#tool steel suppliers

Text

Why Virat Special Steels?

At Virat Special Steels, we are more than just a steel supplier – we are your trusted partner in quality and reliability. With a strong foothold in the industry, we are known as a preferred dealer, wholesaler, and supplier of top-notch Steel Blocks.

Our comprehensive range includes Flats, Squares, and Bars, all manufactured using quality-tested raw materials sourced from reliable vendors in the market.

What sets VIRAT SPECIAL STEELS PVT. LIMITED , INDIA apart is our commitment to excellence. We import Tools & Die Steels from the world's top manufacturing companies, including M/s. Schmiedewerke Groditz Thyssen and Deutsche Edelstahlwerke from Germany, and M/s. Thyssen Krupp from France. This ensures that our customers receive only the best quality products that meet international standards.

We supply steel bars to forging companies across #Ludhiana, #Faridabad, #Bhiwadi, #Sonipat, #Rohtak, #Haryana, #Punjab, #Jamshedpur, #Trichy, #Aurangabad, #Pune, #Gurgaon, #Noida, #Ghaziabad, #Indore, and all locations in India.

Our goal is to support the tool and steel products industry by providing high-quality materials that enable our customers to excel in their businesses.

Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📨 [email protected] 📞 +91 098140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#tool steel suppliers#toolsteel#diesteelsuppier#highspeedsteels#coldworksteel#din 2344#din 2714#din2343#din2738

2 notes

·

View notes

Text

Things to Consider When Choosing A Tool Steel Grade

In India, TGK Special Steel is a well-known supplier of tool steel products. We stock the majority of tool steel grades. We can satisfy customer requests for products that are not often available because we are a full-service master distributor.

0 notes

Link

Buying a reputed tool steel and starting to work with it is not the best way to begin. There’s tons of research required behind the basics, read this article to know more about this.

0 notes

Text

Some Necessary Things You Should Know Before Buying Tool Steel

Buying a reputed tool steel and starting to work with it is not the best way to begin. There’s tons of research required behind the basics, understanding industrial applications, impact, temperature, durability, strength etc. Tool steel indicates a wide range of carbon and alloy steels that are generally used to make tools. Tool steel suppliers explain how tool steel is different from steel used for consumer products. While tool steel is required for industrial purposes and need to be manufactured in a larger amount, consumer steel is manufactured in a much smaller scale. Regulations ensure that a particular grade of tool steel performs a certain kind of task such as – perforating or machining.

1. Will there be high temperatures – Excessively high temperatures has an effect on the mechanical properties of steel. This becomes truer regarding tool steel as tool steel already undergoes rigorous heat treatment. Reheating the tools will actually make the prior heat treatment useless. Therefore, hot work tool steel is preferred by tool steel suppliers while working with high temperatures because there are lower chances for these tool steel to lose their original properties during elevated temperatures. They also retain hardness and wear resistance. It also happens when tool steel grade has higher amounts of molybdenum or tungsten. H12, H13 and H19 are common hot work steel. These are used for hot shear knives, extrusion dies or casting dies etc.

2. Will there be high speed – Constantly working at high temperatures might not be suitable for all kinds of steel. High speed can cause high temperatures that will in turn reduce the hardness or resistance against wears of the tool. Another issue is that, since the tool is run on a machine repeatedly within a short period of time, there is a chance of abrasion. Thus, tool steel suppliers recommend using right tool steel that will not only endure elevated temperatures but also exhibit resistance against wears and tears when exposed to repeated use within a short period of time. M7, M42 and T1 are perfect for such purposes. These can be used as drill bits, pump components or cutting blades.

3. Understanding the budget - If you are looking for an inexpensive tool steel, avoid choosing a tool steel that has various expensive alloy elements. Water hardening tool steel is quite cost effective and exhibits good mechanical properties. Such grades acquire their mechanical properties from high amount of carbon instead of alloying elements. Tool Steel with low budget applications that require high wear resistance are such as – W1, W2 and W3.

4. What to use during low temperature operations – Cold work tool steel is perfect for low temperature operations. This category consists of both sir hardening and water hardening tool steel. This category is a bit expensive compared to water hardening tool steel but, it has elevated mechanical properties. Examples of tool steel in this category are – A7, O2 and D2. These are heavily used for dies, gages, punches and other cold working application.

5. Is there any need for plastic moulding – For plastic moulding, a unique kind of tool steel is essential. This is included in the Type P tool steel. These are not normally used for any other kind of industrial purposes except for plastic moulds or molds used for metals that have low melting temperatures. The examples are – P2, P5 and P3.

Thus, a number of properties and other essential things need to be remembered while choosing a tool steel.

0 notes

Text

6 features of a cold work steel and its uses

In terms of metallurgy, cold work steel can be defined as a metalworking procedure in which a metal is reshaped below its re-crystallization temperature. Procedures like these are directly in contrast with hot work steel mechanisms such as – forging, welding or rolling etc. Cold work helps in increasing the strength of metals as well as making its physical properties better by giving it a new shape and size without using heat. It also allows metal deformation. Due to the procedure that the metals undergo later when they are given hydraulic or mechanical pressure, a defect is naturally formed within the metal. As a consequence, crystal size is reduced it also allows the metal to be moulded into desired shape and size. Other than these, Tool Steel Suppliers suggest using cold work steel for various other reasons. There are also multiple uses of cold work steel across various industries.

Better surface finish – Hot work steel bars always finished manufacturing at higher temperatures. Therefore, the surface has quite hard abrasive scale which is made up of varieties of oxides of iron. The scale is hard in this case and the abrasion level varies between 270 and 1030 DPH. This level also depends upon the type of oxide that is formed. Cold drawing the bars include a few other steps. Cold finishers have to remove the scale by using either acid pickling or shot blasting. This helps in easy removal of hard abrasive scale. Excellent surface finish is achieved in cold work steel because there is no oxidation involved in cold working of metals.

Increased strength – Cold working strain can change properties of metals by a great degree. The metal is subjected to a mechanical stress during the process of cold working brings certain change in the metal. One of those is the permanent change of the crystalline structure of the metal. This causes increase in strength in the metal. After the cold working procedure, the permanent change in the metal reduces the ability of crystals to move inside the metal structure. Hence, the metal generates resistance against further deformation. The strength created in cold work steel allows it to be used across various industries.

Controlled concentricity and dimensional endurance – Tool Steel Suppliers explain that cold work steel has to be cooled down at room temperature and then further annealed into its final shape. This gives the steel more exact dimensional tolerance and much wider range of surface finish. Concentricity of cold work steel is naturally improved by cold drawing operations. This type of steel yields comparatively more benefits compared to other types. It increases tensile strength and yields, thereby reducing the extra cost of undergoing thermal treatment. It also removes imperfections on the surface.

Improved machinability – This simply means that less force or pressure can be applied on the tool and more on the productivity and tool life. Due to the benefits of controlled concentricity and dimensional endurance, the bars can function easily at high speeds without any harmful vibration. Increased straightness also allows cold work steel to have less runouts and gives excellent speed in production.

Improved straightness – Straightness in bars gets reduced due to manhandling during loading or unloading. However, cold work steel exhibits great strength and reduces chances of losing that ability.

Ductility – As opposed to other features of cold work steel, ductility is reduced as cold working increases.

Uses – Cold work steel can be used for broaches, gages, piercing and drawing dies, blanking, shears, lathe centers, reamers, taps, threading dies etc. It is also widely used in construction – pipes, beams, floor covering, studs etc.

Tool steel suppliers suggest using cold work steel for its plenty of benefits and affordable price.

0 notes

Text

The Correct Method for Using Crowfoot Wrenches

For industrial sectors, a variety of tools with varying shapes, uses, and functions are offered. When a torque wrench or socket are close at hand, a crowfoot wrench is an extremely simple tool to use. Once you have any of them, you can use a crowfoot wrench by following the instructions below. Any trustworthy Dubai, United Arab Emirates tap set supplier in dubai uaewill sell you these wrenches. Now let's get going.

KNOW MORE>> https://medium.com/@toolssuppliersinuaedubaiuae/the-right-procedure-for-utilising-the-crowfoot-wrenches-7e1591352182

#tap set suppliers in dubai#tools suppliers in uae dubai uae#stainless steel tools supplier in dubai uae#dubai

0 notes

Text

Best D2 Tool Steel Suppliers in India - TGK Special Steel

Significant amounts of molybdenum, vanadium, chromium, and carbon are included in tool steel D2. It exhibits outstanding through-hardening qualities and stability after being heated. TGK Special Steel is the leading manufacturer of d2 tool steel in India. Please get in touch with us for the lowest pricing on d2 tool steel.

0 notes

Text

Ultimate Guide to Choosing the Best Tool Steel Suppliers

India's leading producer, TGK Special Steel, sells tool steel products. Most grades of tool steel are available. Being a full-service master distributor, we are able to satisfy clients' requests for unusual goods.

0 notes

Text

Comparing 1.2738 Tool Steel with Other Mould Steels: Which One is Right for Your Project

TGK Special Steel in India is your go-to for tool steel supplies. Stocking a wide array of tool steel grades, we cater to diverse client needs, even providing uncommon commodities. As Tool Steel Suppliers in India, our full-service master distribution ensures comprehensive solutions for your requirements.

0 notes

Text

Comparing 1.2738 Tool Steel with Other Mould Steels: Which One is Right for Your Project

As the name suggests, mould steel is basically a type of tool steel. It is different from the other varieties due to the fact that it is particularly helpful to design moulds. That is, it is helpful in shaping things made from metal and plastic. Here are different types of mould steels available. But most of the mechanics and engineers tend to prefer 1.2738 tool Steel over the others. However, if you are currently looking for a tool steel for making moulds, then you would preferably check the properties of all varieties and not simply go by the popular choice. Here's a lowdown on the specific properties of different plastic mould steels.

1.2738 Steel

This type of tool steel contains molybdenum, chromium and nickel. This pre-hardened variety offers excellent wear resistance, machinability and polishability. Also, this plastic mould steel is a good option for chrome plating and nitriding.

P20 (1.2311) steel

This variety of steel tools is low in alloy content. It is a common component for making compression moulds and injection moulds. This type of steel contains manganese, which enhances its overall strength. It also gives good hardness uniformity, and offers wear resistance to a certain degree of pressure and temperature. However, it does not have the strength of the 1.2738 variety of steel. This does not make it the best choice for plastic moulds. However, those looking for an economical alternative to 1.2738 steel might consider it.

1.2312 (AISI P20+S) steel

It has similar properties to that of 1.2738 varieties of steel. In fact, it is more polishable and machinable than the 1.2738 type of steel. Yet, 1.2312 is not as tough as the other. Even then, the 1.2312 tool is ideal for moulds that are intricate in shape. So, if you need a metal that offers excellent cutting performance and precision, then this can be the ideal choice for you.

1.2344 (AISI P20+Mo) steel

This steel has molybdenum, quite similar to 1.2738, but it is tougher. Even then, the 1.2344 is not as machinable as the other types of steel tools. Perhaps this is the reason why it is more common for applications like creating extrusion dies and casting dies.

1.2714 (AISI H13) steel

This variety of steel tools is high in carbon content as well as chromium. It is useful to make moulds that need a high level of wear resistance and high hardness. Though it is tougher than the 1.2738 variety of steel, it does not have the machinability of the latter.

NAK80 (P21) steel

Another pre-hardened variety of tool steel, it is a popular choice for its high level of precision. However, engineers often choose the P21 variety to manufacture plastic moulds with high gloss.

S136 (1.2083) steel

A corrosion-resistant variant of mould steel, it is a bit expensive. That is why it is used to make plastic moulds of very high quality.

Conclusion

You can say that in terms of performance, applications and chemical composition, tool steels have their own differences and advantages. In fact, many of them differ in the procedure of production, as well. It is evident that the 1.2738 variant is ideal as an all-round plastic mould steel. This is why it has become a popular choice not only to create plastic moulds but also to manufacture hydroforming tools, injection moulds, die-casting dies and many more.

0 notes

Text

Discover trustworthy tool steel suppliers. Learn to choose reliable sources for durable and efficient tools. Your go-to guide for tool sourcing

0 notes

Text

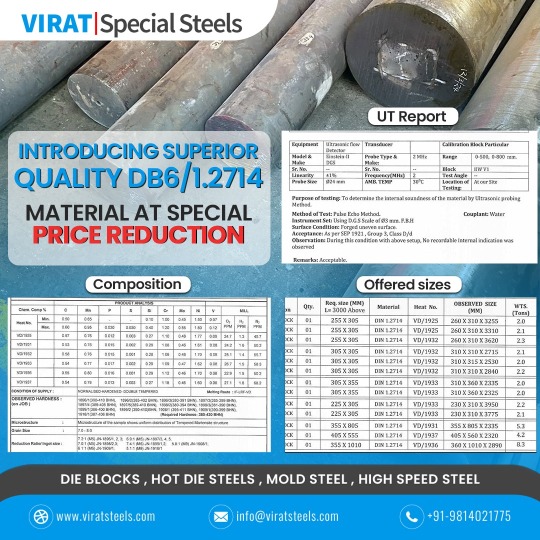

Exciting Offer from VIRAT SPECIAL STEEL! 🎉

We’re thrilled to introduce our latest innovation in tool steel - Material 2714 (#DB6), now available at a Special Price Reduction! Experience superior quality with our meticulously crafted steel, designed for high-performance and durability.

Product Specifications:

🔘Round Bars: Diameter ranging from 130mm to 610mm, with a precision machined surface for seamless integration into your projects.

🔘Die Blocks: Thickness from 255mm to 455mm, Width from 255mm to 805mm, and Length from 3 to 5 meters - all forged to perfection for robust applications.

🛠️ Why Choose Material 2714 (DB6)?

Enhanced Wear Resistance, Ideal for close die forgings, ensuring long-lasting tool life. Exceptional Toughness, provides extra durability against impact and stress. High Hardness, achieved through Cr-Ni-Mo-V high graded alloys for peak performance in demanding conditions.

Don’t miss out on this opportunity to elevate your tooling solutions. Contact us now for more details and secure your order!

For more information visit

https://www.viratsteels.com/din-2714.html

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#din2714#db6 steel#db6#hot work steel#tool steel suppliers#close die forging#diesteelsuppier

2 notes

·

View notes

Text

One of the top providers of die and tool steel in India, TGK Special Steel strives to satisfy customers by producing high-quality tool steel bars, flats, coils, and sheets. Go to our website for additional information.

0 notes

Text

In India, the well-known manufacturer TGK Special Steel provides tool steel products. We have most grades of tool steel in stock. We are able to accommodate client needs for unusual items since we are a full-service master distributor.

0 notes

Text

Steel parts are more dent resistant and are up to 30% stronger than they were a decade ago.

Visit Our website: https://lnkd.in/gRbsWSSB

Follow Our Instagram : https://lnkd.in/gSAdxtPJ

Follow Our Facebook : https://lnkd.in/gx2W9GsW

Follow Our Linkedin : https://lnkd.in/gmy8ukF3

Follow Our Pinterest : https://lnkd.in/gNj5h37q

Mail Us : [email protected]

Call Us : +91-9654956890

#plastic mould steel#die and tool steel#manufacturers#manufacturing#manufacturer#suppliers#sandeep enterprises#steel solution#plastic moulding company

0 notes

Text

4 Types of Steel: What Makes Them Different?

There are various categories of steel depending on processing, application, composition, and other differentiating factors. Each of these steel has unique properties - composition, percentage of carbon, processing techniques, etc. However, all of these are significant in their respective arenas of application. While some of these are good for household work, others are preferred for heavy industrial duty. A wide division of steel includes four broad types of steel – High speed steel, Hot work steel, Cold work steel, and Plastic mould steel. Steel can also be differentiated based on water hardening, air hardening, oil hardening, etc. Furthermore, steel can also be divided into four completely different categories, such as – Carbon steel, Stainless steel, Alloy steel, and Tool steel.

Here are the details about High speed steel, hot work steel, Cold work steel, and Plastic mould steel.

High-speed steel – As the name rightly suggests, high-speed steel has the efficiency to cut metals and other objects at a much faster pace compared to conventional high-carbon steel. This is mainly due to the exceptional features of HSS. Hardness, resistance against wear and abrasions, resistance against melting or softening at high temperatures, etc. make this steel a favourite of Tool steel suppliers. The heat treatment used during the manufacturing procedure of high-speed steel ensures its hardenability and robustness. It also has a high percentage of alloy, such as – molybdenum, vanadium, chromium of cobalt. One noteworthy factor is that – depending on the type of alloy present, the grades of high-speed steel differ. For instance – chromium helps in increasing hardenability and also reduces the chances of oxidation damage while the steel undergoes heat treatment. Each of these alloys contributes a special feature to HSS. It has high percentage of carbon, with a minimum of 0.65% by weight. Rockwell hardness is 64 at room temperature. This is used for tool bits, saw blades, broaches, taps, drills, milling cutters, etc.

Hot work steel – Tool Steel Suppliers advise using hot work steel for extrusion, pressure die casting, drop forging, and glass and tube product manufacturing. Tools that are made from hot work steel can withstand high temperatures. These can also tolerate fluctuations in thermic loads which occurs when hot work steel comes in close contact with other materials. Hot work steel has excellent resistance against shocks, and deformation at high temperatures while the steel is at work, heat checking, heat treating deformation, outstanding machinability, etc. H-group steel has low carbon content and medium alloy content. Depending on the grades, the properties slightly vary along with the percentage of that particular alloy – tungsten, chromium, or molybdenum.

Cold work steel – As opposed to hot work steel, cold work steel has a higher percentage of carbon and a lower percentage of alloys. However, the low percentage of alloys ensures hardenability, and lesser distortion and permits oil quenching. These are popularly used for collets, gauges, forming dies, and various types of blanking. Metal in cold work steel is shaped and made into a suitable size below its re-crystallization temperature. This process is in direct contrast with hot working procedures such as – welding, hot rolling, or forging. Cold work steel uses techniques such as – shearing, bending, drawing, and squeezing. Cold work steel is robust and stuff but carries chances of being brittle. It can also be used for making flat sheets, riveted joints, screw heads, etc.

Plastic mould steel – One of the highly praised steels by Tool Steel Suppliers, plastic mould steel is widely recognized due to its excellent dimensional stability while heating, wear resistance, robustness, good lustre etc. Few grades of plastic mould steel provide extra resistance against corrosion to make them perfect to mould chemically strong plastics. Most types of plastic mould steel are sold in pre-hardened form. This is popularly used in industries like – tool manufacturing and mechanical engineering, blow moulds, injection moulds, press brake dies, etc.

While one may seem superior to the other, each of these steel variants has unparalleled applications across various industries.

0 notes