#safety valve

Text

Bellow Seal Safety Valve manufacturer

2 notes

·

View notes

Text

Check Valves: The Key to Preventing Backflow

Check valves are a crucial component in any plumbing system, as they play a vital role in preventing backflow. Backflow occurs when water or other liquids flow in the opposite direction than intended, potentially contaminating clean water sources and posing a health hazard. Check valves are designed to allow flow in one direction only, effectively preventing backflow and protecting the integrity of the plumbing system.

Check valves are commonly used in a variety of applications, including residential, commercial, and industrial settings. They are installed in water supply lines, sewage systems, irrigation systems, and more to ensure that water and other liquids flow in the correct direction and do not contaminate clean water sources.

There are several types of check valves available, including swing check valves, lift check valves, and inline check valves. Each type has its own unique design and functionality, but they all serve the same basic purpose of preventing backflow. Swing check valves have a disc or flap that swings open to allow forward flow and closes to prevent backflow. Lift check valves use a piston or ball to lift and allow flow in one direction only. Inline check valves have a spring-loaded disc that opens and closes based on flow direction.

Proper maintenance and installation of check valves are essential to ensure they function effectively and prevent backflow. Check valves should be inspected regularly for any signs of wear or damage and replaced if necessary. It is also important to install check valves in the correct orientation to ensure they operate properly and prevent backflow.

In conclusion, check valves are the key to preventing backflow in plumbing systems. By installing and maintaining check valves properly, you can protect clean water sources and ensure the safety and integrity of your plumbing system. If you are experiencing issues with backflow in your plumbing system, consider installing check valves to prevent future problems.

2 notes

·

View notes

Text

ok. I am going to have this blog as backstage, the real me (hopefully without revealing all vulnerabilities) and another as frontstage, official writing. Perhaps only give ppl the writing link here bc i don't want ppl going there who I don't want, any naysayers, trolls, etc. Doesn't mean i won't post some things about writing here.

I need to have a fail safe and also an outlet. To avoid totally saying anything-- I will have a safety valve in other blog to calm me down. Perhaps a bridge to real world where i can jump out of any social media fuelled spirals. And this so I don’t start posting personal stuff there. So i have an outlet if needed.

Hopefully this system will work.

And I also have bunches of side blogs to show fragments of myself and what I care about and believe in

But here is all, (or sort of) and the real me with no veneer bc i need. Real.

#Unfiltered yet semi filtered#Safety valve#Outlet#Tumrblr#Also so I don't make yet another blog and leave this one#And make cycle continue#Cycle stops here#And I am moving forward#Perhaps some bc I literally am being more deliberate about tumrblr#Can't let it consume me or be a life substitute#Not make it distract me from real or what I need#But also it's a nice comfort some days#Something to do in time spaces#Lol#Whats the word#Like today#I could not concentrate#Bc weekend#So#Hopefully readjust soon#So get all my things going#Not like I won't be myself on other blog#Mean I share less of my self#Still true

2 notes

·

View notes

Text

#B2B#Industrial Machinery and Supplies#Industrial Supplies#Industrial Machinery#safety relief valve supplier#Safety Valve

0 notes

Text

Best Pressure Relief Valves (PRVs) in Industrial Safety

In any industrial setting, maintaining a safe and controlled environment is critical to the smooth functioning of operations. One of the most essential components in ensuring safety is the Pressure Relief Valve (PRV). These valves play a crucial role in preventing over-pressurization, which can lead to equipment failure, hazardous leaks, or even catastrophic explosions.

What is a Pressure Relief Valve (PRV)?

A Pressure Relief Valve is a safety device designed to release excess pressure in a system when it exceeds a preset limit. PRVs are commonly used in industries dealing with gases, liquids, or steam, where pressure fluctuations are a constant risk. By releasing excess pressure, the PRV protects the system from potential damage and ensures continuous, safe operation.

How Does a PRV Work?

The functionality of a PRV is quite simple yet effective. When pressure builds up in a system and reaches unsafe levels, the valve automatically opens, allowing the excess pressure to escape. Once the pressure is reduced to a safe level, the valve closes again, maintaining a balance within the system.

The key feature of a PRV is its ability to respond instantly to pressure changes, providing real-time protection to your equipment and processes.

Why PRVs are Critical for Industrial Applications

Prevents Equipment Damage

Over-pressurization can cause severe damage to pipelines, tanks, pumps, and other critical industrial components. By releasing the pressure at the right time, a PRV helps extend the lifespan of your equipment.

Ensures Safety

In gas, liquid, or steam applications, unchecked pressure build-up can create hazardous situations that endanger personnel and the environment. PRVs act as the first line of defense in preventing such incidents.

Regulatory Compliance

Industries that deal with pressure systems are often subject to strict regulations and standards. Pressure Relief Valves ensure that your systems remain compliant with these safety standards, avoiding penalties or shutdowns.

Cost Efficiency

Downtime due to equipment failure or accidents can lead to huge financial losses. PRVs minimize these risks by maintaining the system's integrity, helping businesses avoid costly repairs and unscheduled downtime.

Choosing the Right PRV for Your Application

When selecting a PRV, it's essential to consider factors such as pressure range, material compatibility, and the type of media (gas, liquid, or steam) in your system. The valve must be suited to the specific demands of your operation to ensure optimal performance and safety.

At Prabha Electronics, we offer high-quality PRVs designed for a wide range of industrial applications. Our valves are crafted with precision engineering, and durable materials, and adhere to stringent safety standards. Whether you need a PRV for gas, liquid, or steam systems, we have a solution that fits your needs.

Conclusion

The Pressure Relief Valve is a small but vital component in maintaining the safety, efficiency, and longevity of industrial systems. By choosing the right PRV, you protect your equipment and ensure your workforce's safety and compliance with industry standards.

Explore our range of Pressure Relief Valves at Prabha Electronics and equip your system with the best safety solution available.

#Pressure Relief Valve#PRV#industrial PRV#safety valve#over-pressure protection#pressure release valve#gas pressure relief#liquid pressure relief#steam pressure valve#system protection valve#industrial safety valve#high-performance PRV

0 notes

Text

#Pressure Safety Valves#Switching safety valve#Safety Valve#Safety Valve China#Pressure Safety Valve#Pressure Safety Valve Manufacturer#Pressure Safety Valve Supplier#B2B#Business services And Consultants#Industrial Machinery And Supplies#Logistics And Transportation#Industrial Supplies#Construction

0 notes

Text

1 note

·

View note

Text

Cylinder Relief Valve | Svarrnim Forgings

The cylinder relief valve protects the cylinder against excessive pressure. The blow-off pressure should be adjusted 20 to 30% above the normal working load. The pressure relief valve is designed to keep a cylinder from exploding in case of fire or extreme temperature. The main purpose is to lift when overpressure occurs in the combustion area; the resultant combustion gas is expelled through a flanged pipe to the deck.

visit source url : https://www.svarrnimforgings.com/compact-safety-relief-valves.html

0 notes

Text

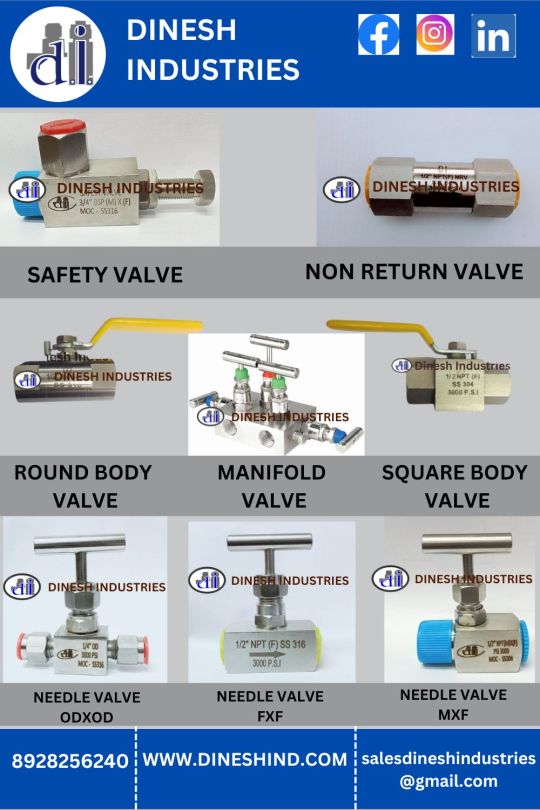

Pressure gauge valves: Your control center for precision! 🌡️ From the versatile SS ball valve for flow control to the precise SS needle valve for fine adjustments 📌, and the reliable SS non-return valve for fluid direction 🔄. Don't forget the safety with SS safety valves ⚠️ and the convenience of SS manifold valves for multiple connections 🤝. Choose accuracy, choose reliability! ⚙️🔧 #GaugeValvesMatter 🌟💧 #valves #pressuregaugevalves

0 notes

Text

#safety relief valve#safety valve#safety relief valve supplier in india#safety relief valve supplier in UAE#safety relief valve supplier in Singapore#bliss flow systems#industrial equipment#safety relief valve distributor in india#safety relief valve distributor in UAE#safety relief valve distributor in Singapore

0 notes

Text

safety valve

Pressure safety relief valve is applied to keep the pressure of the system or pressure containing parts through the over pressure scenarios to obtain the purpose of preventing the pressure from exceeding the specific valve. When the operating pressure inside the pressure system or pressure vessel exceeds the set pressure of the pressure relief valve, the valve will open automatically and discharge the excess flowing fluid. When the system pressure reduces to the normal pressure, the valve will automatically re-close, which will prevent the medium from keeping to be discharged, resulting in excessive waste of media in the system.

our webite is:

www.safetyvalve1.com

The unstable operation of the safety relief valve causes unbelievable harm, which is mainly described as follows: reduction of discharge capacity, insufficient function of constant pressure regulation or overpressure protection and the resonance of the whole pipeline system, or the serious damage to the sealing area of the safety relief valve. So that proper operation of the safety relief valves is very important problem for all clients in oil & gas industries. Because proper operation of safety relief valves guarantees safety of the system and prevents from terrible events.

1 note

·

View note

Text

A48sH High Temperature Spring full lift Safety Valve

A48sH-C high temperature spring full lift safety valve is suitable for working temperature ≤425℃, A48sH-I high temperature spring full lift safety valve is suitable for working temperature ≤510℃, A48sH-V high temperature spring full lift safety valve is suitable for It is used as an overpressure protection device on equipment or pipelines with media such as steam whose working temperature is ≤560℃.

#Safety Valve#A48sH high temperature spring full lift safety valve#Safety Valve China#Safety Valve New Mexico

1 note

·

View note

Text

Best Combo Multifunctional Valve -Prabha Electronics

In industries and households where LPG (liquefied petroleum gas) is a critical energy source, maintaining system safety and efficiency is paramount. One essential component that ensures the smooth operation of LPG systems is the Combo Multifunctional Valve. This versatile valve, available from Prabha Electronics, brings together multiple key functions into one device, providing a comprehensive solution for controlling, regulating, and securing gas flow.

What Is a Combo Multifunctional Valve?

A Combo Multifunctional Valve integrates several important features into a single, compact unit. Its primary functions include:

Pressure Regulation: Ensuring the correct pressure in LPG systems is vital for safe and efficient operation. This valve helps maintain optimal pressure levels, preventing gas leaks or malfunctions caused by overpressure.

Safety Relief: In the event of excess pressure buildup, the safety relief mechanism automatically releases gas to avoid hazardous situations like gas explosions.

Shut-Off Control: The valve also includes a shut-off feature that allows users to stop gas flow quickly, providing an essential safety measure for maintenance or in the event of an emergency.

Key Benefits of the Combo Multifunctional Valve

Enhanced Safety

Safety is the primary concern in any gas-powered system, whether it’s for residential use or large-scale industrial applications. With built-in pressure regulation, safety relief, and shut-off mechanisms, this valve reduces the risk of accidents, ensuring peace of mind for users.

Increased Efficiency

By combining multiple functions into one device, the Combo Multifunctional Valve streamlines the operation of your LPG system. This means fewer components are needed, reducing installation time and improving system efficiency.

Space-Saving Design

Instead of installing separate valves for each function (pressure regulation, safety relief, shut-off), this multifunctional valve saves space and minimizes the complexity of your system setup.

Durability and Longevity

Made from high-quality materials, the valve is built to withstand harsh environments and extended use. Whether you’re using it in residential, commercial, or industrial settings, it promises long-lasting performance.

Applications of the Combo Multifunctional Valve

The Combo Multifunctional Valve is ideal for various applications:

Residential LPG Systems: Homes that rely on LPG for cooking or heating will benefit from the valve's safety features.

Commercial Kitchens: Restaurants and large-scale catering services using LPG require precise pressure control and safety mechanisms to prevent accidents.

Industrial Gas Systems: Factories and manufacturing plants, where large quantities of gas are used, need reliable valves to maintain operational safety.

Why Choose Prabha Electronics’ Combo Multifunctional Valve?

Prabha Electronics is a trusted name in the LPG and gas equipment industry. With decades of experience, they offer products designed to meet international safety and performance standards. The Combo Multifunctional Valve is no exception, boasting a combination of innovation, reliability, and cost-effectiveness.

Conclusion

The Combo Multifunctional Valve is an essential component for any LPG system that demands safety, efficiency, and ease of use. By integrating pressure regulation, safety relief, and shut-off control into one unit, it provides a compact, versatile solution for both residential and industrial applications. Explore the full range of gas control solutions at Prabha Electronics, and ensure your LPG systems are operating at peak safety and performance levels.

#Combo multifunctional valve#LPG combo valve#gas system valve#safety valve#pressure regulation valve#shut-off valve#LPG control valve#multifunctional gas valve#industrial gas valve

0 notes

Text

A411 Breathing Safety Valve

A411 Breathing Safety Valve is a safety device used to install on light oil tank trucks and storage tanks. The function is to reduce the evaporation loss of oil products and protect the tank body from overloading. The hydraulic safety valve is a safety backup device for the (flap-type) breathing valve. Its inhalation and exhalation action pressure is slightly higher than that of the (flap-type) breathing valve. Once the breathing valve fails or its flap freezes in winter At this time, the liquid seal of the hydraulic safety valve is destroyed to protect the oil tank from damage. The hydraulic safety valve is a safety backup device for the (flap-type) breathing valve. Its inhalation and exhalation action pressure is slightly higher than that of the (flap-type) breathing valve. Once the breathing valve fails or its flap freezes in winter At this time, the liquid seal of the hydraulic safety valve is destroyed to protect the oil tank from damage.

0 notes

Text

LESER LNG and LPG make gas mobile

Demand for the compressed form of natural gas and petroleum gas is growing steadily and is expected to account for one third of global gas consumption in the medium term. Investments must pay off in the short term in order to remain profitable despite ever shorter supply contracts and trading on energy exchanges.The shortening and flexibilization of supply chains by combining production and…

View On WordPress

#วาล์วนิรภัย#Biztonsági szelep#Предохранительный клапан#Сақтандырғыш клапан#Сигурносни вентил#injap keselamatan#katup pengaman#LESER Safety Valve#LESER Valve#safety valve#van an toàn#صمام الأمان

0 notes