#stainless steel sheet metal screws

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

To all my peeps who need hardware/home improvement/DIY stuff but don’t know how to go about getting it, here’s a little guide on how to navigate the hardware store:

If you know exactly what item you need

Bring as many visual aids are you can. Bring a picture of the item, a link to the store you found it on, even better, a link to the hardware store’s website showing the item, heck even a drawing of the item would help

What we want most from you is the brand name, the size, the UPC or manufacturer number or SKU if you have it, and the name of the item if you know it.

We also want the purpose you’re using the item for in a general sense. Hardware stores tend to be laid out by general area of work and being able to say, I need a light for a car is going to get you a different location than I need a light for a standing lamp in my house

If you know what purpose you want the item to serve but don’t know what item you need

Tell us about your project and what role the item plays in it. Use words like connect or bend or secure. We want to know the limits of what you need the item to do.

We also want to know the materials the item is interacting with. Drill bits for wood differ greatly from drill bits for cement and drill bits for sheet metal.

Do you need raw material? What items will probably be interacting with it? Ex: you’re putting up a shelf. Important info: the shelf must be made of wood and you plan to use screws and brackets to connect it to drywall.

If you know any unusual stressors the item will have to put up with, say them. Ex: I’m going to leave this item outside in all seasons, I plan to put heavy things on top of this item, I need this item to secure a delicate object

If you know what type of item you’re looking for but not which one you need

Stressors, again. How strong do you need the item to be? Some hooks can hold 10lbs, some can hold 50lbs, what are you planning on hanging from the hook?

Do you know the color or material you’re looking for? Does the pipe fitting have to be bronze or stainless steel?

Ask for the pluses and minuses of objects we present you, hopefully usually we’ll know and we work for the store not the supplier so we’ll give it to you straight if something’s of higher quality

I’m gonna give some quick examples here that sound more like natural conversation to show you how to convey this information

Ex: first bullet point

Hi I’m looking for some chains (name of item) for my trailer hitch (purpose of item, role item plays). The trailer is pretty heavy (strength needed) and I drive with it a lot (possible stressor). I’ll need about six feet of them (size) and they’ll have to be thick (size and appearance). I noticed you had them listed on your website here *shows phone* (visual aid)

Ex: second bullet point

Hi I need to join (type of connection) two pieces of wood (materials interacting with item, role item plays) together for a bookshelf (purpose of item, identifiable stressor). I don’t really know what’s best for that (asking for advice).

Ex: third bullet point

Hi I’m looking for a paint primer (type of item). It’s going on drywall that already has painter’s paint on it (material it’s interacting with, strength of item needed) I’ve heard there are some types that include paint and primer (mentioning options you want to consider)?

All of these will help you get the hobby or project item you need as quickly and efficiently as possible, best of luck!

2 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

The Role of Sheet Metal Fabricators in the Sciences and Arts of Sheet Metal Fabrication

Modern industries and buildings are based on sheet metal fabricators, which are essential to the production of everything from industrial components to architectural elements. Find the ideal partner for your requirements by looking into local fabricators, then enjoy the advantages of accuracy and creativity in sheet metal fabrication.

If you have the appropriate hardware and bolts, installing stainless steel handrails suppliers is simple. Usually, you have to drill pilot holes before screwing the barrier in place. But you have to be sure that the fasteners you use are suitable for the material the railing is attached to. For instance, masonry screws are required if you are mounting it to masonry.

Sturdiness and Robustness With An Affordable Solution

Fabricated metal components are renowned for their robustness and longevity. This dedication to environmental responsibility is consistent with more general sustainability objectives. Large-scale manufacturing can benefit greatly from the cost-effectiveness of fabrication methods. Working with standardised materials and effective production processes lowers costs and increases total value.

Designers and engineers frequently collaborate closely with fabricators to provide creative solutions for challenging issues. Their knowledge enables the development of unique parts and assemblies that push the limits of functionality and design. Many metal sheets fabricators reduce waste and recycle scrap metal as part of their sustainable business practices.

Durable And Simple To Clean

Given that stainless steel is among the world's hardest metals, it should come as no surprise that handrail and balustrades composed of stainless steel have a very long lifespan. They are resilient to wear and tear and can withstand the test of time before needing to be replaced. The advantages of stainless steel balustrades and handrails are guaranteed.

When it comes to converting flat metal sheets into items that are practical, long-lasting, and visually appealing, sheet metal fabricators are essential. Their proficiency in bending, cutting, shaping, welding, and finishing guarantees that bespoke metal structures and components are advantageous to a broad spectrum of businesses.

Source

0 notes

Text

Understanding Different Types of Fasteners Use Cases

Fastener supplier are crucial additives in nearly every construction, production, and engineering project. They are available numerous types, each designed for specific packages to ensure balance, strength, and security in assemblies. Whether you're worried in building infrastructure, production products, or project DIY projects, understanding the specific varieties of fasteners and their use cases can substantially effect the success and sturdiness of your paintings. In this blog, we will discover diverse forms of fasteners and their packages, with insights from Bullion Pipe, a leading fasteners producer and fastener provider.

1. Bolts

Bolts are flexible fasteners used to join materials collectively. They are typically paired with nuts and are regarded for his or her sturdy keeping energy. Bolts are available in various sorts, such as hex bolts, carriage bolts, and eye bolts, each designed for extraordinary packages.

Use Cases:

Construction: Used in building frameworks and bridges for structural integrity.

Automotive: Essential in assembling engine additives and chassis parts.

Manufacturing: Employed in machinery and system for meeting and restoring.

Key Features:

High tensile strength

Available in various sizes and substances, including stainless-steel and alloy metal

2. Screws

Screws are threaded fasteners designed to keep substances collectively with the aid of developing a robust inner grip. They come in numerous head types and thread patterns, together with flat-head screws, Phillips-head screws, and self-tapping screws.

Use Cases:

Woodworking: Ideal for joining timber components and cabinetry.

Electronics: Used to stable components within digital devices.

Drywall Installation: Employs drywall screws to connect sheets to framing.

Key Features:

Variety of thread styles for exceptional substances

Easy to power with not unusual gear like screwdrivers or drills

3. Nuts

Nuts are hexagonal fasteners used alongside bolts to stable or more additives together. They are to be had in distinctive styles, along with fashionable hex nuts, lock nuts, and wing nuts.

Use Cases:

Mechanical Assemblies: Used with bolts to assemble equipment and structural factors.

Automotive: Common in engine assemblies and suspension systems.

Furniture: Employed in the meeting of flat-p.C. Furnishings.

Key Features:

Provides secure fastening whilst paired with matching bolts

Available in diverse materials and coatings for unique applications

4. Washers

Washers are flat discs used to distribute the load of a fastener and offer an easy floor among the fastener and the material. They are available in kinds along with flat washers, lock washers, and spring washers.

Use Cases:

Preventing Loosening: Lock washers are used to save you nuts and bolts from loosening through the years.

Protecting Surfaces: Flat washers protect the fabric floor from damage resulting from the fastener.

Even Load Distribution: Used in diverse mechanical and structural applications.

Key Features:

Helps in load distribution and stopping damage

Available in numerous materials inclusive of metal and plastic

5. Rivets

Rivets are permanent fasteners used to join two or greater materials collectively through deforming one cease to create a steady bond. There are available sorts consisting of strong rivets, blind rivets, and pa rivets.

Use Cases:

Aerospace: Used in plane production for robust, vibration-resistant joints.

Construction: Ideal for fastening steel sheets in structural programs.

Automotive: Employed in automobile assembly for a strong, permanent connection.

Key Features:

Provides a permanent, tamper-evidence fastening

Suitable for applications wherein welding or other fasteners are not practical

6. Anchors

Anchors are fasteners designed to steady substances to a base or substrate. They come in various kinds, which include growth anchors, toggle anchors, and concrete anchors.

Use Cases:

Construction: Used to stable furnishings, hangings, and structural elements to concrete or masonry.

DIY Projects: Ideal for mounting cabinets, brackets, and other objects to walls.

Industrial: Used in system and machinery installations.

Key Features:

Provides a stable hold in numerous substrates

Available in unique designs for unique applications

7. Clips and Clamps

Clips and clamps are fasteners designed to maintain items collectively temporarily or permanently. They are available in various sorts, including spring clips, hose clamps, and panel clips.

Use Cases:

Automotive: Used for securing hoses, panels, and other components.

Manufacturing: Employed in assembly lines for containing parts in the area.

Electrical: Clips are used to steady cables and wires.

Key Features:

Offers brief and smooth fastening answers

Available in special designs to healthy particular desires

Conclusion

Understanding the extraordinary forms of fasteners and their applications is vital for making sure the achievement of your tasks, whether they are in construction, manufacturing, or any other industry. At Bullion Pipe, we pride ourselves on being a main fasteners manufacturer and fastener provider, presenting a wide range of exquisite fasteners tailored to meet various wishes. Our know-how guarantees that you get the proper fasteners to your precise programs, improving the durability and reliability of your assemblies.

For extra information on our fastener merchandise or to find the great fasteners in your venture, contact Bullion Pipe today. Our group of professionals is here to provide you with the help and solutions you need to achieve the fine outcomes.

0 notes

Text

India’s High Quality Stainless Steel Strips Supplier - Metal Supply Centre

Metal Supply Centre is one of the best Stainless Steel Strips Suppliers in India. Stainless steel strips are made of thin, flat pieces of steel that are usually produced in rolls or coils. Numerous industries, such as the automotive, aerospace, construction, and industrial sectors, frequently employ them. Strips of stainless steel come in a variety of grades and finishes, each having unique qualities appropriate for a range of uses.

These Stainless Steel Strips are provided with the highest grade raw materials. These SS Strips are supplied to a wide range of industries and applications, including the pulp and paper, petrochemical, power generating, pharmaceutical, heat exchanger, and condenser sectors. Our stainless steel strips are available in a variety of standards, including ASTM, ASME, AISI, DIN, BS, EN IS, JIS, and other international standards. They are also long-lasting and resistant to corrosion.

Types of Stainless Steel Strips

Stainless Steel 309 Strips- Metal Supply Centre is one of the largest SS 309 Strips Suppliers in India, We provide these strips in a range of sizes, shapes, and details. We make these items with premium quality raw materials and cutting-edge technologies in order to satisfy client demand and be the supplier of choice.

Stainless Steel 309s Strips- Stainless Steel 309s Strips Supplier is widely used in important fields such as boilers, energy (nuclear power, thermal power, fuel cells), industrial furnaces, incinerators, heating furnaces, chemical industry, petrochemicals industry, etc.

Stainless Steel 310s Strips- We specialise in the supply of Stainless Steel 310s Strips. Strips with export grade stainless steel raw material. Our company has been maintaining the stock of Stainless Steel 310s Strip at our godown in Mumbai. We supply SS 310s Strip that is made from the highest quality raw materials.

Stainless Steel 314 Strips- Metal Supply Centre is also called SS 314 Strips Supplier in India. Our highly competent experts ensure that quality is never compromised and as a leading Stainless Steel 314 Strips Supplier in India our Strips meet national and international requirements.

Stainless Steel 439 Strips- Many top-quality Stainless Steel 439 Strips Suppliers across the globe offer goods with complete certifications and faster response times. We can help you source the best quality product from the right source at the best price from any SS 439 Sheet Stockist globally.

What are stainless steel strips used for?

As stainless steel strips have a special blend of strength, durability, and corrosion resistance, they are utilised extensively in many different sectors. Stainless steel strips are used in architectural constructions, roofs, and facades by the building sector because of their durability.They are made from primary steel that has been heated, rolled to the appropriate thickness, and sliced to the appropriate width after it has been formed into a slab.

Benefits Of Stainless Steel Strips

Developing and Architecture

Structural Components: Because stainless steel strips are strong and resistant to climatic conditions, they are utilised for structural elements including columns, beams, and support systems.

Cladding and Facades: They are used in building facades and cladding for their aesthetic appeal and resistance to weathering.

Strength and Durability: SS Strips Suppliers are high tensile strength and resilience, making them suitable for applications requiring robust materials.

Manufacturing and Industrial Applications:

Machinery Parts: Stainless steel strips are used to manufacture various machinery parts due to their strength and resistance to wear and tear.

Springs and Fasteners: They are used in making springs, screws, bolts, and other fasteners for their flexibility and resilience.

Consumer Goods:

Kitchenware: steel strips are used to make kitchenware such as knives, forks, spoons, and cookware for their rust resistance and ease of cleaning.

Home Appliances: They are used in the construction of home appliances like refrigerators, dishwashers, and washing machines due to their durability and aesthetic appeal.

Energy Sector:

Oil and Gas: SS Strips are used in pipelines, storage tanks, and offshore rigs in the oil and gas industry for their resistance to corrosion and harsh environmental conditions.

Renewable Energy: They are used in solar panels, wind turbines, and other renewable energy systems for their durability and efficiency.

In Conclusion, Stainless steel strips are an essential component in various industries due to their remarkable properties and versatile applications. Known for their exceptional resistance to corrosion, high tensile strength, and durability, these strips are widely used in manufacturing, construction, automotive, and household goods. The ability to withstand extreme temperatures and harsh environments without degrading ensures their longevity and reliability in demanding applications.

For more detail,visit

Website: metalsupplycentre.com

Product source: SS Strips Suppliers in India.

#Stainlesssteelstripssuppliersinindia#Stainlesssteelstripssuppliers#Stainlesssteelstripssupplier#Stainlesssteelstrips#SSStripsSuppliersinIndia#SSStripsSuppliers#SS309StripsSuppliersinIndia#StainlessSteel309sStripsSupplier#StainlessSteel310sStrips#SS314StripsSupplierinIndia#StainlessSteel439SheetSuppliers

0 notes

Text

Types of Screws for Every Construction Project

In the area of manufacturing, screws are imperative components that play a critical feature in becoming a member of substances and presenting structural assist. From woodwork and steel fabrication to drywall installation and fixtures meeting, screws are available in several sorts, every designed for unique packages. As a high screw producer and company, FastenersLLP is dedicated to imparting super screws tailor-made to meet the numerous desires of advent responsibilities. Let's find out the brilliant styles of screws and their programs.

Understanding the Basics

Before delving into the types of screws, it's critical to understand the number one additives of a screw:

Head: The top is a part of the screw, in which using the device is finished for set up.

Thread: The spiral grooves that wrap at some point of the shaft of the screw, supplying grip and preserving energy.

Shaft: The essential frame of the screw, generally cylindrical in shape.

Point: The tapered saves you of the screw that permits it to penetrate the fabric.

Types of Screws

Wood Screws: Designed for use in woodworking responsibilities, timber screws feature coarse threads and a sharp factor for smooth penetration into wood. They are available in several head types, which encompass flat head, oval head, and spherical head, every appropriate for particular applications.

Sheet Metal Screws: These screws are especially designed for fastening thin steel sheets or panels. They have sharp threads and a flat or pan head, making them ideal for attaching metallic to metallic or metallic to wood.

Drywall Screws: Used for putting in drywall panels, those screws have wonderful threads and a bugle head, which allows to prevent tearing of the drywall paper. They are available in awesome lengths to house numerous drywall thicknesses.

Concrete Screws: Also known as masonry screws, those screws are used for fastening materials to concrete, brick, or block. They function as a hardened metal frame with coarse threads and a flat, hex, or Phillips head designed for use with a drill and reason pressure.

Machine Screws: Machine screw manufacturer is designed to be used with nuts or tapped holes and are normally carried out in metalworking and tool meeting. They have finer threads and are to be had loads of head kinds, which include flat head, spherical head, and pan head.

Choosing the Right Screw for Your Project

When deciding on the proper screw on your introduction challenge, go through in mind the subsequent factors:

Material: Choose a screw crafted from a fabric appropriate for the software program application, together with stainless steel for out of doors use or hardened steel for heavy-duty programs.

Length and Diameter: Ensure the screw duration and diameter are nicely matched with the materials being joined and the thickness of the cloth.

Head Type: Select the right head type based on the preferred appearance and capability of the finished assignment.

Why Choose FastenersLLP?

As a relying on screw supplier and company, FastenersLLP gives a widespread form of superb screws designed to fulfill the numerous desires of manufacturing tasks. From timber screws and sheet steel screws to drywall screws and concrete screws, we provide dependable solutions for all of your fastening dreams.

With our willpower to terrific reliability, and customer satisfaction, FastenersLLP is your one-save you destination for pinnacle-notch screws that supply wonderful everyday traditional average overall performance and durability. Contact us in recent times to investigate approximately our whole fashion of screws and the manner we are capable of using to aid your creation projects.

In the give up, deciding on the proper shape of screw is vital for the fulfillment of any creation challenge. By statistics approximately the outstanding sorts of screws to be had and considering factors at the side of fabric, length, and head kind, you may make knowledgeable alternatives and make certain pinnacle-rated regular not unusual standard performance and longevity in your projects. Trust FastenersLLP to provide notable screws that meet your unique specifications and exceed your expectancies.

0 notes

Text

Fasteners Manufacturer in India - Sachiya Steel International

Fasteners Manufacturer in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Fasteners worldwide. We are India's largest Bolts Exporter, exporting to more than 85 countries. We are known as Fasteners Manufacturers and Exporters due to exporting and manufacturing on a large scale worldwide.

Sachiya Steel International manufacture a wide variety of Fasteners. There is a different types of fastener used for different needs. Some fasteners are used with each other such as Bolts and Nuts. Our Fasteners are available in different grades, sizes and shapes. Sachiya Steel International manufactures and exports high-quality industrial Fasteners. We are Manufacturers Suppliers Exporters of the following Fasteners -Bolts, Nuts, Screws, Washers, Rings, Threaded Rods.

About Bolt Fasteners -

A bolt is a form of threaded fastener with an external male thread. Bolts are closely related to screws. People misunderstand the difference between bolts and screws. Bolts are often used to make a bolted joint. This is a combination of the nut applying an axial clamping force and also the shank of the bolt acting as a dowel, pinning the joint against sideways shear forces. For this reason, many bolts have a plain unthreaded shank (called the grip length) as this makes for a better, stronger dowel. The presence of the unthreaded shank has often been given as characteristic of bolts vs. screws, but this is incidental to its use, rather than defining.

About Nut Fasteners -

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction (with slight elastic deformation), a slight stretching of the bolt, and compression of the parts to be held together. Today Hex Nuts are used when a maximum amount of torque and grip is needed for a given size. Sachiya Steel International manufactures and exports high-quality Nuts.

About Screws Fasteners -

A screw is a type of fastener, in some ways similar to a bolt, typically made of metal, and characterized by a helical ridge, known as a male external thread. Screws are used to fasten materials by digging in and wedging into a material when turned, while the thread cuts grooves in the fastened material that may help pull fastened materials together and prevent pull-out. There are many screws for a variety of materials; those commonly fastened by screws include sheet metal, wood, and plastic.

About Washers Fasteners -

A washer is a thin plate (usually disk-shaped) with a hole (usually in the middle) that is normally used to distribute the load of a threaded fastener, such as a bolt or nut. Other uses are as a spacer, spring washer, wear pad, preload indicating device, locking device, and to reduce vibration (rubber washer). Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely. Washers are usually made of metal or plastic depending on the use.

About Rings Fasteners -

A Ring is a fastener that holds components or assemblies onto a shaft or in a housing/bore when installed - typically in a groove - for one time use only. Once installed, the exposed portion acts as a shoulder which retains the specific component or assembly. Circlips are a type of Rings. Rings are typically made from carbon steel, stainless steel and may feature a variety of finishes for corrosion protection depending on the type of environment in which they are used.

Fasteners Rods Manufacturers in India:

About Threaded Rods Fasteners - A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod. They are designed to be used in tension. Threaded rod in bar stock form is often called all-thread. Threaded Rods are of different types, depending on the use the type is selected. Sachiya International has Fully Threaded Studs, Double Ended Threaded Studs, Zinc Plated Threaded Rods, and Body Studs. Sachiya Steel International is known as Manufacturer Exporter of Threaded Rods.

Fasteners Manufacturers In Mumbai

Welcome to Sachiya Steel International. We are your top manufacturer of high quality stud bolts. We also produce nut bolts. Our products are made with the finest raw materials. This is our commitment to excellence. Our High Quality products include high tensile fasteners. They meet the industry's demanding standards. We focus on quality. Thus, we ensure that our products exceed customer expectations. You can trust Sachiya Steel International. Select us for reliable fastening solutions. Our products are durable. They are precision-engineered, too. Join our satisfied clients. Choose us as your source for supreme stud bolts. Choose us for nut bolts, too.

Fasteners Manufacturers in India: Industrial Fasteners uses -

Oil & Gas Industries

Petroleum Industries

Nuclear Energy Sector

Aerospace Industry

Defence Industry

Cities we supply Fasteners to -

Sachiya Steel International is manufacturer supplier of fasteners in most of the major Indian cities in more than 20 states. We are leading supplier of Fasteners in Mumbai, Ahmedabad, Ludhiana, Delhi, Rajkot, Pune, Coimbatore, Chennai, Bangalore and many other cities.

Sachiya Steel International Exports Fasteners to following countries -

Fasteners exporters in Saudi Arabia, Oman, Dubai, UAE, Mexico, Kuwait, Qatar, Iraq and many other countries. Sachiya Steel International has created a brand name for itself in the international market, by exporting large quantities of high-quality fasteners.

Read More: https://sachiyasteel.com/fasteners-manufacturers-in-india.php

0 notes

Text

The Power of Ecosyn®-MRX Self-Drilling Screws

In the world of construction, manufacturing, and engineering, efficiency and reliability are paramount. Ecosyn®-MRX self-drilling screws have emerged as a game-changing solution, revolutionizing fastening processes and setting new standards for performance and durability.

Let's explore the innovative features and benefits of Ecosyn®-MRX self-drilling screws and their impact on various industries.

The Evolution of Fastening Technology

Traditional fastening methods often involve multiple steps, including pre-drilling holes and tapping threads, which can be time-consuming and labor-intensive. Ecosyn®-MRX self-drilling screws simplify this process by combining drilling and fastening into a single step. The unique self-drilling point of these screws eliminates the need for pre-drilling, allowing for faster installation and significant time savings.

Superior Performance in Metal-to-Metal Applications

Ecosyn®-MRX self-drilling screws are specifically engineered for use in metal-to-metal applications, where conventional fasteners may struggle to provide secure connections. Whether it's joining steel beams in construction projects or assembling metal components in manufacturing processes, Ecosyn®-MRX screws excel in providing high-strength, reliable connections that withstand the rigors of heavy-duty applications.

Advanced Features for Enhanced Durability

One of the key features of Ecosyn®-MRX self-drilling screws is their advanced design and construction, which ensures superior durability and performance. These screws are manufactured from high-quality materials, such as hardened steel or stainless steel, to withstand corrosion, wear, and extreme environmental conditions. Additionally, they may feature specialized coatings or treatments for added protection against rust and corrosion, prolonging the lifespan of the fasteners and the structures they secure.

Efficiency and Cost Savings

By eliminating the need for separate drilling operations, Ecosyn®-MRX self-drilling screws offer significant efficiency gains and cost savings. The streamlined installation process reduces labor costs and minimizes downtime, allowing projects to be completed faster and more efficiently. Additionally, the high-strength, reliable connections provided by Ecosyn®-MRX screws help prevent rework, repairs, and maintenance, further reducing overall project costs and maximizing return on investment.

The screws are manufactured from a martensitic, hardened and tempered chrome steel with higher resistance to corrosion (comparable with A2 grade stainless steel). Besides aluminium also sheet steel and rust-resistant thin sheet metal can be drilled through.

Advantages:

Strength greater than A2 or A4

No erosion in the thread, even when using rust-resistant thin steel sheet

No surface corrosion

High drilling performance

Corrosion-resistant connections are economic and offer top reliability

Areas of applicaiton and use:

Sheet metal construction

Heating and ventilation ducts

Household machines

Vehicle body construction

Window frames and blinds

Façade construction

Conservatories and winter gardens

Construction of cabins

...and many more

Brochure Self-Cutting Screws - Direct Screwing in One Step

Download Now

Visit our E-Shop for more technical details and orders or contact us directly

View product details in the E-Shop.

Learn more about LPS Bossard

Phone : +91 1262 205 205 Whatsapp : +91 9817708334

Email : [email protected] Website : www.bossard.com

About Bossard India

0 notes

Text

The Essential Role of Aviation Hardware Parts in Modern Aircraft

In the high-stakes world of aviation, where precision and reliability are non-negotiable, aviation hardware parts form the backbone of aircraft construction and maintenance. These components, though often small, are integral to the safe and efficient operation of aircraft. In this blog, we will explore the significance of aviation hardware parts, discuss their various types and functions, and answer some common questions related to this crucial aspect of aviation.

Understanding Aviation Hardware Parts

Aviation hardware parts encompass a wide range of components used in the construction, maintenance, and repair of aircraft. These include fasteners, bolts, nuts, washers, rivets, and other small yet essential pieces that hold the aircraft together and ensure its structural integrity.

Types of Aviation Hardware Parts

Fasteners: These are used to join two or more components securely. Fasteners include bolts, screws, and nuts, which are designed to withstand the high-stress conditions of flight.

Rivets: Rivets are permanent mechanical fasteners commonly used in aircraft assembly. They are critical for securing metal sheets together, providing strength and stability to the aircraft’s structure.

Washers: These are used in conjunction with bolts and nuts to distribute load and prevent damage to the surfaces being joined. Washers help in maintaining the integrity of the fastening system.

Clamps and Brackets: These components are used to hold various systems and equipment in place within the aircraft. They ensure that cables, pipes, and other elements are securely fastened, preventing movement during flight.

Pins and Cotter Pins: These are used to secure joints and other parts that require a secure, yet easily removable, connection. They are essential in areas where frequent disassembly and reassembly are necessary.

The Importance of Aviation Hardware Parts

Ensuring Structural Integrity

Aviation hardware parts are critical for maintaining the structural integrity of an aircraft. They hold various parts of the aircraft together, ensuring that all components remain securely in place during flight. The reliability of these parts is crucial for the overall safety of the aircraft.

Enhancing Safety and Performance

High-quality aviation hardware parts are designed to withstand extreme conditions, including high stress, vibration, and temperature variations. Their durability and precision are vital for the safe operation of the aircraft, preventing potential failures that could lead to accidents.

Facilitating Maintenance and Repairs

The standardization of aviation hardware parts simplifies maintenance and repair processes. These parts are designed to be easily replaced and are available in standardized sizes and specifications, making it easier for maintenance crews to perform repairs quickly and efficiently.

Frequently Asked Questions (FAQs)

What are aviation hardware parts, and why are they important?

Aviation hardware parts include a variety of small components such as fasteners, rivets, washers, and clamps used in aircraft construction and maintenance. They are important because they ensure the structural integrity and safety of the aircraft by securely holding various parts together.

How do rivets contribute to the structural integrity of an aircraft?

Rivets are used to permanently fasten metal sheets and components together, providing strength and stability to the aircraft's structure. They are essential in areas where welding is not feasible, ensuring a secure and durable connection that can withstand the stresses of flight.

What are the common materials used in aviation hardware parts?

Common materials used in aviation hardware parts include aluminum, titanium, and stainless steel. These materials are chosen for their strength, lightweight properties, and resistance to corrosion and high temperatures, making them ideal for the demanding conditions of aviation.

How does the quality of aviation hardware parts impact aircraft safety?

The quality of aviation hardware parts directly impacts aircraft safety by ensuring that all components are securely fastened and capable of withstanding the rigors of flight. High-quality parts reduce the risk of mechanical failures, contributing to the overall safety and reliability of the aircraft.

Conclusion

Aviation hardware parts are indispensable components in the aviation industry, playing a crucial role in ensuring the safety, performance, and reliability of aircraft. From fasteners and rivets to washers and clamps, these small parts are vital for maintaining the structural integrity and operational efficiency of aircraft. As aviation technology continues to advance, the importance of high-quality hardware parts remains paramount. For comprehensive maintenance solutions and access to top-quality aviation hardware parts, consider Aero Logistic Support, your trusted partner in aviation excellence.

0 notes

Text

Rivet Applications in Modern Construction

Strength and Versatility in Building

Rivets have been a cornerstone in construction for centuries, providing robust and reliable fastening solutions for various structures. In modern construction, rivet technology has evolved significantly, offering advanced solutions that cater to the industry's dynamic needs. This blog post explores the diverse applications of rivets in contemporary construction, highlighting their benefits and specific use cases.

Structural Steel Construction

One of the primary applications of rivets in modern construction is in the assembly of structural steel frameworks. Rivets provide strong and permanent joints that are essential for the integrity of large structures such as skyscrapers, bridges, and industrial buildings. Unlike bolts and screws, rivets do not loosen over time, making them ideal for joints subjected to constant stress and heavy loads.

Example: Rivets are extensively used in the construction of high-rise buildings. They ensure that the steel beams and columns are securely fastened, providing the necessary stability and strength to support the entire structure.

Facade and Cladding Systems

Modern buildings often feature complex facade designs that require reliable fastening solutions. Rivets are commonly used to attach cladding panels to the building's framework. Their ability to provide a clean and aesthetically pleasing finish makes them a preferred choice for architects and builders.

Example: The installation of metal cladding on commercial buildings is carried out using aluminium and steel rivets, which makes it look smooth and makes it durable and resistant to different weather conditions.

HVAC and Ductwork Installation

In HVAC (Heating, Ventilation, and Air Conditioning) systems, rivets are used to affix and form ductwork. Their quick-to-do and strong stability make them perfect for connecting and supporting rods and shafts to walls and ceilings.

Example: Sometimes, blind rivets are the best choice especially in HVAC applications where access to the backside of the joint is limited. They make it easier to fix without causing any leaks. This method works effectively for joining these steel ducts.

Roofing and Gutter Systems

Attaching metal sheets for the roofing, channel strips and, assemble

gutter systems, are the main applications for rivets. The security and

resistance to climatic conditions of the rivets make the above materials

permanent for decades. Example: It's no wonder that they would choose stainless steel rivets in the aforementioned situation, as they provide the best performance in terms of moisture and salt resistance.

Window and Door Frames

Rivets are a common fastening method for installing windows and doors due to the reason they could keep security and protection of the structures along with windows frames and other parts of the building. They are simply used to linking frames during the installation process and also for fastening beading panels which forming a firm junction for the windows and doors.

Example: Rivets belong to the category of fasteners, mostly used in

situations of splintering of windows sis doors in modern commercial

buildings and organizations which are used for unwanted entry.

Innovative Architectural Designs

Nowadays we see different designs of architecture which have put custom fastening solutions at the forefront of the designer's attention. For the bond, the goods constructed from the mentioned material such as titanium or high-strength aluminium, as the primary element, are being displayed.

Since they are so important, they can serve projects beyond the mainstream, such as those with complex geometric facades or those who possess highly minimalist yet extremely durable structures.

Example: In the construction of contemporary art museums

and innovative commercial spaces, rivets provide the flexibility and strength needed to bring complex architectural visions to life.

Conclusion

Rivets are currently recognized to be an essential or essential component in the building sector and are popularly known for their toughness, long life span, and their attraction specifically to customers. No matter what the use, such as industrial steel constructions, exterior facades, cladding to HVCC systems, or futuristic design, rivets should be thought of as a crucial link between the integrity and life of the new structure and as such deserve due attention from professional builders in using them. As building techniques get better and materials change, rivets are still going to be useful by providing access to better fastening methods that will always correspond to the needs of the industry.

1 note

·

View note

Text

Threaded Equal Tee Exporters in India

INTRODUCTION:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

The most popular kind of pipe fitting that can be used to combine or divide liquid streams is a threaded tee fitting. The ASTM A182 SS Threaded Tees can be accessed via a female-threaded side outlet and female thread sockets, solvent-weld sockets, or solvent-weld sockets.

Threaded Equal Tees can be used to divert a pipe run, connect pipes of different diameters, or do both. A stock list of forged threaded tees made in various materials, sizes, and wraps is available at Shasan Piping Solution. Additionally, the screwed tee made of alloy steel can also be used to transfer two liquid combinations. Based on their three connections, tees can be classified as equal or unequal in size, with equal tees being the most often produced kind.

DESCRIPTION:-

These threaded tee fittings have undergone additional treatments, one of which includes surface treatments, to improve their outer layer. The threaded tee ASME B16.11 is available in several completions. Typical finishes for the outer layer of the threaded tee include electroplating, nickel plating, white coating, dark cast, gold plating, excited finish, and so forth. While these treatments provide an external advantage to the ASME B16.11 threaded tee features, there should occasionally be an opportunity to further enhance its mechanical qualities, such as by boosting its resistance to and tensile strength of erosion.

Most commonly, cast metal or bronze, forged alloy and carbon steel, or cast dark or flexible iron could be used to make threaded screwed tee fittings. Alternatively, alternative materials such as stainless steel, aluminum, nickel, cast iron, bronze, plastic, elastic, copper, metal, polypropylene, etc. might also be used to make the ASTM A182 SS Threaded Tees. There are three tension ratings available for the ASME B16.11 threaded tee fitting aspects: Class 2000, Class 3000, and Class 6000.

Presumably, the earliest technique for connecting pipe systems is represented by the threaded tee fitting characteristics of ASME B16.11. The ASME B16.11 threaded tee fittings, often called little drag pipework, are mostly used for small pipe diameters, much as socket weld fittings. Little drag pipe is typically defined as piping with an apparent diameter of NPS 2 or less.

SPECIFICATIONS:-

1. Specifications- Forged Threaded equal tee

2. Dimension Specification- ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

3. Threaded equal tee Forged Fittings Thread- NPT, BSPT, BSPP

4. Threaded equal tee FittingsType- DN15-DN1200

5. End- Threaded, Welding, JIC

6. Threaded equal tee Fittings Pressure Rating- Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee, Connection, Welding

7. Bending Radius- R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 8. Threaded equal tee

8. Size Range- 1/8" NB TO 4" NB

9. Manufacturing process- Push, Press, Forge, Cast, etc.

10. Threaded equal tee Test Certificates- EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc

11. Origin & Mills - Japanese, Indian, USA, Korean, European, Ukraine, Russian

12. Key markets and industries for Threaded equal tee Fittings- Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals and acids.

13. Application - Threaded equal tee To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc.

BENEFITS:-

High-Quality Products: Threaded equal tee exporters provide products that meet international standards such as ASME 16.11, MSS SP-79, and BS 3799. This ensures that the tees are of superior quality and suitable for various industrial applications.

Wide Range of Options: Exporters offer a diverse range of threaded equal tees, including different sizes, pressure ratings, and materials. This variety allows customers to find the perfect fit for their specific requirements, enhancing flexibility and compatibility with existing systems.

Ease of Installation: Threaded connections offer ease of installation, allowing for quick and hassle-free assembly of piping systems. Threaded equal tees provide a secure and reliable connection without the need for specialized tools or welding, saving time and labor costs during installation.

Versatility: Threaded equal tees are versatile components that can be used in a wide range of industries and applications, including petroleum, chemical, construction, and shipbuilding. Their ability to connect three pipes of equal diameter at right angles makes them essential for branching and distributing fluid flow in piping systems.

Customization Options: Exporters often offer customization options for threaded equal tees, allowing customers to tailor the fittings to their specific needs. Whether it's a particular size, material, or threading requirement, exporters can accommodate various customization requests to meet customer specifications.

Reliable Supply Chain: Exporters ensure a reliable supply chain, ensuring timely delivery of threaded equal tees to customers worldwide. With a robust manufacturing infrastructure and efficient logistics network, exporters can fulfill orders promptly, minimizing downtime and maximizing operational efficiency for businesses.

CONCLUSION:-

In conclusion, threaded equal tee exporters play a crucial role in providing high-quality fittings for industrial piping systems. By offering a wide range of options, ease of installation, versatility, customization capabilities, and a reliable supply chain, exporters empower businesses to optimize their piping systems for enhanced efficiency and performance. Threaded equal tees serve as integral components in various industries, facilitating the distribution and control of fluid flow in piping networks. With a commitment to quality, reliability, and customer satisfaction, threaded equal tee exporters contribute to the success and competitiveness of industries worldwide.

CONTACT US:-

Phone :+91-88797-09191

Phone :+91-22-6651 8642

E-mail : [email protected]

#Threaded Equal Tee Manufacturers#Threaded Equal Tee Suppliers#Threaded Equal Tee Stockists#Threaded Equal Tee Exporters#Threaded Equal Tee Manufacturers in India#Threaded Equal Tee Suppliers in India#Threaded Equal Tee Stockists in India

0 notes

Text

Steel Market — Forecast (2024–2030)

Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

Steel Market Segment Analysis – By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis – By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

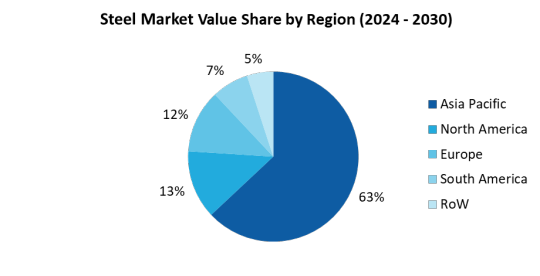

Steel Market Segment Analysis - By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market - Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

0 notes

Text

Door Skin A Comprehensive Overview for Homeowners

As a homeowner, selecting the right door materials is crucial for enhancing the aesthetic appeal, functionality, and durability of your home's interiors. Door skin, also known as door facing or door veneer, is a popular choice due to its versatility, cost-effectiveness, and aesthetic options. In this comprehensive overview, we'll delve into the features, benefits, types, installation, maintenance, and design possibilities of door skin for homeowners.

Features of Door Skin:

Material Composition: Door skin is typically made from thin sheets of materials such as wood veneer, PVC (Polyvinyl Chloride), HDF (High-Density Fiberboard), MDF (Medium-Density Fiberboard), or metal. These materials offer varying degrees of durability, finish options, and customization possibilities.

Durability: High-quality door skins are durable, scratch-resistant, moisture-resistant, and easy to clean, making them suitable for both interior and exterior doors.

Design Options: Door skins come in a wide range of designs, colors, textures, and finishes to suit different interior styles, from classic and traditional to modern and contemporary.

Cost-Effective: Compared to solid wood or metal doors, door skins are more affordable while offering similar aesthetic appeal and functionality.

Benefits of Door Skin for Homeowners:

Aesthetic Appeal: Door skins enhance the visual appeal of doors with their decorative patterns, wood grain finishes, textured surfaces, and vibrant colors, adding a touch of elegance to your home.

Versatility: Door skins can be used for various types of doors, including interior doors, exterior doors, wardrobe doors, cabinet doors, and more, providing design consistency throughout your home.

Customization: Homeowners can customize door skins by choosing specific designs, colors, textures, and finishes that complement their interior décor and personal preferences.

Easy Installation: Installing door skins is relatively straightforward and can be done by professionals or DIY enthusiasts using adhesives, screws, or nails to secure the skin onto the door frame.

Low Maintenance: Door skins require minimal maintenance, occasional cleaning with a damp cloth or mild detergent, and routine inspection for any damages or wear and tear.

Types of Door Skin:

Wood Veneer Door Skin: Made from thin slices of natural wood, wood veneer door skins offer a classic and authentic wood grain appearance, available in various wood species such as oak, walnut, maple, cherry, and more.

PVC Door Skin: PVC door skins are durable, moisture-resistant, and come in a wide range of colors, patterns, and textures, including matte, glossy, embossed, and printed designs.

HDF/MDF Door Skin: High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) door skins are engineered wood products that offer versatility, durability, and a smooth surface for painting, laminating, or veneering.

Metal Door Skin: Metal door skins, such as stainless steel or aluminum, provide a sleek and modern appearance, ideal for contemporary interiors or commercial applications.

Installation Process:

Prepare the Door: Ensure that the existing door frame is clean, dry, and free from any defects or damage. Remove old paint, varnish, or adhesive residues as needed.

Cut the Door Skin: Measure the dimensions of the door frame and cut the door skin to fit using a sharp utility knife, saw, or scissors, leaving allowances for edges and corners.

Apply Adhesive: Apply a suitable adhesive (recommended by the manufacturer) evenly on the backside of the door skin, covering the entire surface area but avoiding excessive application to prevent seepage.

Attach the Door Skin: Carefully position the door skin onto the door frame, starting from one edge and smoothing out any air bubbles or wrinkles as you go along. Use a roller or flat tool to press the door skin firmly onto the surface.

Trim and Finish: Trim any excess door skin material using a sharp blade or router, and finish the edges with edge banding, trim pieces, or molding for a clean and seamless appearance.

Allow for Drying and Curing: Allow the adhesive to dry and cure as per the manufacturer's instructions before using the door. Avoid excessive moisture exposure during this period to ensure proper bonding.

Maintenance Tips for Door Skin:

Regular Cleaning: Wipe the door skin surface regularly with a soft cloth or sponge dampened with mild detergent and water to remove dust, dirt, or stains.

Avoid Harsh Chemicals: Avoid using abrasive cleaners, solvents, bleach, or harsh chemicals on the door skin as they may damage the finish or surface texture.

Protective Measures: Use door mats, rugs, or protective pads near doors to prevent scratches, dents, or impact damage from heavy objects or footwear.

Inspect for Damage: Periodically inspect the door skin for any signs of damage, peeling, or delamination, and address any issues promptly to prevent further deterioration.

Design Possibilities with Door Skin:

Wood-Look Finishes: Achieve the warmth and elegance of natural wood with wood veneer door skins, available in various wood species and finishes like oak, walnut, cherry, mahogany, and more.

Contemporary Patterns: Explore modern and contemporary designs with PVC door skins featuring geometric patterns, abstract motifs, floral prints, metallic finishes, or minimalist textures.

Textured Surfaces: Add depth and tactile appeal to your doors with textured door skins, including embossed patterns, brushed textures, leather-like surfaces, or stone-inspired finishes.

Customized Graphics: Personalize your doors with custom graphics, artwork, logos, or branding elements printed on PVC or metal door skins for a unique and distinctive look.

Color Options: Choose from a spectrum of colors and shades to match your interior color scheme, create contrasts, or make a bold statement with vibrant hues or subtle neutrals.

Conclusion:

Door skin offers homeowners a cost-effective, versatile, and stylish solution for enhancing the appearance of doors throughout their homes. With a wide range of materials, designs, textures, finishes, and customization options available, door skins allow homeowners to achieve luxurious aesthetics, durability, and functionality while staying within budget constraints. Whether you prefer the classic charm of wood veneer, the contemporary appeal of PVC patterns, the durability of metal surfaces, or customized graphics, door skin provides endless design possibilities to elevate your home's interior décor.

0 notes

Text

Mastering Socket Screws: Your Guide to Efficient Fastening | Anand steels

A crucial component of manufacturing and building is fastening, and the end product's strength and longevity can be significantly impacted by the fasteners used. The socket screw is one kind of fastener that has grown in popularity due to its effectiveness and dependability. We will delve into the world of socket screw fasteners in this extensive guide, covering their uses, advantages, and how to utilize them effectively.

Understanding Socket Screw Fasteners

Because of its remarkable strength and dependability, socket screw fasteners—also referred to as bolt and screw fasteners—are extensively utilized in a variety of industries. Because of their recessed drive design, these fasteners can be inserted using an Allen wrench or hex key. Its low-profile design, effective torque transfer, and increased security are just a few benefits of this design element.

The Versatility of Socket Screw Fasteners

One of the key advantages of socket screw fasteners is their versatility. They are available in a wide range of materials, including stainless steel, nickel alloys, and other specialty metals, making them suitable for diverse applications. Whether it's for construction, machinery, automotive, or electronics, socket screw fasteners offer a reliable solution for fastening needs.

Exploring the Types of Socket Screw Fasteners

Socket screw fasteners come in various types, each designed for specific applications. Self-tapping screw fasteners, for instance, are ideal for creating threads in materials such as metal, plastic, or wood without the need for pre-drilling. Threaded rod fasteners, on the other hand, provide a flexible fastening solution for structural and mechanical applications, allowing for adjustable lengths and easy installation.

Mastering the Art of Socket Screw Fastening

To achieve efficient and reliable fastening with socket screw fasteners, it is crucial to understand the proper techniques and best practices. Ensuring the correct selection of fasteners based on material, load requirements, and environmental factors is essential for achieving optimal performance. Additionally, proper installation techniques, including torque specifications and thread engagement, play a critical role in the success of socket screw fastening applications.

Anand Steels: Your Trusted Partner for Quality Fastening Solutions

When it comes to sourcing high-quality socket screw fasteners and other fastening solutions, Anand Steels stands out as a leading importer and exporter in the industry. With a commitment to excellence and customer satisfaction, Anand Steels offers a comprehensive range of stainless steel shims, strips, coils, foils, round bars, and specializes in nickel alloys. Their expertise and years of experience have established them as a reliable and trusted supplier in the industry.

Contact Anand Steels for Your Fastening Needs

In conclusion, mastering socket screw fasteners is essential for achieving efficient and reliable fastening in various applications. With their unwavering commitment to quality and customer satisfaction, Anand Steels is your go-to partner for high-quality stainless steel solutions. Whether you require duplex and super duplex sheets and plates or any other stainless steel products, Anand Steels has the expertise and resources to meet your specific requirements. Contact Anand Steels today to experience excellence in fastening solutions and benefit from their comprehensive range of products tailored to various industries.

In summary, socket screw fasteners, including self-tapping screw fasteners and threaded rod fasteners, offer versatile and reliable solutions for diverse fastening needs. Anand Steels' dedication to quality and customer satisfaction makes them the ideal partner for sourcing high-quality fastening solutions. With their wide range of products and industry expertise, Anand Steels is poised to meet the specific requirements of various industries, delivering durable and corrosion-resistant materials for efficient and reliable fastening solutions.

0 notes

Text

Fastener Manufacturer, fastener supplier

Fasteners are vital components used to join or regular or more objects together. From simple screws and bolts to specialized rivets and anchors, fasteners are available in severa sorts and sizes, each designed for precise packages. In this blog publish, Fasteners LLP will help you discover the tremendous kinds of fasteners, their uses, and provide recommendations on a way to pick out the right one to your desires.

Types of Fasteners:

1. Screws: Screws are threaded fasteners with a helical ridge that allows them to be pushed into substances which includes wooden, metal, or plastic. They are to be had in numerous head sorts, such as flat head, spherical head, pan head, and countersunk head, each appropriate for extremely good packages.

2. Bolts: Bolts are much like screws however are usually used with a nut to lock or more elements collectively. They are to be had in one-of-a-kind lengths, diameters, and thread pitches, and are to be had in a vast sort of materials, which incorporates steel, stainless steel, and brass.

3. Nuts: Nuts are internally threaded fasteners which can be used collectively with bolts to secure gadgets together. They are available in various sorts, which includes hex nuts, lock nuts, wing nuts, and acorn nuts, every designed for particular packages and environments.

4. Washers: Washers are skinny, flat discs with a hole inside the middle which might be placed some of the top of a bolt or screw and the surface of the material being fixed. They distribute the burden and prevent damage to the material, in addition to offer an easy bearing surface for the fastener.

5. Rivets: Rivets are permanent fasteners used to enroll in or greater substances collectively. They include a cylindrical shaft with a head on one give up and are hooked up thru deforming the shaft to form a 2d head, growing a sturdy and constant connection.

Uses of Fasteners:

Fasteners by Fasteners LLP are used in an extensive sort of industries and applications, together with advent, automotive, aerospace, electronics, and manufacturing. Some not unusual uses of fasteners embody:

- Joining structural components in buildings and bridges.

- Assembling fixtures and cabinetry.

- Securing electric and plumbing furniture.

- Mounting hardware and system.

- Repairing device and device.

- Installing car components and add-ons.

- Fabricating sheet metal assemblies.

- Constructing and repairing fences, gates, and railings.

How to Choose the Right Fastener:

Choosing the right fastener on your application is based upon on numerous elements, along side:

1. Material Compatibility: Consider the material of the gadgets being joined and select fasteners made from compatible substances to save you corrosion and make certain long-time period durability.

2. Strength Requirements: Determine the load and stress necessities of the utility and pick out fasteners with the right electricity score to face up to the forces they may be subjected to.

3. Environmental Conditions: Consider the running environment, collectively with factors together with temperature, humidity, exposure to chemical substances, and corrosion, and select fasteners with appropriate coatings or substances that may withstand the ones conditions.

4. Size and Dimensions: Ensure that the dimensions, diameter, length, and thread pitch of the fastener are well suited with the substances being joined and the layout specifications of the software.

5. Head Type: Choose the first-rate head kind for the software, thinking about elements together with accessibility, look, and the want for flush or countersunk set up.

6. Installation Method: Consider the method of set up, whether or not guide or automated, and pick fasteners which are probably well suited with the installation equipment and techniques to be had.

Conclusion:

Fasteners are crucial components applied in a large form of programs to enroll in or stable devices together. By recording the special types of fasteners they make use of, and the manner to select the proper one for your wishes, you can ensure strong, steady, and reliable connections to your tasks. Whether you're building a shape, assembling fixtures, or repairing equipment, deciding on the right fastener is crucial for accomplishing maximum beneficial general overall performance and sturdiness.

0 notes