#rigid packaging suppliers

Text

https://thinkcmykstudios.com/

Premium Packaging Boxes Supplier in Noida

Give your business and brand a feel of uniqueness with our premium box manufacturing services. We are Noida's leading personalized & custom carton boxes supplier in terms of quality craftsmanship, customization, versatility, and price affordability. To reach our services, feel free to visit our website now.

#Personalized Rigid Box Supplier in Noida#Premium Packaging Boxes Supplier in Noida#Packaging Boxes Supplier

2 notes

·

View notes

Text

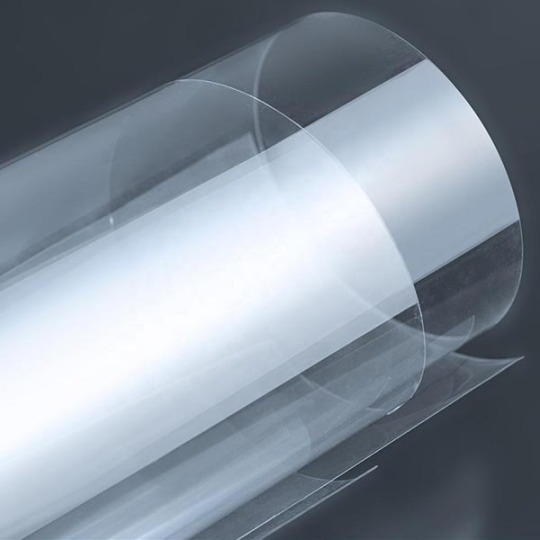

Leading PET Sheets Manufacturer for Sustainable Blister Packaging Solutions: Lyka Global Plast LLC

In the realm of blister packaging, the choice of material plays a pivotal role in ensuring product safety, durability, and visual appeal. As industries demand packaging solutions that are both reliable and visually appealing, Lyka Global Plast LLC emerges as a beacon of excellence, offering top-notch PET sheets tailored for blister packaging needs.

PET Sheet for Medical Blister Packaging:

Lyka Global Plast LLC takes pride in providing PET sheets specifically designed for medical blister packaging. With stringent quality control measures and adherence to international standards, their PET sheets ensure the safe and secure packaging of medical supplies, including capsules and tablets.

PET Sheets Manufacturer for Sustainable Packaging:

As a pioneer in sustainable packaging solutions, Lyka Global Plast LLC leads the industry as a PET sheets manufacturer committed to environmental stewardship. Their PET sheets are crafted with a focus on reducing environmental impact while maintaining superior performance, making them ideal for eco-conscious businesses.

PET Sheet for Medical Blister Packaging Price:

Offering competitive pricing without compromising on quality, Lyka Global Plast LLC makes PET sheets for medical blister packaging accessible to businesses of all sizes. Their transparent pricing ensures affordability without compromising on product excellence.

Transparent Rigid PET Sheet for Blister Packing:

Transparency is key in showcasing products effectively while maintaining product integrity. Lyka's PET sheets offer exceptional transparency, allowing consumers to view the packaged products clearly. The rigid nature of these sheets ensures structural integrity, safeguarding the contents during transportation and storage.

Blister Packing PET Film Sheet:

Lyka Global Plast LLC's PET film sheets are specifically engineered for blister packing applications. With superior puncture resistance and barrier properties, these sheets provide optimum protection to the packaged products, keeping them safe from external elements and preserving their quality.

Blister Packing PET Sheet Rolls:

Offering convenience and versatility, Lyka's PET sheet rolls are tailored to meet the diverse needs of blister packaging. Available in various widths and thicknesses, these rolls empower businesses to customize packaging solutions according to their requirements, optimizing efficiency and minimizing waste.

Medical Supplies Capsule Blister Packaging:

Lyka's PET sheets are widely utilized in the pharmaceutical industry for capsule blister packaging. Designed to meet stringent quality standards, these sheets ensure the integrity and safety of medical supplies, contributing to the overall reliability of the packaging.

Transparent RPET Blister Sheet:

Lyka Global Plast LLC also specializes in transparent RPET blister sheets, offering enhanced sustainability without compromising on performance. These sheets are crafted from recycled PET material, reflecting Lyka's commitment to environment-friendly packaging solutions.

In conclusion, Lyka Global Plast LLC stands as a trusted PET sheets manufacturer, offering sustainable blister packaging solutions that prioritize product safety, durability, and environmental responsibility. With a steadfast commitment to quality and sustainability, Lyka's PET sheets are the preferred choice for businesses seeking reliable and eco-friendly packaging solutions.

Lyka Global Plast LLC stands as a trusted partner for businesses seeking premium PET sheets for blister packaging applications. With a focus on quality, affordability, and sustainability, Lyka's PET sheets epitomize excellence, ensuring the integrity and visual appeal of packaged products across various industries.

#Pet sheet for medical blister packaging price#Pet sheet for medical blister packaging india#pet sheet for blister packaging#pet sheet manufacturer and supplier for blister packaging#PET Sheet Blister Packing rolls#Transparent Rigid PET Sheet for Blister Packing#Blister packing PET film sheet#Medical Supplies Capsule Blister Packaging#Transparent RPET Blister Sheet

0 notes

Text

Cosmo Plastech is the end-to-end rigid packaging solutions division of Cosmo Films that specializes in creating customized packaging solutions for a variety of fast-moving consumer goods (FMCG) products. At Cosmo Plastech, we use injection molding and thermoforming techniques to manufacture our products, which are made from high-quality materials to ensure durability and reliability.

0 notes

Text

Innovations in Corrugated Box Manufacturing: Meeting Modern Packaging Needs

In the realm of modern packaging, corrugated boxes have held their ground as an essential solution for transporting and protecting goods. Over the years, innovations in corrugated box manufacturing have not only sustained the relevance of this packaging staple but have also propelled it into the future. Let's delve into some of the cutting-edge trends that are reshaping the corrugated box manufacturing landscape.

Sustainable Materials for a Greener Tomorrow

In an era dominated by environmental consciousness, corrugated box manufacturers are taking significant strides towards sustainability. Traditional materials are being replaced with eco-friendly options, such as recycled cardboard and plant-based inks. These initiatives not only reduce the carbon footprint but also resonate with eco-conscious consumers.

Customization and Personalization

Modern consumers seek products that resonate with their individuality, and packaging is no exception. Corrugated box manufacturers are leveraging digital printing technologies to offer customization and personalization options. From intricate designs to incorporating a customer's name, this trend adds a personal touch that can enhance brand loyalty.

Intelligent Packaging for Enhanced Traceability

With the rise of e-commerce, the ability to track and trace packages has become crucial. Corrugated box manufacturers are integrating technologies like QR codes and RFID tags into their designs. This enables companies and customers to monitor the package's journey from manufacturer to doorstep, enhancing transparency and security.

Strength Reinvented: Lightweight yet Durable

Advancements in material science have given rise to lightweight yet robust corrugated boxes. These boxes offer the same level of protection while minimizing material usage. This not only reduces shipping costs but also contributes to a more sustainable packaging approach.

Automation and Efficiency

Automation has revolutionized the manufacturing industry, and corrugated box production is no exception. Automated processes for cutting, folding, and gluing have streamlined production, resulting in higher efficiency, reduced lead times, and minimized errors.

E-Commerce-Centric Designs

The rapid growth of online shopping has led to the development of corrugated box designs tailored for e-commerce needs. These boxes are designed to fit standardized shipping methods, reduce excess space, and ensure the safe arrival of products even after being subjected to the rigors of the logistics process.

Interactive Packaging for Consumer Engagement

In the age of smartphones and augmented reality, corrugated box manufacturers are exploring interactive packaging solutions. QR codes that unlock engaging digital content or augmented reality experiences are becoming popular, creating a bridge between the physical and digital worlds.

In conclusion, corrugated box manufacturers are undergoing a transformation to meet the demands of a rapidly evolving packaging landscape. Through sustainable materials, customization, intelligent tracking, lightweight durability, automation, e-commerce optimization, and interactive engagement, these manufacturers are reshaping the way products are packaged and delivered. As consumer expectations continue to evolve, so will the innovations in corrugated box manufacturing, ensuring that this traditional packaging solution remains a cornerstone of the modern packaging ecosystem.

#interiors#recycled cosmetic packaging suppliers#Carton Manufacturer in Delhi#Custom Rigid Box Manufacturing#Recyclable Clothing Packaging

0 notes

Text

Luxury Gift Box & Customized Packaging Manufacturer in Delhi

Indicolour is one of the leading luxury gift boxes and custom packaging solution provider companies in Delhi. It has been providing solutions in multiple variants such as gift boxes, product boxes, wedding invitation boxes, MDF boxes, Kappa rigid boxes, MDF or Kappa trays, boxes of ribbons, wedding favors and invitations.

#Gift Boxes Manufacturer in Delhi#Gift Boxes Supplier in Delhi#Gift Boxes Wholesaler in Delhi#Rigid Boxes Manufacturer in Delhi#Rigid Boxes Supplier in Delhi#Rigid Boxes Wholesaler in Delhi#Luxury Packaging Manufacturer in Delhi#Luxury Packaging Wholesaler in Delhi#Wooden Boxes Manufacturer in Delhi#Wooden Boxes Supplier in Delhi#Wooden Boxes Wholesaler in Delhi

0 notes

Text

🎁🏭 Elevate Your Packaging Game with Dongguan Pinchuang Automation Equipment Co., Ltd! 🏭🎁

🌟 Founded in 2015, we are a leading supplier of automated box-making machinery based in Dongguan City, China.

✨ Our state-of-the-art factory spans 5000 square meters and boasts a dedicated team of over 50 skilled employees.

🔍 With a focus on research, development, and innovation, we've emerged as a key player in the rigid box machinery industry.

🎀 Specializing in rigid box making and case making machines, our products cater to a wide range of packaging needs, from shoe boxes to chocolate boxes, and everything in between!

🌍 We're proud to be certified by Europe CE and EAC, ensuring top-notch quality and compliance with international standards.

🌟 Our machines have made their mark across the globe, from Europe to South Africa, the Middle East, and Southeast Asia.

🎉 Elevate your packaging process and join the ranks of satisfied customers worldwide with Dongguan Pinchuang Automation Equipment Co., Ltd! 🎉

o learn more about our products and services, please visit our official website: https://www.pcboxmachinery.com. We look forward to collaborating with you! 🌟🏭

2 notes

·

View notes

Text

The Science Behind Calcium Carbonate Starch Granules in Pharmaceutical Development

A Perfect Binder for Tablet Integrity

Cost-Effective Calcium Carbonate Starch Granules Manufacturers India says that this material serves as an excellent binding agent in pharmaceutical formulations, providing tablets with the strength needed to hold their shape through production, packaging, and consumption. Their adhesive properties ensure that active ingredients and excipients remain tightly packed, preventing the tablet from crumbling or losing integrity. The science behind their binding capability lies in the interaction between the calcium carbonate’s rigidity and starch’s natural cohesiveness, creating a durable tablet that retains its potency. This dual-action makes calcium carbonate starch granules a vital component for ensuring tablet durability without compromising drug efficacy.

Swelling Properties for Rapid Disintegration

One of the key scientific benefits of calcium carbonate starch granules is their ability to swell when exposed to moisture, which facilitates rapid tablet disintegration in the digestive tract. The starch component absorbs water and expands, causing the tablet matrix to break apart and release the active ingredients. This disintegration process is essential for medications requiring quick absorption, as it ensures the drug is released promptly. By leveraging the swelling nature of starch, pharmaceutical scientists can design tablets that optimize the release profile of drugs, ensuring efficient absorption and improved therapeutic outcomes. Bulk Calcium Carbonate Starch Granules suppliers for Pharmaceuticals India.

Maintaining Stability of Sensitive Ingredients

In pharmaceutical development, ensuring the stability of active ingredients is crucial. Calcium carbonate starch granules help stabilize sensitive APIs (active pharmaceutical ingredients) by forming a protective matrix around them. The calcium carbonate component acts as a buffer, neutralizing potential pH changes or moisture exposure that could degrade the active ingredient. This protective role extends the shelf life of the medication and maintains the efficacy of the drug over time. By incorporating calcium carbonate starch granules, pharmaceutical developers can create formulations that safeguard fragile ingredients while ensuring the drug remains effective and stable. Indian Suppliers of Calcium Carbonate Starch Granules for Cosmetics Industry.

0 notes

Text

Dazzle Customers with Luxury Rigid Boxes Crafted by America's Top Makers

In the luxury world, presentation is power. From the moment customers first unbox a product to the satisfaction of holding a premium package in their hands, the little details leave a huge impression. For brands looking to upgrade their image in the US market, investing in custom luxury rigid boxes is a foolproof way to wow discerning American consumers and take your brand prestige to the next level.

Made right here in the USA by some of the country's most talented paper engineers and graphic designers, bespoke luxury rigid boxes offer a totally tailored experience - where every material, dimension, and design feature is crafted just for your brand.

This guide will cover everything brands need to know about how luxury rigid boxes can elevate your product experience and brand perception. Read on to learn:

What sets luxury rigid boxes apart

The key design elements that contribute to their allure

How to select the best rigid box producer for your US brand

The powerful benefits these boxes bring for shaping customer impressions

With America's deep expertise in both structural box design and stunning graphics, the opportunity is yours to develop truly distinctive, high-end packaging that captures attention and delights your customers.

What Makes Rigid Boxes Feel Like Pure Luxury?

Truly luxury rigid boxes have a few special traits that set them leagues apart from everyday packaging:

Opulent Materials - Textured specialty papers, real wood veneers and textiles give tactile richness. Metallic foils and inks add elegance.

Artistic Design Details - Subtle refinements like foil stamping, dimensional embossing, and soft touch laminates create visual interest and depth.

Fully Bespoke - Every dimension, fold, and functional element is tailored specifically to integrate seamlessly with your product and brand story.

Clever Constructions - Unique lift-off lids, pull-out trays, and unfolding box structures charm and surprise customers.

Eco-Friendly Production - Sustainable materials like bamboo and non-toxic coatings appeal to earth-conscious consumers.

This harmonious blend of sensorial materials, innovative functional design, total customization, and green production is what makes luxury rigid boxes truly transcendent.

Key Design Elements That Elevate Rigid Boxes to Heirloom Status

So how exactly do US rigid box suppliers or manufacturers transform a basic box into a treasure box? They have a few tricks up their sleeves:

Luxe Textures and Finishes - Options like soft-touch matte coatings, linen finishes, and letterpress patterns create tactile richness.

Decadent Embellishments - Metallic foil stamping, blind embossing, and spot UV gloss provide tasteful ornate accents.

Tailored Graphics - From custom patterns to photorealistic product shots, graphics are designed to reinforce brand themes.

Clever Reveals - Magnetic open-and-close mechanisms, pull-out trays, and multi-fold constructions add an element of surprise and delight.

Custom Interiors - Die-cut slots, luxe linings, and branded compartments keep contents secure while continuing brand storytelling.

Truly gifted packaging designers can translate the heart and soul of your brand into tangible details that connect on an emotional level.

How to Select the Top Rigid Box Producers for Your Brand

When vetting a luxury rigid box partner, make sure to evaluate:

Packaging Prowess - Look at past work to ensure they have mastered the fine details.

Customization Range - The best will offer completely tailored boxes that fulfill your vision.

Production Quality - Examine samples closely to see stellar assembly, hinge function, precision cutting and more.

Sustainability - Ask about eco-friendly material sourcing and production methods.

Added Services - Consolidate with a producer that also handles design, storage and fulfillment.

Collaborating closely allows designers to perfectly translate your brand essence into packaging.

The Powerful Benefits of Investing in Luxury Rigid Boxes

For discerning brands, custom luxury rigid boxes provide major rewards:

Make Memorable First Impressions - The unboxing becomes a magical reveal customers adore.

Spotlight Quality - Striking and substantial packaging amplifies the perceived value of products.

Build Customer Relationships - Clients appreciate the special experience and become brand devotees.

Strengthen Identity - Details immediately pique curiosity and convey what your brand is about.

Stand Apart - Bespoke boxes help you rise above competitors with mass-produced packaging.

Minimize Waste - Reusable, renewable materials prevent your packaging from polluting landfills.

By tangibly demonstrating quality and care through materials and design, luxury rigid boxes speak volumes about your brand's values.

Thrill Customers with Bespoke Boxes from America's Rigid Box Masters

Thanks to a legacy of packaging ingenuity, America's talented rigid box craftspeople make the ultimate partners for brands aiming to captivate customers and stand out from the crowd. Their mastery of structural design, vivid graphics, and keen attention to luxury details empower them to create packaging that leaves an impression as unique as your product itself.

Are you ready to treat your brand and customers to the packaging experience they deserve? Reach out to top American rigid box producers today. Their custom designs will shape experiences and perceptions that epitomize your brand identity for years to come. When it comes to presentation, these boxes bring pure packaging magic.

0 notes

Text

1. Understand Your Product’s Compatibility with Tube Packaging

The first step in using round plastic tubes is ensuring that your product is compatible with this type of packaging. Round plastic tubes are ideal for semi-solid and liquid formulations such as:

Lotions and creams

Gels and serums

Sunscreens and scrubs

Lip balms or ointments

If your product requires precise dispensing, such as gels or liquids, tubes with narrow tips may be the best option. For thicker products, tubes with wider openings or applicators work better for easy squeezing and application.

Tip: Test different tube sizes and nozzles to ensure smooth and controlled dispensing of your product.

2. Choose the Right Tube Material

Round plastic tubes come in various materials, each offering specific benefits depending on your product’s formulation and your brand’s requirements.

LDPE (Low-Density Polyethylene) is flexible, making it easy to squeeze, and ideal for lotions and creams.

HDPE (High-Density Polyethylene) is more rigid and offers excellent product protection.

Laminated tubes (such as ABL or PBL) provide an extra layerof protection for sensitive or high-end products. They offer a premium feel and are resistant to air and moisture.

Tip: For eco-conscious brands, opt for post-consumer recycled (PCR) plastic or bio-based materials to reduce environmental impact.

3. Customize Your Tube Design

The design of your round plastic tube plays a key role in brand recognition and product differentiation. Customizing your tube’s appearance helps your product stand out on shelves and resonates with your target audience.

Color and printing options: Choose from a variety of colors, finishes (matte or glossy), and printing techniques such as silkscreen, hot stamping, or digital printing to showcase your branding.

Tube shape and size: While round tubes are the standard, you can vary the diameter, length, and even the cap style to give your product a unique look and feel.

Decorative elements: Add eye-catching designs with embossed or debossed logos, metallic accents, or clear windows to highlight the product inside.

Tip: Work closely with your packaging supplier to explore the best options for customization that align with your brand image.

4. Select the Right Cap or Closure

Caps and closures are a vital part of tube packaging as they ensure the product remains sealed, fresh, and easy to use. There are various types of closures available, depending on your product and its intended application.

Flip-top caps are ideal for daily-use products like moisturizers and sunscreens because they offer quick and convenient access.

Screw caps provide a more secure seal, perfect for travel-sized products or formulations that require extra protection.

Applicator tips can be used for precise application, such as for eye creams, spot treatments, or liquid products.

Tip: Ensure the cap or closure complements the functionality and convenience of the product, particularly for on-the-go use.

5. Consider Tube Size and Volume

The size and volume of your round plastic tube should match your product’s intended use and customer preferences. For daily-use items, larger tubes (50ml–150ml) are common, while travel-size products often use smaller tubes (10ml–30ml). Offering multiple sizes can cater to different segments of your market.

Tip: Smaller tubes are perfect for samples or travel kits, which can help introduce new customers to your brand.

6. Maximize Sustainability with Your Tube Packaging

With increasing consumer demand for eco-friendly packaging, round plastic tubes can be designed to support sustainability efforts. You can implement the following strategies to make your packaging more eco-conscious:

Use recyclable materials: Opt for HDPE or LDPE tubes that can be easily recycled by consumers.

Incorporate PCR (Post-Consumer Recycled) content: Using recycled plastic in your tubes helps reduce waste and minimize the environmental impact.

Design refillable tubes: Consider creating refillable packaging solutions to encourage reuse and reduce the need for single-use plastics.

Tip: Promote your sustainability efforts on your packaging and marketing materials to appeal to environmentally conscious customers.

7. Test for Durability and Functionality

Before launching your product, it’s essential to test the durability and functionality of your round plastic tube packaging. Factors such as temperature changes, pressure during transportation, and everyday consumer use can impact the performance of your packaging.

Durability tests ensure the tube doesn’t crack, warp, or leak under different conditions.

Dispensing tests confirm that the product can be easily squeezed out without clogging or excessive effort.

Shelf life tests assess how well the tube maintains product freshness and protects it from contamination.

Tip: Always run product compatibility tests to ensure the packaging protects your formula effectively.

Conclusion

Round plastic tube packaging offers a versatile, customizable, and practical solution for a wide range of personal care, skincare, and beauty products. By carefully selecting the right material, size, design, and closures, you can ensure your product is well-protected and presented in a way that enhances the customer experience.

At Enki Packaging, we provide a wide range of round plastic tube solutions that can be tailored to your product's unique needs. Contact us today to explore how we can help elevate your packaging.

0 notes

Text

FoamFlex: Tailor Diversity

youtube

Australia's foam industry is an ever-evolving sector, offering a wide array of solutions for various applications. From adaptable foam types with different grades to sturdy foam varieties serving industries like sign writing and construction, and dense cellular materials boasting buoyancy and thermal insulation properties, the foam sector is a cornerstone of modern manufacturing.

Flexible Foams

Manufactured in varying grades, adaptable foam types cater to a range of needs. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Higher density foams last longer but are pricier, while hardness, measured in Newtons, signifies the 'feel' of the foam. This flexibility allows for tailored solutions, from packaging to comfortable cushions.

Rigid Foams

The foam industry extends its reach by providing sturdy foam varieties, which are crucial in sign writing, building, and construction. Materials like polystyrene (EPS and XPS), PIR, and rigid polyurethanes serve diverse industries, enhancing structural integrity and insulation. The closed-cell and resilient nature of EPS make it suitable for thermal insulation systems, decorative surfaces, packaging, and even stage sets.

Closed Cell Foams

Crafted from polyethylene or ethyl vinyl acetate co-polymers, dense cellular materials exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. Their applications span expansion joints, packaging, impact absorption, thermal insulation, and backing rod. These foams, resistant to common chemicals, are ideal where durability and performance are crucial.

Environmental Considerations and Innovation

With the growing focus on global sustainability, the foam industry is aligning with environmental goals. Materials and manufacturing processes are evolving, and recycling initiatives, along with the introduction of eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact.

In conclusion, Australia's foam industry is a versatile and innovative force, offering essential materials for diverse applications. From adaptable foam types to sturdy and dense cellular materials, these materials have become integral to daily life, showcasing the adaptability and ingenuity within the Australian manufacturing landscape.

https://foamflextailordiversity217.blogspot.com/2024/09/foamflex-tailor-diversity.html

foam WA

foam insulation Perth

Polystyrene WA

styrofoam perth

EPS Perth

closed cell foam insulation

Foam Supplier in Perth

https://vistacarproblems53.blogspot.com/

https://massagecertificationshermanoa270.blogspot.com/2024/09/vista-car-problems.html

https://www.tumblr.com/jessica-harlowe/762038781836754944

https://selfstoragesaffronwalden328.blogspot.com/2024/09/self-storage-saffron-walden_047508592.html

https://www.tumblr.com/gerardgallagherlot/762036193657569280

0 notes

Text

Festival Luxury Packaging Boxes Manufacturer and Suppliers in Delhi - Sellers and Traders

Luxury packaging boxes play a vital role in enhancing your brand image and influencing customer perceptions. Papers Gallery, a premium packaging supplier, highlights how well-designed luxury boxes are an investment that can set your business apart from competitors. These boxes go beyond mere aesthetics—they help elevate product value, create memorable first impressions, and foster brand loyalty. Papers Gallery offers custom packaging with a focus on high-quality, visually stunning boxes. They cater to small businesses as well as large brands, providing eco-friendly and luxurious packaging options for various industries.

If you're looking for manufacturers of luxury packaging boxes, here are a few well-known companies in India that are the best suppliers to the USA, Canada, UK.

Papers Gallery specializes in premium packaging boxes, offering customized luxury solutions like rigid boxes, collapsible boxes, and magnetic lock boxes. They provide both aesthetics and protection for products, with a focus on enhancing brand value

High-quality materials, customization options, and thoughtful designs contribute to making your product feel exclusive and desirable. Customers often associate luxury packaging with premium product quality, which can drive sales and justify higher price points (Papers Gallery)

Additionally, luxury packaging helps protect products during shipping, ensuring they arrive in pristine condition, which boosts customer satisfaction. Papers Gallery also emphasizes the importance of sustainability by offering eco-friendly options that align with consumer preferences for environmentally conscious packaging ( Papers Gallery).

For businesses seeking to boost their brand through packaging, investing in luxury boxes is a strategic choice that can leave a lasting impact on consumers. These manufacturers provide a range of luxurious packaging solutions, helping businesses enhance their product presentation while maintaining durability and design quality.

0 notes

Text

A Comprehensive Guide to Selecting the Right Gusseted Poly Bags

When it comes to packaging, few options are as versatile and functional as gusseted poly bags. These bags, characterized by their expandable sides, are ideal for a variety of applications across different industries. Whether you're a business owner looking to enhance your packaging solutions or a DIY enthusiast organizing your home, selecting the right gusseted poly bag can make all the difference. Here’s a comprehensive guide to help you choose the right gusseted poly bags for your needs.

What Are Gusseted Poly Bags?

Gusseted poly bags are plastic bags with pleats or folds along the sides that allow for extra space. This design enables the bags to expand, making them perfect for packaging bulkier items or products that require extra room. Unlike flat bags, the gusseted variety can stand up on their own, providing ease of access when filling or storing items.

Benefits of Gusseted Poly Bags

Increased Capacity: The main advantage of gusseted poly bags is their ability to hold more products than regular flat bags. This makes them excellent for bulk items.

Versatility: These bags can be used for various applications, including food storage, retail packaging, and shipping.

Durability: Typically made from high-quality polyethylene, gusseted bags offer significant protective qualities against moisture, dust, and dirt.

Cost-Effectiveness: Often more economical than rigid containers, gusseted bags reduce shipping weights and can save on storage costs.

Customizable: Many manufacturers offer customizable options in terms of size, thickness, and printing solutions, allowing businesses to enhance their branding.

Key Factors to Consider When Choosing Gusseted Poly Bags

Material Type

Gusseted poly bags are primarily made from two types of polyethylene: low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

LDPE Bags: These are softer, more flexible, and typically have a higher clarity. They’re suitable for applications requiring more pliability.

HDPE Bags: These are stronger, more rigid, and generally more suitable for items that need additional support. They are less transparent but provide better puncture resistance.

Size and Dimensions

Selecting the right size is crucial. Gusseted bags come in different widths, heights, and gusset depths. Consider:

Width and Height: Ensure the dimensions fit your product. Take into account the total volume needed, including any additional layers of product.

Gusset Depth: The depth of the pleats is important for items that need stability. A deeper gusset provides more space, while a shallow gusset works for slimmer items.

Thickness

The thickness of the material is measured in mils (thousandths of an inch).

Standard Thickness: Most gusseted poly bags range from 1.5 mil to 6 mil. The choice of thickness should depend on the weight and fragility of the contents. Heavier or more delicate items typically require thicker bags to prevent tearing.

Closure Types

Gusseted bags come with various closure types:

Open-Top: Ideal for items that do not need sealing but still require a sturdy structure.

Zip-Top: Offers security and reusability, ideal for storing items safely.

Heat-Sealable: Best for those requiring a tamper-proof seal.

Choose a closure option that aligns with your packaging requirements.

Clarity and Print Options

Depending on your needs, you might want a clear bag for visibility or a colored one for branding. Custom printing options are widely available, which can help promote your business or communicate essential information about the product.

Environmental Considerations

As environmental concerns grow, many suppliers are producing recyclable and biodegradable poly bags. If sustainability matters to your brand, investigate these options and certifications before making a purchase.

Common Applications for Gusseted Poly Bags

Food Packaging: Ideal for snacks, bulk ingredients, or baked goods due to their durability and ability to form seals.

Retail Packaging: Excellent for clothing items, accessories, and promotional materials.

Industrial Uses: Perfect for parts, components, and bulk items in manufacturing and warehouses.

Storage Solutions: Great for organization at home or in commercial settings by providing protection against dust and moisture.

Selecting the right gusseted poly bags requires careful consideration of multiple factors—from material type and size to thickness and closure options. By understanding the unique characteristics and benefits of these bags, you can make informed decisions that not only enhance the look and functionality of your products but also ensure their safety during transport and storage. Take the time to evaluate your specific needs, and you’ll find that gusseted poly bags can offer a flexible and efficient packaging solution to meet your requirements.

0 notes

Text

Tablet Container Manufacturers & Suppliers in India | Singh Enterprise

The pharmaceutical organisation is a cornerstone of worldwide healthcare, responsible for the improvement and distribution of medicine that shop and enhance lives. Within this enterprise, pill bins play an important function in making sure the protection, efficacy, and luxury of pharmaceutical products. In India, a country identified for its sturdy pharmaceutical quarter, the decision for outstanding tablet containers pharmaceutical is incredible. This blog delves into the panorama of tablet area producers and companies in India, highlighting the significance of these products, the crucial difficulty of game enthusiasts within the market, and the elements that make India a hub for pill field production.

The Importance of Tablet Containers within the Pharmaceutical Industry

Tablet bins are important in the pharmaceutical organization for several motives:

Protection from Contamination: Tablet containers defend pharmaceutical capsules from out of doors contaminants, collectively with dirt, moisture, and air, that could degrade the satisfactory quality of the product.

Preservation of Potency: The right pill boxes ensure that the medicine remains effective all through their shelf lifestyles. This is especially critical for tablets which are probably in contact with environmental elements like humidity and moderation.

Easy Dispensation: Tablet containers are designed for ease of use, permitting patients and healthcare providers to dispense the right dosage without issue and properly.

Compliance with Regulations: Pharmaceutical tablet bins want to observe stringent regulatory necessities to ensure they are normal for storing medicinal tablets. Manufacturers want to stick to suggestions set through techniques of government which encompass the Food and Drug Administration (FDA) and the World Health Organization (WHO).

Key Tablet Container Manufacturers and Suppliers in India

India is home to severa manufacturers and suppliers of pill boxes, catering to both domestic and global markets. These companies produce an amazing range of pill containers in several sizes, shapes, and substances, which includes plastic, glass, and aluminum. Below, we find out a number of the first-rate game enthusiasts within the Indian marketplace.

1. Singh Enterprises

Singh Enterprises is a reputed producer and dealer of a huge collection of chemical bottles and packing containers, collectively with tablet containers. Their products are seen for his or her leak resistance and ease of use, making them a preferred choice amongst pharmaceutical businesses. Singh Enterprises focuses on producing great pill containers that meet the stringent needs of the pharmaceutical company enterprise.

2. Pioneer Plastics

Pioneer Plastics is a great manufacturer of plastic pill containers in India. They provide a numerous type of pill containers in numerous sizes, designed to satisfy the particular desires of pharmaceutical companies. Their containers are cited for their durability, chemical resistance, and compliance with worldwide necessities.

3. Alpha Packaging

Alpha Packaging is a global organization of pharmaceutical packaging answers, with a robust presence in India. They manufacture a huge variety of tablet bins which might be used by essential pharmaceutical organizations globally. Their products are recognized for their tremendous innovation, and adherence to regulatory requirements.

4. Glenroy India Pvt. Ltd.

Glenroy India is a renowned producer of pharmaceutical packaging, collectively with tablet boxes. They provide quite a few field designs that cater to specific pharmaceutical products. Glenroy India is recognized for its recognition of niceness, sustainability, and customer pleasure.

5. Parekhplast India Limited

Parekhplast India Limited is a primary manufacturer of rigid plastic packaging products, which encompass pill containers. They have a strong cognizance on innovation and sustainability, offering green packaging solutions that meet the evolving desires of the pharmaceutical corporation.

Factors Contributing to the Growth of Tablet Container Manufacturing in India

India's tablet concern manufacturing business enterprise has experienced massive boom because of several factors:

Booming Pharmaceutical Industry: India is taken into consideration one of the maximum critical producers of common tablets globally, with a sturdy pharmaceutical agency. This has introduced approximately an advanced call for pharmaceutical packaging solutions, alongside tablet bins.

Cost-Effective Manufacturing: India offers price-effective production solutions, making it an appealing tour spot for pharmaceutical agencies looking to supply tablet boxes. The availability of uncooked materials, expert exertions, and superior production facilities similarly enhances India's competitiveness in this location.

Technological Advancements: Indian producers have embraced technological enhancements in packaging, letting them produce notable tablet containers that meet international requirements. This consists of enhancements in substances, format, and manufacturing techniques.

Regulatory Compliance: Indian producers are more and more focused on complying with worldwide regulatory necessities, making sure that their tablet containers are strong and dependable. This has helped Indian organizations gain an aggressive problem inside the international marketplace.

Sustainability Initiatives: With developing troubles approximately environmental sustainability, Indian manufacturers are making an investment in green packaging solutions. This includes the use of recyclable substances and the development of boxes that reduce environmental effects.

Types of Tablet Containers

Tablet boxes are available in several sorts, each designed to meet particular requirements of the pharmaceutical enterprise. Here are some of the most commonplace sorts:

Plastic Tablet Containers: These are the most normally used bins within the pharmaceutical industry due to their durability, charge-effectiveness, and flexibility. They are available in particular styles and sizes, with competencies together with toddler-resistant caps and tamper-apparent seals.

Glass Tablet Containers: Glass packing containers are used for storing drugs which are probably sensitive to moisture and air. They provide amazing protection in opposition to environmental elements and are desired for immoderate-charge pharmaceutical products.

Aluminum Tablet Containers: Aluminum containers provide a mild-weight and sturdy packaging solution for pharmaceutical pills. They are regularly used for products that require excessive stages of safety toward moderate and oxygen.

Blister Packs: While no longer bins within the traditional revel in, blister packs are a famous packaging desire for tablets. They offer personal protection for every pill and are typically used for over-the-counter tablets.

Quality Control in Tablet Container Manufacturing

Ensuring the extremely good pill boxes are critical in the pharmaceutical enterprise. Manufacturers want to impact rigorous great control measures ultimately of the manufacturing device to make certain that the containers meet the desired necessities. Key elements of tremendous manage embody:

Material Selection: The desire of raw materials is the first step in ensuring the awesomeness of tablet containers. Manufacturers want to choose out substances which might be strong, durable, and compliant with regulatory necessities.

Design and Testing: Tablet containers need to be designed to meet the particular goals of the pharmaceutical product they will embody. This consists of ensuring that the containers are leak-evidence, tamper-apparent, and clean to use. Manufacturers want moreover behavior through testing to ensure the boxes carry out as expected.

Regulatory Compliance: Manufacturers want to stick to regulatory requirements set with the useful resource of the presidency which includes the FDA and WHO. This includes ensuring that the packing containers are free from contaminants and do now not interact with the pharmaceutical product.

Inspection and Validation: Continuous inspection and validation techniques are critical to preserve the first rate of tablet boxes. Manufacturers want to regularly take a look at the packing containers at some stage in manufacturing and validate that they meet the favored specifications.

The Role of Innovation in Tablet Container Manufacturing

Innovation is the usage of strain in the pill box production agency organization. Manufacturers are continuously exploring new substances, designs, and generation to beautify the first-rate and functionality of their product. Some of the vital trouble regions of innovation embody:

Smart Packaging: The integration of technology into tablet containers is a growing style. This consists of the development of bins with integrated sensors which could screen factors which incorporate temperature and humidity, ensuring the medicine is stored below maximum useful situations.

Eco-Friendly Materials: As sustainability will become a situation, manufacturers are exploring the usage of green substances in tablet place production. This consists of biodegradable plastics and recyclable materials that lessen the environmental impact of pharmaceutical packaging.

Customization: Manufacturers are imparting customized tablet containers pharmaceutical that cater to the specific goals of pharmaceutical companies. This consists of boxes with specific shapes, sizes, and capabilities that enhance the product's marketplace enchantment.

Advanced Manufacturing Techniques: The adoption of superior manufacturing strategies, which incorporates three-d printing and automation, is allowing manufacturers to offer tablet bins with greater precision and well known regularly occurring overall performance. This resulted in better high-quality products and decreased manufacturing costs.

Challenges Faced thru Tablet Container Manufacturers in India

Despite the boom and innovation within the pill field production industry, producers in India face severa stressful situations:

Regulatory Compliance: Meeting the stringent regulatory requirements of various international locations may be hard for manufacturers. They want to ensure that their product observes numerous guidelines, which can range from one marketplace to three distinctive.

Competition: The tablet location production corporation in India is quite competitive, with numerous game enthusiasts vying for market proportion. Manufacturers need to constantly innovate and enhance their product to live earlier than the opposition.

Supply Chain Disruptions: The availability of uncooked substances and the overall performance of the delivery chain can affect manufacturing. Manufacturers must navigate the ones demanding conditions to ensure nicely timed shipping of their products.

Cost Pressures: While India offers price-effective manufacturing, developing expenses of raw materials and difficult artwork can create strain on manufacturers. They must discover techniques to manipulate prices at the same time as preserving the excellence of their product.

Future Outlook for Tablet Container Manufacturing in India

The destiny of pill subject production in India appears promising, with continued boom expected inside the coming years. Several factors make a contribution to this superb outlook:

Growing Pharmaceutical Industry: As the pharmaceutical enterprise in India continues to boom, the call for pill containers is expected to boom. This gives big opportunities for producers and carriers.

Increased Focus on Quality: As regulatory standards grow to be more stringent, manufacturers will need to hobby on enhancing the wonderfulness of their products. This will stress innovation and the adoption of superior manufacturing techniques.

Sustainability Initiatives: The growing emphasis on sustainability will cause the development of inexperienced packaging answers. Manufacturers that encompass sustainability might be nicely-located to fulfill the evolving desires of the market.

Export Opportunities: With its price-effective production talents, India is nicely-located to emerge as a number one exporter of tablet containers. Manufacturers can faucet into global markets via a way of supplying terrific products that test international requirements.

Conclusion

Tablet containers pharmaceutical are an important problem of the pharmaceutical business enterprise, ensuring the safety, efficacy, and comfort of medicinal capsules. In India, a robust production region has emerged, generating great tablet containers that meet the stringent goals of the pharmaceutical employer. Companies like Singh Enterprises have installed themselves as leaders in this location, imparting a massive form of tablet containers which is probably known for their leak resistance, ease of use, and compliance with regulatory requirements.

As the pharmaceutical enterprise agency continues to boom, the selection for tablet boxes is expected to rise, imparting giant opportunities for manufacturers and companies. With a focal point on innovation, top notch, and sustainability, India's pill discipline production organization is well-positioned to fulfill the evolving desires of the worldwide market.

For extra facts on top notch tablet containers and awesome pharmaceutical packaging answers, please contact them, a name in the enterprise.

0 notes

Text

Luxury Rigid Box Packaging

Find premium, eco-friendly packaging solutions. We specialize in sustainable materials, innovative designs, and exceptional quality.

0 notes

Text

Good quality Carton packaging boxes

When looking for high-quality carton packaging boxes, there are several factors to consider to ensure they meet your needs:

1. Material Quality

Corrugated Cardboard: Ideal for shipping and heavy-duty storage. It’s durable and offers excellent protection.

Paperboard (Folding Cartons): Suitable for lighter products like cosmetics, pharmaceuticals, and food items. It’s easy to print on and can be customized.

Rigid Boxes: Often used for luxury items like electronics or jewelry. They’re sturdier and provide a premium feel.

2. Customization

Printing: High-quality printing options include offset, digital, and flexographic printing. Ensure the printing quality is sharp and vibrant.

Finishing: Consider options like gloss/matte lamination, UV coating, embossing, or foil stamping for a premium look.

Size & Shape: Custom sizing is crucial for fitting your product perfectly, reducing waste, and improving the unboxing experience.

Branding: Good carton boxes can serve as a marketing tool with logos, brand colors, and other design elements.

3. Strength & Durability

Weight Capacity: Check the box’s weight capacity to ensure it can safely hold your products.

Edge Crush Test (ECT): Measures the box's strength and durability under pressure. Higher ECT values indicate better quality.

4. Environmental Considerations

Recyclable Materials: Opt for boxes made from recycled or eco-friendly materials to support sustainability efforts.

Certifications: Look for certifications like FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) for eco-friendly sourcing.

5. Supplier Reliability

Reputation: Choose suppliers known for consistent quality and reliable delivery times.

Samples: Request samples before placing a bulk order to check the quality firsthand.

6. Cost

Balance Quality and Price: High-quality materials and printing might cost more, but it’s often worth the investment for better protection and branding.

If you're interested in acquiring carton packaging boxes from Papers Gallery or learning more about their offerings, you might want to visit their website or contact them directly for quotes and more detailed information.

Visit Us At

G-603, JM Aroma, Sector 75, Noida-201301

25A, Amar Enclave, Behind Flipkart Best Price,

Ambala - Chandigarh Road, Zirakpur- 140603

93, SP Mukherjee Park, Tilak Nagar, New Delhi- 110018

Contact Us At

+91 (9996) 444 060

#detachable style#collapsible#foldable style#luxury boxes#rigid box- cardboard premium and luxury#top-bottom#custom_box#corrugated

1 note

·

View note

Text

Ideal Technoplast Industries IPO: Key Details, Dates, and Insights

The Ideal Technoplast Industries IPO, launching on August 21, 2024, is an SME IPO offering a fixed price issue of ₹16.03 crore. Established in 2012, Ideal Technoplast Industries Ltd. specializes in rigid plastic packaging solutions, serving industries such as paint, agro, chemical, cosmetic, and food, both domestically and internationally.

Ideal Technoplast Industries IPO Overview

The IPO consists of a fresh issue of 13.25 lakh shares, totaling ₹16.03 crore. The price per share is ₹121. The IPO date is set from August 21 to August 23, 2024, with an expected listing on August 28, 2024, on NSE SME. The allotment is 50% for retail investors and 50% for others.

Company Financials

As of February 29, 2024, Ideal Technoplast Industries Ltd IPO. reported total assets of ₹1,508.51 lakh, total revenue of ₹2,424.11 lakh, and a PAT of ₹326.61 lakh. The company’s net worth stands at ₹743.07 lakh, and EBITDA at ₹398.04 lakh.

The Objective of The Issue

The funds from the IPO will be used to meet the working capital needs and for general corporate purposes.

Peers of Ideal Technoplast Industries Ltd.

Mold-Tek Packaging Ltd.

Time Technoplast Ltd.

Tpl Plastech Ltd.

Evaluation

The IPO is priced at ₹121 per share. The P/E ratio, based on FY 2024's EPS of ₹23.29, is 5.20x. For the last three years' weighted EPS of ₹2.18, the P/E ratio is 55.46x.

IPO’s Strengths

Diverse range of rigid plastic packaging solutions.

Advanced manufacturing technologies.

High customer retention.

Experienced management team.

IPO’s Weaknesses

Reliance on a few states for major revenue.

Dependence on a limited number of suppliers.

Negative cash flows in recent fiscal years.

Ideal Technoplast Industries IPO GMP Today

As of today, the IPO GMP is ₹0.

Promoters And Management

The promoters include Mr. Prafulbhai Karshanbhai Vaghasia, Mrs. Vaishnavi Prafulbhai Vaghasiya, and others.

IPO Lead Managers

Swastika Investmart Ltd.

Dividend Policy

The company has not declared dividends since its incorporation.

Conclusion

Ideal Technoplast Industries Ltd. has shown strong financial growth in FY 2024. However, potential investors should consider the company’s past negative cash flows and its dependence on a few states and suppliers. The IPO provides an opportunity for Financial growth, but careful evaluation is recommended.

0 notes