#sewage treatment equipment suppliers

Text

Sewage Treatment Plant By- Kelvin Water Technologies... .

#water treatment plant#effluent treatment plant manufacturers#sewage treatment plant in india#wastewater#etp plant manufacturers#sewage treatment equipment suppliers

0 notes

Text

Best Air Blowers Australia | Durable & Energy-Efficient

Find the best air blowers Australia for durability and energy efficiency. Our blowers are ideal to improve industrial processes and reduce operational costs.

#side channel blowers#air blower australia#air blower for industrial use#industrial blowers#premium air blower for sewage treatment plant#industrial equipment supplier

0 notes

Text

Sewage treatment plants (STPs) play a crucial role in managing wastewater and ensuring environmental sustainability in urban and industrial settings. As populations grow and urbanization intensifies, the need for effective wastewater management becomes increasingly critical. In this comprehensive guide, we explore everything you need to know about sewage treatment plants, their components, technologies, benefits, and their role in promoting a cleaner and healthier environment.

#Sewage Treatment Plant#Sewage Treatment Plant manufacturer in pune#Sewage Treatment Plant manufacturer in india#Sewage Treatment Plant manufacturer in Maharashtra#Sewage Treatment Plant suppliers in india#Sewage Treatment Plant suppliers in Maharashtra#Sewage Treatment Plant suppliers in pune#Sewage Treatment Plant maintenance services#Sewage Treatment Plant equipment in Pune#Sewage Treatment Plant equipment supplier in Pune#business

0 notes

Text

#Sewage Treatment Plant#Sewage Treatment Plant manufacturer in pune#Sewage Treatment Plant manufacturer in india#Sewage Treatment Plant manufacturer in Maharashtra#Sewage Treatment Plant suppliers in india#Sewage Treatment Plant suppliers in Maharashtra#Sewage Treatment Plant suppliers in pune#Sewage Treatment Plant maintenance services#Sewage Treatment Plant equipment in Pune#Sewage Treatment Plant equipment supplier in Pune

0 notes

Text

Exploring Large Diameter Pipes – Construction Challenges and Solutions

Understanding Large Diameter Pipes

Large diameter (Dia) pipes are essential components in many infrastructure projects, including water supply systems, sewage treatment plants, and oil and gas pipelines. Their size and functionality enable the efficient transport of large volumes of liquids and gases, making them indispensable in modern construction. However, working with large diameter pipes presents unique challenges that require specialized solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, has extensive experience in addressing these challenges. This article explores the construction challenges associated with large diameter pipes and the solutions provided by industry leaders like Tube Trading, a prominent large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

Large diameter pipes are typically defined as pipes with a diameter of 24 inches (600 mm) or more. They are made from various materials, including steel, ductile iron, concrete, and plastic, each offering specific advantages depending on the application. These pipes are used in a variety of sectors, such as:

Water and Wastewater: For transporting potable water and sewage.

Oil and Gas: For transporting crude oil, natural gas, and refined products.

Industrial Applications: For transporting chemicals, slurry, and other industrial fluids.

Construction: As structural elements in large infrastructure projects.

Construction Challenges of Large Diameter Pipes

The installation and maintenance of large diameter pipes pose several challenges, which include:

1. Transportation and Handling

Transporting and handling large diameter pipes can be logistically complex due to their size and weight. These pipes often require special equipment and careful planning to ensure they are transported safely and efficiently.

Solution: Tube Trading, as a leading large Dia pipe distributor in Gujarat, uses specialized transportation methods and equipment to handle large diameter pipes. This includes flatbed trucks, cranes, and forklifts designed to accommodate the size and weight of these pipes. Their logistics team ensures that transportation complies with all safety regulations and standards.

2. Site Preparation and Trenching

Proper site preparation and trenching are critical for the successful installation of large diameter pipes. This involves clearing the site, excavating trenches, and ensuring that the ground conditions are suitable for pipe laying.

Solution: Tube Trading provides comprehensive site assessment and preparation services. They use advanced geotechnical surveys to analyze soil conditions and design appropriate trenching solutions. This minimizes the risk of ground instability and ensures a solid foundation for the pipes.

3. Jointing and Welding

Joining large diameter pipes securely is essential to prevent leaks and ensure the integrity of the pipeline. This can be particularly challenging with materials like steel, which require precise welding techniques.

Solution: As a top large Dia pipe dealer in Vadodara, Tube Trading offers expert welding and jointing services. Their team of certified welders uses state-of-the-art welding equipment and techniques to ensure strong, leak-proof joints. For non-metallic pipes, they provide specialized coupling systems that offer reliable connections.

4. Pressure Testing and Quality Assurance

Large diameter pipes used in critical applications, such as water supply and oil and gas transport, must undergo rigorous pressure testing to ensure they can withstand operational pressures without failing.

Solution: Tube Trading conducts thorough pressure testing and quality assurance checks on all pipes before installation. Their testing procedures comply with international standards, ensuring the pipes’ durability and reliability. This includes hydrostatic testing, where pipes are filled with water and pressurized to detect leaks and weaknesses.

5. Corrosion Protection

Corrosion can significantly reduce the lifespan of large diameter pipes, especially those made from metal. Protecting these pipes from corrosion is essential for long-term durability and performance.

Solution: Tube Trading offers a range of corrosion protection solutions, including coatings, linings, and cathodic protection systems. These measures protect the pipes from environmental factors and extend their service life. Their experts recommend the most suitable protection method based on the pipe material and operating conditions.

6. Environmental and Regulatory Compliance

Construction projects involving large diameter pipes must comply with environmental regulations and standards to minimize their impact on the environment.

Solution: Tube Trading is committed to environmentally responsible practices. They ensure all their projects comply with local and international environmental regulations. This includes using environmentally friendly materials and methods, as well as implementing measures to protect natural habitats and water sources during construction.

Innovative Solutions by Tube Trading

Tube Trading’s extensive experience and expertise in handling large diameter pipes make them a trusted partner for construction projects in Vadodara and Gujarat. Here are some innovative solutions they offer:

1. Custom Pipe Fabrication

Tube Trading provides custom fabrication services to meet specific project requirements. This includes custom lengths, bends, and fittings that ensure seamless integration with existing infrastructure. Their fabrication facilities are equipped with the latest technology to deliver high-precision products.

2. Comprehensive Project Management

From initial planning to final installation, Tube Trading offers comprehensive project management services. Their team of experts oversees every aspect of the project, ensuring timely completion and adherence to budget. This integrated approach minimizes disruptions and ensures smooth project execution.

3. Advanced Material Solutions

Tube Trading supplies a variety of pipe materials, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ductile iron. Each material is chosen based on the specific needs of the project, offering optimal performance and cost-effectiveness. Their material experts provide guidance on selecting the best material for each application.

4. Technical Support and Training

Tube Trading provides technical support and training to ensure that construction teams are well-equipped to handle large diameter pipes. This includes training on installation techniques, safety procedures, and maintenance practices. Their support services ensure that clients have the knowledge and resources needed for successful project execution.

Why Tube Trading Stands Out

As a premier large Dia pipe supplier in Vadodara, Tube Trading has built a reputation for excellence and reliability. Their commitment to quality, innovation, and customer satisfaction sets them apart in the industry. Here’s why Tube Trading is the preferred choice for large diameter pipe solutions:

1. Extensive Industry Experience

With years of experience in the industry, Tube Trading has developed deep expertise in handling large diameter pipes. Their extensive portfolio of completed projects demonstrates their capability and reliability.

2. Quality Assurance

Tube Trading adheres to the highest quality standards in the industry. Their products undergo rigorous testing and inspection to ensure they meet or exceed client expectations. This commitment to quality ensures that clients receive durable, high-performance pipes for their projects.

3. Customer-Centric Approach

Tube Trading’s customer-centric approach ensures that clients receive personalized solutions tailored to their specific needs. Their team works closely with clients to understand their requirements and provide the most effective solutions.

4. Comprehensive Solutions

From supply and fabrication to installation and maintenance, Tube Trading offers end-to-end solutions for large diameter pipes. This comprehensive approach simplifies project management and ensures seamless execution.

Conclusion

Large diameter pipes are critical components in many infrastructure projects, but they come with unique construction challenges. Addressing these challenges requires specialized expertise and innovative solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, excels in providing comprehensive solutions that ensure successful project execution. Their commitment to quality, innovation, and customer satisfaction makes them a trusted partner for large diameter pipe projects in Vadodara and Gujarat. Whether you need custom fabrication, technical support, or comprehensive project management, Tube Trading is your go-to large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

#Large dia pipe distributor in Gujarat#Large dia pipe supplier in Vadodara#Large dia pipe dealer in Vadodara

4 notes

·

View notes

Text

Fenton Technologies Pvt. Ltd. is a professional Engineering equipment’s Manufacturing and Environmental research and development, production and sales of science and technology enterprises. Since its inception, we always adhere to the spirit of craftsmanship, to provide the industry with water treatment equipment and services and systematic solutions, Company Work in Three Verticals- Sewage Water Projects , Wastewater Products, Swimming Pools Products include MBR Membrane , Oil Skimmer, Screw Press, MBR STP Plant, Bar Screen, Dissolved Air Flotation (DAF) many More water treatment Equipment’s . Fenton is also Associating with Overseas partners to Keep in Forefront . Our Water Treatment Equipment Company always welcome innovation & Advance Technologies Developers for Association in Market .

In product quality improvement, the water treatment equipment company “customer first” philosophy for the development, adhering to the “quality, innovation and service” business purposes, the establishment of a set of international standards of quality assurance management system.

youtube

MBR Membrane Manufacturer

Sewage treatment plant manufacturer in india

water Treatment Equipment Manufacturer

water Treatment Equipment Supplier

Belt Type Oil Skimmer Manufacturer

swimming pool manufacturer in india

2 notes

·

View notes

Text

Sewage Treatment Plant Manufacturer in India

Sewage Treatment Plant Manufacturer

The sewage treatment plant is a critical component of the sanitation system. It removes harmful materials from our wastewater before it can enter the environment. The process of treatment typically includes three stages: primary, secondary and tertiary. Primary treatment removes solids and floating materials from the wastewater by screening or skimming, followed by gravity settling to remove lighter particles. Secondary treatment uses microorganisms to break down organic matter in a series of tanks called activated sludge units (ASUs).

Tertiary treatment involves removing any residual chemicals or microorganisms that could harm the environment with additional chemical treatments or chlorination before releasing it into the environment.

A sewage treatment plant is the foundation of a healthy community. It reduces the risk of infectious diseases and protects our water supply. But the sewage treatment industry is not without its challenges - like how to keep up with increasing population growth, climate change, and stricter regulations.

Sewage Treatment Plant Manufacturers are companies that provide solutions to the problem of waste water treatment. They make sure that the sewage is treated in a safe, efficient and cost-effective way.

A sewage treatment plant manufacturer supplier is an important part of any community because they provide a solution to a major problem. The wastewater from homes and businesses go to the plant where it undergoes a series of treatments before it's discharged back into the environment or used for irrigation or other purposes.

Sewage Treatment Plant Manufacturers are responsible for making sure that all of this takes place in an environmentally friendly manner, which means they have to use some form of renewable energy.

The sewage treatment plant manufacturer is the company that manufactures and installs sewage treatment plants. These plants are used in the municipal water treatment process to clean raw sewage before it is released into rivers and streams.

A STP manufacturer can be a private company or a government agency, such as a municipality, county, or state. The plant may be owned by a public utility or operated by a private company under contract to the government.

The sewage treatment plant manufacturer needs to comply with all applicable federal, state, and local regulations governing the design and operation of wastewater systems.

Thanks & Regards

Advance Equipment & Project Pvt Ltd .

#sewage_treatment_plant_manufacturer_supplier_in_noida sewage_treatment_plant_manufacturer_supplier_in_ncr sewage_treatment_plant_manufactur#sewagetreatment#effluent#effluenttreatmentplant#purewaterplant#watertreatmentplantmanufacturerinnoida#water_treatment#water_treatment_plant_manufacturer_in_gurgaon#advancve_equipment

2 notes

·

View notes

Text

Find The Best Sewage Treatment Plant Manufacturer In Delhi ?

The greatest Sewage Treatment Plant manufacturer in Delhi is Netsol Water, thanks to our affordable prices & superior STP plant technology that rivals the finest in the business. In case you're seeking a dependable Sewage Treatment Plant Manufacturer in Delhi which stands tall as the largest supplier in the country as well, so feel free to get in touch with Netsol Water right now.

Definition regarding Sewage Treatment Method

In addition to removing pollutants from sewage to reduce water contamination from raw sewage discharges, sewage treatment, also known as municipal controlled sewage treatment process, is a type of raw water treatment that eventually produces a large volume of output effluent wastewater which is accepted for recycling as well as disposal. Wastewater from homes & businesses, a potentially pre-treated industrial effluent, is referred to as sewage.

What are the methods involved in Sewage treatment?

There are several STP plant techniques available. Examples vary from large-scale centralized systems with a network of pipelines & pump stations(known as sewerage) to separate systems of equipment, such as on-site treatment systems. It transports wastewater to a treatment plant. Additionally, stormwater from combined sewers & urban runoff is routed through the sewers to the STP.

What are the different phases associated with treating sewage in STPs?

Standard STP consists of two processes: primary & secondary; advanced treatment adds a tertiary treatment phase including additional procedures for polishing as well as nutrient removal. Organic matter is treated in the secondary phase by aerobic which utilizes oxygen as well as an-aerobic decomposing methods.

Sewage Treatment Plant Manufacturer in Delhi possess a high level of significance.

The constantly expanding population as well as the industrial environment in India are contributing to an alarming increase in the weight or quantity of wastewater. The fact that freshwater resources, such as rivers, wells, & even groundwater, are running out is a worrying problem. Others fear that water will become extremely valuable in the future.

There are further consequence from higher wastewater levels!

It is dangerous to consume, & it can pollute other water supplies. For example, dangerous water leaks can poison rivers. As contaminated water moves downstream & merges with additional sources of water, including rivers, pollution increases.

Additionally, wastewater taints subsurface water supplies by seeping into the earth. Consequently, almost all of the water sources in contemporary Indian cities, such as Delhi, are contaminated, which also includes rivers, wells, & coastal areas.

Choosing an STP Plant Manufacturer in Delhi based on a range of sewage treatment systems

Many different types of sewage treatment plants have been developed, most of which incorporate biological treatment methods. When choosing a suitable technology, engineers & decision-makers must consider qualitative & quantitative aspects of each solution in addition to technical & economical considerations. When planning & constructing a sewage treatment plant, the subsequent selection criteria or considerations are usually followed:

Desirable Sewage purity & quality;

Estimated building & operating costs;

Land accessibility & constraints;

Energy demands; &

Sustainability concerns.

In Delhi, sewage is occasionally managed on-site rather than being piped away. Septic tanks connecting to drain fields, Vermi Filter systems, on-site sewage systems, & various other systems are implemented. However, to remove micro-pollutants, sewage treatment plant manufacturers like Netsol Water incorporate a fourth treatment stage or tertiary treatment with disinfection.

Conclusion

Selection of the top Sewage Treatment Plant Manufacturer & Supplying facilities. Being one of the best companies in Delhi for treating wastewater, Netsol Water designs excellent sewage treatment plants that clean wastewater for consumption by other industries &then release it to the environment while protecting land & water resources. Commercial RO Plant is the best sewage treatment plant manufacturer in delhi along with Netsol Water.

Our staff, consisting of scientists, engineers, with managers, works constantly, all days a week, throughout the day, to manufacture high-quality equipment implementing with the newest, most popular technologies.

#sewage treatment plant#netsol water#sewage treatment plant manufacturer in delhi#water is life#water treatment plant

0 notes

Text

Are You Looking For The Sewage Treatment Plant Manufacturer In Noida ?

A Sewage Treatment Plant is a facility for wastewater treatment plants that is installed particularly to treat & handle wastewater that is generated within the city of Noida. Sewage is cleaned & treated before being released into the environment or ecosystem to prevent environmental degradation.

Does Noida have a variety of STP plant types?

Yes, Sewage Treatment Plant Manufacturer In Noida such as Netsol Water offers a variety of industrial STP Plants that are created & tested to fulfill the specialized wastewater treatment requirements of these diverse regions. These comprise of various technologies such as MBR- (membrane bio-reactors), SBR- (sequencing batch reactors), & activated sludge processes.

Why are STP Plants Important for the Environment in Noida?

STP Plants in Noida are essential for maintaining sustainable water management in the city, safeguarding public health & reducing contamination of water in the Yamuna River & other nearby water bodies.

Requirements for Regular Maintenance & Servicing of STP Plants

For Sewage Treatment Plant Manufacturer in Noida to function effectively & maintain environmental norms & regulation according to the govt. set standards, they need routine maintenance, which includes complete as well as approproate cleaning, servicing, or inspections.

Management system of STP Plants by the Expertize to minimize or eliminate the Issues & Problems

The improper or incomplete management as well as handling & disposal of hair materials, sanitary-pads or diapers, fabric, & other particles into various plumbing piping sources is one of the challenging problems that most of the major operators of sewage treatment plants encounter. It degrades the treated water's quality for the plants.

Consideringproper method, how to properly dispose of this sewagewastes& effluent wastewater is very much essential since it can progress STP performing efficiency. It must be fixed quickly & given preventative care to reach its maximum potential.

General Considerations to keep on mind for Selecting the best Sewage Treatment Plant Manufacturer in Noida.

Proper as well as Upgraded Technology for implementing best performance: An STP plant facility must have the newest technologies available & running in the industries.

Precision in the processes involved in the raw wastewater treatment in these Plants

Resolutions for making utilization of the Treatment Plant: It might contribute in selecting an appropriate treatment plant if clients are very much clear about why theydesires to get one. Select the greatest as well as the recent ones for managing dangerous toxins & chemical compounds as well as treating residual impure wastewater.

However, contact Netsol Water directly for information on STP pricing & other necessities including all pricing.

Netsol Water as an efficiently performing Sewage treatment plant manufacturer In Noida can assist in avoiding following errors while installing an STP:

Inadequate Plant Design: The Noida water sewage treatment plant's inadequate operation is a result of inadequate plant design. It is essential to consider (i.e., take into account) certain site requirements that might increase the plant's efficiency rate.

Maintenance & Operational Issue: An improperly constructed sewage treatment plant in Noida might not function as well & it may require more maintenance than what normal is. Here is where knowledgeable& the most experienced manufacturer may assist in extending the life of the plants by using technology properly.

Insufficient monetary resources: Within Noida, a high-standard sewage water treatment facility that is capable of effective removal & filtration may be created with sufficient funds. Correct & Efficient upkeep maintenance has a great potential to minimize an STP plant's operating strength or power.

Low-Quality Building Supplies: Purchasing equipment from well-known STP suppliers guarantees that the STP plant will utilize high-quality building supplies. The plant's operational capacity is measured through its quality. The machineries are the most robust ones& effective with the better class of the material.

Conclusion

Placing complete trust over a Reputable Sewage Treatment Plant Manufacturer in Noida like Netsol Water, take care of these issues & work to provide customers with high-quality STP treatment plants. Netsol Water provides a wide range & selection of their most cost-effective efficient Sewage treatment plants along with innovations that affect the gross costing. The water & wastewater treatment equipment of Netsol Water also determines the manufacturer's capacity to supply excellent products for proper sewage treatment in contaminated regions around Noida.

#sewage treatment plant#sewage treatment plant manufacturer#sewage treatment plant manufacturer in noida#netsol water#water is life

0 notes

Text

Best Stainless Steel Tube Exporters in Laos

Why Midland Alloys Inc. is Laos’ Premier Stainless Steel Tube Exporter

Laos is experiencing rapid growth in its infrastructure and industrial sectors, increasing the need for reliable and high-quality materials. Among these essential materials, stainless steel tubes have become indispensable, offering durability, corrosion resistance, and versatility. In this article, we explore how Midland Alloys Inc. has emerged as the premier stainless steel tube exporter for Laotian industries, addressing their unique demands and delivering solutions that support the country’s economic development.

Best Stainless Steel Tube Exporters in Laos

1. The Growing Importance of Stainless Steel Tubes in Laos

As Laos advances, its industries are becoming more diverse, ranging from construction and manufacturing to water treatment and energy. The need for materials that can withstand harsh conditions while maintaining performance is greater than ever, and stainless steel tubes perfectly meet these requirements. Their applications are vast, spanning multiple industries, and their importance cannot be overstated.

1.1 Construction and Infrastructure Development

Laos is undergoing significant construction and infrastructure projects, driven by urbanization and the need for modern commercial and residential buildings. Stainless steel tubes are critical components for structural support, plumbing, heating, and cooling systems in these projects. Their strength and resistance to environmental factors like rust and moisture make them ideal for the Laotian climate, ensuring that structures remain reliable and long-lasting.

1.2 Water Treatment and Distribution

Clean water is crucial for a developing country like Laos. Stainless steel tubes play a pivotal role in water treatment plants, distribution networks, and sewage systems. These tubes are resistant to corrosion from chemicals used in water treatment, making them ideal for ensuring a clean and consistent water supply. Additionally, their strength minimizes the risks of leaks and ruptures, contributing to efficient water distribution systems across the country.

1.3 Oil, Gas, and Energy Sectors

Laos is also expanding its energy and resource sectors. Stainless steel tubes are essential for transporting oil, gas, and other energy sources, providing durability and resistance to the elements in challenging environments. Whether it’s in pipelines, offshore installations, or refineries, stainless steel tubes ensure the integrity of energy infrastructure, making them a vital material for these industries.

1.4 Manufacturing and Industrial Growth

In the manufacturing sector, stainless steel tubes are widely used for various machinery, equipment, and production lines. Their ability to withstand high temperatures and corrosion makes them a key material in industries such as automotive, food processing, and heavy machinery. By using stainless steel tubes, manufacturers in Laos can ensure the longevity of their equipment, reducing maintenance costs and improving production efficiency.

2. Midland Alloys Inc.: The Trusted Partner for Laos’ Industrial Needs

Midland Alloys Inc. has established itself as a top exporter of stainless steel tubes to Laos by understanding the unique requirements of the country’s growing industries. Our dedication to quality, customization, and customer service makes us the go-to supplier for businesses across multiple sectors.

2.1 Understanding the Laotian Market

Having worked with businesses in Laos for years, Midland Alloys Inc. has developed a deep understanding of the local market’s specific needs. We know that different industries require tailored solutions, which is why we offer a wide range of stainless steel tubes that cater to various applications. Whether it’s for large infrastructure projects, industrial manufacturing, or water treatment systems, our products are designed to perform at the highest level in any environment.

2.2 Quality Assurance You Can Rely On

At Midland Alloys Inc., quality is at the forefront of everything we do. Our stainless steel tubes meet strict international standards, ensuring they can withstand even the most demanding applications. From raw material selection to the final product inspection, our rigorous quality control process ensures that every tube we export to Laos is of superior quality. This commitment to excellence is what sets us apart as a trusted supplier.

2.3 Customer-Centric Solutions

We believe in building lasting partnerships with our clients by understanding their needs and delivering customized solutions. Midland Alloys Inc. works closely with Laotian businesses to provide products that meet their exact specifications, ensuring smooth operations and long-term success. Our team of experts is always available to offer technical advice and support, ensuring that our clients receive the right products for their projects.

Best Stainless Steel Tube Fittings Exporters in Laos

3. Key Features of Midland Alloys Inc.’s Stainless Steel Tubes

What makes Midland Alloys Inc. the leading exporter of stainless steel tubes in Laos is our dedication to providing high-quality, reliable products. Here are some key features of the stainless steel tubes we export:

3.1 Superior Corrosion Resistance

One of the most critical qualities of stainless steel tubes is their ability to resist corrosion, especially in industries like water treatment, oil and gas, and chemical processing. Our tubes are manufactured using advanced techniques and high-grade materials to ensure they can withstand exposure to harsh environments, chemicals, and extreme temperatures without deteriorating. This durability makes them ideal for Laotian industries that require long-lasting materials.

3.2 Strength and Durability

Our stainless steel tubes are built to last. They are designed to handle high-pressure environments and demanding industrial conditions without losing their structural integrity. This strength ensures that the tubes can perform reliably across various applications, from heavy-duty construction to high-precision manufacturing. By choosing Midland Alloys Inc., businesses in Laos can rest assured that they are investing in products that will stand the test of time.

3.3 Precision Engineering

At Midland Alloys Inc., precision is key. Our stainless steel tubes are engineered to exact specifications, ensuring that they meet the most stringent quality standards. Whether it’s the tube’s thickness, diameter, or tolerance levels, we ensure that every aspect is meticulously crafted to deliver consistent performance. This level of precision makes installation easier, reduces the risk of defects, and enhances overall operational efficiency.

3.4 Versatile Applications

We understand that different industries have different needs, which is why we offer stainless steel tubes in various sizes, grades, and configurations. Whether you need large-diameter tubes for infrastructure projects or smaller tubes for specialized machinery, Midland Alloys Inc. has the right solution for your business. Our versatile range of products allows us to serve clients across multiple sectors, making us a one-stop-shop for stainless steel tubes in Laos.

4. Why Midland Alloys Inc. is Laos’ Leading Stainless Steel Tube Exporter

Several factors contribute to why Midland Alloys Inc. is considered the leading stainless steel tube exporter in Laos. Our expertise, commitment to quality, and focus on customer satisfaction set us apart from the competition.

4.1 Decades of Experience

With years of experience in the stainless steel industry, Midland Alloys Inc. has built a solid reputation for delivering high-quality products and exceptional service. Our expertise allows us to understand the complexities of different industries and offer tailored solutions that meet the unique needs of our clients in Laos.

4.2 Commitment to Quality

Quality is non-negotiable at Midland Alloys Inc. We adhere to international quality standards, ensuring that every stainless steel tube we export meets the requirements of the most demanding industries. Our commitment to quality ensures that our clients receive products that perform reliably, even in challenging conditions.

4.3 On-Time Deliveries

We understand that time is critical for businesses, especially those working on large-scale projects or time-sensitive operations. At Midland Alloys Inc., we prioritize efficient logistics and supply chain management, ensuring that our products are delivered on time, every time. Our timely deliveries help our clients stay on schedule and avoid costly delays.

4.4 Competitive Pricing

While we maintain high-quality standards, we also strive to offer competitive pricing. We believe that businesses in Laos should have access to premium stainless steel tubes without overextending their budgets. Our cost-effective solutions allow our clients to optimize their expenditures while benefiting from top-grade products.

Best Stainless Steel Tube Exporters in South Africa

5. Supporting the Growth of Laos’ Industries

Midland Alloys Inc. isn’t just a supplier—we’re a partner in the success of Laotian industries. By providing high-quality stainless steel tubes and exceptional customer service, we help businesses in Laos achieve their goals and drive the country’s economic development.

5.1 Partnering with Laotian Businesses

We take pride in building strong, long-term relationships with our clients in Laos. By offering tailored solutions and ongoing support, we ensure that our clients can carry out their operations efficiently and effectively. Whether it’s through technical advice, customized products, or prompt deliveries, Midland Alloys Inc. is dedicated to supporting the growth and success of Laotian industries.

5.2 Contributing to Laos’ Infrastructure and Economic Growth

As Laos continues to develop its infrastructure and industrial base, the need for high-quality materials like stainless steel tubes will only grow. Midland Alloys Inc. is proud to contribute to this growth by providing reliable, durable products that help drive the country’s progress. Our commitment to quality and customer satisfaction ensures that we will remain a trusted partner for Laotian industries for years to come.

Best Stainless Steel Tube Exporters in Singapore

6. Conclusion: Why Midland Alloys Inc. is Laos’ Premier Stainless Steel Tube Supplier

In conclusion, Midland Alloys Inc. has established itself as a leading exporter of stainless steel tubes in Laos by consistently delivering high-quality products, exceptional customer service, and tailored solutions for various industries. Our expertise in the stainless steel market, coupled with our commitment to quality and on-time deliveries, makes us the go-to partner for businesses across the country.

By choosing Midland Alloys Inc., Laotian businesses can rest assured that they are receiving the best products on the market, backed by years of experience and a dedication to excellence. We look forward to continuing to support the growth and development of industries in Laos with our premium stainless steel tubes.

0 notes

Text

Sewage Treatment Plant Manufacturer, Supplier from Indore

The Importance of Sewage Treatment Plants in Indore

One of India's fastest-growing cities, Indore, has led the way in urban development. But as cities become more and more populated, there is an urgent need for efficient waste management techniques. A crucial component of this is Wastewater Treatment Processes, which makes sure that wastewater is cleaned and repurposed to reduce its negative effects on the environment. This blog examines the importance of Sewage Treatment Plants in Indore, the different technologies at play, and the ways in which these facilities support a sustainable future.

Understanding Sewage Treatment Plants (STPs)

STP Plants are necessary for the treatment of wastewater generated by businesses, homes, and industry. There are usually multiple stages involved in the therapeutic process:

During the preliminary treatment stage: big debris including sticks, plastics, and other non-biodegradable elements are screened out of the wastewater. Grit removal, which involves settling out sand and other heavy particles, comes next.

Primary Treatment: In this stage, the wastewater is let to settle in enormous tanks. Grease and oils float to the top where they are skimmed off, while heavier solids sink to the bottom and produce sludge.

Secondary Treatment: In this phase, organic matter in the wastewater is broken down by microorganisms through biological processes. Commonly, aerobic techniques are employed, in which the growth of bacteria that eat organic contaminants is encouraged by pumping air into the tanks.

Tertiary Treatment: The last phase entails getting rid of any leftover impurities, like bacteria, phosphorus, and nitrogen. To provide high-quality water that can be safely released into the environment or reused, sophisticated filtering techniques, chemical treatments, and disinfection procedures are employed.

Choosing the Right Sewage Treatment Plant Suppliers

Selecting a provider is essential for putting a Sewage Water Treatment Plant into practice. The design of the plant, the supplier's experience, and the equipment quality all have a significant impact on how well a sewage treatment system works. These are some important aspects to take into account while choosing Suppliers of Sewage Treatment Plants:

Experience and Expertise: Seek vendors who have a track record of success in the Wastewater Treatment sector. Reliability can be well-indicated by experience in building and implementing STPs for a range of applications, including municipalities, industries, and residential complexes.

Best Sewage Treatment Plant Manufacturers & Suppliers

Choosing the right Sewage Treatment Plant Manufacturer and Supplier is critical to the success of any wastewater management project. With Inhibeo Water Solutions, you are partnering with a company that brings expertise, innovation, and a commitment to sustainability to every project. Our comprehensive Sewage Recycling Plant is designed to meet the diverse needs of our clients, ensuring that their wastewater is managed efficiently and responsibly.

Conclusion

The success of any wastewater management project depends on selecting the appropriate manufacturer and supplier for Sewage Treatment Plants. When you work with Inhibeo Water Solutions, you are collaborating with a business that approaches every project with knowledge, creativity, and a dedication to sustainability. Our all-inclusive sewage treatment options are made to satisfy our customers' various demands while guaranteeing that their wastewater is handled sensibly and effectively.

#Sewage Treatment Plant in Indore#STP Plant#Sewage Water Treatment Plant#Sewage Recycling Plant#Sewage Treatment Plant Suppliers#Sewage Treatment Company

0 notes

Text

#water treatment plant#wastewater#waste management#sewage treatment equipment suppliers#jobsearch#latest jobs#jobopportunity#job interview#jobalert

0 notes

Text

Semiconductor Capital Equipment Market Outlook to 2030

The Insight Partners recently announced the release of the market research titled Semiconductor Capital Equipment Market Outlook to 2030 | Share, Size, and Growth. The report is a stop solution for companies operating in the Semiconductor Capital Equipment market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Semiconductor Capital Equipment Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Semiconductor Capital Equipment market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Semiconductor Capital Equipment market research has all that you need.

What are Key Offerings Under this Semiconductor Capital Equipment Market Research?

Global Semiconductor Capital Equipment market summary, current and future Semiconductor Capital Equipment market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Semiconductor Capital Equipment Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Semiconductor Capital Equipment Market?

Semiconductor Capital Equipment market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Semiconductor Capital Equipment market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Semiconductor Capital Equipment market share.

Report Attributes

Details

Segmental Coverage

equipment type

Automated Test Equipment

Die-Level Packaging and Assembly Equipment

Wafer-Level Manufacturing Equipment

end-user

Water and Sewage Treatment

Food and Beverage

Pharmaceuticals

Oil and Gas

Power Plants

Pulp and Paper

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Tencor

Kulicke and Soffa

Lam Research

Nikon

Planar

Tokyo Electron

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Semiconductor Capital Equipment market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Semiconductor Capital Equipment market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Are you Looking for Sewage Pump Manufacturer?

If you are looking for Sewage Pump, Creative Engineers have been offering ISO-9001:2008 certified Sewage Pump Manufacturer We are the best Sewage Pump manufacturer and Supplier in the industry providing premium Sewage Pump.

Sewage pumps are key equipment for discharging and treating sewage, and play an important role in municipal, industrial and commercial fields. Sewage Pump has features like sturdy construction, precision engineering, superior quality, excellent functionality, efficient output and high durability, our offered products have gained huge appreciation by clients

APPLICATIONS OF SEWAGE PUMP

Scum pumping at waste water treatment plant

Municipal projects

Industrial packaged pump station

Home and domestic application (Special for kitchen)

Pumping agricultural manure (dairy, hog and poultry)

For More Details

Click here : https://www.sspumpsindia.com/

0 notes

Text

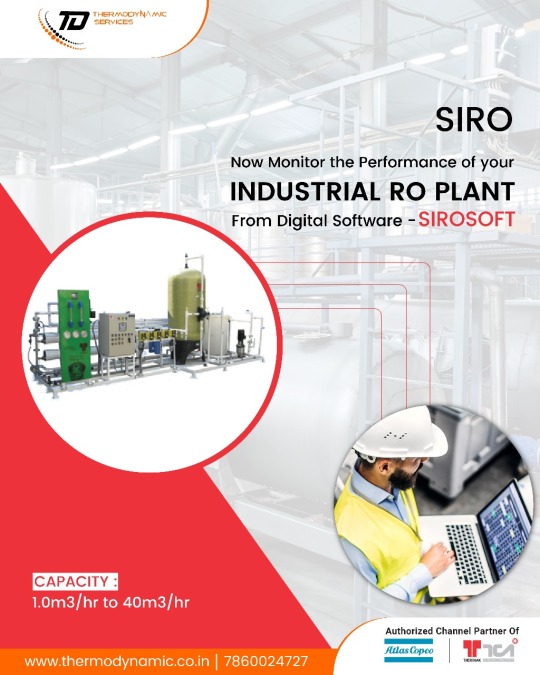

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

Are You Looking for Sewer Suction Machine Manufacturers in India

We are a successful manufacturer and supplier of Sewer Suction Mchines in India, which is used to create a vacuum that is essential for siphoning of various materials like mud, slurry, and grit from storm, sanitary, and combined sewerage systems. This machine is manufactured using the best grades of material that ensures its finest quality and high performance. This hydraulic sewer suction machine comes with an unloader or a pressure relief valve that is used for controlling the pressure.

Sewer Suction Machine Manufacturers play a vital role in the efficient removal of sewage and waste materials from various drainage systems. These machines are designed to suction and transport liquid and solid waste, helping to maintain clean and functional sewer networks.

What is a Sewer Suction Machine?

A sewer suction machine, also known as a vacuum tanker or sewer cleaning truck, is a specialized vehicle equipped with powerful suction pumps and storage tanks. It is used for clearing blockages, cleaning sewer lines, and transporting sewage and sludge to treatment facilities.

How Does a Sewer Suction Machine Work?

Sewer suction machines utilize vacuum technology to create suction pressure, which effectively pulls waste materials into the storage tank. The collected waste is then transported to disposal sites or treatment plants for proper disposal or processing.

Types of Sewer Suction Machines

There are various types of sewer suction machines available, including truck-mounted units, trailer-mounted units, and skid-mounted units. Each type offers unique features and capabilities to suit different applications and environments.

Applications of Sewer Suction Machines

Sewer suction machines are used in a wide range of applications, including municipal waste management, industrial cleaning, and emergency response services. They are essential for maintaining clean and functional sewer systems in urban and rural areas alike.

Benefits of Using Sewer Suction Machines

Efficiency: Sewer suction machines offer efficient waste removal, reducing the risk of blockages and backups in sewer lines.

Versatility: These machines can handle various types of waste, including liquid and solid materials, making them versatile tools for waste management.

Cost-Effectiveness: By preventing costly repairs and minimizing downtime, sewer suction machines help save money in the long run.

Safety Precautions When Operating a Sewer Suction Machine

Operating a sewer suction machine requires adherence to strict safety protocols to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE), follow operational guidelines, and exercise caution when working near sewer lines.

Contact us right away, if you want to learn more about our wide range of sewer suction machine products. Call us at .+919311309436 or send an email to [email protected], we are India’s largest sewer suction machine manufacturers and suppliers.

#sewer suction machine manufacturers#sewer suction machine#sewer suction machine manufacturers in India#sewer suction machine manufacturers in Ghaziabad#sewer suction machine manufacturers in Uttar Pradesh#sewer suction machine suppliers#sewer suction machine suppliers in India#sewer suction machine suppliers in Ghaziabad#sewer suction machine suppliers in Uttar Pradesh

0 notes