobial packaging market. Furthermore, packaged food has always been a major health concern, and for the same reason, government bodies across the world established many regulations. Food processing industries invest heavily in the development of healthier packaging methods to meet these statutory requirements. This, in turn, increases the demand for antimicrobial packaging. Further, the healthcare industry is one of the major end-users of antimicrobial packaging. Moreover, consumers are becoming very keen on hygiene and packaging other product related to food, grooming solutions, and medicines. In addition, the healthcare industry has grown significantly in recent years, thereby driving the demand during the antimicrobial packaging market forecast period. Such instances support the antimicrobial packaging market overview.

The antimicrobial packaging market is segmented on the basis of material, technology, type, and region. By material, the market is classifed into paperboard, plastic, biopolymer, and others. By technology, the market is bifurcated into active release and controlled release. By type, the market is divided into carton, bags, pouches, and others.

Region wise, the antimicrobial packaging market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa).

COMPETITION ANALYSIS

The major players profiled in the antimicrobial packaging market include Avient Corporation, BASF SE, BioCote Limited, Dow, Dunmore, Klockner Pentaplast, Microban International, Mondi, Sciessent, and Takex labo Co.,Ltd.

Major companies in the market have adopted acquisition and product launch as their key developmental strategies to offer better products and services to customers in the antimicrobial packaging market.

Some examples of acquisition and partnership in the market

In August 2022, Mondi plc acquired Duino mill near Trieste (Italy) from the Burgo Group which total consideration of €40 million in order to expands its packaging unit. The mill currently operates one paper machine producing lightweight coated mechanical paper. Mondi plans to convert this paper machine to produce around 420,000 tonnes per annum of high-quality recycled containerboard for an estimated investment of around €200 million.

In June 2022, Confoil and BASF collaborated to develop a certified compostable dual ovenable paper tray for packaging ready-to-eat meals. This will strengthen the product portfolio of the company and increase its customer base.

In May 2020, Cartro, has collobirated with Mondi Ltd., one of the major market competitors, partnered. by meamns of Their collobortation may have enhanced the market value for anti-microbial packaging because they were successful in developing eco-friendly packaging for both fresh and regional goods.

In September 2022, Mondi has collaborated with Austrian bacon producer Handl Tyrol in order to provide a new mono-material polypropylene (PP) high barrier packaging solution for bacon. In addition, The eye-catching ‘wood effect’ film ensures safe vacuum packaging and offers excellent protection to prevent food waste..

In December 2022, BASF has collaborated to StePac to create contact-sensitive packaging solution for the preservation of fresh produce, making use of BASF’s ChemCycling technology to facilitate the production of Ultramid Ccyled polyamide 6 for StePac’s Xgo Circular series.

In December 2020 Touchguard and DS Smith have partnered to develop range of cardboard packaging with antimicrobial properties for e-commerce industry. Thus, all such factors collectively are expected to drive the growth of the company and expand its customer base by strengthening the product portfolio.

The product launch in the market

In May 2021, Avient has launches GLS thermoplastic elastomers with antimicrobial technology that protects against microbial growth. In addition, tested in accordance with JIS Z2801 and ASTM G21–15 standards, these additives protect molded plastic parts by inhibiting bacterial growth (99.9 percent or more) and resisting fungal and mold growth..

In June 2022, Avient Corporation, a premier provider of specialized and sustainable material solutions and services has launched its breakthrough PCR Color Prediction Service for polyolefins and polyethylene terephthalate (PET) resins, and the company’s new polyolefin antioxidants, Cesa Nox A4R Additives for Recycling.

In February 2021, Toppan Company developed film called “Virusweeper” for packaging with antibacterial and antiviral functions. Such instances are anticipated to boost growth of the antimicrobial packaging market.

In August 2020, Parkside Company and Touchguard Company collaborated to launch “Coating” for packaging solutions with an antimicrobial coating that protects against harmful bacteria. This will enhance and strengthen the product portfolio for the customer.

In June 2020, Designsake company has launched new coating with antimicrobial properties called “Matter” which kills/reduces harmful bacteria by 99.99%. The matter consist of a barrier made of silver ion technology. The company is taking lots of efforts to fulfill rising demand of customers by making innovations in the antimicrobial coating. Such instances are expected to drive the growth of the company.

Full Report With TOC:-https://www.alliedmarketresearch.com/antimicrobial-packaging-market-A16502

0 notes

Text

New uncoated paperboard enables graphical applications with a natural touch

Invercote Touch, an innovative uncoated paperboard, is designed to meet the growing demand for sustainable and visually appealing packaging materials while maintaining excellent printability.

The latest addition to the Invercote portfolio, the new uncoated product uniquely delivers a natural-looking and tactile experience along with the high-quality properties of other Invercote products, such as strength, stiffness, creasability, and strong sustainability credentials.

“Invercote Touch is a unique combination of uncoated paperboard, where the appearance and tactile feeling is key, and other characteristics that make Invercote so suitable for superior packaging applications,” says Edvin Thurfjell, product manager, Invercote Packaging and Graphics, Holmen Board and Paper. “Invercote Touch enables brands, for the first time, to prioritize a natural look and feel with a product that has the right combination of printing and converting properties for an uncoated paperboard.”

“With Invercote Touch, you touch the raw fibers and hear the sound of friction on the paperboard,” adds Thurfjell. “It provides a sensory interactive experience for the customer that feels easy and natural to handle. It also has the superior embossing features that are inherent with Invercote. It frees up what you can do with the surface and opens up more possibilities for creative messaging.”

Holmen’s mill in Iggesund developed Invercote Touch by applying the knowledge it has built up over 60 years of what premium packaging customers require and by listening to changing customer needs. While an uncoated paperboard will inherently print differently compared with coated paperboards, the development of Invercote Touch focused on steering the properties of the fiber layer to induce as little variation in print quality as possible.

“Invercote Touch provides a unique and natural addition to our product portfolio that we are very proud of,” says Thurfjell. “It widens Holmen’s product offering to existing customers and provides opportunities for new customers who are not familiar with Invercote. We are therefore also very excited to see how it will be used.”

Invercote Touch is suitable for all types of packaging and graphics applications. It is initially available in a 330 GSM version.

0 notes