#ptfe sheet gaskets

Text

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

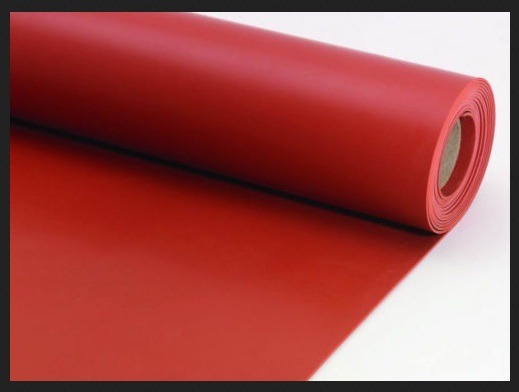

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

PTFE Stamped and Turned Parts Components Supplier from India

Rubber Gaskets for Sealing and Teflon Components supplier from India, specializing in PTFE Stamped (Sheet) and Turned Parts (Rod)

#Rubber Gaskets for Sealing and Teflon Components supplier from India#PTFE Stamped(Sheet) and Turned Parts( Rod) components supplier from India

0 notes

Text

Seal Tight with Expanded PTFE Sheets and Gaskets

0 notes

Text

Exploring The Excellence of PTFE Sheets- The Ultimate in Versatile and Durable Sealing Solutions

In the dynamic landscape of industrial applications, the demand for materials that offer superior performance, reliability, and versatility is ever-present. Polytetrafluoroethylene (PTFE) sheets stand out as a remarkable innovation, offering a unique combination of properties that make them indispensable in various sectors. This article delves into the world of PTFE sheets, exploring their…

View On WordPress

1 note

·

View note

Text

Manufacturer, Supplier, Exporter of PTFE Products like PTFE Sheets, Teflon Sheets, PTFE Gasket Sheets, PTFE Moulded Sheets

1 note

·

View note

Text

Your Guide to Choosing the Perfect Expanded PTFE Gaskets

In general, Expanded PTFE gaskets can also be used as sealing solutions in various types of industrial applications. These gaskets are commonly utilized across the industries because of high chemical resistance, flexibility and the durability. However, if you are in the food and beverage industry, the petrochemical industry, the pharmaceuticals industry or any other industry that may require robust sealing solutions, it is imperative to know how to select the best Expanded PTFE gaskets.

We will focus on important aspects that you should consider if you are to purchase the best Expanded PTFE gaskets for your particular application in this comprehensive guide.

What are expanded PTFE gaskets?

The Expanded Polytetrafluoroethylene (ePTFE) gaskets are a type of gaskets that are made from expanded PTFE material. PTFE is a fluorine plastic that is used in a wide range of applications primarily due to its chemical inertness and non-stick surface. During the expansion process, the PTFE develops a microporous formation that greatly improves its flexibility, conformability, and sealing properties.

ePTFE gaskets are preferred for use in most of the circumstances where standard gaskets may fail through chemical attack, high temperature or mechanical stress. The properties that set them apart make them ideal for sealing applications across many industries.

Advantages of Using Expanded PTFE Gaskets

Now, it cannot be emphasised enough why ePTFE gaskets are recommended in diverse industries before we proceed with the selection criteria. Here are the main benefits:

1. Chemical Resistance

The chemical compatibility of the expanded PTFE gaskets is excellent and it is not affected by most of the commonly used acids, alkalis, solvents, and corrosive agents. This makes them suitable to be used in chemical works, laboratories, and other facilities that use aggressive chemicals.

2. Temperature Tolerance

Sealing members produced from ePTFE gaskets can be used in a wide temperature range, commonly, from a minimum of -268°C (-450°F) to a maximum of 260°C (500°F). Their tolerance of temperature changes makes them suitable for low-temperature use and high-temperature use.

3. Non-Stick Properties

Due to the non-stick characteristics of the PTFE, the gaskets would not stick to the sealing surfaces. In this case, this property is valuable especially where there is often the need to change or service the gasket frequently.

4. Flexibility and Conformability

Gaskets made from expanded PTFE are very elastic and will easily fold to fit around uneven shape surfaces. This provides a secure and firm closure, which is rather important in vigorous conditions.

5. Characterized by a Low Cree and Good Cold Flow

Some aspects of ePTFE gaskets’ properties include low creep and cold flow, which implies that they are able to retain their initial shape and seal effectively over time in response to changes in pressure and temperature.

6. Biocompatibility

For instance, in the pharmaceutical and food industries, the gasket material cannot contribute to the contamination of the products that are being processed hence the suitability of ePTFE gaskets. This makes them a popular choice for applications where cleanliness is mandatory such as the food industry.

Factors to Consider When Choosing Expanded PTFE Gaskets

Choosing the best Expanded PTFE gasket involves the following factors that assist in achieving the best outcome. The following factors should be observed.

1. Application Environment

It is critical to know the specific operating conditions of the gasket so as to be able to meet its requirements. Consider factors such as:

Chemical Exposure: Determine the classes of chemicals that will come into contact with gasket to avoid interactivity.

Temperature Range: Find out the operating temperature limits to use when choosing a gasket that will not melt or fail under extreme temperatures.

Pressure Conditions: Evaluate the pressure conditions and opt for a gasket that will be strong enough to support the necessary sealing force.

2. Gasket Thickness

The thickness of the gasket is a very crucial factor when it comes to carrying out its functions. Thicker gaskets are appropriate for use in machines that possess irregular and rough adjacent surfaces since they offer better sealing as opposed to thin gaskets that are suitable for smooth and plain adjacent surfaces. If the gasket is used to cover the flanges or sealing faces, it is necessary to take into account the thickness of the gasket.

3. Compression and Recovery Properties

Compression characteristics and recovery characteristics are features of resistance of the gasket to the increase of pressure and the ability to return to its original state after the pressure has been removed. These properties prove very important when it comes to creating a good seal which can also be sustainable. The best c-glass and F-glass gaskets shall show good compression and recovery values for sustained sealing effectiveness.

4. Load Requirements

As it has been previously seen, the load that has to be applied can be very different depending on the application that has to be performed. The nature of the load it has to bear during the operation of the engine is another important factor that has to be considered when choosing the gasket. Since bolt load acts as the driving force, it should be factored in when determining the loading on the gasket as well as aspects of flange designs.

5. Surface Finish

The roughness of the areas where the gasket will interconnect can either enhance its sealing ability or inhibit it. If the surface roughness is increased relative to the surface flatness then a more conformable gasket material is required to provide the necessary seal. Determine the condition of the mating surface and identify the appropriate gasket that suits the surface roughness.

6. Size and Shape

ePTFE gaskets are available in many different sizes and forms to suit with the type of sealing required. Make sure that the gasket you order should be of same size as the shape and geometry of the sealing surfaces. In circumstances where customer requirements are outside that of an industry standard gasket, then non-standard or bespoke gaskets can be produced.

7. Regulatory Compliance

The foremost concern is the compliance with regulations as it is crucial in industries like the food or pharmaceutical industries. When choosing your ePTFE gasket it is also important that it comes with the standards and approvals that are relevant to its use for example it should be FDA for use in food industries or USP Class VI for drugs.

Common Applications of Expanded PTFE Gaskets

PTFE gaskets are extensively used in many industries because of these great characteristics that have been enhanced by expanding the polytetrafluoroethylene. Here are some uses of the most ordinary kind:

1. Chemical Processing

The main application area of the gaskets is chemical processing industries, where the ePTFE sealing is used for the pipelines, valves and reactors exposed to harsh chemicals. This way their chemical resistance absolutely guarantees long-time and seal-proof performance.

2. Food and Beverage

Many industries such as food and beverage employ ePTFE gaskets in equipment and pipelines that make contact with food products. Due to their ability not to contaminate food and their compatibility with the food safety requirements, they are ideal.

3. Pharmaceuticals

In the pharmaceutical manufacturing, the ePTFE gaskets are used especially in places that require high purity and cleanness. This helps to prevent contamination at each stage of the pharmaceutical production line with the final products.

4. Oil and Gas

In the oil and natural gas sector, ePTFE gaskets are used in pipelines, flanges, and equipment for high pressure and temperature application. Due to their robust characteristic, they can be applied in these harsh conditions.

5. Semiconductor Manufacturing

In semiconductor manufacturing, ePTFE gaskets are installed in cleanrooms and equipment for clean and chemically resistant application. They assist in ensuring that the overall production process is not compromised.

Conclusion

It is important to select the appropriate ePTFE gasket product based on the characteristics of the application and properties of Expanded PTFE gaskets. It means that when you’re choosing a gasket, some things to think about include chemical environment, temperature, pressure, and code requirements so that you can be sure to get the one that will work best for you.

There are many advantages of the expanded PTFE gaskets, these are chemical inertness, thermal stability, flexibility, and biocompatibility, which enable using the gaskets in many industries. Whether you are in Chemical processing, Food and beverage, Pharmaceuticals, Oil and gas or semiconductor manufacturing, ePTFE gaskets offer a durable sealing system.

Sourcing for the right ePTFE gasket is a way of improving the productivity as well as the safety of the operations while at the same time reducing on time spent on repairs and other maintenance activities. So, by going through this guide, you are fully prepared to make the best choice and to decide on the type of Expanded PTFE gasket that you need. At Sealmax, we understand the critical importance of reliable sealing solutions. Our Expanded PTFE gaskets are designed to meet the highest standards of quality and performance, ensuring that your operations run smoothly and efficiently.

Resource: https://what-are-the-uses-of-ptfe-gasket.blogspot.com/2024/06/your-guide-to-choosing-perfect-expanded.html

0 notes

Text

0 notes

Text

Flange Gaskets: A Critical Component in Piping Systems

Flange gaskets are essential components in piping systems, used to create a seal between two flanges that are bolted together. These gaskets prevent leaks and ensure the integrity of the piping system.

Types of Flange Gaskets

There are numerous types of flange gaskets available, each with its own unique properties and applications. Some common types include:

Flat gaskets: These are the simplest type of gasket, made from a flat sheet of material.

Compressed fiber gaskets: These gaskets are made from compressed fibers, such as asbestos or graphite.

Metallic gaskets: Metallic gaskets are made from various metals, such as copper, aluminum, or stainless steel.

Spiral wound gaskets: These gaskets are made from a metal strip wound into a spiral shape, often with an inner core of graphite or PTFE.

Expansion joint gaskets: These gaskets are designed to accommodate thermal expansion and contraction in piping systems.

Factors to Consider When Selecting Flange Gaskets

When selecting flange gaskets, several factors must be considered:

Pressure: The gasket must be able to withstand the operating pressure of the piping system.

Temperature: The gasket must be compatible with the temperature range of the fluid being transported.

Chemical compatibility: The gasket material must be resistant to the chemicals being handled.

Flange type: The type of flange (e.g., slip-on, weld neck) will determine the appropriate gasket type.

Joint sealing requirements: The gasket must be able to create a reliable seal under the specific conditions of the application.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including flange gaskets. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex flange gaskets are known for their:

Superior quality: Platinex gaskets are manufactured using advanced techniques and adhere to strict quality standards.

Wide range of materials: They offer a variety of gasket materials to suit different applications.

Customizable solutions: Platinex can provide customized gaskets to meet specific requirements.

Additional Manufacturers and Suppliers

Apart from Platinex, there are several other reputable manufacturers and suppliers of flange gaskets:

Parker Hannifin: A global leader in motion and control technologies, Parker Hannifin offers a wide range of gaskets and seals.

Garlock: A leading manufacturer of gaskets and seals for various industries.

Flexitallic: A global supplier of high-performance gaskets and sealing solutions.

Local Plumbing Supply Stores: Consider local plumbing supply stores for smaller quantities or specific regional requirements.

By carefully considering these factors and selecting the appropriate flange gasket, you can ensure the integrity and reliability of your piping system.

0 notes

Text

Thermoplastic Tapes Market Share, Trends, and Growth Reports | Global Insight Services

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

Thermoplastic Tapes are tapes composed of plastic materials that can be repeatedly softened and hardened by the application of heat. They are commonly used in a variety of industrial and consumer applications. They are well suited for applications requiring good electrical insulation, chemical resistance, and a wide range of temperature performance.

Thermoplastic tapes can be divided into two broad categories: thermoplastic elastomers (TPEs) and thermoplastic films (TPFs). TPEs are generally softer and more flexible than TPFs. TPEs are generally used in applications where flexibility and conformability are needed, such as electrical insulation, sealing, splicing, and gaskets. TPFs are generally stiffer and more rigid than TPEs and are used in applications where strength and dimensional stability are important, such as protective packaging, labeling, and insulation.

To Know More@ https://www.globalinsightservices.com/reports/thermoplastic-tapes-market/?utm_id=Pranalip

Thermoplastic tapes are available in a wide variety of materials including polypropylene, polyethylene, polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), and many others. Each material has its own unique properties and characteristics, and each can be tailored to meet the specific requirements of the application.

Thermoplastic tapes can be fabricated in a variety of ways. They can be extruded, cast, or laminated. Extrusion is the most common method and involves pushing the material through a die to form a continuous sheet or strip. Cast tapes are created by pouring the material into a mold and then curing it. Laminated tapes are created by bonding multiple layers of material together.

Thermoplastic tapes are widely used in a variety of industries and applications. They are used for electrical insulation, sealing, splicing, gaskets, and protective packaging. They are also used in medical and food packaging, labeling, and insulation.

Thermoplastic tapes are a versatile and cost-effective solution for a variety of applications. They offer good electrical insulation, chemical resistance, and a wide range of temperature performance. They are available in a variety of materials and can be tailored to meet specific application requirements.

Key Trends

Thermoplastic tapes are a type of adhesive tape that is heat-activated and used for a variety of applications. These tapes are made of a variety of materials such as polyethylene, polypropylene, polyvinyl chloride, polyester, and nylon. They are used in a variety of industries and applications, from medical and automotive to industrial and consumer products.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS24880/?utm_id=Pranalip

The thermoplastic tape market has seen significant growth in recent years due to the increasing demand for lightweight, durable, and cost-effective solutions. This growth is driven by the rising demand for energy-efficient and sustainable products. As such, manufacturers are striving to develop products with improved performance and optimized cost. To meet this demand, manufacturers are exploring the latest trends in thermoplastic tapes technology.

One of the key trends in thermoplastic tapes technology is the development of advanced adhesive systems. Traditional thermoplastic tapes rely on solvent-based adhesives, which can be difficult to use and can have a negative environmental impact. To address this issue, manufacturers are developing new adhesive systems that are more user-friendly and environmentally friendly. These advanced adhesives are designed to provide superior adhesion and durability while also minimizing environmental impacts.

Another key trend in thermoplastic tapes technology is the development of new materials. Traditional thermoplastic tapes are made from polyethylene and polypropylene. However, manufacturers are now exploring the use of new materials such as polyvinyl chloride, polyester, and nylon. These materials offer improved performance characteristics and are more durable than traditional materials. As such, they are becoming increasingly popular in a variety of applications.

A third key trend in thermoplastic tapes technology is the development of self-adhesive tapes. Self-adhesive tapes are designed to be easily applied without the need for an adhesive. This makes them ideal for use in applications where an adhesive would be difficult to apply. In addition, self-adhesive tapes are also less expensive than traditional tapes, making them a more cost-effective solution.

Finally, manufacturers are also exploring the use of smart thermoplastic tapes. Smart thermoplastic tapes are designed to be used with sensors to monitor and control temperature and humidity levels. This technology can be used in a variety of applications, from packaging to medical devices. Smart thermoplastic tapes are also becoming increasingly popular in the automotive industry due to their ability to monitor and control temperature and humidity levels in vehicles.

In conclusion, the thermoplastic tape market is rapidly evolving, and manufacturers are exploring a variety of new trends in order to meet the growing demand for energy-efficient and sustainable solutions. Advanced adhesive systems, new materials, self-adhesive tapes, and smart thermoplastic tapes are some of the most important trends in thermoplastic tapes technology. These trends are helping to improve performance and optimize cost, making thermoplastic tapes an attractive solution for a variety of applications.

Key Drivers

The thermoplastic tapes market is driven by a number of factors. These include the increasing demand for thermoplastic tapes in a variety of industries, the growing use of thermoplastic tapes for packaging and labeling, the rising demand for thermoplastic tapes in medical applications, and the increasing availability of low-cost thermoplastic tapes.

The demand for thermoplastic tapes has increased significantly over the past few years due to their versatile nature and wide range of applications. Thermoplastic tapes can be used in a variety of industries, including automotive, construction, electronics, and medical. For instance, thermoplastic tapes are used for insulation in automotive wiring harnesses, sealing and joining in construction, and for protection against electromagnetic interference in electronics. In medical applications, thermoplastic tapes are used to secure dressings, catheters, and other medical devices.

The increasing use of thermoplastic tapes for packaging and labeling is another key driver of the thermoplastic tapes market. Thermoplastic tapes are used for sealing, labeling, and protecting products during shipping and handling. Additionally, thermoplastic tapes are used in a variety of labeling applications, including bar codes, product identification, and warning labels.

The growing demand for thermoplastic tapes in medical applications is another driver of the thermoplastic tapes market. Thermoplastic tapes are used in medical applications for a variety of reasons, including securing dressings, catheters, and other medical devices. Additionally, thermoplastic tapes are used in wound closure and as a barrier against infection.

The increasing availability of low-cost thermoplastic tapes is also driving the thermoplastic tapes market. Low-cost thermoplastic tapes are becoming increasingly available, which has enabled a wider range of customers to access them. This has increased the demand for thermoplastic tapes, as customers are able to purchase them at a lower cost.

In summary, the thermoplastic tapes market is driven by the increasing demand for thermoplastic tapes in a variety of industries, the growing use of thermoplastic tapes for packaging and labeling, the rising demand for thermoplastic tapes in medical applications, and the increasing availability of low-cost thermoplastic tapes. These drivers are expected to continue to support the growth of the thermoplastic tapes market over the coming years.

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS24880/?utm_id=Pranalip

Market Segmentation:

Thermoplastic Tapes Market is segmented into resin type, application, technology and region. Based on resin type the market is categorized into Polyethylene, Polypropylene, Polyvinyl Chloride, Polyamide and Others. On the basis of application, it is further segmented into Automotive, Aerospace and Defense, Electrical and Electronics, Building and Construction, Sports and Leisure and Others. Based on technology it is segmented into Hot-Melt Extrusion, Solvent Dipping, Pultrusion and Others. Whereas based on region it is divided into North America,Europe,Asia-Pacific and Rest of the World .

Key Players:

The Thermoplastic Tapes Market Report includes players such as 3M Company (U.S), Avery Dennison Corporation (U.S), DuPont de Nemours, Inc. (U.S), Toray Industries, Inc. (U.S), Teijin Limited (Japan), Nitto Denko Corporation (Japan), Sekisui Chemical Co., Ltd. (Japan), Tesa SE (Germany), Saint-Gobain Performance Plastics (France) and BASF SE (Germany), among others.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS24880/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com

About Global Insight Services:

lobal Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Excellence in PTFE Production and Global Reach - Goa Polymer

In the dynamic world of industrial materials, Polytetrafluoroethylene (PTFE) stands out as a versatile and high-performance polymer. Known for its exceptional chemical resistance, low friction, and high thermal stability, PTFE is a go-to material in various applications, from electrical insulation to chemical processing. In India, Goa Polymer has emerged as a leading name in the manufacturing of PTFE products, setting benchmarks for quality, innovation, and reliability. This comprehensive guide explores Goa Polymer's journey, its role as a premier PTFE product manufacturer in India, and how it stands out in the competitive landscape.

Goa Polymer: A Legacy of Excellence

Goa Polymer was founded with a vision to revolutionize the polymer industry in India. With years of expertise and a commitment to quality, the company has established itself as a leading player in the PTFE market. From its humble beginnings to becoming a trusted name among industrial giants, Goa Polymer's journey is marked by relentless pursuit of excellence and innovation.

The Significance of PTFE Products

PTFE, commonly known by its brand name Teflon, is celebrated for its remarkable properties. The material's resistance to high temperatures, chemicals, and electrical conductivity makes it indispensable across a range of industries:

Chemical Processing: PTFE's non-reactive nature allows it to withstand harsh chemicals, making it ideal for linings, seals, and gaskets in chemical reactors.

Electrical Insulation: With its excellent dielectric properties, PTFE is widely used for insulating wires and cables in high-frequency applications.

Food Processing: The non-stick nature of PTFE is used in cooking equipment and food processing machinery to prevent sticking and ensure easy cleaning.

Aerospace and Defense: PTFE's resistance to extreme temperatures and chemicals makes it suitable for various aerospace and defense applications.

Given its importance, the demand for high-quality PTFE products is ever-growing, and Goa Polymer has risen to meet this need with unparalleled expertise.

Goa Polymer’s Product Portfolio

Goa Polymer offers an extensive range of PTFE products designed to meet diverse industrial requirements. Each product is crafted with precision to ensure it adheres to the highest standards of quality and performance. The company’s product portfolio includes:

PTFE Sheets: Ideal for use as liners, seals, and gaskets, these sheets are available in various thicknesses and sizes.

PTFE Rods: Used in manufacturing custom components, these rods offer excellent machinability and durability.

PTFE Films: Thin and flexible, PTFE films are used in applications requiring high clarity and electrical insulation.

PTFE Tubes and Pipes: Essential for conveying fluids and gases in corrosive environments, these tubes and pipes maintain their integrity under extreme conditions.

PTFE Gaskets and Seals: Customized to fit specific applications, these gaskets and seals provide reliable performance in sealing applications.

Quality Assurance at Goa Polymer

Quality is the cornerstone of Goa Polymer's operations. The company employs stringent quality control measures at every stage of production to ensure that each product meets the highest standards. Key aspects of their quality assurance process include:

Raw Material Inspection: Only the highest quality PTFE resins are used in manufacturing, sourced from reputable suppliers.

Advanced Manufacturing Techniques: Goa Polymer utilizes state-of-the-art machinery and processes to produce PTFE products with precise dimensions and superior performance.

Rigorous Testing: Each product undergoes thorough testing for chemical resistance, temperature tolerance, and mechanical strength to ensure it performs reliably in real-world applications.

Certifications: Goa Polymer holds various industry certifications that affirm its commitment to quality, including ISO 9001 for quality management systems.

Innovation and Technology

At Goa Polymer, innovation is a driving force. The company invests in research and development to enhance its product offerings and stay ahead of industry trends. Some of the technological advancements include:

Custom Solutions: Goa Polymer offers tailored PTFE solutions to meet specific customer needs, including bespoke dimensions and specialized formulations.

Advanced Manufacturing Techniques: The use of cutting-edge technologies in extrusion, molding, and machining ensures the production of high-quality PTFE products.

Sustainability Initiatives: Goa Polymer is committed to sustainability, implementing eco-friendly practices in its manufacturing processes and striving to reduce its environmental footprint.

Industry Applications and Success Stories

Goa Polymer’s PTFE products are employed across various industries, each benefiting from the material’s unique properties. Some notable applications and success stories include:

Chemical Industry: Goa Polymer has supplied PTFE liners and seals for major chemical processing plants, enhancing their operational efficiency and safety.

Electrical Industry: The company’s PTFE insulating materials are used in high-frequency cable assemblies, ensuring reliable performance in critical applications.

Food Processing: PTFE-coated equipment provided by Goa Polymer has been instrumental in improving the efficiency and hygiene of food processing operations.

Aerospace: Goa Polymer’s PTFE components have been used in aerospace applications, contributing to the performance and reliability of advanced systems.

Customer-Centric Approach

Goa Polymer’s commitment to customer satisfaction is evident in its customer-centric approach. The company values long-term relationships and strives to understand and meet the unique needs of its clients. Key aspects of their approach include:

Consultative Sales Process: Goa Polymer’s sales team works closely with clients to provide expert advice and recommendations tailored to their specific requirements.

Timely Delivery: The company ensures prompt delivery of products, adhering to agreed timelines and minimizing downtime for clients.

After-Sales Support: Goa Polymer offers comprehensive after-sales support, addressing any issues or concerns that may arise post-purchase.

Global Presence and Market Reach

While Goa Polymer is a prominent name in India, its reputation extends globally. The company has established a strong market presence through strategic partnerships and export operations. By adhering to international quality standards, Goa Polymer has successfully catered to clients across various countries, further solidifying its position as a leading PTFE product manufacturer.

Future Outlook and Expansion Plans

Looking ahead, Goa Polymer is poised for continued growth and innovation. The company plans to expand its product range, enhance its manufacturing capabilities, and explore new markets. With a focus on sustainability and technological advancements, Goa Polymer aims to maintain its leadership position in the PTFE industry and continue delivering exceptional value to its customers.

Conclusion

Goa Polymer’s standing as one of the leading PTFE product manufacturers in India is a testament to its unwavering commitment to quality, innovation, and customer satisfaction. Through its extensive product portfolio, state-of-the-art manufacturing processes, and customer-centric approach, Goa Polymer has set new standards in the industry. As the demand for PTFE products continues to grow, Goa Polymer remains at the forefront, driving excellence and shaping the future of polymer technology.

For more information about Goa Polymer and its range of PTFE products, visit their website or contact their sales team to explore how they can meet your industrial needs with precision and reliability.

0 notes

Text

PTFE Wear Strips Bands, Manufacturer, Supplier, Mumbai, India

Hindustan Nylons : PTFE Wear Strips / Bands, PTFE Wear Strips Bands manufacturer, PTFE Wear Strips Bands supplier in India. Call us : 9373054560.

ptfe ram extruded rods, ptfe molded sheets, ptfe ram extruded pipe, ptfe gaskets, ptfe wear strips / bands, ptfe molded rods, ptfe molded bush, ptfe skived sheets, ptfe paste extruded tubings, ptfe bellows / expansion joints, ptfe valve component, ptfe bridge bearing pads, trexonn machine tool slideway liners, chemically treated ptfe parts, satara, sangli, kolhapur, mumbai, india.

0 notes

Text

Non-metallic Gasket Material

Non-metallic Gaskets

Non Metallic Gasket Material refers to a broad category of different gasket materials that do not contain metal. These materials, which include rubber, silicone, graphite, and PTFE, are known for their flexibility, adaptability, and excellent sealing capabilities. They can be easily cut and shaped to fit a wide range of applications, from automotive and plumbing to industrial machinery. Some non-metallic gasket materials can withstand high temperatures and resist a variety of chemicals, making them a versatile choice for many sealing needs. The lifespan and environmental impact of these gaskets can vary depending on the specific material and application.

What Are the Advantages of Non-metallic Custom Gasket Material?

Non metallic seal gasket materials offer several advantages. They are highly flexible and adaptable, allowing them to be easily cut and shaped to fit a wide range of applications. This makes them ideal for complex or custom sealing needs. Many non-metallic materials, such as rubber, silicone, and PTFE, have excellent sealing properties and can effectively seal under low bolt load. They also have good resistance to a variety of chemicals and can withstand different temperature ranges, enhancing their versatility. Additionally, non-metallic gaskets are often more cost-effective than their metallic counterparts. Lastly, many non-metallic materials are recyclable or biodegradable, making them a more environmentally friendly option.

What Are the Applications of Non-metallic Gasket Material?

Non-metallic gasket materials are used in a wide range of applications due to their versatility and adaptability. In the automotive industry, they are used for sealing engines, transmissions, and fuel systems. In plumbing, they are used to create watertight seals in pipes and fittings. In industrial machinery, they are used to prevent leaks and maintain pressure in various systems. They are also used in the electronics industry for insulation and protection. Non-metallic gaskets can be found in appliances, HVAC systems, and even in the food and beverage industry, where they are used to seal containers and machinery to ensure hygiene and prevent contamination.

FAQS

FAQs of Non-metallic Gasket Material

How is Non-metallic Gasket Material made?

The manufacturing process varies depending on the specific material. For example, rubber gaskets can be molded, while PTFE gaskets are often cut from sheets.

Can Non-metallic Gasket Material withstand high temperatures?

How long does Non-metallic Gasket Material last?

Is Non-metallic Gasket Material environmentally friendly?

0 notes