#rubber transmission belt industry

Text

Optibelt Maintenance Free Belts

Optibelt Red Power is a brand of high-performance power transmission belts manufactured by Optibelt, a leading supplier of drive solutions for various industries. Optibelt Red Power belts are known for their advanced design, durability, and efficiency. Here’s an overview of Optibelt Red Power belts:

Features and Benefits:

High Power Transmission Capacity: Optibelt Red Power belts are engineered to deliver high power transmission capacity, making them suitable for demanding applications where reliable performance is essential.

Advanced Material Composition: These belts are constructed using advanced materials such as EPDM (ethylene propylene diene monomer) rubber, which offers excellent resistance to heat, ozone, and weathering, ensuring long-term durability and reliability.

Enhanced Flexibility: Optibelt Red Power belts feature a flexible design that allows for smoother operation and reduced vibration, resulting in quieter performance and extended belt life.

Low Maintenance: With their robust construction and resistance to wear and tear, Optibelt Red Power belts require minimal maintenance, leading to reduced downtime and lower operating costs.

Energy Efficiency: Optibelt Red Power belts are designed to minimize energy losses during power transmission, contributing to improved overall system efficiency and reduced energy consumption.

Wide Range of Sizes and Configurations: These belts are available in various sizes, lengths, and configurations to suit different drive systems and applications, providing flexibility and versatility in design and installation.

Applications:

Optibelt Red Power belts are used in a wide range of industries and applications, including:

Industrial Machinery: Conveyors, packaging equipment, machine tools, and other industrial machinery that require reliable power transmission.

Automotive: Engine drives, power steering systems, and other automotive applications where high performance and durability are essential.

Agriculture: Farm equipment, including tractors, combines, and harvesting machinery, that require dependable power transmission in harsh operating conditions.

Mining and Construction: Equipment such as crushers, conveyors, and excavators used in mining and construction operations that demand robust and reliable power transmission solutions.

HVACR: Air Handlers and Cooling towers providing a maintenance free installation for the life of the belts.

Conclusion:

Optibelt Red Power belts are a trusted choice for industries and applications that require high-performance power transmission solutions. With their advanced design, durability, and efficiency, these belts provide reliable operation, reduced maintenance requirements, and improved overall system performance. Whether in industrial machinery, automotive systems, agriculture, mining, or construction equipment, Optibelt Red Power belts deliver the power and reliability needed to keep operations running smoothly.

Click here for more information

0 notes

Text

Unleashing the Power of Efficiency: Fenner Ecodrive V-Belts

In the dynamic world of industrial machinery and power transmission, selecting the right components is crucial for optimal performance and efficiency. When it comes to V-belts, one name stands out as a beacon of reliability and innovation – Fenner. Among its impressive lineup, the Fenner Ecodrive V-Belts have emerged as the best in class, setting new standards for efficiency, durability, and cost-effectiveness.

Efficiency Redefined:

Fenner Ecodrive V-Belts are engineered with precision to deliver unparalleled efficiency in power transmission. Their advanced design minimizes energy loss, ensuring that your machinery operates at peak efficiency. This not only translates to lower energy consumption but also extends the lifespan of your equipment, contributing to long-term cost savings.

Cutting-edge Materials:

What sets Fenner Ecodrive V-Belts apart is the use of high-quality materials that are meticulously selected to withstand the rigors of industrial applications. These belts are crafted from a special blend of synthetic rubber and high-strength polyester cords, ensuring exceptional durability and resistance to wear and tear. This robust construction not only enhances the belt's longevity but also reduces maintenance requirements, resulting in increased operational uptime.

Environmental Friendliness:

In an era where sustainability is paramount, Fenner Ecodrive V-Belts shine as an environmentally responsible choice. These belts are designed to operate with minimal friction, reducing energy consumption and carbon footprint. The eco-friendly nature of Fenner Ecodrive V-Belts aligns with the growing demand for sustainable solutions in industries, making them an excellent choice for environmentally conscious businesses.

Cost-Effective Solution:

Investing in Fenner Ecodrive V-Belts is a strategic move for businesses looking to optimize their operational costs. The extended lifespan, reduced maintenance needs, and lower energy consumption contribute to a significant decrease in the total cost of ownership. The initial investment in Fenner Ecodrive V-Belts pays off in the long run, making them a cost-effective solution for industries aiming to maximize efficiency without compromising on quality.

Wide Range of Applications:

Fenner Ecodrive V-Belts are versatile, catering to a diverse range of industrial applications. Whether it's manufacturing, agriculture, mining, or any other sector that relies on power transmission, these belts provide a reliable and efficient solution. The adaptability of Fenner Ecodrive V-Belts makes them a go-to choice for industries seeking a one-size-fits-all solution for their power transmission needs.

Call 9810330020 Fenner Ecodrive vbelts

1 note

·

View note

Text

Unveiling the Resilience of Trapezoidal Belts in Italy's Industrial Landscape

Italy, renowned for its rich cultural heritage and picturesque landscapes, harbors a lesser-known facet of industrial prowess. Amidst the cobblestone streets and ancient monuments, Italian engineering quietly thrives, especially in the realm of trapezoidal belts, or "cinghie trapezoidali". These seemingly humble components play a pivotal role in various industrial applications, embodying resilience and efficiency in the face of demanding tasks.

Trapezoidal belts are ubiquitous in machinery across diverse sectors, from automotive to manufacturing. Their design, characterized by a trapezoidal cross-section, facilitates smooth power transmission between shafts, ensuring optimal performance of machines even under substantial loads. Within Italy's industrial panorama, the demand for trapezoidal belts echoes the nation's commitment to precision engineering and reliable manufacturing.

One of the distinguishing features of Italian trapezoidal belts lies in their resilience. Crafted from high-quality materials such as rubber or polyurethane, these belts exhibit exceptional durability, capable of withstanding extreme temperatures, heavy loads, and harsh operating conditions. Whether it's powering agricultural equipment in the fertile fields of Emilia-Romagna or driving conveyor systems in bustling factories of Lombardy, Italian trapezoidal belts stand as stalwart guardians of efficiency and productivity.

The manufacturing processes behind these belts reflect Italy's dedication to excellence. State-of-the-art facilities equipped with cutting-edge technology ensure stringent quality control measures are met at every stage of production. From material selection to precision machining, each step is meticulously executed to guarantee the final product meets the highest standards. This commitment to quality not only enhances the performance of trapezoidal belts but also instills confidence in industries relying on them for seamless operations.

Moreover, Italian trapezoidal belts are engineered for versatility. They come in a myriad of sizes and configurations, tailored to suit specific application requirements. Whether it's driving machinery in the textile mills of Piedmont or powering ventilation systems in the industrial complexes of Veneto, these belts offer a bespoke solution to diverse operational needs. This adaptability underscores Italy's ingenuity in catering to the evolving demands of modern industries, positioning trapezoidal belts as indispensable assets across various sectors.

Beyond their functional utility, trapezoidal belts embody sustainability—an increasingly pivotal aspect of industrial practices. By optimizing power transmission efficiency, these belts minimize energy consumption, contributing to a greener operational footprint. In a world increasingly conscious of environmental impact, Italian trapezoidal belts emerge as eco-friendly allies, aligning with the nation's commitment to sustainable development and responsible manufacturing practices.

In conclusion, the prominence of trapezoidal belts within Italy's industrial landscape transcends their utilitarian role. They embody the essence of Italian craftsmanship—precision, resilience, and versatility. As integral components powering machinery across diverse sectors, these belts serve as testaments to Italy's engineering prowess and unwavering dedication to excellence. In the ever-evolving realm of industrial technology, Italian trapezoidal belts continue to stand as enduring symbols of reliability and innovation, driving forward the nation's industrial legacy into the future.

0 notes

Text

Non-Slip Meshing Transmission Rubber Double-Sided Tooth Synchronous Belt

Web:https://www.belt.tm/product/rubber-doublesided-tooth-synchronous-belt/rubber-doublesided-tooth-synchronous-belt-2.html

Communication cables and other industries are recognized, recognized and widely used. It not only integrates the advantages of gear transmission, chain transmission and belt transmission, but also overcomes the shortcomings of other transmission belts such as slipping and elongation.

It constitutes a unique transmission mode, and is deeply rooted in the hearts of the people with its many advantages such as constant speed ratio, large speed range, compact structure, farm multi-axis transmission, oil resistance, moisture resistance, and no need for lubrication.

0 notes

Text

Industrial Belts: Powering France's Manufacturing Sector

France, renowned for its rich cultural heritage and picturesque landscapes, is not just a tourist destination but also a powerhouse in the manufacturing sector. Among the myriad components driving the industrial machinery forward, industrial belts stand as unsung heroes, ensuring smooth operations across diverse sectors. Let's delve into how industrial belts play a vital role in France's industrial landscape and the significance they hold for companies like Courroies Industrielles.

Industrial Belts: The Backbone of Manufacturing

Industrial belts are the silent force behind the seamless operation of various machinery in industries ranging from automotive and aerospace to food and beverage and beyond. These belts, made of robust materials like rubber, polyurethane, or metal, transmit power efficiently, enabling the movement of components, materials, and finished products along assembly lines.

In France, where manufacturing is a cornerstone of the economy, the demand for high-quality industrial belts is incessant. From the assembly lines of automobile giants like Renault and Peugeot to the precision machinery in aerospace companies like Airbus, industrial belts are indispensable. Their reliability, durability, and efficiency are crucial factors in ensuring uninterrupted production processes, which directly contribute to the competitiveness of French industries in the global market.

Courroies Industrielles: Meeting the Demand

In this dynamic industrial landscape, companies like Courroies Industrielles play a pivotal role. Specializing in the manufacturing and distribution of industrial belts, Courroies Industrielles has carved a niche for itself as a trusted partner for numerous French industries. With a diverse range of products tailored to meet specific industry requirements, Courroies Industrielles ensures that French manufacturers have access to top-notch belt solutions.

Whether it's timing belts for precise synchronization in automotive engines or conveyor belts for efficient material handling in warehouses, Courroies Industrielles leverages advanced manufacturing techniques and materials to deliver belts that exceed industry standards. Moreover, their commitment to innovation ensures that they stay ahead of the curve, offering cutting-edge solutions to address the evolving needs of French industries.

Driving Efficiency and Sustainability

Beyond powering industrial machinery, industrial belts also play a crucial role in driving efficiency and sustainability initiatives. By optimizing power transmission and reducing energy consumption, modern industrial belts contribute to lowering carbon footprints and enhancing the overall sustainability of manufacturing processes. This aspect aligns perfectly with France's ambitious goals for reducing greenhouse gas emissions and transitioning towards cleaner and greener industrial practices.

Courroies Industrielles recognizes the importance of sustainability and actively incorporates eco-friendly practices into its operations. From using recyclable materials in belt manufacturing to optimizing logistics to minimize carbon emissions, the company is committed to supporting France's efforts towards a more sustainable future.

Looking Ahead: Challenges and Opportunities

While the future looks promising for the industrial belt sector in France, challenges persist. Rapid technological advancements, shifting market dynamics, and the emergence of new materials pose both challenges and opportunities for companies like Courroies Industrielles. Staying abreast of these changes and continuously innovating will be key to maintaining competitiveness and meeting the evolving needs of French industries.

In conclusion, industrial belts serve as the backbone of France's manufacturing sector, enabling the smooth operation of machinery across diverse industries. Companies like Courroies Industrielles play a vital role in meeting the demand for high-quality belt solutions, driving efficiency, sustainability, and innovation in the process. As France continues to strengthen its position in the global manufacturing landscape, industrial belts will remain indispensable, powering the machinery that fuels economic growth and innovation.

0 notes

Text

Navigating Agricultural Efficiency: A Comprehensive Guide to Tractor Belts

In the realm of agricultural machinery, tractor belts stand as indispensable components, embodying rugged reliability and essential functionality. From navigating rugged terrains to optimizing farm efficiency, these belts play a pivotal role in ensuring seamless operations and enhanced productivity for farmers and industry professionals. In this comprehensive guide, we delve into the intricacies of tractor belts, exploring their vital features, functions, and diverse applications.

Essential Features and Functions

Tractor belts are engineered with durability and traction in mind, designed to withstand the rigors of demanding agricultural tasks. Constructed from high-quality materials such as rubber or reinforced fabric, these belts exhibit exceptional strength and resilience, capable of enduring prolonged use in harsh environments. Their ability to provide reliable traction enables tractors to traverse challenging terrains with confidence, facilitating efficient plowing, seeding, and harvesting operations.

Moreover, tractor belts contribute to the seamless power transmission within agricultural machinery, transferring energy from the engine to various components with precision and efficiency. Their role in driving essential functions such as the transmission system, power take-off (PTO), and hydraulic systems underscores their significance in ensuring optimal performance across different farm tasks.

Applications and Benefits

The applications of tractor belts span across a wide spectrum of agricultural activities, ranging from field cultivation to material handling. Whether it's pulling heavy implements, powering agricultural attachments, or driving auxiliary machinery, these belts serve as linchpins in facilitating diverse farm operations. Their reliability and versatility empower farmers to tackle tasks with ease, thereby enhancing overall efficiency and productivity on the farm.

Furthermore, the benefits of utilizing high-quality tractor belts extend beyond mere functionality. By minimizing downtime and maintenance requirements, these belts contribute to cost savings and operational efficiency, allowing farmers to maximize their resources and achieve greater output. Additionally, their robust construction and long service life ensure sustained performance even in the most demanding operating conditions, providing peace of mind to farmers and operators.

Maintenance and Innovation

To ensure optimal performance and longevity, proper maintenance of tractor belts is paramount. Regular inspection for signs of wear, tension adjustment, and timely replacement of worn-out belts are essential practices to uphold their reliability and efficiency. Additionally, advancements in belt technology continue to drive innovation in the agricultural sector, with features such as self-tensioning systems, enhanced grip patterns, and improved durability further enhancing the performance of modern tractor belts.

Conclusion

In conclusion, tractor belts represent a cornerstone of agricultural machinery, embodying rugged reliability and essential functionality. By understanding their features, functions, and maintenance requirements, farmers and industry professionals can harness the full potential of these critical components to optimize farm efficiency and productivity. With ongoing innovations shaping the landscape of belt technology, staying informed and empowered is key to unlocking seamless operations and driving success in the dynamic world of farming machinery.

0 notes

Text

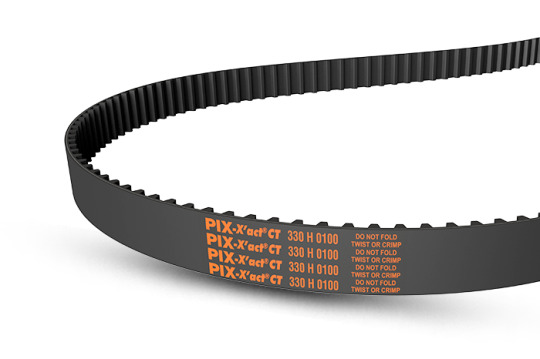

.PIX manufacture an exhaustive range of Automotive Belts and covers the whole range of vehicle engines. V-belts are made of rubber with polyester or aramid cords to transmit mechanical power. There are two types of V-belts:

1. Wrap construction

V-belts 2. Raw edge cogged V-belts

V-belts are intended to be a replacement for gear and chain drive, with minimal transmission losses and low maintenance. V-Belts are widely used in Industrial, Automotive, Agricultural, Lawn and Garden applications and various other applications, where they are classified as Application Specific V-Belts

0 notes

Text

Lusida Rubber - Your Trusted Source for Quality Industrial Solutions

At Lusida Rubber, we pride ourselves on delivering high-quality industrial products to meet diverse needs. Explore our range of top-tier products, including Timing Belts, Conveyor Belts, Vibration Mounts, Oil Seals, and Rubber Sheets.

Timing Belts: Precision and reliability are paramount in industrial timing applications. Our Timing Belts are engineered for optimal performance, ensuring synchronous power transmission with minimal maintenance.

Conveyor Belts: Streamline your material handling processes with our Conveyor Belts. Designed for durability and efficiency, these belts are the backbone of seamless material transportation across various industries.

Vibration Mounts: Reduce noise and vibrations in machinery with our Vibration Mounts. Engineered for stability, these mounts enhance equipment longevity and improve workplace safety.

Oil Seals: Guard against leaks and contamination with our high-quality Oil Seals. Precision-manufactured to withstand harsh conditions, these seals ensure the integrity of your machinery.

Rubber Sheets: Versatile and reliable, our Rubber Sheets find applications across industries. From gaskets to flooring, these sheets are crafted to meet the diverse demands of industrial environments.

Explore Lusida Rubber's comprehensive range, including Timing Belts, Conveyor Belts, Vibration Mounts, Oil Seals, and Rubber Sheets. Trust in our commitment to quality for your industrial needs.

0 notes

Text

The complete guide on cogged belts to enhance power transmission

Cogged belts are essential in the field of power transmission because they provide dependable and efficient performance in a wide range of industrial applications. Compared to conventional flat belts, these specialty belts offer improved performance and grip due to the cogs or notches on the bottom of the belt.

Power transmission systems facilitate the efficient flow of energy from one source to another, making them the foundation of many industries.

Power transmission has been transformed by these specialty belts, which have distinct advantages over their conventional counterparts. Stay here to learn about the complete guide on cogged belts to enhance power transmission:

What are Cogged Belts?

Cogged belts are power transmission belts with teeth or cogs on the inside of the belt. They are sometimes referred to as notched or toothed belts. These teeth provide better power transfer capabilities and positive engagement by meshing with the pulley grooves. The cogged belt is often built of robust materials that can withstand harsh industrial environments, such as rubber or synthetic composites. Jigna sales the leading industrial belt manufacturers in India offers the best Cogged Belts.

Advantages of Cogged Belts

Enhanced power transmission

Cogged belt teeth greatly enhance power transmission capabilities, particularly in high-speed or high-torque situations. This makes it possible for energy to be transferred more effectively, lowering the loss of energy and improving system performance overall. To buy the raw edge cogged belt at an affordable price, compare prices from one shop to another.

Decreased slippery nature

Under severe circumstances or with big loads, traditional V-belts may slip. Because of their toothed structure, cogged belts keep a tighter hold on the pulleys, reducing slippage and guaranteeing steady power transfer.

Greater ability to bear loads

Compared to flat belts, a cogged v belt is made to support larger load capabilities. The belt experiences less stress and gains more strength due to the teeth and pulley grooves engaging to distribute the weight more evenly. Cogged belts are a great fit for heavy-duty manufacturing, agriculture, and construction applications because of their higher load-carrying ability.

Enhanced robustness

Cogged belts have a more uniformly distributed design that minimizes wear and lengthens lifespan. The extended lifespan of a cogged timing belt is particularly beneficial for businesses where uninterrupted operation is essential.

Small-scale layout

Compared to their V-belt equivalents, cogged belts frequently have smaller sizes, making them appropriate for applications with limited space.

How do you choose the right cogged belt?

The choice of cogged belt for a given application is influenced by several factors, including:

Torque and load

The load and torque the belt will encounter should be considered. Larger tooth profiles and stronger materials may be needed for higher loads and torque belts. To buy a durable toothed v belt, choose a reputable shop.

Environment of operation

Examine operational parameters, including humidity, temperature, and exposure to chemicals or oils. Select belts that maintain performance despite withstanding certain environmental conditions.

Quickness and accuracy

Synchronous belts are preferred for applications that demand precision timing and high-speed operation because of their precise power transfer capabilities.

As a result, the above detailed are about the complete guide on cogged belts to enhance power transmission. Jigna Sales is one of the leading cogged belt manufacturers and suppliers in India. Their primary goal is to provide clients with the highest-quality products possible to maximize output, maximize efficiency, and minimize operating costs.

0 notes

Text

3PE ANTI-CORROSION STEEL PIPE PRODUCTION LINE

The 3LPE Anti-corrosion Steel Pipe Production Line is a specialized system used for manufacturing steel pipes with a triple-layer coating designed to resist corrosion. This production line is specifically designed to provide efficient and accurate production of 3PE anti-corrosion steel pipes, commonly used in oil and gas pipelines, water pipelines, and other industrial applications. The 3LPE coating production process includes surface preparation, epoxy powder coating, adhesive application, and final polyethylene coating, ensuring excellent corrosion resistance and extending the lifespan of the pipes. The 3PE Anti-corrosion internal pipe coating equipment for sale is a reliable and economical solution for producing high-quality anti-corrosion pipes.

FEARURES OF 3PE ANTI-CORROSION STEEL PIPE PRODUCTION LINE

1. The company's equipment performance standards are strictly followed Coating standard: API RP 5L2, GB/T 23257, GOST R 51164, GOST R 52568, DIN30670, DIN30678, CSA Z245.20, CSA Z245.21, ADNOC 3099370017-1.

2. The equipment produced by the company has the characteristics of stable performance, high production efficiency, simple operation and high degree of automation.

COMPONENT OF 3PE ANTI-CORROSION STEEL PIPE PRODUCTION LINE

Shot blasting upper pipe stand:

H-shaped steel beam and vertical leg, the beam is covered with flat iron, reducing friction, the welding process between the vertical leg and the beam, and the use of double beam design, greatly improving the stability and durability of the equipment.

Steel pipe external shot blasting screw transmission line:

The sliding plate structure is adopted, the vertical plate, slide seat and ball cup are welded by steel plate, the fixed base is made of rectangular steel pipe, the solid wheel support is made of national standard channel steel, the transmission wheel is made of φ457×203 wear-resistant solid core rubber tire, the wheel core is made of cast steel, the axle is made of 45 steel machined galvanized, the transmission wheel is driven by a reducer and equipped with variable frequency motor. The screw Angle is adjusted by ratchet wrench and joint bearing, and the lane is changed by electric screw

Steel pipe external shot blasting machine:

It adopts the dropdown structure and can also be designed and customized according to specific requirements.

Cleaning room of external shot blasting machine:

The chamber body adopts steel plate welding process to make it more firm and stable. The chamber body is lined with high-wear-resistant Mn13 steel plate, and the inlet and outlet of the steel pipe are equipped with pipe diameter adjustment flanges, which are made of rolled Mn13 high steel plate. The inlet and outlet of the steel pipe body is equipped with sealed soft polyurethane plate.

Steel sand circulation device:

Bucket elevator equipped with reducer for steel shot circulation. And set up the top bin for pellet sand separation, throwing head feed. Pneumatic ball valve is installed to improve automation.

Shot blast machine:

Adopt imported technology shot blasting head equipped with high power motor drive.

External shot blasting dust collector:

Cyclone separator plus bag dust collector secondary dust treatment device. The filter surface of the bag filter can reach 400 square meters, and the dust emission concentration is less than 40mg/m3. The equipment of the company adopts high power and high pressure centrifugal fan as the pumping power.

Shot blasting electrical control cabinet:

One XGL equipment control electrical cabinet is selected. Low-voltage electrical appliances and frequency converters are used in order to make their stability higher using high-end brands.

Internal shot blasting machine:

The main part of the inner shot blasting machine consists of an inner wall shot blasting device and a large rod part, a hydraulic drive system, a shot slag separator, a bucket elevator, a shot controller, a belt shot supply device, a shot recovery belt, a shot blasting mobile car, etc. Shot blast is 32 inches. The shot blasting device adopts high-performance wear-resistant parts.

Steel sand circulation device:

One sand belt is used for transverse and longitudinal conveyance, and two sand conveyance channels are adopted.

Before/after inner shot blasting:

The front bin is a movable structure, and the rear bin is fixed. The front bin is a casing head bin body on the same side as the shot blasting car; The rear bin is a bin body connected with a large suction dust collector. The silo body is made of steel plate and rectangular tube welded shell, and the main shot blasting area is sealed by rolled Mn13 rolled high manganese steel (high chromium molybdenum) lining plate and polyurethane plate. The movement of the front warehouse is driven by KA series shaft hung reducer, and the moving speed of the front warehouse is adjusted by domestic frequency conversion governor. The specific option parameters are designed and produced by customer requirements. The trolley track is 22# light rail.

Internal shot blasting dust collector:

The inner shot blasting dust collector adopts cloth bag as filter material, and the dust collector bin body is welded by steel plate and channel steel. The pellet dust collector consists of an inertial settling device and a pulsed backblown bag dust collector. Three high-pressure centrifugal fans are used to pump air, and the thickness of connected air pipes is made according to customer requirements under the premise of ensuring performance and stability. Pulse cleaning can be performed offline between each bin.

Internal shot blasting tube trolley:

Equipped with two independent tube trolley, respectively with walking and rotating tube functions. High precision T-screw is used to adjust wheel spacing. Each lifting rotary roller is equipped with four solid core compression tires and two Ka reducer. The rotating roller frame is welded with section steel material.

Electronic control system:

The control system includes: frequency converter, soft starter, low-voltage electrical components and detection components. Among them, the inverter adopts domestic famous brand products, other electrical components adopt Chint brand, and the soft starter adopts domestic famous brand products. The cable collecting pipe attached to the car is installed and protected by the tow chain.

Car dust collector and spray rod:

Vehicle dust removal It is used for the end of the spray rod air removal. The car dust collector adopts 18-core filter dust collector, pulse back blowing compressed air dust, equipped with frequency conversion speed regulating high pressure centrifugal fan, the spray rod through the intermediate frequency coil part are made of S304 stainless steel material. The spray rod is equipped with an air extraction channel, connected with the dust collector with a hose, and the tail of the spray rod is equipped with a weight box to ensure that the spray rod is in a cantilever state. The spray rod is mounted on the spray car with adjustable height.

Tube tail follow dust removal device:

The dust extraction trolley and air hood are installed on the top of the steel pipe with an integral overhead support. The trolley is driven by frequency conversion and can move forward and back with the air hood. The dust collector adopts 32 core filter dust collector, pulse back blowing compressed air dust, equipped with high power frequency conversion fan, used for pipe tail dust collection. The car is made of steel plate and section steel, and is driven by motor reducer. Variable frequency speed control is available. The duct hood is made of aluminum alloy plate, and can also be customized according to customer requirements.

3PE coated screw drive line:

Adopt the skateboard structure, the vertical plate and the ball cup are welded by steel plate, the fixed base is made of rectangular steel pipe, and the solid wheel bracket is made of national standard channel steel. The transmission wheel is made of pressed wear-resistant solid core rubber tire, the wheel core is made of cast steel, and the axle is made of 45 steel machined and galvanized. The installation method is shaft hanging and torque arm. The number of reducer, bearing type and number shall be determined by the final design as required by the customer. The spiral Angle is adjusted by ratchet wrench and joint bearing, and the distance between two solid core wheels is adjusted by pulling slide seat with screw rod. The solid wheel of the intermediate frequency transmission wheel group is made of high temperature resistant silicone wheel. Considering the serious corrosion of the water cooling section, the hinge shaft of the water cooling section transmission wheel group, the adjusting screw and all the solid parts and connecting parts are made of stainless steel material. Water-cooled housing bearing seat installed waterproof cover.

0 notes

Text

What is carbon black in rubber?

Carbon black is a common pigment and filler that is widely used in rubber products. It is used to enhance the performance of rubber, providing wear resistance, strength and other special properties. This article will introduce in detail the role of carbon black in rubber and its application in different rubber products.

Paragraph 1: Enhance the wear resistance and strength of rubber

Carbon black acts as a reinforcing agent in rubber and can significantly improve the wear resistance of rubber products. As a filler, carbon black can fill the gaps between rubber molecules and increase the compactness and strength of the material. By adding an appropriate amount of carbon black, the wear resistance of rubber products is significantly improved and the service life is extended.

Paragraph 2: Improve the weather resistance and anti-aging properties of rubber products

Carbon black can also increase the weather resistance and anti-aging properties of rubber products. Rubber is prone to aging when exposed to environmental conditions such as UV rays, oxygen and moisture for a long time. By adding carbon black, it absorbs and disperses ultraviolet rays and prevents the light energy from converting into heat energy, thereby slowing down the aging rate of rubber.

Paragraph 3: Improve the conductive properties of rubber products

Certain rubber products require conductive properties, such as wires, power transmission cables, and rubber seals. Carbon black, as a conductive filler, can increase the conductive properties of rubber. Carbon black particles can form a conductive network and provide electronic conduction paths, giving rubber materials good conductive properties.

Paragraph 4: Application areas

Tire Industry: Carbon black is one of the most important additives in tire manufacturing. It can enhance the wear resistance, crack resistance and anti-aging properties of tires, and improve the service life and safety performance of tires.

Rubber seals: Carbon black is widely used in the manufacture of rubber seals. It can improve the weather resistance, wear resistance and penetration resistance of the seal, ensuring the sealing effect and service life.

Industrial rubber products: Carbon black is widely used in industrial rubber products, such as conveyor belts, sealing rings, rubber tubes and rubber pads. They provide excellent wear resistance, oil resistance and weather resistance to meet the needs of different industrial fields.

Auto parts: Carbon black is also used in the manufacture of auto parts, such as rubber gaskets, rubber shock absorbers and rubber pipe fittings. They enhance the wear and weather resistance of components, improving vehicle performance and safety.

If you want to choose a suitable carbon black product, you might as well try DERY. As a leading manufacturer specializing in the production of carbon black, DERY has rich experience and advanced production technology and is committed to providing high-quality carbon black products. Whether it's enhancing stability in geosynthetics or improving weathering and crack resistance, DERY's carbon black products can meet your needs. By choosing DERY, you can get reliable quality assurance and excellent customer service, providing strong support for project quality and sustainable development.

Carbon black plays an important role in rubber and can improve the wear resistance, weather resistance and strength of rubber products. They are widely used in the tire industry, rubber seals, industrial rubber products, and automotive parts. Through the rational use of carbon black, rubber products can be given more special properties and functions to meet the needs of different industries and application fields. With the advancement of science and technology and the promotion of innovation, the application prospects of carbon black in the rubber field are still broad.

0 notes

Text

🚗 Drive Smoothly with Quality V-Belts! 🚗

Looking for reliable power transmission solutions? Look no further than our premium V-belts! They're engineered for efficiency, durability, and dependable performance. 🛠️

Key Features:

✅ High-Quality Rubber Compound for Longevity

✅ Precision-Engineered Design for Optimal Efficiency

✅ Resistant to Heat, Oil, and Wear

✅ Suitable for a Wide Range of Applications

✅ Trusted by Mechanics and Industries Worldwide

Whether you're maintaining your vehicle or managing industrial machinery, our V-belts are designed to keep things running smoothly.

✅ Visit our store to B - 80, B Block, Sector 5, Noida, Uttar Pradesh 201301.

📞 Call us at [+91 7377017377] for expert advice.

🌐 Visit our website at [https://industrywaala.com/] for online ordering.

0 notes

Text

How many kinds of linkage types are there for WINROLLER motorized roller?

There are two main linkage types for motorized rollers: chain-driven and belt-driven. Learn from www.drum-roller.com

1. A chain-driven motorized roller is a type of motorized roller that utilizes a chain to transmit power from the motor to the roller. The chain is typically wrapped around sprockets on the motor and roller shafts, allowing the rotational motion of the motor to be transferred to the roller. This type of linkage provides a reliable and efficient means of power transmission in motorized roller systems. Chain-driven motorized rollers are commonly used in various conveyor systems and industrial applications.#chain#roller

2. A belt-driven motorized roller is a type of motorized roller that uses a belt to transmit power from the motor to the roller. The belt is typically made of rubber or other flexible materials and is wrapped around pulleys on the motor and roller shafts. As the motor rotates, the belt transfers the rotational motion to the roller, causing it to turn. Belt-driven motorized rollers are often used in conveyor systems and other industrial applications where a smooth and quiet operation is required. They are also known for their energy efficiency and low maintenance requirements.#belt

3. What are the advantages of chain-driven motorized rollers?

High durability: Chain-driven motorized rollers are known for their durability and long service life. They are designed to withstand heavy loads and harsh operating conditions.

High torque: Chain-driven rollers can handle high torque loads, making them suitable for applications that require high starting and stopping forces.

Easy maintenance: Chain-driven rollers are easy to maintain and repair. Chains can be easily replaced if they become worn or damaged.

Precise speed control: Chain-driven rollers provide precise speed control, which is important in applications where accurate positioning is required.

Cost-effective: Chain-driven rollers are often less expensive than other types of motorized rollers, making them a cost-effective choice for many applications.

4. What are the advantages of belt-driven motorized rollers?

Smooth and quiet operation: Belt-driven motorized rollers operate smoothly and quietly, making them ideal for applications where noise levels need to be kept low.

Energy-efficient: Belt-driven rollers are highly energy-efficient, as they require less power to operate compared to other types of motorized rollers.#automatic

Low maintenance: Belt-driven rollers require minimal maintenance, as there are no chains that need to be lubricated or adjusted.

High speed capability: Belt-driven rollers can achieve high speeds, making them suitable for applications that require fast conveyor speeds.#conveyor

Cost-effective: Belt-driven rollers are often less expensive than other types of motorized rollers, making them a cost-effective choice for many applications.#motorized

Learn more from Winroller Simon by Whatsapp:+86 181 6839 9322

Email:[email protected]

0 notes

Text

Exploring the Advantages of Cinghie Dentate: A Key Component in Italy's Engineering Landscape

In Italy's rich engineering landscape, the utilization of cinghie dentate, or toothed belts, stands out as a cornerstone technology in various industries. These precision-engineered belts play a pivotal role in a wide array of applications, ranging from automotive systems to industrial machinery and beyond. In this article, we delve into the intricacies of cinghie dentate, exploring their benefits and significance in Italy's engineering sector.

Precision and Reliability

Cinghie dentate are renowned for their exceptional precision and reliability. Unlike traditional belts, which rely on friction for power transmission, toothed belts utilize interlocking teeth to maintain constant synchronization between the driving and driven components. This precise synchronization ensures smooth and efficient operation, minimizing the risk of slippage or misalignment. In Italy's automotive industry, where precision is paramount, cinghie dentate are widely employed in timing systems to control the opening and closing of engine valves with utmost accuracy.

Efficiency and Performance

One of the key advantages of cinghie dentate is their high efficiency and performance. The toothed design allows for greater power transmission capabilities compared to traditional V-belts, making them ideal for applications requiring high torque transmission. This efficiency not only enhances the overall performance of machinery but also contributes to energy savings, making cinghie dentate a cost-effective solution for industries seeking to optimize their operations.

Durability and Longevity

In Italy's industrial landscape, where reliability is non-negotiable, cinghie dentate are prized for their exceptional durability and longevity. Constructed from high-quality materials such as reinforced rubber and fiberglass tensile cords, these belts are engineered to withstand the rigors of demanding operating conditions, including high speeds, heavy loads, and extreme temperatures. As a result, they offer extended service life and minimal maintenance requirements, reducing downtime and enhancing productivity in various industrial applications, from manufacturing to packaging.

Versatility and Adaptability

Another notable aspect of cinghie dentate is their versatility and adaptability to diverse engineering challenges. Available in a wide range of sizes, configurations, and materials, these belts can be tailored to meet the specific requirements of different applications. Whether it's powering conveyor systems in the food and beverage industry or driving precision machinery in the medical sector, cinghie dentate offer unmatched flexibility and compatibility with various components and systems, making them a preferred choice for engineers and manufacturers across Italy.

Environmental Sustainability

In an era where environmental sustainability is a top priority, cinghie dentate offer distinct advantages over alternative power transmission solutions. Their efficient operation and minimal friction reduce energy consumption and carbon emissions, contributing to a greener and more sustainable manufacturing environment. Additionally, the durability and longevity of these belts result in fewer replacements and less waste generation, further minimizing their environmental footprint.

Conclusion

In conclusion, represent a quintessential component of Italy's engineering landscape, embodying precision, reliability, efficiency, and versatility. From automotive timing systems to industrial machinery, these toothed belts play a vital role in powering the nation's diverse industries. With their exceptional performance, durability, and environmental sustainability, cinghie dentate continue to be the go-to solution for engineers and manufacturers seeking to optimize their operations and stay ahead in an increasingly competitive market landscape.

0 notes

Text

We are a leading Flat Belt Manufacturers in India. These Belts are used for power transmission, and its made of rubber, synthetic composites, or leather and have a flat surface. They are commonly used in conveyor systems and industrial equipment to transfer rotational power.

Features:

-> High tensile strength

-> High power transmission

-> Dimensional accuracy

-> Resistant to oils and greases

-> Resistant to benzene and benzole

-> Strong & Flexible

-> Non-absorbent & Non-Fraying

#flatbelt#conveyorbelt#belts#products#industrialbelts#industrial#suppliers#exporters#manufacturers#kamothe#navimumbai#dktengineeringenterprises#india

0 notes

Text

Exploring the Efficiency and Versatility of Pix France Courroies Hexagonales

In the realm of industrial engineering and machinery, the significance of high-quality components cannot be overstated. Among these crucial elements, Courroies Hexagonales (Hexagonal Belts) by Pix France stand out for their exceptional performance and versatility. In this article, we delve into the characteristics and applications of Pix France Courroies Hexagonales, highlighting their role in various industries.

Pix France Courroies Hexagonales are engineered with precision to deliver optimal performance in a wide array of applications. These belts are characterized by their unique hexagonal cross-section, which offers several advantages over traditional V-belts or flat belts. The hexagonal shape allows for better distribution of tension, resulting in enhanced power transmission efficiency and reduced slippage. This feature is particularly advantageous in high-torque applications where reliable power transmission is essential.

One of the key benefits of Pix France Courroies Hexagonales is their versatility. These belts are suitable for use in diverse industries such as agriculture, manufacturing, construction, and automotive. Whether it's driving agricultural machinery, conveyor systems, industrial equipment, or automotive accessories, Pix France Courroies Hexagonales excel in delivering consistent performance under demanding conditions.

Furthermore, Pix France Courroies Hexagonales are renowned for their durability and longevity. Constructed from high-quality materials such as rubber compounds reinforced with strong synthetic fibers, these belts exhibit excellent resistance to wear, abrasion, and environmental factors. This ensures prolonged service life and minimizes downtime, resulting in cost savings for businesses.

Another notable feature of Pix France Courroies Hexagonales is their ability to operate smoothly and quietly. The precision manufacturing processes employed by Pix France ensure uniformity in belt dimensions, reducing vibration and noise levels during operation. This not only contributes to a quieter working environment but also indicates efficient power transmission with minimal energy losses.

In addition to their mechanical properties, Pix France Courroies Hexagonales are designed for easy installation and maintenance. Their flexibility and adaptability simplify the process of fitting the belts onto pulley systems, saving valuable time and effort for maintenance personnel. Moreover, periodic inspection and routine maintenance tasks such as tension adjustment can be performed with ease, ensuring optimal belt performance throughout its service life.

The adoption of Pix France Courroies Hexagonales presents a sustainable solution for businesses aiming to enhance operational efficiency and reduce environmental impact. By minimizing energy consumption through improved power transmission efficiency and prolonging equipment lifespan, these belts contribute to overall resource conservation and carbon footprint reduction.

In conclusion, Pix France Courroies Hexagonales represent a pinnacle of engineering excellence in the realm of power transmission components. Their superior performance, versatility, durability, and ease of maintenance make them indispensable in various industrial applications. As businesses strive for greater efficiency and productivity, Pix France Courroies Hexagonales emerge as a reliable solution to meet the demands of modern-day machinery and equipment.

0 notes