#rate of tmt bar

Text

Understanding the Dynamics of Steel Prices in Bangalore: Factors, Trends, and Implications

Steel, the backbone of modern infrastructure and construction, plays a pivotal role in shaping urban landscapes like Bangalore. As one of India's fastest-growing cities, Bangalore's demand for steel is perennial, driven by its booming construction, automotive, and manufacturing sectors. However, the fluctuating nature of steel prices often poses challenges for stakeholders. In this blog, we delve into the intricacies of steel pricing in Bangalore, exploring the factors influencing its volatility, prevalent trends, and the implications for various industries.

Factors Influencing Steel Prices:

Global Market Dynamics: Bangalore's steel market is intricately linked to global trends. Fluctuations in global steel prices, driven by factors like geopolitical tensions, trade policies, and economic conditions in major steel-producing countries, directly impact local prices.

Raw Material Costs: The cost of raw materials, particularly iron ore and coking coal, significantly influences steel prices. Any disruption in the supply chain or fluctuations in raw material prices can lead to price volatility in Bangalore's steel market.

Domestic Demand and Supply: Local demand-supply dynamics play a crucial role in determining steel prices. Rapid urbanization, infrastructural projects, and industrial growth in Bangalore create substantial demand for steel, affecting its prices.

Government Policies: Government regulations, such as import tariffs, taxation policies, and infrastructure spending, can influence steel prices. For instance, initiatives like "Make in India" may boost domestic steel production, thereby stabilizing prices.

Exchange Rates: Fluctuations in currency exchange rates impact the cost of imported steel, which, in turn, affects local prices in Bangalore.

Trends in Steel Prices:

Volatility: Steel prices in Bangalore exhibit periodic fluctuations, reflecting the dynamic nature of the market. Rapid changes in global demand-supply dynamics, geopolitical events, and economic uncertainties contribute to price volatility.

Seasonal Variation: Like many commodities, steel prices in Bangalore often display seasonal patterns. Demand tends to peak during the construction season, leading to temporary price spikes, while prices may stabilize or dip during off-peak periods.

Long-term Trends: Despite short-term fluctuations, long-term trends in steel prices reflect broader economic and industrial developments. Bangalore's growing urbanization, infrastructure projects, and industrial expansion contribute to a generally upward trajectory in steel prices over time.

Implications for Industries:

Construction Sector: The construction industry in Bangalore, a major consumer of steel, is particularly sensitive to price fluctuations. Fluctuating steel prices can impact project costs, profit margins, and overall viability, influencing investment decisions and project timelines.

Automotive Industry: Bangalore's burgeoning automotive sector relies heavily on steel for vehicle manufacturing. Price volatility in steel can affect production costs, pricing strategies, and competitiveness, ultimately impacting the automotive industry's growth trajectory.

Manufacturing Sector: Steel is a key input in various manufacturing processes, ranging from machinery and equipment to consumer goods. Fluctuating steel prices can disrupt supply chains, affect production costs, and influence pricing strategies in the manufacturing sector.

Mitigating Strategies:

Risk Management: Stakeholders can adopt risk management strategies, such as hedging, forward contracts, and inventory management, to mitigate the impact of steel price volatility.

Diversification: Diversifying sourcing channels, exploring alternative materials, or adopting modular construction techniques can help reduce dependency on steel and mitigate price risks.

Long-term Contracts: Establishing long-term contracts with suppliers or customers can provide stability amidst price fluctuations, enabling better cost management and planning.

Conclusion:

Steel price in Bangalore, like elsewhere, are influenced by a myriad of factors, ranging from global market dynamics to local demand-supply conditions. Understanding these factors, tracking prevalent trends, and adopting appropriate mitigating strategies are crucial for stakeholders across industries to navigate the volatile steel market effectively. As Bangalore continues to evolve as a dynamic urban hub, the resilience and adaptability of its industries in managing steel price fluctuations will be instrumental in sustaining growth and development in the region.

Source: https://ksteelw.blogspot.com/2024/02/understanding-dynamics-steel-prices-bangalore.html

0 notes

Text

Remember the benefits of TMT bars the next time you search for top rated TMT steel bar manufacturers. These bars can strengthen your construction and make them strong enough to the wrath of nature.

0 notes

Text

Beyond Strength: Advanced Features of Highly Rated TMT Bars for Superior Construction

The choice of materials plays a pivotal role in ensuring the longevity and resilience of structures. Among these materials, Thermo-Mechanically Treated (TMT) bars have gained prominence for their superior strength and durability. However, the excellence of Highly rated TMT bars extends beyond mere strength. This comprehensive guide delves into the advanced features that set highly-rated TMT bars apart, transforming them into indispensable elements for superior construction projects.

Advanced Features Unveiled:

1. Superior Strength and Yield Stress:

Highly rated TMT bars exhibit superior tensile strength and yield stress, ensuring they can withstand heavy loads and seismic forces. This feature contributes to the overall stability and safety of structures.

2. Optimized Elongation and Ductility:

The advanced manufacturing processes of Highly rated TMT bars result in optimized elongation and ductility. This means the bars can undergo deformation without losing their structural integrity, making them ideal for seismic-prone regions.

3. Corrosion Resistance Capabilities:

One of the standout features is the enhanced corrosion resistance of highly-rated TMT bars. This is achieved through specialized alloying elements, protecting the bars from rust and deterioration even in challenging environmental conditions.

4. Weldability for Seamless Integration:

Highly rated TMT bars are designed for optimal weldability, allowing for seamless integration into construction projects. This feature enhances the ease of handling during the construction process.

Innovations in TMT Bar Technology:

1. Micro-Alloying for Enhanced Properties:

The incorporation of micro-alloying elements such as vanadium, niobium, and copper contributes to the enhanced properties of highly-rated TMT bars. These elements refine the microstructure, improving strength and durability.

2. Thermal Treatment for Uniformity:

Advanced thermal treatment processes ensure uniformity in the structure of Highly rated TMT bars. This uniformity translates to consistent mechanical properties across the entire length of the bar, a crucial factor in construction reliability.

3. Quenching and Tempering:

The quenching and tempering processes are optimized in highly rated TMT bars to achieve the desired balance of strength and ductility. This meticulous treatment results in bars that excel in both load-bearing capacity and flexibility.

Environmental Sustainability:

1. Recyclability and Eco-Friendly Practices:

Many highly-rated TMT bars prioritize recyclability and eco-friendly manufacturing practices. This aligns with the global shift toward sustainable construction materials, making them an environmentally conscious choice.

2. Reduced Carbon Footprint:

The production of Highly rated TMT bars often involves processes that reduce carbon emissions. This commitment to a reduced carbon footprint further positions these bars as leaders in environmentally responsible construction.

Sustainable Construction Practices:

1. Energy-Efficient Manufacturing:

Highly-rated TMT bars often undergo energy-efficient manufacturing processes, reducing the overall energy consumption during production. This commitment to energy efficiency aligns with sustainable construction practices and global efforts to minimize environmental impact.

2. Lifecycle Assessment Benefits:

Conduct a lifecycle assessment of highly-rated TMT bars, emphasizing their positive contribution to the overall sustainability of a construction project. From manufacturing to installation and eventual recycling, these bars offer a comprehensive and eco-friendly solution.

Innovative Design Possibilities:

1. Slim and Lightweight Designs:

Advanced features of highly-rated TMT bars allow for the creation of slim and lightweight structural designs without compromising on strength. Architects and designers can leverage this feature to explore innovative and aesthetically pleasing construction possibilities.

2. Flexible Construction:

The optimized elongation and ductility of highly-rated TMT bars contribute to the flexibility of construction designs. This flexibility is particularly valuable in projects where intricate or unconventional architectural elements are desired.

Sustainability Initiatives:

1. Carbon-Capture Technologies:

Some manufacturers of highly-rated TMT bars actively invest in carbon-capture technologies during the production process. This commitment to sustainability aligns with global efforts to mitigate the environmental impact of construction materials.

2. Zero-Waste Production Practices:

Zero-waste initiatives in production facilities of highly-rated TMT bars focus on minimizing waste and optimizing resource utilization. This environmentally conscious approach further solidifies the position of these bars as leaders in sustainable construction.

User-Centric Features:

1. User-Friendly Packaging and Transportation:

Innovations extend to user-centric features, such as packaging and transportation. Highly-rated TMT bars are designed for easy handling and transport, minimizing the risk of damage during transit and ensuring convenience for end-users.

2. Smart Labels for Information Access:

Some highly-rated TMT bars incorporate smart labels that enable users to access detailed information about the bars' specifications, certifications, and manufacturing processes. This empowers construction professionals to make informed choices.

As the construction industry evolves, the demand for materials that go beyond conventional standards continues to rise. Highly rated TMT bars, with their advanced features encompassing strength, durability, corrosion resistance, and sustainability, stand as beacons of innovation in construction. Beyond serving as load-bearing elements, these bars contribute to the creation of structures that embody longevity, safety, and environmental responsibility. For construction professionals and project managers seeking excellence, highly-rated TMT bars represent a transformative choice that not only meets but exceeds the expectations of superior construction.

0 notes

Text

Buy Tata Tiscon TMT Bars, Rebars, and Stirrups online for superior strength and earthquake resistance to make your dream home stronger and safer.

#best tmt rebars#tata tiscon dealer#tmt rebars manufacturers in india#tata tiscon rate#top 10 tmt bar in india#tata tiscon online purchase

0 notes

Text

Buy Vizag TMT Bar Fe-500 Grade-8mm online at BuildersMART for the lowest price. In Hyderabad, we offer premium steel bars in various sizes.

#Vizag Steel 8mm Price#Vizag Steel Price today Hyderabad#Steel Price today#TMT Bar price#TMT Bars price today#steel rate today#steel rate per kg#Vizag Steel 8mm rod cost#Vizag Steel price per ton today

0 notes

Text

High-quality Fe-500 Grade Jindal TMT Bar-8mm online

High-quality Fe-500 Grade Jindal TMT Bar-8mm online. We are wholesale suppliers of steel bars for the best price with free shipping and COD in Hyderabad.

For more information please see below link:-

https://www.buildersmart.in/jindal-fe-500-grade-8mm

#Fe-550 Grade Jindal Panther#Fe-550 Grade Jindal Panther price in hyderabad#Fe-550 Grade Jindal Panther steel rate#Fe-500 Grade Jindal TMT Bar-8mm price#Jindal TMT bars online#Today steel price#steel price per kg#Fe-500 Grade Jindal TMT Bar Per ton

0 notes

Text

Steel Price Today | SAIL-TMT Bar Fe-500 Grade-12mm -BuildersMART

Get SAIL-TMT Bar Fe-500 Grade- 12mm at Lowest price from BuildersMART. Check with TMT Bar price list. We offer high-strength TMT Bars of all sizes in Hyderabad.

for more informaction please vist ouor website:

https://www.buildersmart.in/12mm-20968

#Sail TMT pric#Sail TMT Bar#Today Steel rate#Steel price#Steel price today Hyderabad#TMT bar price#Steel price today

0 notes

Text

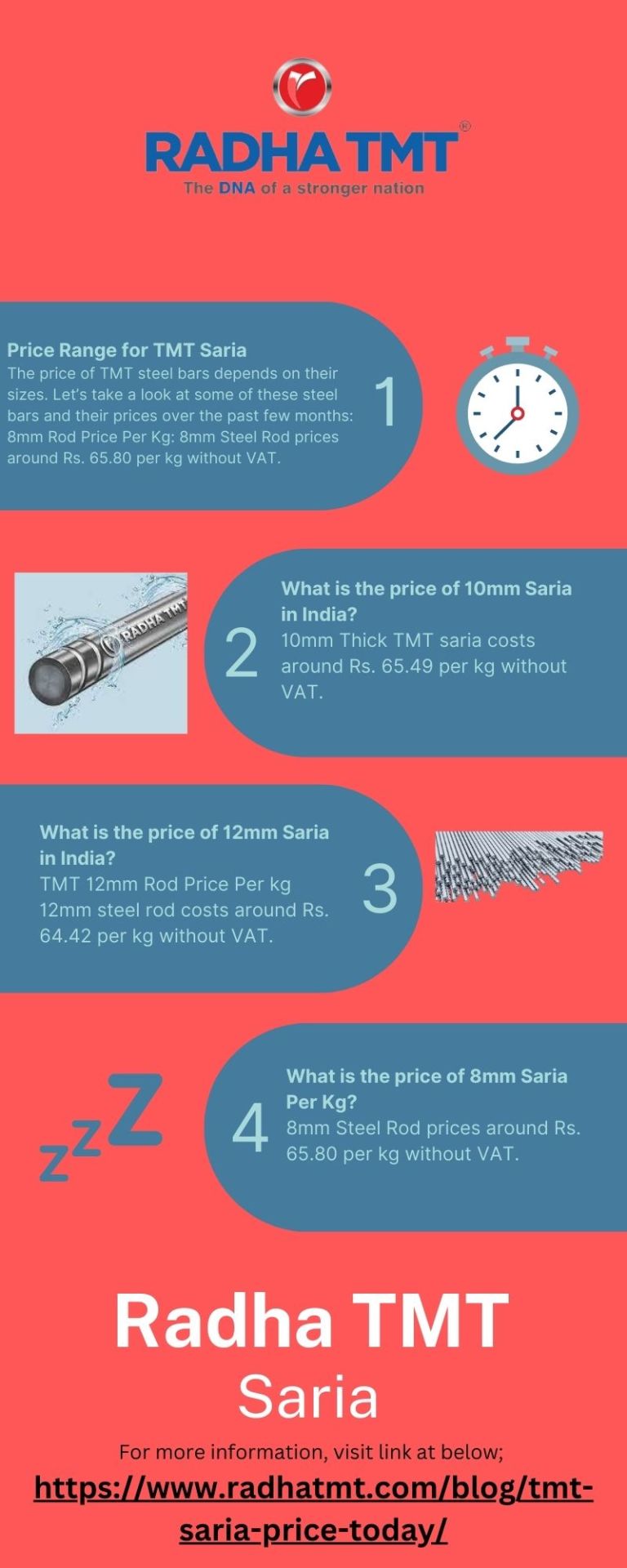

Radha TMT Saria Price Today, TMT Saria Price - Radha TMT

Find out the Radha TMT Saria Price Today and TMT Saria Price from Radha TMT. Get reliable and accurate information on current market trends to make informed construction decisions. Contact us now for more information and an order.

0 notes

Text

Best sariya and their letest prices - Comaron

Kamdhenu TMT price today. Know the letest price of Mongia Steel. Sariya prices varries accoring to the brand, quality and locality. Here in this blog we are mentioning top TMT and their prices along with the releated information about the TMT. Goel TMT prices. Vizag TMT. Jyoti TMT. BALMUKUND TMT letest price and more..

Visit our website https://www.comaron.com/blog/sariya-rate

Call us at 83-770-440-77

#sariya ka rate#sariyakarate#tmtprice#tmt price#kamdhenu tmt#vizak tmt#letest sariya price#letest tmt price#jindal price list#jindal tmt 550 price list 2022#Mangal TMT#jindal panther price list#srmb tmt#tmt bar price in kolkata#rathi saria#rathi saria price today#TMT steel bar price#STEEL BAR price

0 notes

Text

Current Steel Rates in Bangalore: A Comprehensive Breakdown

The steel industry is a cornerstone of economic development, playing a pivotal role in the construction, infrastructure, and manufacturing sectors. Bangalore, a bustling metropolis known as the Silicon Valley of India, is witnessing unprecedented growth in various industries, fueling demand for steel. In this blog post, we'll delve into the current steel rate in Bangalore, providing a comprehensive breakdown to help businesses, builders, and individuals navigate the dynamic steel market.

Understanding the Dynamics of Steel Pricing:

Steel prices are influenced by a myriad of factors, both global and local. Understanding these dynamics is crucial for anticipating market trends and making informed decisions. Here are some key factors that contribute to the fluctuations in steel rates:

Raw Material Costs:

The price of steel is intricately linked to the cost of raw materials, primarily iron ore and scrap metal. Any changes in the prices of these materials can have a direct impact on the overall cost of steel production.

Global Economic Trends:

Steel is a globally traded commodity, and economic conditions in major steel-producing countries, such as China and the United States, can influence global steel prices. Economic downturns may lead to a decrease in demand, affecting steel rates.

Trade Policies and Tariffs:

Trade policies and tariffs imposed by different countries can significantly impact the cost of importing or exporting steel. Trade tensions between nations can lead to fluctuations in steel prices.

Industry Demand:

The demand for steel in various industries, including construction, automotive, and manufacturing, plays a pivotal role in determining prices. Rapid urbanization and infrastructure development in Bangalore contribute to the city's substantial steel demand.

Currency Exchange Rates:

Steel prices are also affected by currency exchange rates. Fluctuations in currency values can impact the cost of imported steel, influencing local rates.

Current Steel Rates in Bangalore:

As of [Current Date], the steel rates in Bangalore are reflective of the dynamic market conditions. It's important to note that steel prices are subject to change, and consumers should check for the latest rates before making any purchasing decisions. Below is a breakdown of the current steel rates in Bangalore, focusing on different types of steel commonly used in construction and manufacturing:

TMT Bars:

Thermo-Mechanically Treated (TMT) bars are widely used in construction for their high tensile strength and durability. The current rates for TMT bars in Bangalore range from [Price Range] per ton, depending on the brand, grade, and diameter.

Structural Steel:

Structural steel, including angles, channels, and beams, is essential for building frameworks and supporting structures. The current rates for structural steel in Bangalore vary between [Price Range] per ton, with different specifications and sizes contributing to the pricing variations.

Mild Steel (MS) Plates:

MS plates find applications in various industries, including construction and manufacturing. The current rates for MS plates in Bangalore are approximately [Price Range] per ton, with thickness and dimensions influencing the pricing.

Galvanized Iron (GI) Pipes:

GI pipes are widely used for water supply, plumbing, and structural applications. The current rates for GI pipes in Bangalore range from [Price Range] per meter, with variations based on diameter and thickness.

Stainless Steel:

Stainless steel is valued for its corrosion resistance and aesthetic appeal, making it suitable for a range of applications. The current rates for stainless steel in Bangalore depend on the grade and finish, with prices ranging from [Price Range] per kilogram.

Factors Influencing Current Rates:

To better understand the current steel rates in Bangalore, it's essential to explore the factors influencing these prices:

Global Steel Market Trends:

Bangalore, being a major consumer of steel, is not isolated from global market trends. Any shifts in global steel prices due to geopolitical events, economic conditions, or supply chain disruptions can impact local rates.

Infrastructure Development in Bangalore:

The rapid urbanization and infrastructure development in Bangalore contribute significantly to the demand for steel. Government initiatives, such as Smart City projects, influence the construction sector and, consequently, steel rates.

Construction Boom:

The construction industry is a major driver of steel demand. Bangalore's booming real estate sector, coupled with commercial and residential projects, has a direct impact on the current steel rates.

Supply Chain Disruptions:

Disruptions in the supply chain, whether due to natural disasters, transportation issues, or other unforeseen circumstances, can lead to fluctuations in steel prices.

Government Policies and Regulations:

Changes in government policies, including taxation and import/export regulations, can influence the overall cost structure of the steel industry, affecting the current rates in Bangalore.

Tips for Navigating the Steel Market in Bangalore:

Given the dynamic nature of the steel market, individuals and businesses in Bangalore can adopt the following strategies to navigate the current steel rates effectively:

Stay Informed:

Regularly monitor industry news, market trends, and global economic conditions to stay informed about factors influencing steel prices.

Build Strong Supplier Relationships:

Establishing strong relationships with reliable steel suppliers in Bangalore can provide access to timely information on price changes and market dynamics.

Consider Bulk Purchases:

Negotiate bulk purchases with suppliers to potentially secure more favorable rates and discounts.

Evaluate Alternatives:

Explore alternative steel materials or suppliers to ensure competitiveness and mitigate risks associated with market fluctuations.

Plan Ahead:

Anticipate future steel requirements and market conditions to plan purchases strategically and potentially benefit from more stable pricing.

Conclusion:

In conclusion, understanding the current steel price in Bangalore requires a holistic view of the global and local factors influencing the market. As a key player in the steel industry, Bangalore's growth and development contribute significantly to the demand for steel, making it essential for businesses and individuals to navigate the market wisely. By staying informed, building strong supplier relationships, and adopting strategic purchasing practices, stakeholders can effectively manage the impact of fluctuating steel prices, ensuring the success of construction and manufacturing projects in the dynamic landscape of Bangalore.

Source: https://ksteelw.blogspot.com/2023/12/current-steel-rates-in-bangalore-a-comprehensive-breakdown.html

0 notes

Text

TMT Rod Price in West Bengal | Comaron

There is a huge consumption of TMT bars of varied brands in the construction industry of West Bengal. There is a long list of TMT brands here. Nevertheless, there are only a few which have stood among all because of their features like exceptional ductility, inordinate strength, corrosion resistance, fire resistance as well as earthquake resistance.

Call us:- 83-770-440-77

Visit our website:- https://www.comaron.com/blog/tmt-price-west-bengal

#tmt rod in west bengal#tmt wholesale#tmt bar in west bengal#tmt rod price in kolkata#tmt rod image#rod tmt bar#tmt bars manufacturers in west bengal#tmt rod price per kg#tmt rod price in india#top tmt bars in west bengal#tmt rod rate per kg#tmt rod price list#which tmt bar is best in west bengal#tmt rod price today#top 5 tmt bar in west bengal

0 notes

Text

https://www.buildersmart.in/vizag-tmt-fe-550-grade-8mm

#Vizag Steel 8mm Price#Vizag Steel Price today Hyderabad#Steel Price today#TMT Bar price#TMT Bars price today#steel rate today#steel rate per kg#Vizag Steel 8mm rod cost#Vizag Steel price per ton today

0 notes

Text

TMT Sariya Provides The Best Protection For Buildings In Central India

Regardless of what you are building – a home, a shop, or a multi-storied office building – you want to plan for the long term. After all, no one constructs for just a few years!

To ensure the longevity of your buildings in Central India, you need to ensure that it is constructed with the right materials and follow the best construction practices and design.

In this article, we will discuss one key material that gives a building its durability and strength – STEEL.

To build a long-lasting building in Central India, you need to protect it from three things –

Earthquakes

Some parts of Central India are classified under the seismic zone III, and RCC construction here must proactively include earthquake resistant measures. From the point of view of the material, a critical earthquake-resistant item is the TMT sariya or TMT bar used throughout the building.

TMT steel bars are manufactured using a special technology that makes its inner core more flexible than ordinary sariya. This feature helps it weather the sideways motion of earthquakes fairly well and ensures that the building stays standing even during a massive earthquake.

Corrosion

Another big damage creator for buildings in Central India is corrosion. While this problem is exponentially worse in coastal or tropical regions, the effect of corrosion is equally deadly all across the world. Even little exposure to air or moisture leads to rust formation on steel bars, and there are only two ways to ensure rust doesn’t eat up your building’s insides; one is to make sure that steel is not exposed to the atmosphere and the second is to use steel with rust resistance traits.

TMT bars have intrinsic corrosion-resistant properties, which is due to their manufacturing process (for example, Moira Sariya adds chrome, nickel, and copper, which gives its TMT bars enhanced anti-rust and anti-corrosion properties).

Structural weakness

The third and most hidden problem is intrinsic structural weakness. Low quality, poorly manufactured materials will lead to a building that might look normal but is weak from the inside.

Using TMT bars, which are proven to have higher tensile strength, ductility, enhanced elongation, is one way to ensure the foundational strength of the whole RCC structure. TMT bars also have a cross ribbed pattern, which gives it better bonding with concrete and adds an extra layer of durability that goes beyond the strength of the materials.

If you are building in Central India, then you have one of the country’s leading TMT bar manufacturers close to hand! Moira Sariya– a TMT bar manufacturer in Indore – has been manufacturing and selling steel products across the country for the last 3 decades. Our TMT bars are made with world-leading CRS technology licensed from HSE Germany, and we supply TMT bars of various grades and thickness.

Do get in touch to find out more about our manufacturing process or to locate our dealers.

#tmt bars manufacturers in indore#tmt saria rate#tmt saria price#tmt bars#tmt bar price#tmt saria price in Bhopal#saria rate in indore#Thermex TMT Sariya#TMT Bar dealers#tmt saria dealership

0 notes

Text

Process Involved in Making Quality TMT Bars

TMT or Thermo Mechanically Treated bars are high-strength support bars having a toughened external core and a malleable internal core. They are manufactured under a procedure called Thermo Mechanical Treatment, after which they have been named. TMT bar have become an important part of construction whether commercial or residential, apart from house construction they are also used for various other purposes. RodiDust Marketing & Distributions Pvt. Ltd. is a building material supplier in Delhi NCR, which have years of experience in the construction industry. Here are the steps in making superior quality TMT bars as explained by experts at RodiDust.

Steps involved in making quality TMT bars:

Extraction of iron from ore and its conversion to steel

Raw Materials such as coke, Iron ore, and fluxes are used to extract iron kept in the molten state. It is then subjected to pre-treatment, conversion, and refining. Molten steel is then poured into the casting machine.

Heating, undulating, and creation of toughened bars

Steel billets are heated to a temperature of 1200 °C to 1250 °C and then they are reshaped by rolling gradually forming steel bars.

Quenching:

Quenching can be simply understood as sudden heating and cooling of steel reinforced bars. Quenching prevents the occurrence of undesired processes. Upon this process of quickly heating and cooling outer surface of the bar is converted into Martensite, a hard form of steel. While the outer surface is cooled but the core remains hot

Self-Tampering:

Upon the completion of quenching wholly a temperature gradient is formed through the cross-section of the Quenched bar. The heat from the core naturally flows outside where the temperature is relatively lower. As a result, a pattern of correct tampering of an outer layer and the configuration of a middle ring of Martensite and Bainite (a plate-like microstructure) is formed.

Atmospheric cooling:

Bars are then subjected to atmospheric cooling to equalize the temperature. Once the bars are entirely cooled down, the austenitic core gets changed into a ductile ferrite-pearlite arrangement.

Cross-section of the concluding product exhibits a distinction in its crystal microstructure having a hard, burly, tempered martensite in its outmost layer, a transitional layer of Martensite and Bainite, and a polished, rough, and ductile ferrite and pearlite core.

RodiDust Building Material Suppliers in Gurgaon and Delhi NCR provide steel TMT bar from all various brands and different grades making it one of the most reliable marketplaces for online building materials in Delhi.

How RodiDust Marketing & Distributions Pvt. Ltd. can be your best construction partner:

RodiDust has always been committed to customer service and satisfaction. We are dedicated to providing the best quality material, services, and assistance. Through years of hard work and dedication, we have emerged as one of the most reliable construction material suppliers in Gurgaon. You can reach us out through our website or contact number.

Note: Also Please Like Share and Comment on Facebook Page

#today saria rate in gurgaon#tmt steel price per kg#tmt bars supplier in gurgaon contact number#tmt bars supplier in gurgaon contact no#TMT bars supplier in gurgaon#tmt bars full form#tmt bar price today#steel rate in gurgaon#Steel Dealers in Gurgaon#steel bars for construction#steel bar price per kg#steel bar 12mm price#sariya ka rate today gurgaon

0 notes

Photo

Are you want to know the tmt steel price today in Hyderabad. Radha Tmt - Tmt steel bar manufacturers & dealers in the Hyderabad India which provide the best tmt bar 8mm, 10mm , 12mm, 16mm, 20mm, 25mm and 32mm TMT steel bars an affordable prices. for more information visit our website.

0 notes