#temperature sensor manufacturers in india

Text

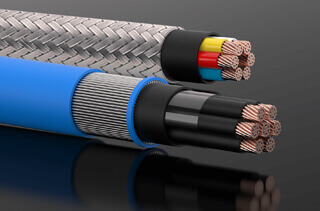

Discover India's Leading Cable Manufacturers | Top Quality Cables at Tempsens

Explore the excellence of top cable manufacturers in India at Tempsens Instruments. Elevate your connectivity with precision-engineered cables, ensuring reliability and performance. Uncover a world of trusted quality for your diverse needs.

#tempsens#cable manufacturer in india#tempsens instruments#wires and cables manufacturers in india#temperature sensor manufacturers in india#thermal solutions#tempsens india#thermocouple india

0 notes

Text

Precision in Every Degree: Temperature Sensor Manufacturers in India

Explore excellence in temperature sensing technology with General Instruments, among the leading Temperature Sensor Manufacturers in India. Our state-of-the-art sensors are crafted for precision, reliability, and versatility, meeting the diverse needs of industries across the nation.

Visit us at General Instruments to discover a comprehensive range of temperature sensors designed to elevate your industrial processes. Trust the experts for accuracy that goes beyond degrees.

Explore Precision with General Instruments - Your Trusted Temperature Sensor Manufacturers in India!

#Temperature Sensor Manufacturers#Trusted Temperature Sensor Manufacturers in India#General Instruments consortium#GIC

0 notes

Text

Precision in Every Degree: Temperature Sensor Manufacturers in India

Description: Explore excellence in temperature sensing technology with General Instruments, among the leading Temperature Sensor Manufacturers in India. Our state-of-the-art sensors are crafted for precision, reliability, and versatility, meeting the diverse needs of industries across the nation.

Visit us at General Instruments to discover a comprehensive range of temperature sensors designed to elevate your industrial processes. Trust the experts for accuracy that goes beyond degrees.

Explore Precision with General Instruments - Your Trusted Temperature Sensor Manufacturers in India!

#Temperature Sensor Manufacturers#Trusted Temperature Sensor Manufacturers in India#General Instruments consortium#GIC

1 note

·

View note

Text

#dew point meter#portable dew point meter#online dew point meter#dew point transmitter#dew point meters#dew point sensor for compressed air#dew point temperature sensor#moisture meter#humidity meter#moisture meter price#temperature and humidity meter#moisture tester#humidity meter price#moisture checking machine#humidity tester#humidity checker#humidity check meter#dew point meter price#dew point meter manufactures in India#top dew point meter#top dew point sensor#best dew point meter#dew point meter suppliers in India#puc device#puc monitor#vehicle emission#emission control

0 notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

PTFE Lined Sight Flow Indicators: Understanding their Functionality and Applications

In many industrial processes, it is important to monitor the flow of liquids or gases through a pipeline or system. This is where sight flow indicators come in, providing a visual way to monitor the flow of fluids. Sight flow indicators can come in a range of materials and designs, but in this blog, we will focus on PTFE lined sight flow indicators manufacturers in India and their functionality and applications.

PTFE (Polytetrafluoroethylene) is a highly non-reactive and versatile material that is resistant to many corrosive chemicals and has a high temperature tolerance. When PTFE is lined on the inside of a sight flow indicator, it provides excellent corrosion resistance and makes it suitable for use in highly corrosive environments.

Functionality of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators are used to visually monitor the flow of liquids or gases through a pipeline. They consist of a transparent window, usually made of glass or acrylic, and a PTFE lined body that allows the fluid to flow through. The window is typically circular in shape and allows operators to see the flow of the fluid.

The PTFE lining helps protect the sight flow indicator from corrosive substances and ensures the fluid does not come into contact with any metal parts. This lining also helps to reduce friction between the fluid and the sight flow indicator, making it easier for the fluid to flow through.

Applications of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators have a wide range of applications across various industries due to their excellent resistance to corrosive substances. Some common applications Include:

Chemical Processing: PTFE Lined Sight Flow Indicators in Vadodara are used in the chemical industry to monitor the flow of corrosive chemicals such as acids, alkalis, and Solvents.

Pharmaceutical Industry: In the pharmaceutical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of high-purity liquids such as purified water, pharmaceutical solutions, and sterile liquids.

Food and Beverage Industry: PTFE Lined Sight Flow Indicators are used in the food and beverage industry to monitor the flow of liquids such as fruit juices, milk, and beer.

Petrochemical Industry: In the petrochemical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of corrosive liquids such as hydrochloric acid, sulfuric acid, and other hazardous substances.

Manufacturers of PTFE Lined Sight Flow Indicators:

There are many manufacturers of PTFE Lined Sight Flow Indicators manufacturers in India around the world. These manufacturers offer a range of designs and materials to suit various applications. Some of the top manufacturers of PTFE Lined Sight Flow Indicators include:

- L.J. Star Incorporated

- Kenco Engineering Company

- Techniquip Corporation

- Mettler-Toledo International Inc.

- Gems Sensors & Controls

Conclusion:

PTFE Lined Sight Flow Indicators are an essential component in many industrial processes, providing a visual way to monitor the flow of fluids through a pipeline or system. Their excellent resistance to corrosive substances and high temperature tolerance make them ideal for use in a range of applications across various industries. With the increasing demand for PTFE Lined Sight Flow Indicators, manufacturers are constantly improving their designs and materials to meet the needs of their customers.

#PTFE lined sight flow indicators manufacturers in India#PTFE Lined Sight Flow Indicators in Vadodara#manufacturers#india#vadodara

2 notes

·

View notes

Text

Interactive Kiosk Market - Structure, Size, Trends, Analysis and Outlook 2022-2030

Interactive Kiosk Industry Overview

The global interactive kiosk market size was valued at USD 28.45 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2022 to 2030.

Due to the high development in payment and security technologies, the market has witnessed rapid growth over the past few years. Many of the self-service kiosk manufacturers will continue to extract these technologies’ maximum potential and are expected to include them as an indispensable component of their product offering. Interactive kiosks help prevent long queues at public places, such as inquiry counters at railway stations, banks, and malls and check-in counters at airports. At places, such as hospitals and government offices, they help reduce the paperwork associated with visitor data collection and enhance visitors’ experiences.

Gather more insights about the market drivers, restrains and growth of the Interactive Kiosk Market

An increase in product adoption in the BFSI and retail segments is expected to be a major growth driver for the market. Some of the major manufacturers are already working on developing and integrating Artificial Intelligence (AI)-based technology in interactive kiosks. For instance, ViaTouch Media has introduced AI-based kiosks, which enable shoppers to examine the products before making a purchase. As products are removed from the retailer’s shelf, a video screen above displays product information to the customer. The growing problems due to the outbreak of COVID-19 have increased the adoption of self-checkout kiosks to avoid human interaction. As self-checkout kiosks ensure social distancing in stores, they pave the way for a little human interaction.

Looking forward to driving the adoption of and advantages offered by interactive kiosks to customers, the vendors operating in the market have launched various advanced solutions and technologies in response to the COVID-19 pandemic. The COVID-19 pandemic has doubled the R&D spending and innovation by the vendors. For instance, kiosk systems with temperature sensors, Personal Protective Equipment (PPE)-dispensing kiosks, smart kiosks that collect swab samples for COVID-19 tests, and mobile testing kiosks are some of the latest solutions launched by the vendors operating in the market. The vendors are expected to continue focusing on product innovation and development to gain a significant share in the years to come.

Interactive Kiosk Market Segmentation

Grand View Research has segmented the global interactive kiosk market report on the basis of component, type, end use, and region:

Component Outlook (Revenue, USD Million, 2017 - 2030)

Hardware

Display

Printer

Others

Software

Windows

Android

Linux

Others (iOS, Others)

Service

Integration & Deployment

Managed Services

Type Outlook (Revenue, USD Million, 2017 - 2030)

Automated Teller Machines (ATMs)

Retail Self-Checkout Kiosks

Self-Service Kiosks

Vending Kiosks

End Use Outlook (Revenue, USD Million, 2017 - 2030)

BFSI

Retail

Food & Beverage

Healthcare

Government

Travel & Tourism

Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Asia Pacific

China

India

Japan

Singapore

Thailand

Indonesia

Malaysia

Vietnam

Australia

Latin America

Brazil

Middle East & Africa (MEA)

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global hybrid printing technologies market size was estimated at USD 4.59 billion in 2023 and is projected to grow at a CAGR of 12.3% from 2024 to 2030.

The global 4D printing market size was estimated at USD 156.8 million in 2023 and is anticipated to grow at a CAGR of 35.8% from 2024 to 2030.

Key Companies & Market Share Insights

The market is characterized by the presence of a few players accounting for significant industry share. New product launches and technology partnerships are some of the major strategies adopted by key companies to strengthen their market position. Key industry players are also heavily investing in research & development projects and focusing on establishing production infrastructure to develop and offer differentiated and cost-effective self-service solutions. The Meridian, Advanced Kiosk, and Kiosk Information System have a strong market presence due to the availability of a strong R&D department and production facilities. The companies mainly focus on product innovation and effective distribution through a strong network of partners in multiple countries, such as the U.S., Germany, India, and Brazil. Some of the key players in the global interactive kiosk market include:

NCR Corp.

Diebold Nixdorf AG

ZEBRA Technologies Corp.

Advanced Kiosks

Embross Group

GRGBanking

IER SAS

Order a free sample PDF of the Interactive Kiosk Market Intelligence Study, published by Grand View Research.

0 notes

Text

Electronic Pressure Sensors: Precision & Performance by Indication Instruments

In the fast-moving world of today’s industry, most processes are required to be maintained and controlled by pressure. The electronics of these sensors have become an important element in safety, accuracy, and reliability in many applications-from automotive to healthcare. For your smooth operation, Indication Instruments provides you with industry-standard electronic pressure sensors, precision designed.

Plot №19, Sector 6, Faridabad-121006 (INDIA)

Contact No: +91 129 4195300

Whatsapp

91 8810607901

What are Electronic Pressure Sensors?

Electronic pressure sensors are instruments that measure the force fluids or gases exert in a system. They translate a physical force of pressure into an electrical signal that can be traced and interpreted with a control system. Such sensors are particularly very important for keeping pressure levels within safe and optimal ranges in industrial machinery, automotive systems, medical devices, and many others.

Electronic Pressure Sensors of Indication Instruments’

Key Features High Accuracy: It is the high accuracy readings such that even very minute changes in pressure are detected and reported. Also, it becomes pretty much relevant for applications where industry, for instance, automotive or aerospace, demands high precision control or monitoring.

They are indications by indication instruments, therefore capable of perceiving a very wide range of pressure values, making them applicable in various industrial settings where pressures could either be low as in HVAC units, or highly elevated as in hydraulics.

Robustness & Reliability: Indication Instruments designs sensors with exceptional properties that enable them to be more resistant to several environmental factors, and they could, therefore, endure for long and even function uniformly with time irrespective of very high temperatures as well as aggressive environments.

Easy Installation: The Indication Instruments’ sensors are designed to fit well into several industrial systems; thus their installation is plain easy. Whether one seeks to replace old equipment or introduce new ones, Indication Instruments’ electronic pressure sensors integrate easily.

Compact Design: Our pressure sensors function so effectively yet are designed to be rather compact, thereby making them ideal for any application where space may be a significant restraint.

Applications of Electronic Pressure Sensors

Electronic pressure sensors are broadly used on a very wide basis in virtually all kinds of industries:

Automotive Industry: These sensors are positioned to measure the conditions in a car, which include the pressure of the tire, engine oil, and fuel system so that it improves performance as well as security.

HVAC Systems: Our pressure Tractor Sensors are always important in pressure control because it maintain pressure within the HVAC systems to preserve the maximum level of energy management.

Health care: Ventilators and oxygen supply systems use pressure sensors to provide a desired service to the patient and simultaneously protect the patient.

Industrial Automation: Pressure sensors would be a handy tool for the regulation of pressure in hydraulic and pneumatic systems in that safe and effective operation exists within manufacturing operations.

Why Indication Instruments?

Indication Instruments is the name we have entrusted our trust to for the last 30 years — we have faced reliable sensing solutions along with new ideas. We know how to address the point of view of the element in pressure sensing and continuously tell everyone how we remain committed to excellence in all of these areas.

Quality Assurance: Our electronic pressure sensors are tested against stringent industry standard as our objective.

Tailor-made Solutions: We give the clients tailor-made solutions to fit all that each application requires for it. This way, we attempt to have every application at its highest state for each.

Global Reach: Having a range of contented customers across the world in different industries, it is the way for us to get to the client’s needs for quality products in time each time.

Conclusion:

Pressure sensing technology requires nothing less than reliable accuracy. Indication Instruments developed some of the most advanced electronic Truck Sensors to meet every niche demand of the modern industry, from the automobile and healthcare to industrial automation. The precision and high performance define smooth and safe running operations.

Indication Instruments is investing in quality electronic pressure sensors. No matter your application, you simply can’t do any better. Call us today to learn more about our products and how we may design a package for your business.

1 note

·

View note

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

What is the Cost of Non IBR boiler?

Steamax Energy India is a well-established manufacturer and supplier of Non-IBR Steam Boilers in India, known for its faithfulness to innovation and quality. Non-IBR steam boilers are boilers that do not fall under the horizon of the Indian Boiler Regulations (IBR), making them simpler to operate, maintain, and install. These boilers are typically used in industries that require low to medium-pressure steam for various processes.

Uses:

Non-IBR steam boilers by Steamax Energy India find applications across a broad range of industries, including:

Food Processing: For sterilization, cooking, and cleaning processes.

Textile Industry: Used in dyeing, finishing, and ironing.

Pharmaceuticals: Essential for sterilizing equipment and materials.

Chemical Industry: Useful in chemical reaction processes and heating requirements.

Laundries: To generate steam for pressing and washing.

Features:

Steamax Energy India’s Non-IBR steam boilers are designed with several user-friendly and safety features:

Compact Design: Ideal for small spaces, these boilers are easy to install and maintain.

Energy Efficient: They are engineered to provide maximum efficiency while reducing fuel consumption.

Fast Steam Generation: These boilers heat up quickly, ensuring rapid steam availability.

Low Maintenance: With robust construction and fewer complex components, these boilers require minimal maintenance.

Safety Features: Equipped with automatic pressure controls, temperature sensors, and safety valves to ensure safe operation.

How it Works:

The Non-IBR steam boiler works by heating water through the combustion of fuels like coal, oil, or gas. The heat produced is used to convert water into steam, which can then be utilized in various industrial processes. The system is straightforward, ensuring reliable performance with minimal supervision.

Steamax Energy India’s Non-IBR steam boilers provide a cost-effective, reliable, and efficient solution for industries looking for hassle-free steam generation.

For Price Please Contact Us

For more details, please contact us!

Website :- www.steamaxenergyindia.com

Contact No. :- +91-7053901803

Email :- [email protected]

0 notes

Text

Looking for reliable temperature sensor manufacturers in India? Look no further than our range of temperature gauges, designed and manufactured in accordance with the latest international standards including ASME B 40.200 and EN 13190. Our gauges come in a variety of types including bimetal dial thermometers, gas-filled dial thermometers, and liquid-filled dial thermometers. We offer a wide range of temperature ranges, from (-) 200 to (+) 800 Deg C, with the fastest response time and special features such as hermetically sealed cases, high accuracy and repeatability, low hysteresis, case compensation, and colour bands. Our gauges come in 4", 5", and 6" dial sizes, with rigid stems that can be bottom or back entry and rotatable construction. With accuracy of +/- 1% FSD (standard), the latest IP-68 protection is offered as standard feature for all gauges, and they are supplied with internal/external micrometer pointers.

General Instruments Consortium is serving the engineering industry worldwide as single largest manufacturer and engineering solution provider for Pressure, Temperature, Level and Flow instruments, since 1966 .For more information kindly visit our website.

#pressure gauge manufacturers in india#pressure gauges#general instruments consortium#level gauge manufacturers#temperature sensor manufacturers in mumbai

0 notes

Text

#dew point meter#portable dew point meter#online dew point meter#dew point transmitter#dew point meters#dew point sensor for compressed air#dew point temperature sensor#moisture meter#humidity meter#moisture meter price#temperature and humidity meter#moisture tester#humidity meter price#moisture checking machine#humidity tester#humidity checker#humidity check meter#dew point meter price#dew point meter manufactures in India#top dew point meter#top dew point sensor#best dew point meter#dew point meter suppliers in India#puc device#puc monitor#vehicle emission#emission control

1 note

·

View note

Text

Rafia Film Scrap Plastic Recycling Plant in Tanzania

R Mech Machines LLP Offers Rafia Film Scrap Plastic Recycling Plant in Tanzania.

Our manufacturing unit is in Ahmedabad, Gujarat, India.

R Mech Machines LLP are Manufacturer, Exporter and Supplier of Plastic Scrap Turbo Washing Machines, Plastic Scrap Grinder Machines, Plastic Scrap Shredder Machines, Blade Sharpening Machines, Screw Press Squeezer Machines, and Friction Washer Machines.

A Rafia Film Scrap Plastic Recycling Plant is a specialized facility designed to process and recycle scrap plastic film, particularly raffia film, which is used extensively in packaging and industrial applications.

This plant transforms discarded plastic film into reusable material, contributing to waste reduction and resource conservation.

Utilizes sensors and conveyor belts to sort and separate different types of plastic films, ensuring high purity in the final product.

Employs extruders to melt and reform the shredded plastic into pellets or other forms, ready for reuse in manufacturing.

Work Process:

Collection and Sorting: Scrap raffia film is collected and fed into the sorting system where it is separated by type and quality.

Shredding: We shred the sorted plastic film into smaller pieces to facilitate easier handling and processing.

Granulation: We process the shredded plastic in granulators to produce uniform granules or flakes.

Extrusion: We melt the granulated plastic and extrude it into pellets or other forms using high-temperature extruders.

Cooling and Packaging: We cool and package the extruded pellets for distribution to manufacturers and end-users.

Quality Control: We inspect the final products to ensure they meet quality standards and are free from contaminants.

Application:

Packaging Industry

Agricultural Sector

Industrial Use

R Mech Machines LLP Offers Rafia Film Scrap Plastic Recycling Plant in Tanzania and including locations like Mwanza, Arusha, Dodoma, Mbeya, Morogoro, Tanga, Kahama, Tabora, Zanzibar City, Kigoma, Sumbawanga, Kasulu, Songea, Moshi, Musoma, Shinyanga, Iringa, Singida, Njombe, Bukoba, Kibaha, Mtwara, Mpanda, Tunduma, Makambako, Babati, Handeni, Lindi, Korogwe, Mafinga, Nansio.

For any questions or further information, please contact us.

View Product: Click Here

Read the full article

0 notes

Text

How to Choose a Lab Test Chamber ?

Roch Mechatronics Inc. is a trusted manufacturer and supplier of high-quality Test Chambers in India. These chambers are designed to provide precise and controlled environments for testing products under various conditions, such as temperature, humidity, and pressure. Industries like electronics, pharmaceuticals, automotive, aerospace, and manufacturing rely on test chambers to ensure product durability, reliability, and performance.

Features:

Wide Range of Testing Conditions: Roch Mechatronics offers test chambers capable of simulating extreme temperatures, from -70°C to 180°C, and controlling humidity from 10% to 98%, allowing versatile testing environments.

Advanced Control System: The chambers come equipped with state-of-the-art control systems that monitor and adjust environmental conditions with precision.

Durable Construction: These chambers are built from corrosion-resistant materials and designed for long-term use, ensuring reliability during rigorous testing cycles.

Energy Efficient: Roch Mechatronics' Test Chambers are designed to consume minimal energy while delivering consistent performance, making them cost-effective for businesses.

Customizable Options: Test chambers are available in various sizes and configurations, with customizable features to meet the specific needs of industries and research labs.

Safety Features: The chambers are equipped with alarms and safety mechanisms to prevent overheating or equipment malfunction, ensuring safe operation during testing.

Uses:

Test chambers from Roch Mechatronics Inc. are used for a wide array of applications:

Product Testing: They help in evaluating how products will perform under varying environmental conditions, ensuring they meet quality standards.

Material Stress Testing: Used to test the resilience of materials to extreme temperatures and humidity.

Research & Development: Laboratories and research institutions use these chambers to simulate real-world conditions for experiments and innovation.

How It Works:

The test chamber controls environmental factors like temperature and humidity inside the chamber using integrated sensors and systems. Products placed inside the chamber undergo cycles of extreme conditions, simulating real-life scenarios such as freezing, heating, or humid environments. This helps manufacturers assess product performance, longevity, and durability before launching them into the market.

Roch Mechatronics Inc. ensures precision, reliability, and durability with its cutting-edge Test Chambers, making them a top choice for industries across India.

For more details, please contact us!

Website :- /https://www.rochmechatronics.com/

Contact No. :- +91–7011654652Email :- [email protected]

0 notes

Text

Offices & Corporates opt for WAE's Touchless Drinking Water Fountains

Advancements in Science and Technology have consistently led to innovations and upgrades that pave the way for a better and more progressive future. From monumental technological achievements to the smallest developments, these innovations are transforming every aspect of human life today. One such example is the growing demand for drinking water fountains with bottle fillers, a technological innovation that enhances the drinking water experience with a focus on sustainability.

Today's drinking water fountains are no longer just integrated with single or dual bubblers to satisfy people's hydration needs sustainably; they are a range of versatile drinking water machines designed to provide clean water at different temperatures while prioritizing hygiene and convenience like never before!

The Hygiene Factor: WAE's drinking water fountains with chillers are increasingly favoured by corporates, offices, and educational institutions because they eliminate the need for plastic vessels such as bottles or jars for drinking water. Users can simply press the lever to activate the bubbler, creating a water flow that allows them to easily quench their thirst. Moreover, the latest models of these drinking water machines, equipped with touchless sensors, further enhance hygiene by reducing the risk of contamination from viruses or bacteria spread through contact by multiple users.

Sustainability: A key driver behind the rising demand for drinking water fountains in corporate settings is sustainability. Installing a drinking water fountain eliminates the need for plastic water jars or bottles, which are harmful to the environment.

To sum it up, installation of these bottle filling stations cum fountains plays a crucial role in sustainable water management. Among the trusted names in drinking water fountain manufacturing in India is WAE! With over 15 years of industry experience and expertise in producing drinking water products, WAE offers an extensive product line, including drinking water dispensers, bottle filling stations, drinking water stations, ROs, drinking water fountains, and more.

Drinking water fountains, drinking water fountains with bottle fillers, drinking water fountains with chillers, bottle filling stations cum fountains, drinking water fountain manufacturers, wae

for more:-https://www.waecorp.com/drinking-water-fountains

#drinking water fountain tap#drinking water fountain#drinking water fountains for corporates#drinking water fountain manufacturers

0 notes

Text

Chillers Market Size, Share, Growth, Analysis Forecast to 2030

Chillers Industry Overview

The global chillers market size was estimated at USD 9,928.3 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030.

The market is driven by the rising need for cost-effective and energy-efficient space cooling solutions in commercial and industrial sectors. This, in turn, is expected to augment the demand for the chillers market over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Chillers Market

According to the U.S. Department of Agriculture (USDA), the growing population, rising consumer disposable income, and ongoing urbanization are expected to augment the growth of commercial and residential sector in the country in the forecast period. The demand for chillers in the U.S. residential sectors is driven by a combination of factors, including the need for efficient and reliable air conditioning systems. With a focus on energy efficiency, homeowners are increasingly adopting chillers equipped with advanced technologies and smart controls to ensure precise temperature regulation while minimizing environmental impact. In the commercial sector, the demand for chillers remains robust, particularly in industries such as hospitality, healthcare, and data centres.

Moreover, chillers play a pivotal role in maintaining optimal temperatures for occupant comfort, equipment reliability, and critical processes. The trend towards sustainable building practices and stringent energy efficiency standards further accelerates the adoption of chillers in both residential and commercial applications across the U.S.

The integration of advanced technologies is transforming the global market. Smart chillers, equipped with IoT capabilities, sensors, and predictive maintenance features, allow for remote monitoring and optimization. These technologies enhance overall system efficiency, reduce downtime, and contribute to cost savings. These aforementioned factors are further expected to drive the demand for market over the forecast period.

Global Chillers Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this report, Grand View Research has segmented the global chillers market report based on product, application, compressor type, and region

Product Outlook (Revenue, USD Million, 2018 - 2030)

Water-Cooled

<50kW

51-100kW

101-500kW

501-1000kW

1001-1500kW

>1501kW

Air -Cooled

<50kW

51-100kW

101-500kW

501-1000kW

1001-1500kW

>1501kW

Application Outlook (Revenue, USD Million, 2018 - 2030)

Commercial

Corporate Offices

Data Centers

Public Buildings

Mercantile & Service

Healthcare

Others

Industrial

Chemicals & Pharmaceuticals

Food & Beverage

Metal Manufacturing & Machining

Medical & Pharmaceutical

Plastics

Others

Residential

Compressor Type Outlook (Revenue, USD Million, 2018 - 2030)

Screw Chillers

Centrifugal Chillers

Absorption Chillers

Scroll Chillers

Reciprocating Chillers

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Spain

Russia

Asia Pacific

China

Japan

India

Australia

Thailand

South Korea

Indonesia

Malaysia

Central & South America

Brazil

Argentina

Middle East and Africa

Saudi Arabia

South Africa

UAE

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global hardfacing welding market size was estimated at USD 1.73 billion in 2023 and is forecasted to grow at a CAGR of 5.3% from 2024 to 2030.

• The global advanced phase change materials market size was valued at USD 3.01 billion in 2023 and is anticipated to reach a CAGR of 8.2% from 2024 to 2030.

Key Chillers Company Insights

The global market is highly competitive on account of the presence of global and local manufacturers. Companies are engaged in expansion through mergers & acquisitions and joint ventures. These companies offer a wide range of systems that are sold through multiple channels, including distributors, company-owned websites, retailers & their websites, and e-commerce websites. For instance, in May 2023, Trane acquired MTA, an Italian manufacturer and distributor specializing in industrial refrigeration and air conditioning equipment. This strategic acquisition is expected to enhance Trane's commercial HVAC capabilities, particularly in key markets, by incorporating MTA's process chillers and expanding the rental and services business. With manufacturing sites located in Tribano and Conselve and a workforce of approximately 500 employees, MTA has an annual production capacity of 13,500 systems.

Key Chillers Companies:

The following are the leading companies in the chillers market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these chillers companies are analyzed to map the supply network

Trane

Cold Shot Chillers

Tandem Chillers

Drake Refrigeration, Inc

Refra

Carrier

FRIGEL FIRENZE S.p.A.

Midea

Daikin Industries, Ltd.

Johnson Controls

Rite-Temp

General Air Products

ClimaCool Corp.

Fluid Chillers, Inc.

Multistack International Limited

Honeywell International, Inc

Recent Developments

In December 2022, Trane unveiled its latest offerings, the water-cooled XStream eXcellent GVWF and air-cooled Sintesis eXcellent GVAF chillers. These innovative chillers incorporate magnetic-bearing compressors and utilize the low global warming potential (GWP) refrigerant R1234ze. Equipped with high-speed centrifugal compressor technology, these chillers deliver larger capacities, wider operating maps to meet challenging European climate conditions, and enhanced seasonal efficiencies, all while maintaining a compact size

In April 2021, refrigeration equipment manufacturer Refra initiated production operations at its newly established facility in Vievis, located in close proximity to the capital city, Vilnius, Lithuania. Spanning an area of 12,000 square meters, the factory is situated approximately 40 kilometers northwest of Refra's headquarters in Vilnius. The expansion has resulted in the creation of employment opportunities for an additional 100 individuals

Order a free sample PDF of the Chillers Market Intelligence Study, published by Grand View Research.

0 notes