#sterilizeation

Explore tagged Tumblr posts

Text

PES Membrane Filters Manufacturer in India - Trinity Filters

Explore PE Series Membrane Filters Manufacturer in India, offering high-quality filtration for sterile applications. Ideal for pharmaceutical & biotech industries.

#Sterile Filters#Bacteria removal Filters#Polyether Sulfone Filters#Sterile Polyether Sulfone Filters#Sterile PES Filters#Sterile PES Membrane filters#Sterile membrane filters#Bioburden reduction filters#Bioburden Removal filters#PES Filters#PES Membrane filters#PES Sterile filters#PES Sterile Membrane filters#Steam sterilizable filters#autoclavable filters#Sterilizing Grade filters#Sterilizing Grade PES Filters#Sterilizing Grade PES membrane filters#industrial filters manufacturers in India#Suppliers in India#Dealers in India#Distributors in India.

0 notes

Text

we as humans do have a tendency to project our labels and boxes onto animals

all animals ever only have male and female sex options, specially dogs and cats, and almost every pet owner in this hellsite projects onto their pets without realizing it. u give ur dog your pronoubs and oftentimes your gender on wether they have balls or not and don't even think abt how ur unintentionally labeling them that way too.

me and my friends love to label our animals (either with genuine vibes-based assumptions, or as jokes) and I wonder how normal this practice is

#Animals can be gay#But that's just a label we give them#They don't know about sexuality nor gender#They are primitives that we domesticated#They just think on shit pee eat and fuck#And that last one is why you must sterilizate your pet#Rant

7K notes

·

View notes

Text

You can’t just put WHATEVER through an autoclave. That has plastic parts only certain plastics are sterilizable why are you the way you are show?

14 notes

·

View notes

Text

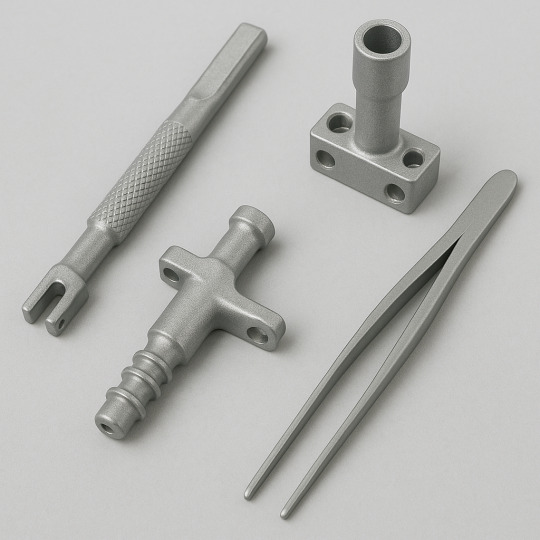

#Lightweight #Durable #Sterilizable #AluminumDieCasting #Surgical #tools offer unmatched #ergonomics & #Strength reducing #Fatigue while maintaining high #performance in the #operating #room #GoyalInc #help bring surgical #innovation to #life http://incgoyal.com https://x.com/goyal_inc https://www.youtube.com/@GoyalInc https://www.instagram.com/goyalinc https://in.pinterest.com/goyalinc https://www.facebook.com/incgoyal https://www.threads.net/@goyalinc #DigitalMarketing #PrecisionMachining #CNC #DieCasting #PrecisionMachinedParts #MachinedComponents #Engineering #Manufacturing #hpdc

2 notes

·

View notes

Note

Hey! Just read the new chapter! It was amazing!

One cool detail I saw, was the mention of merfolk skin grafting on mcs burn wounds!

I thought it was a really cool reference to the techniques that some surgeons use for severe burns where they take fish skins (of course sterilizated) like Tilapia as an alternative to using the same skin of the same organism.

Apparently some studies even claim higher success rates compared to typical human grafts as well.

It's really interesting seeing these medical methods referenced! :)

Yup!! I have so many tidbits of knowledge especially relating to the human body cause I'm studying to go into med stuff

It is hell

Anyways ty so much!! Im glad it was understood!!

19 notes

·

View notes

Note

Not sure who the dysgenics post is vaguing, and I don't want to get into this off anon, but sterilization (ostensibly voluntary) of genetically inferior potential parents is an idea that I've seen advocated by someone concerned about dysgenics

It's a side post to big discussion involving some people I follow about Scott Alexander's pessimistic predictions for the future. All very silly Decline and Fall stuff, as @discoursedrome put it.

(And even then I think he was being too charitable--"the whole world looks like it's decaying if you live in the political and economic center of it and even small things are shifting around you" is true, but I actually don't think very big shifts are occurring--I could go on at length here, but suffice it to say I think US hegemony is assured for the time being, we're making progress even on the biggest issues facing our society, like climate change, and I simply do not think a 50/50 chance of humans destroying themselves within 100 years--or even experiencing a major global collapse--is realistic. I think Acott Alexander lives inside a bubble of people with a lot of really silly ideas about the world and how it works, where being clever is seen as a sufficient substitute for expertise, and he is there because he is fundamentally gullible to any idea packaged in the right aesthetic.)

But historically, the idea of dysgenics/eugenics arose in the context of Social Darwinism. I think Social Darwinism is a funny animal; it is a surface-level retread of some ideas that were in circulation in Britain for a long time before Darwin. Specifically, the idea of a hierarchy of virtue that exists alongside and underpins a hierarchy of class is nothing new--that in itself may be as ancient as human civilization, since every society needs an ideology to legitimate its power structures. But in the context of early 1800s Britain, you had the Whigs, the new middle class of the burgeonining Industrial Revolution, looking to join the ranks of power--either to position themselves against the lazy shiftless aristocracy who did not work for a living, or to join them, to be like "yes, we don't have titles [but please give us some!], but we're also not like those awful lazy/drunk/Irish poors." I think alongside the Whiggish enthusiasm for science and progress, Social Darwinism nicely blends both that older idea of a hierarchy of virtue with newer ideas about dispassionate natural processes to produce an idea with a lot more mimetic heft for the new age (if you don't know much about either Darwinism or economics) than the unfiltered Anglicanism of the pre-1860s generations, one which takes the exact same policy prescriptions and like 90% of the same underlying rationale ("we cannot improve the social condition of the poor; they will waste their money on drink and gambling, breed like rabbits if their children are no longer often starving to death or dying of cholera, and they will corrupt the virtue of our society") and adds just a light dusting of pseudoscience ("we cannot improve the social condition of the poor; they will waste their money on drink and gambling, breed like rabbits if their children are no longer often starving to death or dying of cholera, and they will have a dysgenic effect on the white race").

(Along with the corollary, obviously, that we should get rich people to breed more, because clearly wealth and intelligence and virtue are heritable.*)

I do not think Scott Alexander is a Social Darwinist. Almost nobody is these days, and while I think he sometimes takes some very bad ideas seriously, I do not think he is at "19th century British racist" levels of taking bad ideas seriously. AFAICT the kind of eugenics Scott Alexander would support is what's sometimes called "positive eugenics," i.e., not sterilizating people against their will, but making sure that (for instance) middle-class people aren't actively discouraged from having kids by the tax structure, and using genetic engineering if/when it becomes available to gradually improve longevity, health, and IQ. But where concerns about dysgenics do pop up in modern authors, they tend to echo or simply restate older Social Darwinist concerns--as a general argument against welfare, for instance. But Scott has also talked about how UBI is a good idea, and that's pretty much the welfariest welfare you could possibly welfare. So I assume he's not worried that if we give the poor food, we will be up to our eyeballs in shiftless drunk Irishmen within a few generations.

(*"Heritable" is a great word! Wealth, for instance, is indeed heritable! How much money you will have is strongly predicted by how much money your parents had. But "heritable" is obviously not the same as "genetic," and this kind of equivocation--like that between intelligence and education, or between virtue and conformity to arbitrary social norms, was the bread and butter of 19th and 20th century Social Darwinists.)

14 notes

·

View notes

Text

Elevating Industry Standards: PVDF Materials by Petron Thermo Plast

In the dynamic landscape of industrial materials, Polyvinylidene Fluoride (PVDF) emerges as a standout choice, renowned for its exceptional properties and diverse applications. Petron Thermo Plast, a leading manufacturer in the field, specializes in delivering top-tier PVDF Materials crafted to surpass industry expectations. This blog meticulously explores the features, benefits, and applications of PVDF materials by Petron Thermo Plast, showcasing why they are the preferred solution for professionals worldwide.

Unveiling PVDF Materials

PVDF materials represent a pinnacle of innovation, characterized by their remarkable chemical resistance, thermal stability, and mechanical strength. Petron Thermo Plast’s PVDF materials are engineered with precision to offer unparalleled performance across a multitude of industrial settings.

Key Attributes of PVDF Materials

1. Chemical Resistance:

PVDF materials exhibit exceptional resistance to a wide spectrum of chemicals, including acids, bases, and solvents, making them ideal for corrosive environments.

2. Thermal Stability:

With a high melting point and remarkable heat resistance, PVDF materials maintain their integrity even under extreme temperatures, ensuring reliability in demanding conditions.

3. Mechanical Strength:

PVDF materials boast high tensile strength and durability, enabling them to withstand mechanical stress and pressure, thus guaranteeing longevity in challenging applications.

4. Low Permeability:

The low permeability of PVDF materials to gases and liquids prevents leakage, making them suitable for applications requiring excellent barrier properties.

5. Weatherability:

PVDF materials exhibit exceptional weather resistance, making them suitable for outdoor applications where exposure to UV radiation and harsh weather conditions is common.

6. Non-Toxicity:

PVDF materials are non-toxic and safe for use in applications involving potable water and food processing, adhering to stringent health and safety standards.

Applications of PVDF Materials

PVDF materials by Petron Thermo Plast find extensive applications across diverse industries:

Chemical Processing: Used for fabricating pipes, fittings, and linings in chemical plants due to their resistance to corrosive chemicals.

Construction: Employed in architectural cladding, roofing, and facades for their durability and weather resistance.

Electronics: Utilized in printed circuit boards and semiconductor manufacturing for their electrical insulation properties.

Transportation: Applied in aerospace and automotive industries for interior and exterior components due to their lightweight and high strength-to-weight ratio.

Medical: Used in medical equipment and devices requiring sterilizability and chemical resistance.

Advantages of Choosing Petron Thermo Plast

Advanced Manufacturing Techniques:

Petron Thermo Plast employs cutting-edge manufacturing processes and rigorous quality control measures to ensure PVDF materials meet the highest standards.

Customization Options:

The company offers PVDF materials in various formulations, sizes, and colors to meet specific customer requirements.

Expert Technical Support:

Comprehensive technical support and guidance are provided to assist customers in selecting the right PVDF materials and ensuring proper integration into their projects.

Sustainability Commitment:

Petron Thermo Plast is committed to sustainable manufacturing practices, ensuring their PVDF materials are environmentally friendly and compliant with global standards.

Why Choose PVDF Materials from Petron Thermo Plast?

Investing in PVDF materials from Petron Thermo Plast guarantees superior quality, reliability, and performance. Here are some compelling reasons to choose Petron Thermo Plast:

Unmatched Quality: PVDF materials from Petron Thermo Plast adhere to the highest quality standards, ensuring consistency and reliability.

Tailored Solutions: With a wide range of formulations and customization options available, you can find the perfect PVDF material for your specific application.

Technical Expertise: Petron Thermo Plast provides expert technical support to guide you through every stage, from material selection to project completion.

Sustainability: By choosing PVDF materials from Petron Thermo Plast, you are supporting environmentally friendly manufacturing practices and contributing to a greener future.

Conclusion

PVDF materials by Petron Thermo Plast redefine excellence in the industrial sector. Their unparalleled properties, reliability, and versatility make them indispensable across various industries. Choose Petron Thermo Plast for PVDF materials that exceed your expectations and elevate your projects to new heights of success.

#pvdf material#engineering plastics#pvc ball valve#pvc butterfly valve#pvdf pipe#explore#union ball valve#hdpe pipe fittings

2 notes

·

View notes

Text

[Image IDs

Image 1 is a cropped screenshot of a Tumblr comment from user pyroaconitine which reads "resistance strength vs twitch muscle strength"

Image 2 is a screenshot of Tumblr tags which read

#chris no one cares don't ramble about the-

#hitachi doesn't make the magic wand anymore they sold it bc they didn't want to be known as the vibrator company

#the magic wand is now owned by vibratex which is actually fantastic bc they changed the material of the head to silicone

#the old material wasn't body safe/sterilizable and would get weird over time texture-wise

#AND they released both the updated magic wand plus and the rechargable

#both of which are huge improvements without compromising what people loved about the original

#they also added additional speeds so there's a bit more of a gradient between 'oh wow that's strong' and 'blows your clit clean off'

#so overall a good thing that hitachi isn't in charge of making them anymore

#*inhales* #what were we talking about

/end ID]

Cis men joke about how the arm they use to jerk off is stronger than the other and act like it's just a dude thing when I damn well know the Hitachi magic wand weighs more than a dick

26K notes

·

View notes

Text

PAN GALACTIC COMMONWEALTH — STARSHIP EUROPA

CREW DOSSIER

SUBJECT: DR. SUHAIR ZAMAN

ASSIGNMENT: CHIEF MEDICAL OFFICER

REGISTRY: “DOC Z”

SPECIES: HUMAN (CYBORG)

⸻

Overview:

Dr. Suhair Zaman, universally referred to by crew and command alike as Doc Z, is the Europa’s Chief Medical Officer and trauma response commander. Aboard a vessel as advanced and volatile as the Vanguard-Class Europa, medical oversight is not a support role—it is a frontline assignment. Doc Z handles this burden with clinical precision and acerbic detachment, her dry sarcasm as iconic as her black humor and signature hijab. She is a survivor of one of the worst battlefield triage disasters in modern history, and her entire cybernetic profile is built not for enhancement, but preservation.

⸻

Medical History & Augmentations:

During the Siege of Arrah’s Divide, Doc Z suffered catastrophic damage when her field hospital was targeted by a directed energy mine. Against all odds, she survived. Her augmentations are extensive but integrated with precision and necessity:

• Left Arm: Replaced with a multi-tool surgical interface prosthetic.

• Left Leg (below knee): Adaptive-pressure cyberlimb with internal diagnostics.

• Eyes: Dual-spectral synthetic ocular implants with sterile field projection.

• Heart & Lung: Artificial cardiac array and single-lung circulatory exchanger.

• Vocal System: Voicebox replacement with tone-calibrated modulator.

• Neural Port: Direct-link interface with shipboard medical systems.

• Hijab: Woven smart-fabric, sterilizable and interface-linked.

Every part of her rebuilt body functions toward one goal—keeping others alive when everything else has failed.

⸻

Personality Profile:

Doc Z is unflinching and blunt, often referred to as “the most terrifying comfort you’ll ever meet.” Her reputation for battlefield miracles is matched only by her intolerance for unnecessary suffering. Her bedside manner might be gruff, but her success rate in surgery and critical care remains unmatched aboard any active vessel in the Commonwealth Fleet.

While her sarcasm is infamous, so too is her loyalty. She will risk herself without hesitation for even the most junior crew member.

⸻

Religious Practice:

Doc Z is a devout Muslim and maintains her spiritual discipline aboard the Europa with quiet dignity. She observes prayer regularly and ensures all medical environments meet appropriate standards for spiritual cleanliness where required. Her faith is not compromised by her augmentation—it is, in her words, “a body remade, not a soul replaced.”

⸻

Notable Interpersonal Relations:

• Captain Cole — A close and mutually respectful bond. He trusts her word over automated diagnostics. She refers to him as “Mr Muscles” with affection.

• Gruhm Braelen — Regular tea companion and philosophical sparring partner. The only person who can out-deadpan her in conversation.

• Bellevelle Charelle — Quietly aligned with Charelle’s fight for bodily autonomy and often provides private consultation for his physical strain.

• Yuville “Wyllie” Maeko — Their dynamic is “exhausted aunt vs manic niece.” Zaman finds her maddening but brilliant, and the only one allowed to touch her internal cybernetics.

⸻

Service Record Summary:

• Over 500 lives saved in active conflict zones.

• Field-tested in 3 planetary wars and 7 containment crises.

• Directly responsible for establishing the Europa’s cryostasis trauma wing.

• Issued permanent medical override on Decks 2, 4, and Medical Labs.

• Only member of the crew who can legally override Captain Cole’s biometric lock in the event of medical incapacitation.

Current Status:

Active. Europa Medical Bay, Forward Sector. On-call rotation 27 hours, with 2 hours set aside daily for prayer, review, and quiet diagnostics. Maintains full combat-response clearance and trauma resuscitation authority.

⸻

0 notes

Text

Plastic Tubes: Engineering Simplicity in a Complex World

Plastic tubes are simple in form yet remarkably diverse in function, serving as essential components across industries such as medical technology, construction, packaging, electronics, and consumer goods. They are flexible, durable, lightweight, and cost-effective—qualities that have made them indispensable in both industrial and everyday applications. This article explores their manufacturing process, functionality, advantages, and the challenges they present in terms of sustainability.Get more news about plastic tube,you can vist our website!

Composition and Manufacturing Plastic tubes are commonly made from a wide array of polymers, including polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), and polytetrafluoroethylene (PTFE), among others. The choice of material depends on the application. For instance, medical-grade tubing requires high chemical resistance and biocompatibility, often achieved using PTFE or silicone-based compounds.

Manufacturing methods include extrusion—where molten plastic is shaped by being forced through a die to form a continuous tube—and injection molding, which is more typical for rigid or specially shaped tubes. Additives like UV stabilizers, colorants, and plasticizers can be included to enhance performance under specific conditions.

Everyday Applications Plastic tubes are present in nearly every part of modern life. In households, they serve as dispensers for toothpaste, ointments, and cosmetics. In gardening and plumbing, flexible tubes are used to carry water, chemicals, or air. Food and beverage industries rely on sanitary-grade plastic tubing to handle liquids safely.

In the medical sector, plastic tubes take on highly specialized roles—used in intravenous therapy, catheterization, respiratory devices, and surgical instruments. The lightweight and sterilizable nature of plastics makes them ideal for such sensitive uses.

Industrial and Technological Use In industries such as automotive manufacturing, construction, and electronics, plastic tubes function as conduits for wiring, fluid transmission, insulation, or structural elements. Cable management, fuel lines, and HVAC systems all depend on the reliable performance of engineered tubing.

Additionally, in laboratories and chemical processing plants, tubing made from chemically inert plastics is crucial to transport corrosive or temperature-sensitive substances safely.

Advantages and Challenges The primary advantages of plastic tubes lie in their adaptability, corrosion resistance, and low production cost. They outperform metal counterparts in weight and chemical tolerance, making them ideal for complex or mobile systems. However, their environmental impact remains a pressing concern.

Many plastic tubes are not readily recyclable due to their composite materials or contamination after use, especially in medical and industrial contexts. Single-use plastic tubes generate considerable waste, contributing to pollution and landfill buildup.

Toward a Sustainable Future Efforts to make plastic tubing more eco-friendly are underway. Bioplastics derived from renewable resources, such as PLA (polylactic acid), are gaining attention, though they currently have limitations in durability and heat resistance. Advances in mechanical and chemical recycling technologies also promise a more circular lifecycle for plastic tubing materials.

Manufacturers are increasingly exploring ways to design products for disassembly, reuse, or safe degradation. In parallel, regulatory frameworks in various regions are pushing industries to reduce dependency on virgin plastics and increase transparency in material sourcing.

0 notes

Text

NTC SMD Thermistor Market: Emerging Opportunities, Growth Drivers, and Forecast to 2025-2032

MARKET INSIGHTS

The global NTC SMD Thermistor market size was valued at US$ 1.34 billion in 2024 and is projected to reach US$ 2.16 billion by 2032, at a CAGR of 7.0% during the forecast period 2025-2032.

NTC SMD thermistors are miniature surface-mount devices that exhibit a negative temperature coefficient, meaning their resistance decreases as temperature rises. These compact components are widely used for temperature sensing, compensation, and protection in electronic circuits. Key product types include chip thermistors in bulk packaging and tape-and-reel formats, catering to various automated assembly processes.

The market growth is driven by increasing demand from consumer electronics, automotive electronics, and industrial automation sectors. Advancements in miniaturization and high-precision temperature measurement capabilities are expanding application areas. Leading manufacturers like TDK, Murata, and Vishay dominate the competitive landscape, collectively holding over 45% market share. Recent industry developments include the launch of ultra-thin 0402 package NTC thermistors by Mitsubishi Materials in Q1 2024, targeting space-constrained IoT applications.

MARKET DYNAMICS

MARKET DRIVERS

Expanding Applications in Consumer Electronics to Propel NTC SMD Thermistor Demand

The proliferation of smart devices and IoT applications is driving significant demand for NTC SMD thermistors, which provide precise temperature sensing capabilities in compact form factors. With smartphones incorporating up to 5-8 thermal sensors per device for battery management and performance optimization, component miniaturization trends directly benefit surface-mount thermistor adoption. The global smartphone market is projected to ship over 1.4 billion units annually, creating sustained demand for reliable temperature monitoring solutions. Furthermore, emerging wearable technologies require ever-smaller yet more accurate thermal protection components, with the wearable device market expected to grow at 14% CAGR through 2030.

Automotive Electrification Creating New Growth Opportunities

The automotive industry’s shift toward electrification represents a major growth vector for NTC SMD thermistors. Modern electric vehicles utilize approximately 300-400% more temperature sensors than conventional vehicles, with critical applications in battery management systems, power electronics, and motor controls. As global EV production is forecast to exceed 40 million units by 2030, thermistor manufacturers are developing specialized automotive-grade components with extended temperature ranges and improved vibration resistance. The recent introduction of AEC-Q200 qualified thermistors by leading suppliers demonstrates the industry’s response to this expanding application space.

Advancements in Medical Technology Driving Precision Requirements

Healthcare applications present substantial opportunities for high-accuracy NTC SMD thermistors. Portable medical devices and diagnostic equipment increasingly require miniature temperature sensors with ±0.1°C accuracy for critical patient monitoring and treatment applications. The global medical electronics market, valued at over $8 billion, continues to grow at 7% annually, creating demand for reliable thermal management solutions. Recent product developments include sterilizable thermistors for surgical equipment and ultra-miniature sensors for minimally invasive diagnostic tools.

MARKET RESTRAINTS

Raw Material Price Volatility Impacting Manufacturing Costs

The NTC SMD thermistor market faces significant margin pressures from fluctuating raw material costs. Critical materials including nickel, manganese, and cobalt have experienced price swings exceeding 50% in recent years, directly affecting production economics. Manufacturers must balance material substitutions against performance requirements, as alternative formulations often compromise key characteristics like thermal response time or stability. This challenge is particularly acute for cost-sensitive consumer electronics applications where component pricing remains under constant downward pressure.

Thermal Accuracy Challenges in Extreme Environments

While NTC thermistors offer excellent sensitivity, their performance limitations in extreme temperature ranges constrain certain industrial applications. Automotive underhood environments, for instance, require reliable operation from -40°C to +150°C, pushing the boundaries of conventional thermistor materials. Advanced packaging solutions and proprietary formulations help mitigate these issues but at significantly higher manufacturing costs. These technical limitations create opportunities for alternative sensing technologies in demanding applications.

MARKET CHALLENGES

Intense Price Competition from Alternative Technologies

The NTC SMD thermistor market faces growing competition from emerging sensing technologies. Silicon-based temperature ICs offer digital outputs and easier integration for certain applications, while RTDs provide superior stability in industrial environments. Although thermistors maintain cost advantages in many scenarios, continuous price erosion in the semiconductor industry makes alternative solutions increasingly attractive. This competitive pressure requires thermistor manufacturers to continually enhance performance characteristics while maintaining cost competitiveness.

Supply Chain Vulnerabilities in Critical Materials

Geopolitical factors and supply chain disruptions have exposed vulnerabilities in the thermistor manufacturing ecosystem. Certain rare earth oxides essential for high-performance formulations face concentrated production in limited geographic regions, creating potential bottlenecks. The industry is responding through strategic inventory management and dual-sourcing initiatives, but these measures add to operational complexity and cost structures. Recent trade policies and export controls have further complicated material procurement strategies for global manufacturers.

MARKET OPPORTUNITIES

5G Infrastructure Development Creating New Application Spaces

The global rollout of 5G networks presents substantial opportunities for NTC SMD thermistor adoption. Next-generation base stations and networking equipment require precise thermal management of power amplifiers and processors, with each unit potentially incorporating dozens of temperature sensors. The projected installation of over 7 million 5G base stations by 2025 creates significant demand for reliable, compact thermal monitoring solutions capable of withstanding harsh outdoor environments.

Energy Storage Systems Driving Specialty Component Demand

Grid-scale energy storage and residential battery systems represent a growing market for specialized thermistor solutions. These applications require sensors capable of precise temperature monitoring across large battery arrays while maintaining long-term reliability. The global energy storage market is projected to grow at 30% annually, with thermal management being critical for both safety and performance optimization. Custom thermistor configurations tailored for battery monitoring present opportunities for differentiation among component suppliers.

Industrial IoT Expansion Fueling Sensor Integration

The Industrial Internet of Things (IIoT) transformation is driving increased adoption of condition monitoring solutions across manufacturing facilities. Predictive maintenance systems often incorporate multiple temperature sensors to monitor equipment health, creating demand for robust, long-life NTC thermistors. With over 35 billion IIoT devices expected to be deployed by 2025, this application space offers significant growth potential for sensor manufacturers able to meet industrial reliability requirements.

NTC SMD THERMISTOR MARKET TRENDS

Miniaturization and High-Performance Demands Drive Adoption of NTC SMD Thermistors

The global NTC SMD thermistor market is experiencing significant growth due to the increasing demand for miniaturized and high-performance electronic components. Surface-mount device (SMD) thermistors offer compact designs with enhanced accuracy, making them indispensable in modern electronics. These components are widely used in applications such as LED control, temperature compensation, and power transistor stabilization. The market is expected to grow at a compound annual growth rate (CAGR) of % from 2024 to 2032, driven by advancements in semiconductor and sensor technologies. Rising demand for IoT-enabled smart devices and automotive electronics further fuels the adoption of NTC SMD thermistors, as they provide reliable temperature monitoring in constrained spaces.

Other Trends

Automotive Electronics and Electrification

The rapid electrification of vehicles is one of the most prominent trends shaping the NTC SMD thermistor market. With electric vehicles (EVs) and hybrid vehicles gaining traction globally, the need for efficient thermal management systems has surged. NTC thermistors play a crucial role in battery temperature monitoring, charging systems, and power electronics, ensuring safety and optimal performance. The automotive sector accounts for approximately 25% of the total demand for NTC thermistors, with China and the U.S. leading in adoption due to aggressive electrification policies. Additionally, the growing integration of advanced driver-assistance systems (ADAS) demands high-precision temperature sensors, further accelerating market growth.

Expansion of Consumer Electronics and Wearables

The consumer electronics sector continues to be a key driver for NTC SMD thermistors, particularly in smartphones, wearables, and smart home devices. Manufacturers are increasingly incorporating these thermistors for thermal management in high-performance processors, battery packs, and fast-charging circuits. The global wearables market, projected to grow at a CAGR of 14% over the next five years, is expected to boost demand for compact and highly responsive temperature sensors. Furthermore, the proliferation of 5G technology necessitates improved thermal regulation in network infrastructure and mobile devices, reinforcing the need for reliable SMD thermistor solutions. Leading suppliers such as TDK, Murata, and Vishay are investing in R&D to develop next-generation thermistors with enhanced sensitivity and durability.

NTC SMD Thermistor Market

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Manufacturers Focus on Precision and Miniaturization to Capture Market Share

The NTC SMD Thermistor market exhibits a moderately fragmented competitive landscape, with established electronics component manufacturers competing alongside specialized sensor producers. In 2024, the top five companies collectively accounted for approximately 38% of global revenue, indicating room for mid-sized players to expand their footprint through technological differentiation.

TDK Corporation and Vishay Intertechnology currently lead the market through their diversified electronic component portfolios and strong distribution networks across Asia-Pacific and North America. These industry giants leverage their economies of scale to offer competitive pricing while investing heavily in miniaturization technologies for next-generation thermistor applications.

Meanwhile, Murata Manufacturing has been gaining significant traction through its proprietary ceramic semiconductor technology, which enables higher temperature stability in compact SMD packages. The company’s recent collaborations with automotive OEMs have positioned it strongly in the vehicle electrification segment, which represents one of the fastest-growing application areas for NTC thermistors.

Chinese manufacturers like Shenzhen Minchuang Electronics and WEILIAN are making strategic inroads through cost-competitive offerings tailored for consumer electronics and IoT devices. These companies are progressively enhancing their quality certifications and production capabilities to compete in higher-margin industrial segments.

Specialist firms such as Ametherm and Semitec Corporation are carving out niche positions through application-specific thermistor solutions. Their focused R&D investments in precision temperature measurement for medical devices and aerospace applications demonstrate how targeted innovation can succeed alongside large-scale manufacturers.

List of Key NTC SMD Thermistor Manufacturers

TDK Corporation (Japan)

Vishay Intertechnology (U.S.)

Murata Manufacturing (Japan)

WEILIAN (China)

Shenzhen Minchuang Electronics Co., Ltd. (China)

HateSensor (China)

Mitsubishi Materials Corporation (Japan)

Ametherm (U.S.)

Semitec Corporation (Japan)

Suzhou Dingshi Electronic Technology CO., LTD (China)

NTC SMD Thermistor Market

Segment Analysis:

By Type

Bulk Packaging Segment Leads Due to High Adoption in Industrial Applications

The market is segmented based on type into:

Bulk Packaging

Tape and Reel Packaging

By Application

Temperature Measurement and Control Dominates Owing to Increasing Demand in IoT and Smart Devices

The market is segmented based on application into:

LED Control

Temperature Compensation

Power Transistor Stabilization

Temperature Measurement and Control

Others

By End User

Consumer Electronics Segment Shows Strong Growth with Rising Smart Device Penetration

The market is segmented based on end user into:

Consumer Electronics

Automotive

Industrial

Medical

Aerospace and Defense

Regional Analysis: NTC SMD Thermistor Market

North America The North American NTC SMD thermistor market is characterized by strong demand from the electronics and automotive sectors, driven by stringent quality standards and rapid technological adoption. The U.S. accounts for approximately 60% of the regional market revenue, supported by a robust semiconductor ecosystem and increasing investments in IoT and 5G infrastructure. Companies like Vishay and Ametherm dominate the space due to their advanced miniaturization technologies. Bulk packaging remains preferred for industrial applications, while tape and reel packaging sees higher demand in consumer electronics. Regulatory standards from Underwriters Laboratories (UL) and the Restriction of Hazardous Substances (RoHS) directive continue to drive compliance-focused innovation.

Europe Europe exhibits steady growth, with Germany and the U.K. leading adoption due to their mature manufacturing bases. The region emphasizes high-precision NTC thermistors for automotive temperature sensors, particularly in electric vehicle (EV) battery management systems. TDK and Murata hold significant market shares, leveraging partnerships with European automakers. Environmental regulations under REACH and WEEE directives push manufacturers toward lead-free and recyclable materials. However, competition from Asian suppliers and higher production costs pose challenges for local players.

Asia-Pacific As the largest and fastest-growing market, Asia-Pacific is driven by China, Japan, and South Korea, which collectively account for over 70% of global NTC thermistor production. China’s dominance stems from cost-efficient manufacturing and extensive electronics supply chains. Temperature measurement and control applications in consumer devices and industrial automation fuel demand. Japanese firms like Semitec Corporation and Mitsubishi Materials Corporation focus on high-reliability thermistors for automotive and medical devices. India emerges as a growth hotspot due to expanding electronics manufacturing under the “Make in India” initiative, though it remains dependent on imports for advanced components.

South America The region shows moderate but inconsistent demand, primarily from Brazil’s automotive aftermarket and Argentina’s energy sector. Economic instability limits large-scale investments, causing reliance on imported thermistors from China and North America. Local assembly of consumer electronics creates niche opportunities, particularly in Brazil, where tape and reel packaging gains traction for PCB assembly lines. However, currency fluctuations and underdeveloped supply chains hinder market expansion.

Middle East & Africa This region represents an emerging opportunity with growth centered in Israel, Turkey, and the UAE for industrial and telecommunications applications. Demand stems from infrastructure projects requiring temperature-stable electronics, though the market remains price-sensitive. Gulf Cooperation Council (GCC) countries show increasing interest in smart city initiatives, driving pilot adoptions of NTC thermistors. South Africa’s automotive sector offers latent potential, but political uncertainties and low local production capacity slow market penetration.

Report Scope

This market research report provides a comprehensive analysis of the global and regional NTC SMD Thermistor markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global NTC SMD Thermistor market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Bulk Packaging, Tape and Reel Packaging), application (LED Control, Temperature Compensation, Power Transistor Stabilization, Temperature Measurement and Control, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The U.S. market size is estimated at USD million in 2024, while China is expected to reach USD million.

Competitive Landscape: Profiles of leading market participants including WEILIAN, TDK, Murata, Vishay, Mitsubishi Materials Corporation, and others, with their product offerings, R&D focus, and recent developments.

Technology Trends & Innovation: Assessment of emerging technologies, miniaturization trends, and evolving industry standards in thermistor manufacturing.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges in supply chain, raw material availability, and regulatory compliance.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, and investors regarding strategic opportunities in the NTC thermistor ecosystem.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/fieldbus-distributors-market-size-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/consumer-electronics-printed-circuit.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-alloy-current-sensing-resistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/modular-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/integrated-optic-chip-for-gyroscope.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/industrial-pulsed-fiber-laser-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/unipolar-transistor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/zener-barrier-market-industry-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/led-shunt-surge-protection-device.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/type-tested-assembly-tta-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/traffic-automatic-identification.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/one-time-fuse-market-how-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pbga-substrate-market-size-share-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nfc-tag-chip-market-growth-potential-of.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silver-nanosheets-market-objectives-and.html

0 notes

Text

Sustainable Bioprocessing Gains Ground with Recyclable Single-Use Systems

The Single-use Bioprocessing Market is entering a transformative growth phase, fueled by the rapid expansion of biopharmaceutical manufacturing, rising demand for flexible production systems, and heightened focus on contamination control. Valued at USD 7.62 billion in 2021, the market is projected to reach USD 25.40 billion by 2031, growing at an impressive CAGR of 18.93% during the forecast period (2024–2031).

Unlock exclusive insights with our detailed sample report :

This market is evolving rapidly with the increasing adoption of single-use bioprocessing systems such as bioreactors, fermenters, mixers, filtration units, bags, and containers. These disposable systems, primarily made of sterilizable plastic components, support critical processes like upstream expression, purification, storage, and separation of biopharmaceutical products. As global biomanufacturing shifts toward agile, cost-effective, and contamination-free solutions, single-use technologies are being embraced by both established pharma giants and emerging biotech firms—especially in alignment with trends seen in the United States and Asia, where scalable, single-use systems are driving next-gen biologics production.

Key Market Drivers

1. Rise in Biologics and Personalized Medicine: The growth of monoclonal antibodies, gene therapy, and personalized medicine has created a strong need for scalable, contamination-free, and faster bioprocessing methods. Single-use systems (SUS) offer agility and ease of implementation, making them ideal for such advanced therapies.

2. Cost Efficiency and Operational Flexibility: Unlike traditional stainless-steel systems, SUS eliminate the need for cleaning and sterilization, significantly reducing downtime and water/chemical usage. This makes them highly attractive for small-to-mid-sized biotech firms and contract manufacturing organizations (CMOs).

3. Pandemic Preparedness and Vaccine Development: COVID-19 and subsequent global health threats highlighted the urgent need for rapid-response manufacturing capabilities. Single-use systems enabled fast-tracked vaccine production and played a pivotal role in scaling mRNA technologies.

4. Regulatory and Environmental Incentives: The U.S. FDA and EMA support the adoption of single-use bioreactors and modular facilities, facilitating market expansion. Meanwhile, vendors are innovating biodegradable materials to tackle concerns over plastic waste and sustainability.

Speak to Our Senior Analyst and Get Customization in the report as per your requirements:

Market Segmentation Snapshot

By Product Type: The market is segmented into bioreactors, mixers, bags, tubes & connectors, sampling systems, and others. Bioreactors and mixing systems account for the largest share due to their central role in upstream processing.

By Workflow: Upstream processing dominates the market share, given the high usage of SUS in cell culture and fermentation.

By End-User: Biopharmaceutical companies hold the majority share, followed by CMOs and academic research institutes.

Regional Insights

United States: The U.S. remains the largest and most mature market, fueled by robust biopharma R&D, government funding, and large-scale manufacturing investments. In 2024, the U.S. government announced a new initiative to strengthen domestic biologics production, allocating over USD 2 billion toward advanced manufacturing platforms—predominantly single-use facilities. Leading companies like Thermo Fisher Scientific, Danaher Corporation, and Sartorius Stedim Biotech are expanding their manufacturing capacities across North America.

Japan: Japan’s biopharma industry is rapidly integrating single-use systems as part of its strategic vision for regenerative medicine and mRNA vaccine production. In 2024, the Japanese Ministry of Health, Labour and Welfare (MHLW) introduced incentives for companies transitioning from conventional systems to disposable solutions. Furthermore, leading Japanese firms such as Asahi Kasei and Nipro Corporation are increasing R&D spending on sustainable single-use materials to enhance product lifecycle management.

Europe and Asia-Pacific: Germany, the UK, and Switzerland continue to be innovation hubs, while emerging economies in the Asia-Pacific region, such as China, South Korea, and India, are rapidly adopting SUS to scale biologics and biosimilars production.

Latest Industry Trends

AI Integration in Bioprocess Monitoring: Vendors are now embedding AI and data analytics into SUS platforms to allow predictive maintenance, batch tracking, and process optimization.

Modular Biomanufacturing Units: Companies are investing in mobile, modular units using SUS to cater to outbreak hotspots and rural regions, enhancing supply chain agility.

Green Bioprocessing Innovations: Environmental concerns are driving innovations in recyclable polymers and closed-loop systems to minimize single-use plastic waste.

M&A Activity on the Rise: The market is witnessing increased mergers and acquisitions. For example, in Q1 2025, Repligen Corporation announced the acquisition of a European tubing and bagging system manufacturer to strengthen its product portfolio.

Buy the exclusive full report here:

Competitive Landscape

The market is highly competitive and fragmented, with major players focusing on product innovation, capacity expansion, and strategic partnerships. Notable players include:

Thermo Fisher Scientific Inc.

Sartorius AG

Danaher Corporation (Cytiva and Pall)

Merck KGaA

Eppendorf AG

Parker Hannifin Corp.

Avantor, Inc.

Corning Incorporated

PBS Biotech, Inc.

Saint-Gobain Performance Plastics

These companies are investing in next-generation single-use assemblies, automation, and flexible manufacturing to meet evolving industry demands.

Growth Opportunities

CMO & CDMO Expansion: As pharmaceutical outsourcing grows, CMOs are increasingly deploying SUS to reduce turnaround time and manage multiple client processes efficiently.

Biosimilar Production: The patent cliff for blockbuster biologics has opened lucrative opportunities for biosimilars, where SUS offers a cost-effective pathway to scale.

Emerging Markets Penetration: Expansion in Latin America, Southeast Asia, and Africa presents a significant untapped opportunity, supported by international funding agencies.

Regenerative Medicine and Cell Therapy: As cell therapy and tissue engineering progress, single-use bioreactors and closed systems will be pivotal in clinical and commercial scale-up.

Stay informed with the latest industry insights-start your subscription now:

Conclusion

The global single-use bioprocessing market is on the cusp of a revolution, catalyzed by innovation in biologics, operational efficiency, and a growing preference for flexible, scalable manufacturing. The United States and Japan stand at the forefront of this transformation, while global demand signals a sustained, long-term market boom. As regulatory and environmental concerns are addressed through innovation, single-use technologies are poised to become the new standard in biopharmaceutical manufacturing.

#single-use bioprocessing market#single-use bioprocessing market size#single-use bioprocessing market growth#single-use bioprocessing market share#single-use bioprocessing market analysis

1 note

·

View note

Text

Japan’s Innovation in Sustainable Thermoplastics Sets Global Trends

The Thermoplastic Resins Market achieved a global valuation of $10.5 billion in 2023 and is forecast to grow at a compound annual growth rate (CAGR) of 5% to reach $16.8 billion by 2031. This growth is propelled by increasing demand across key sectors such as automotive, packaging, construction, medical devices, and consumer electronics. The Asia-Pacific region currently leads the global market with more than 30% share, followed by North America and Europe.

To Get Sample Report: https://www.datamintelligence.com/download-sample/thermoplastic-resins-market

Growth Drivers and Opportunities

1. Automotive Lightweighting and Electrification Thermoplastic resins are crucial in replacing traditional metals in automotive manufacturing. Lightweight thermoplastic composites reduce vehicle weight, enhance fuel efficiency, and support electric vehicle (EV) architecture. Key resins used include polyamides, polycarbonates, and polypropylene blends in parts such as bumpers, dashboards, and battery housings.

2. Sustainability in Packaging Polyolefins such as polyethylene (PE) and polypropylene (PP) are widely used in packaging due to their ease of recyclability and durability. Rising consumer demand for sustainable and recyclable materials is pushing manufacturers to innovate in bioplastics and post-consumer resin blends, especially in countries like Japan and the United States where environmental regulations are strict.

3. Healthcare and Medical Device Adoption Thermoplastics such as PVC, polycarbonates, and polyesters are widely adopted in medical applications. These resins are used in IV bags, diagnostic devices, syringes, and surgical tools due to their sterilizability, durability, and biocompatibility. This demand saw a spike during and after the COVID-19 pandemic and continues to grow with healthcare investments in Asia and North America.

4. Electronics and Consumer Goods Engineering thermoplastics are seeing increased adoption in electronics due to their electrical insulation, flexibility, and heat resistance. Polycarbonates and polyesters are popular in casings, displays, and wiring insulation in devices like smartphones, laptops, and home appliances.

5. Infrastructure and Building Materials Construction applications such as piping, cladding, flooring, and window frames rely on resins like PVC and PE for their low cost and resistance to weather and chemicals. As urbanization intensifies in India, China, and Southeast Asia, the demand for thermoplastics in infrastructure is set to rise.

6. Aerospace and Defense Composites Advanced resins like PEEK, PPS, and high-grade polyamides are used in lightweight aerospace structures and interiors. With countries investing in defense and space technology, demand for ultra-light and heat-resistant composites continues to expand.

Market Segmentation Highlights

Polyolefins dominate the global market due to their widespread use in packaging and automotive components.

Polyamides (Nylons) are gaining traction in engineering applications, especially in electrical systems and under-the-hood automotive parts.

Polyesters (PET & PBT) are widely used in food-grade packaging and fibers.

Polycarbonates are in high demand in the electronics and medical sectors for their transparency and impact resistance.

Fluoroplastics cater to specialized chemical and high-temperature applications.

Regional Market Insights

Asia-Pacific holds the largest share of the thermoplastic resins market. Rapid industrialization in China and India, paired with Japan’s emphasis on innovation and recycling, creates a strong foundation for continued growth. Japan is leading initiatives in chemical recycling and has committed to increasing the domestic plastic recycling rate by 2035.

North America represents around 20% of the global market. Growth here is driven by demand for lightweight vehicles, medical-grade plastics, and advanced packaging solutions. The United States has also seen increasing investment in plastic recycling technologies and sustainability startups.

Europe is focused on circular economy models. EU regulations on single-use plastics and strong recycling mandates are driving growth in biodegradable and bio-based thermoplastic resins.

Latin America, Middle East, and Africa are emerging markets with steady growth, supported by increasing investment in infrastructure and manufacturing sectors.

Industry Trends and News

Japan has seen an increase in resin imports for medical applications and is investing in next-gen plastic recycling technologies.

United States resin producers are collaborating with tech companies to improve plastic upcycling processes.

EVs and hybrid vehicle expansion are major demand centers for advanced thermoplastics like polyamide-imide and reinforced polyesters.

Strategic alliances between global resin manufacturers and automotive suppliers aim to develop resins with higher heat resistance and recyclability.

Strategic Developments

Companies are focusing on bio-based thermoplastics made from corn starch, sugarcane, and cellulose, appealing to green-conscious industries.

Joint ventures are emerging between resin manufacturers and automotive OEMs to co-develop composite materials.

Smart materials and self-healing thermoplastics are in development for aerospace and defense applications.

Market Outlook

The thermoplastic resins market is positioned for robust growth through 2031. With increasing demand across electric vehicles, construction, sustainable packaging, and advanced electronics, the industry is becoming a cornerstone of modern manufacturing. Innovation, regulation, and sustainability will be the key forces shaping its future.

0 notes

Text

Retractable Block Polymer Casing: A Comprehensive Guide

Introduction to Retractable Block Polymer Casing

In modern industrial and engineering applications, Retractable Block Polymer Casing is gaining rapid attention for its efficiency, adaptability, and durability. It plays a crucial role in various sectors such as electronics, aerospace, oil & gas, and medical devices. Known for its retractable mechanism and high-performance polymer structure, this casing solution is redefining protection standards for sensitive components.

What is Retractable Block Polymer Casing?

Retractable Block Polymer Casing refers to a protective enclosure made from high-performance block polymers, designed with a retractable mechanism for easy operation and space optimization. Block polymers are structured materials that combine different polymer blocks in a single macromolecule, offering enhanced mechanical strength, flexibility, and chemical resistance.

The retractable feature allows the casing to expand or collapse based on operational needs, making it highly functional in compact or dynamic environments.

Key Features of Retractable Block Polymer Casing

Retractable Design The most distinctive feature is its ability to extend and retract, which helps in conserving space and offering adjustable coverage.

High Thermal Stability Block polymers used in these casings can withstand a wide range of temperatures, making them ideal for extreme industrial environments.

Chemical Resistance These casings provide excellent resistance to chemicals, oils, and solvents, ensuring long-term protection of internal components.

Mechanical Strength The interlinked block structure delivers improved tensile strength and impact resistance, which is critical for demanding applications.

Lightweight Yet Durable Despite their strength, these casings are lightweight, allowing for easier transportation and installation.

Applications of Retractable Block Polymer Casing

Medical Devices: Used in catheter housings, tubing enclosures, and diagnostic equipment due to its sterilizable and non-reactive nature.

Electronics & Electricals: Ideal for protecting wires, sensors, and circuit boards in portable or retractable electronic devices.

Aerospace & Defense: Ensures secure housing for sensitive components in aircraft, drones, and defense equipment.

Oil & Gas Industry: Used for enclosing retractable tools and monitoring devices in harsh subsurface environments.

Telecommunication Equipment: Provides protective casing for retractable antennas and signal equipment.

Advantages of Using Retractable Block Polymer Casing

Enhanced Component Safety: Offers superior insulation and impact resistance.

Versatile Usage: Suitable for both indoor and outdoor environments.

Saves Space: The retractable mechanism enables compact storage and deployment.

Long-Term Reliability: Resistant to wear, corrosion, and environmental degradation.

Sustainability Potential: Many block polymers used are recyclable or made from eco-friendly materials.

Latest Trends and Innovations (2025)

Smart Casings: Integration of sensors within the casing to monitor temperature, pressure, or stress.

Eco-Friendly Polymers: Rising use of bio-based block polymers for sustainable retractable casing solutions.

3D Printed Designs: Customizable retractable block polymer casings created via additive manufacturing for precise and lightweight structures.

0 notes

Text

Pharmaceutical-grade stainless steel tubing is essential for maintaining hygiene, corrosion resistance, and structural integrity in drug manufacturing environments. This type of tubing meets strict standards for surface finish, material purity, and sterilizability to prevent contamination. It’s widely used in systems transporting sensitive fluids in biotech, medical, and pharmaceutical applications.

0 notes

Text

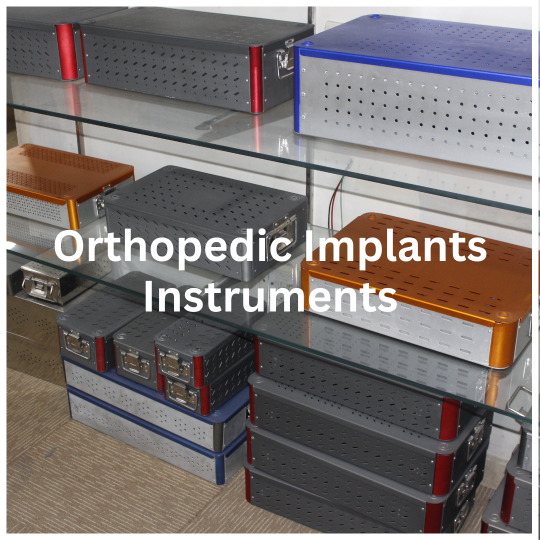

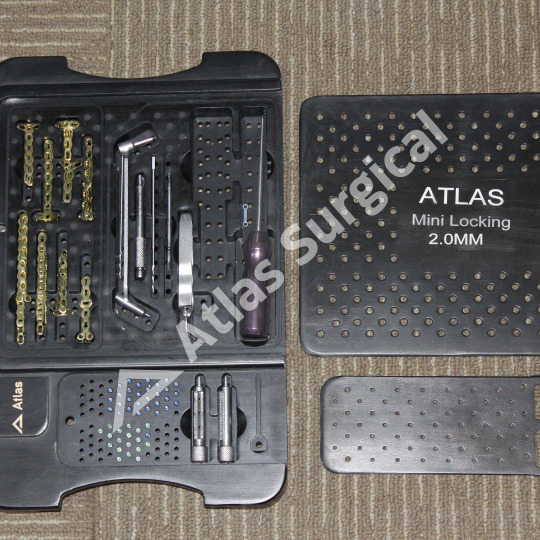

Orthopedic Implants Instrument Set – Precision. Durability. Performance. 🏥 Atlas Surgical – Trusted Manufacturer & Global Supplier of Surgical Excellence for 65+ Years

Upgrade your surgical practice with our comprehensive Orthopedic Implants Instrument Set, designed to meet the highest standards in trauma and orthopedic care. From plates and nails to specialized instruments, each set ensures:

✅ High-grade stainless steel ✅ Ergonomic design for surgical precision ✅ Full compatibility with major implant systems ✅ Sterilizable and CE-certified quality

Whether you're a hospital, clinic, or distributor, trust Atlas Surgical – where quality meets reliability in every instrument.

📦 Available for bulk orders & international shipping 📲 DM us or email [email protected] for enquiries

0 notes