#ultrasonic refrigerant leak detection

Text

Brazed Plate Heat Exchangers: Repair and Service

Brazed Plate Heat Exchangers (BPHEs) are vital components in a wide range of industrial and commercial applications due to their efficiency, compact size, and ability to handle high pressures and temperatures. However, like any mechanical equipment, BPHEs are susceptible to wear and tear over time. Proper maintenance and timely repairs are crucial to ensure their longevity and optimal performance. This article delves into the intricacies of BPHE repair and service, highlighting common issues, preventive maintenance strategies, and the benefits of professional servicing.

Understanding Brazed Plate Heat Exchangers

BPHEs consist of a series of thin, corrugated plates brazed together, typically using copper or nickel. The design allows for efficient heat transfer between two fluids without mixing them. These heat exchangers are commonly used in HVAC systems, refrigeration, power plants, and various industrial processes.

Common Issues with BPHEs

Fouling: The accumulation of contaminants on the heat transfer surfaces can significantly reduce efficiency. Fouling can result from various sources, including mineral deposits, biological growth, and particulate matter.

Corrosion: Exposure to aggressive chemicals or unsuitable operating conditions can lead to corrosion, compromising the structural integrity of the plates and the brazing material.

Leaks: Cracks or gaps in the brazing can cause leaks, leading to cross-contamination of fluids and loss of pressure.

Thermal Fatigue: Repeated heating and cooling cycles can cause thermal fatigue, leading to cracks and eventual failure.

Preventive Maintenance

Preventive maintenance is essential to extend the lifespan of BPHEs and prevent unexpected breakdowns. Key maintenance practices include:

Regular Cleaning: Implementing a routine cleaning schedule helps prevent fouling. Cleaning methods can include chemical cleaning, backflushing, or using specialized cleaning agents designed for heat exchangers.

Inspection and Monitoring: Regular visual inspections and monitoring of performance parameters (such as pressure drop and temperature differential) can help identify early signs of issues. Non-destructive testing methods, like ultrasonic testing, can also detect internal problems.

Fluid Quality Management: Ensuring the quality of the fluids used in the system can prevent fouling and corrosion. This includes using appropriate additives, filtration, and maintaining proper fluid chemistry.

Repair Techniques

When issues arise, timely and effective repairs are crucial to restore BPHE functionality. Common repair techniques include:

Leak Detection and Repair: Leaks can be detected using pressure testing or dye penetrant testing. Once identified, leaks can be repaired through methods such as re-brazing or applying specialized sealants.

Plate Replacement: In cases of severe damage or corrosion, replacing individual plates may be necessary. This requires disassembling the heat exchanger, replacing the damaged plates, and re-brazing the unit.

Reconditioning: For extensively fouled or corroded units, reconditioning involves thorough cleaning, inspection, and replacement of any damaged components. This process can restore the heat exchanger to near-original performance levels.

Benefits of Professional Service

While some maintenance tasks can be performed in-house, professional service providers offer several advantages:

Expertise and Experience: Professional technicians have the training and experience to diagnose and repair BPHE issues accurately. They are familiar with the latest techniques and technologies, ensuring effective repairs.

Specialized Equipment: Professionals have access to specialized tools and equipment that may not be available in-house. This allows for more precise and efficient repairs.

Comprehensive Service: Professional service providers can offer a complete range of services, from routine maintenance and cleaning to complex repairs and reconditioning. This ensures that all aspects of BPHE maintenance are covered.

Conclusion

Brazed Plate Heat Exchangers are critical components in many systems, and their proper maintenance and repair are essential for reliable operation. By understanding common issues, implementing preventive maintenance, and utilizing professional repair services, businesses can ensure the longevity and efficiency of their BPHEs. Regular servicing not only prevents costly downtime but also enhances the overall performance of the systems in which these heat exchangers are used.

0 notes

Text

APAC GAS LEAK DETECTORS MARKET ANALYSIS

APAC Gas Leak Detectors Market, By Technology (Electrochemical, Infrared, Semiconductor, Catalytic and Others), By Application (Industrial (Oil and gas, Chemical, Petrochemicals), Commercial (hospitals, hotels & restaurants, others), Residential and Others), By Product Type (Fixed and Portable), and by Country (China, India, Japan, ANZ, South Korea, Rest of APAC) - Size, Share, Outlook, and Opportunity Analysis, 2019 - 2027

Market Insight- APAC Gas Leak Detectors Market

Market Overview

A gas detector is an equipment that detects the presence of gases in an area. Generally, it is used as part a of safety system to detect gas leak or other emissions. These gas detectors are, generally, linked to control systems so that appropriate actions can be taken to ensure safety. There are different types of gas leak detectors available in the market including electrochemical, photoionization, infrared point, ultrasonic, semiconductor, etc. Gas leak detectors are used in various industrial and commercial enterprises. The major use of gas leak detectors is in oil & gas industries, chemical and power industries, while in commercial segment, it finds applications in restaurants, hotels, and hospitals. Furthermore, gas leak detectors find applications in municipal water, wastewater treatment, automotive manufacturing, mining, and iron & steel industries.

The global gas leak detector market was valued for US$ 1,242.7 Mn in 2019 is expected to exhibit a CAGR of 5.9 % during the forecast period.

Market Dynamics- Drivers

Growing application in oil & gas industry to ensure safety of workers is expected to drive growth of the APAC gas leak detectors market during the forecast period

Gas leak detectors are one of the many must-have devices in oil & gas industry that are necessary for protection of personnel and property hazards such as deadly, toxic, and combustible gases. Furthermore, gas detectors offer high reliability and high responsive methods to monitor toxicity, oxygen levels, and flammability. Development of gas infrastructure pipelines, warehouses, and gas stations is expected to increase, owing to growing demand for gas in the region. According to Coherent Market Insights’ analysis, natural gas liquefaction capacity in the region is expected to exhibit growth of around 66% between 2014 and 2020. Moreover, expansion of capabilities and establishments of new facilities is expected to boost the demand for gas leak detectors and thereby drive growth of the APAC gas leak detectors market in the near future.

Strict regulatory policies and safety norms regarding gas leaks in numerous industries are expected to propel the APAC gas leak detectors market growth over the forecast period

Stringent regulatory policies, laws, and safety norms are being implemented in various industries including chemical, pharmaceuticals, energy, petrochemicals, etc. Gas leak detectors are used in these aforementioned industries to detect toxic and flammable gas leaks from process containers and chambers. For instance, hazardous CO2 gas is produced during the brewing process, which needs to be safely disposed of. There are number of strict regulatory policies, safety norms, operational safety rules, and management procedures for environmental accountability that are being enforced to ensure safety operational environment for personnel and property. For instance, according to the Australia/New Zealand standard AS/NZS60079.29.2:2008, it is mandatory to install a gas detector as per work regulations, to detect flammable gases and oxygen. Thus, these factors are expected to support the market growth over the forecast period.

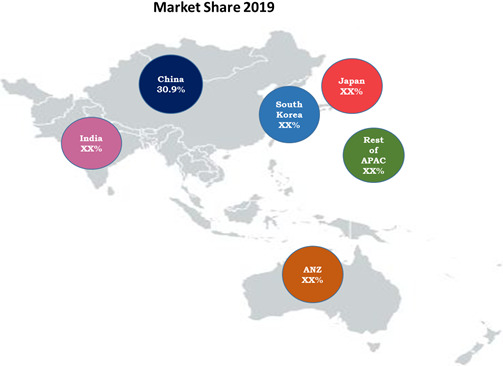

The market in China dominated the APAC gas leak detectors market 30.9 % in 2019 followed by Japan and South Korea, respectively

Source: Coherent Market Insights

Market Dynamics- Restraints

Low profit margins due to strong competition in the region are expected to hinder growth of the APAC gas leak detectors market during the forecast period

The APAC gas leak detectors market is highly fragmented and competitive with presence of small regional players and very few large international enterprises. Such intense competition between SMEs and large organizations has resulted in low profit margins from products. This, in turn, is expected to hinder the APAC gas leak detectors market growth over the forecast period.

Lack of highly skilled workers is expected to restrain growth of the APAC gas leak detectors market growth over the forecast period

Training associated with specific application of gas leak detectors is essential, typically for personnel using portable gas leak detectors apart from guidelines from the manufacturer’s side such as quick-start guides and electronic simulators. Gas leak detectors are designed to alarm people in the form of light, sound, or vibrate when some gas is detected, but in case of critical situations, it is very important to understand technical limitations and environmental influences to avoid misinterpretations, major accidents, or personnel panic. Relative operational complexities and costs associated with advanced technology based systems hampers their wide-scale adoption especially among relatively smaller scale end users. Hence, these factors are expected to hinder the market growth during the forecast period.

Market Opportunities

Increasing development of infrastructure in Asia Pacific is expected to present lucrative growth opportunity

In commercial and residential applications, gas leak detectors are primarily used for detection of propane gas leak from appliances, gas pipe fittings, and propane tank. Increasing development of commercial infrastructure combined with various large-scale projects such as malls, company headquarters, airports, and hospitals in the region are expected to offer lucrative growth opportunities in the near future. These opportunities are majorly available in emerging economies such as India and China due to increasing demand for safety and security features in residential projects.

Rising use of industrial gases is expected to provide major growth opportunities in the near future

Growing consumption of industrial gases such as helium, nitrogen, and argon across different manufacturing industries is expected to provide significant growth opportunities for major vendors to capitalize on the market. Moreover, the use of gases in refrigeration and HVAC processes in automotive application is expected to provide excellent growth for market players over the forecast period.

Source: Coherent Market Insights

Market Trends

Integration of advanced technology in gas leak detectors

Many manufacturers are focused on development of gas detectors incorporated with advanced features and novel technologies such as artificial neutral network (ANN) and Internet of Things (IoT), in order to make gas detectors highly efficient. For instance, Honeywell partnered with Houston-based Accudata Systems to develop ConneXt Pro, the first-of-its-kind wireless gas detection system based in the IoT technology. Moreover, General Monitor – a U.S.-based manufacturer of gas leak detectors – developed Observer-i, an ultra-sonic multiple gas leak detector, based on ANN technology platform, which can distinguish between real gas leaks and false alarms.

Advent of portable gas detectors is another major trend in the market

Various manufacturers in the industry are involved in incorporation advanced technologies including data logging, recording, streamline compliance, wireless connectivity, etc. into gas leak detectors. Furthermore, advanced portable gas detectors are focused on increasing applications as personal protective devices in different industries and also for mobile testing of widespread manufacturing plants. This is owing to the capability of these detectors to detect multiple gases and store data for analysis.

Segment information:

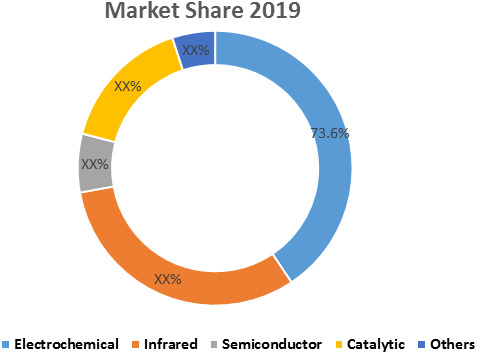

In APAC gas leak detectors market, by technology segment, electrochemical sub-segment dominated the APAC market in 2019, accounting for 73.6% share in terms of value.

Source: Coherent Market Insights

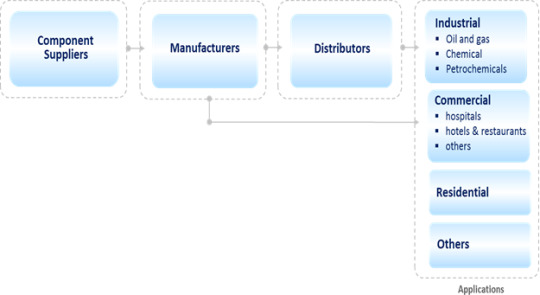

Value Chain Analysis

Competitive Section

Key players operating in the APAC gas leak detectors market are Honeywell International, Inc., MSA, New Cosmos Electric Co. Ltd, Emerson Electric Co., Industrial Scientific, Thermo Fisher Scientific Inc., Tyco International plc, Drägerwerk AG & Co. KgaA, United Technologies Corporation, and General Electric.

Key Developments

Key companies in the market are focused on mergers and acquisitions, in order to gain competitive edge in the market. For instance, in December 2019, Honeywell International Inc. acquired Rebellion Photonics, a U.S.-based provider of intelligent, visual gas monitoring solutions.

Major market players are involved in collaborations and partnerships, in order to enhance their market presence. For instance, in June 2018, New Cosmos Electric Co. Ltd, a supplier of gas detection equipment, collaborated with Itron Inc. to improve gas safety for utilities with methane detectors.

About Us:

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

Customized Market Research Services

Industry Analysis Services

Business Consulting Services

Market Intelligence Services

Long term Engagement Model

Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address: 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

Press Release/Source

Request Sample

Download PDF

0 notes

Text

Astronauts finally find location of elusive leak on the International Space Station

https://sciencespies.com/space/astronauts-finally-find-location-of-elusive-leak-on-the-international-space-station/

Astronauts finally find location of elusive leak on the International Space Station

On Monday night, NASA flight controllers woke the three men living on the International Space Station. A small air leak seemed to have grown quickly, and ground control wanted to find it fast.

NASA and Roscosmos, Russia’s space agency, had already narrowed down the likely location of the leak to several modules on the station’s Russian side.

So astronaut Chris Cassidy and cosmonauts Anatoly Ivanishin and Ivan Vagner tested those modules by shutting the hatches between each one and using an ultrasonic leak detector to collect data through the night. The tool measures noise caused by airflow too quiet for humans to hear.

By Tuesday morning, they’d figured out that the leak is in the Zvezda Service Module, the main module on the station’s Russian side.

Zvezda provides that half of the station with oxygen and drinkable water, and it’s also equipped with a machine that scrubs carbon dioxide from the air. The module contains the section’s sleeping quarters, dining room, refrigerator, freezer, and bathroom.

NASA and Roscosmos still haven’t pinpointed the source of the leak within the module, but they know it’s in Zvezda’s cylindrical “work compartment,” where crew members live and work.

“Additional work is underway to precisely locate the source of the leak,” NASA wrote in a blog post on Tuesday morning.

The agency added, however, that further investigation revealed the leak “poses no immediate danger to the crew at the current leak rate and only a slight deviation to the crew’s schedule.”

That’s because the leak did not actually change suddenly; the shift detected this week turned out to be related to “a temporary temperature change” aboard the station, NASA wrote.

Air has been leaking from the station for more than a year

A diagram of the International Space Station. (NASA)

The International Space Station always leaks a little air. Normally, the air it loses gets replaced by highly pressurised containers full of a mix of oxygen and nitrogen. These are sent up on resupply missions and designed to mimic Earth’s breathable air.

But in September 2019, officials noticed that the regular rate of air loss had increased. The change wasn’t major, but then this summer, they saw a new uptick in that already higher-than-usual rate.

So in August, crew members aboard the station began testing for leaks by sealing each section off and monitoring air pressure. They sealed themselves in the Zvezda module for the duration of the initial, four-day test, so didn’t assess it.

Because those tests didn’t find any leaks, NASA concluded that the source must have been in one of the two models not assessed: either the Zvezda module or the Poisk Mini-Research Module 2, which serves as a port for docking spaceships and a place where crew members prepare for spacewalk.

“With the crew living and working in these modules, it was impossible to achieve the proper environmental conditions necessary for this test,” a NASA spokesman, Daniel Huot, previously told Business Insider.

NASA and Roscosmos were hesitant to seal off and test the Zvezda module, however, because it connects directly to the Soyuz spacecraft attached to the ISS. Ivanishin, Cassidy, and Vagner would need to use that ship get back to Earth in an emergency, so closing the module’s hatches decreases the crew’s ability to make a quick getaway.

However, by Monday night, controllers on the ground decided that sealing off Zvezda was worth the risk.

“At that point, we made the decision that it had gotten large enough, that we felt like we had a pretty good opportunity to to get the crew up, start working through a more focused isolation procedure,” Kenny Todd, deputy program manager for the space station, told reporters on Tuesday.

The test went smoothly. While Zvezda was inaccessible, the crew relied on the life-support system on the US side of the station, which also has oxygen generators, a kitchen, and drinkable-water systems.

A busy time for the space station

The crew members located the leak ahead of a busy time for the ISS. This weekend, a Northrop Grumman spacecraft is slated to bring up an experimental new toilet and other supplies.

Then on October 14, the next crew members are expected to launch to the station from Kazakhstan: NASA astronaut Kate Rubins and cosmonauts Sergey Ryzhikov and Sergey Kud-Sverchkov.

At the end of October they will be joined by the members of NASA’s Crew-1 mission, the next mission in the agency’s partnership with SpaceX: NASA astronauts Shannon Walker, Victor Glover, and Michael Hopkins, and Japan Aerospace Exploration Agency astronaut Soichi Noguchi.

NASA was originally aiming to launch Crew-1 this month, but the timeline has been pushed back to October 31. That’s mostly to accommodate other mission schedules, though also in part because of the leak.

The delay, NASA wrote in a blog on Monday, “will provide a good window of opportunity to conduct additional testing to isolate the station atmosphere leak if required.”

Cassidy, Ivanishin, and Vagner are expected to return to Earth shortly before the Crew-1 group arrives.

Not the first leak on the space station

This isn’t the first leak found on the space station’s Russian side. In August 2018, crew members discovered a 2-millimetre drill hole in part of a Russian Soyuz spaceship that was docked to the station.

That hole seemed to indicate a manufacturing defect – it appeared that someone on Earth had attempted to plug it with paint, but that paint had broken off.

(NASA via Chris Bergin/Twitter)

So in December 2018, two cosmonauts donned spacesuits and studied the hole in detail on a spacewalk. They spent nearly eight hours hacking at the insulation with a knife to find and document it.

After that, the crew patched up the hole with an epoxy sealant. Roscosmos has since stayed quiet about the incident.

“We know exactly what happened, but we will not tell you anything,” Roscosmos head Dmitry Rogozin said at a youth science conference in September 2019, according to the Russian state news agency Ria Novosti.

This article was originally published by Business Insider.

More from Business Insider:

#Space

0 notes

Text

Ultrasonic Gas Leak Detector Market to Develop Rapidly by 2027

Ultrasonic gas leak detector is a device that is used to quickly detect leakages in compressed air or vacuum systems. It works well in open, ventilated area where other gas detection methods may not be independent of ventilation. Ultrasonic gas leak detectors are available in the market in two different types, namely fixed leak detector and portable leak detector. Moreover, this device is highly reliable and robust in nature. Ultrasonic gas leak detectors use leak rate method to determine the amount of gas leak per unit time. This method is helpful to alert on minor leak rate, significant leak rate, and major leak rate. This detector uses acoustic sensors to identify variation in noise that is inaudible to human hearing. The sensor and associated electronics are able to detect these ultrasound frequencies from 25kHz to 100kHz, while at the same time it excludes audible frequency from acoustic background noise which are not related to gas leak. In conventional gas leak detection, gas concentration is measured either in parts per million (ppm) or in lower explosive limit (LEL) whereas, in ultrasonic gas leak detection, gas concentration is measured in terms of sound pressure level (SPL).

In oil & gas industry, due to increase in incidents of leakage in oil & gas pipelines and storage tank at production facilities, construction of new pipelines, and advancement and expansion of present pipelines are supporting the growth of ultrasonic gas leak detector market. The global ultrasonic gas leak detector market is primarily driven by wide range of applications such as chemical processing plants, underground gas storage facilities, and gas turbine power plants among others. Moreover, in heating, ventilation, air conditioning and refrigeration (HVAC/R) industry ultrasonic gas leak detectors are increasingly adopted due to their versatility in leak detection and other applications. Furthermore, owing to increasing investment in emerging economies across the globe, focused on chemical and oil & gas industry and stringent safety regulation mandated by government authorities, are expected to fuel the overall market growth during forecast period. However, due to irregularities in payment cycles, and low profit margins in the oil & gas industry is expected to be the major restraining factor for global ultrasonic gas leak detector market. However, Incorporation of artificial neutral network technology and inclusion of internet of things (IoT) to upgrade ultrasonic gas leak detection technology is observed to be the key trend governing the growth of ultrasonic gas leak detector market.

Request to View Brochure of Report -

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=61089

The global ultrasonic gas leak detector market has been segmented based on product type, application, technology, and region. Based on product type, the global ultrasonic gas leak detector market can be classified into portable leak detector and fixed leak detector. Based on application, the market can be segmented into residential, industrial, and commercial applications. Based on technology, the market can be segmented into simple analog high pass filter technology, single acoustic pattern recognition, and artificial neural network technology (ANN). Additionally, based on geography the market is further segregated into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

Some of the key players operating in the global ultrasonic gas leak detector market with significant developments include Mitchell Instrument Company, Amprobe, SKF, UE Systems, Honeywell International Inc., Mine Safety Appliances or (MSA), ABB, Industrial Scientific, Yokogawa Electric Corporation, Drägerwerk AG & Co. KGaA, Emerson Electric Co., and Johnson Controls among others.

Request to View ToC of the report -

https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=61089

0 notes

Text

Refrigerant Leak Detector and Finding Leaks in your Air Conditioner

As summer approaches, it is time to start thinking about our car's air conditioning system and if it is working properly. One of the most common problems with an A/C system is refrigerant leaks and locating them. Finding the source of the leak can be a tedious and time consuming. The leaking Freon could come literally anywhere in the system from tubing to a accumulator to a tiny pressure switch gone bad. The EPA has made it much more stringent rules in dealing with refrigerant leaks. The days of topping off the air conditioner with a few cans of R12 are long over. Now even small leaks must found and corrected. Here comes technology to the rescue. There are several methods air conditioning repair shops employ to locate and fix refrigerant leaks. Each method has its pros and cons and their use depends on the situation. The three most commonly used are a electronic refrigerant leak detector, ultraviolet dye leak detection kit, and ultrasonic leak detector units.

Electronic Refrigerant Leak Detectors

Electronic Refrigerant Leak Detectors are the quickest and easiest to use of the three methods. Most of the time you will have no idea where the refrigerant is leaking and have to narrow down the possible areas. A electronic refrigerant leak detector can get you very close to the location of the leak and from there you can get more precise. Some of the better models will allow to crank up the sensitivity once you get the area found. For very small leaks you can wrap the suspected area in cling wrap or a rag to try and contain the refrigerant. When you unwrap the area, put in the refrigerant leak detector and see if you get a reading. Remember, refrigerant is heavier than air and it will sink to the ground. It is best to sniff under tubing and compartments when looking for it.

Ultrasonic Leak Detectors

These are state of the art leak detectors and are the newest tool to find refrigerant leaks. They operate on the principle of sound detection. Instead of sniffing for refrigerant gas they listen for the sound it makes as Freon escapes the system. To use an ultrasonic leak detector the system should be pressured in order for the refrigerant to leak out and make noise. Also, the work area must be totally silent. Remember it is looking for sound and no background noise is imperative. This is the main drawback to using an ultrasonic leak detector. Very few auto shops are quiet enough to use it effectively. Details here

Home Team Air

401 N Ashley Dr #172814

Tampa FL 33602

813-701-3430

0 notes

Text

New Post has been published on Plaz Media

New Post has been published on http://www.plazmedia.com/2017/basic-methods-for-refrigerant-leak-detection/

Basic Methods for Refrigerant Leak Detection

Introduction

Each administration technician who is environmentally cognizant must know ways and methods to check for leaks in air conditioners and refrigerators. The increasing expenses of refrigerants, global warming and ozone exhaustion have brought about technicians becoming better leak detectors.

Leakage can happen in all sealed systems. This is because flaws are available at each weld, seam or joint fitting. Indeed, even the best gear of leak detection can fail to detect to a great degree small flaws. In any case, given environmental anxiety, temperature, vibration and time, even these flaws get to be distinctly detectable. This article will reveal insight into some ways and methods to detect leaks in refrigerators.

The vapors of refrigerant are able to stream under layers of pipe insulation, slag, rust, flux and paint. Habitually, the site of the leak is away from the point where the refrigerant gas appears. This is the reason for the importance of cleaning the site of the leak by removing rust, flux, slag and free paint. Grease and oil ought to also be expelled from the leak site since they may contaminate the tips of electronic detectors, which are very delicate.

Diagnosing a refrigerant leak issue is straight-forward, however locating the leak source is troublesome. There are several methods that can be utilized by technicians to find these leaks. Each strategy has its own upsides and downsides. A few methods may function admirably in the location of a leak in certain conditions, yet may not function admirably in another system in altogether unique conditions.

There are certain circumstances when it is advantageous to utilize more than one leak detection technique while searching the leak – one to locate the general leakage area and the other to pinpoint the exact location of the leak.

Following are a few methods to detect leaks of refrigerants.

Visual inspection:

In a system, when the refrigerant leaks, the refrigeration oil also leaks. The area surrounding the location of the leak gets stained by this oil. A basic way to detect a leak is to inspect visually the fittings and lines for indications of oil. It may give the general idea about the area of the leak.

Using Soap bubbles:

For locating leaks in a system, a typical strategy is to utilize a soap arrangement. The arrangement will begin to rise in case a leak is available. This technique is helpful if there is adequate weight in the system or if the area where the leak is available is known. It is ideal to utilize a soapy arrangement that is purchased from a supply house. Homemade arrangements can also be utilized. They will function the length of they don’t solidify onto the fittings or tubing and they don’t cause consumption.

Electronic detectors:

Electronic Refrigerant Leak Detectors are the snappiest and easiest to utilization of the three methods. More often than not you will have no idea where the refrigerant is leaking and have to narrow down the conceivable areas. An electronic refrigerant leak detector can get you near the location of the leak and from that point you can get more exact. A portion of the better models will allow to crank up the affectability once you get the area found.

For small leaks you can wrap the speculated area in cling wrap or a rag to attempt and contain the refrigerant. When you unwrap the area, put in the refrigerant leak detector and check whether you get a reading. Keep in mind, refrigerant is heavier than air and it will sink to the ground. It is best to sniff under tubing and compartments when looking for it.

These are state of the art leak detectors and are the most current tool to find refrigerant leaks. They operate on the principle of sound detection. Instead of sniffing for refrigerant gas they tune in for the sound it makes as Freon escapes the system. To utilize a ultrasonic leak detector the system ought to be influenced all together for the refrigerant to leak out and make clamor. Also, the work area must be totally quiet.

Recollect that it is looking for sound and no background commotion is imperative. This is the main drawback to using a ultrasonic leak detector. Not very many auto shops are sufficiently calm to utilize it effectively. Most electronic detectors adequately detect leaks. The working of such detectors must be confirmed by the technician before its usage. There are a few detectors whose sensors should be changed after a certain season of usage. Their working must be tried periodically so that the technician don’t waste their time by using a faulty detector to search the leak.

Refrigerant dyes:

Certain dyes can be utilized to detect refrigerant leaks by injecting them into the system. The dye gets blended with the refrigerant oil and the leakage point builds up a dye stain. The area of leak can be located via searching for the dye stained area. Generally, fluorescent and red dyes are utilized.

Ultrasonic detectors:

A sound, having recurrence somewhat higher than normal is discharged when there is a leak of refrigerant. These sound waves can be detected with the assistance of ultrasonic detectors. This strategy gives accurate outcomes the length of there are no different sources within the area of the system that discharge same recurrence sound waves.

Ultraviolet Dye Leak Detectors

This strategy ultraviolet dye is injected into the air conditioning system and in principle ought to escape with the refrigerant. Regularly, an auto shops have a ultraviolet leak detection pack that has all of the tools necessary to finish this task. Generally these packs accompany ultraviolet lamp or ultraviolet flashlight, a dye injector, safety glasses and ultraviolet dye. This technique is the most technically complex of the three and is the messiest. You have to inject the ultraviolet dye into the system and wait for it to leak out. The dye can be muddled and get all over the place. It gets in you’re A/C system, your refrigerant manifold gages and you. However once you shine your ultraviolet flashlight and detect the leak, you usually can see exactly where it is.

Conclusion

Regulations on refrigerant leak detection depicts and administers the correct repair of a leak and appropriate disposal of any refrigerant system which can’t be repaired. These broad prerequisites are in constrain in the United States, as well as several outside nations. The treaties put forward an overall reaction to improving and protecting the planet.

Fast action of refrigerant leak detection is a great importance to the earth. Refrigerant contains gasses that have been distinguished as damaging to the ozone layer and demonstrate a high potential for causing global warming. To agree to environmental standards, many companies are investing in a refrigerant management program to monitor and track hardware usage.

Because of environmental and cost concerns related to refrigerant leak detection, many facilities with systems that utilization refrigerants are relying on refrigerant tracker applications. A refrigerant tracker monitors refrigeration and air-conditioning (RAC) systems and heating, ventilation and air conditioning (HVAC) systems around the clock and instantly detects the location of any leaks. Various reviews affirm that industrial and commercial facilities will have the capacity to save cash each year by using leak detection monitoring systems.

Author bio:

Alva is considered as one of the most prestigious experts in terms of driving. with more than 10 years of experience in working for the driving organization, he is good at understanding all the driving equipment as well as the equipment which is mainly used in order to protect the safety for all the users. That is a reason why we suggest all of you guys should get on well with the following website in order to update the newest information about the drivinglife.net or find him on Twitter here: @alva_russel1984.

0 notes

Text

New Post has been published on Plaz Media

Basic Methods for Refrigerant Leak Detection

Introduction

Each administration technician who is environmentally cognizant must know ways and methods to check for leaks in air conditioners and refrigerators. The increasing expenses of refrigerants, global warming and ozone exhaustion have brought about technicians becoming better leak detectors.

Leakage can happen in all sealed systems. This is because flaws are available at each weld, seam or joint fitting. Indeed, even the best gear of leak detection can fail to detect to a great degree small flaws. In any case, given environmental anxiety, temperature, vibration and time, even these flaws get to be distinctly detectable. This article will reveal insight into some ways and methods to detect leaks in refrigerators.

The vapors of refrigerant are able to stream under layers of pipe insulation, slag, rust, flux and paint. Habitually, the site of the leak is away from the point where the refrigerant gas appears. This is the reason for the importance of cleaning the site of the leak by removing rust, flux, slag and free paint. Grease and oil ought to also be expelled from the leak site since they may contaminate the tips of electronic detectors, which are very delicate.

Diagnosing a refrigerant leak issue is straight-forward, however locating the leak source is troublesome. There are several methods that can be utilized by technicians to find these leaks. Each strategy has its own upsides and downsides. A few methods may function admirably in the location of a leak in certain conditions, yet may not function admirably in another system in altogether unique conditions.

There are certain circumstances when it is advantageous to utilize more than one leak detection technique while searching the leak – one to locate the general leakage area and the other to pinpoint the exact location of the leak.

Following are a few methods to detect leaks of refrigerants.

Visual inspection:

In a system, when the refrigerant leaks, the refrigeration oil also leaks. The area surrounding the location of the leak gets stained by this oil. A basic way to detect a leak is to inspect visually the fittings and lines for indications of oil. It may give the general idea about the area of the leak.

Using Soap bubbles:

For locating leaks in a system, a typical strategy is to utilize a soap arrangement. The arrangement will begin to rise in case a leak is available. This technique is helpful if there is adequate weight in the system or if the area where the leak is available is known. It is ideal to utilize a soapy arrangement that is purchased from a supply house. Homemade arrangements can also be utilized. They will function the length of they don’t solidify onto the fittings or tubing and they don’t cause consumption.

Electronic detectors:

Electronic Refrigerant Leak Detectors are the snappiest and easiest to utilization of the three methods. More often than not you will have no idea where the refrigerant is leaking and have to narrow down the conceivable areas. An electronic refrigerant leak detector can get you near the location of the leak and from that point you can get more exact. A portion of the better models will allow to crank up the affectability once you get the area found.

For small leaks you can wrap the speculated area in cling wrap or a rag to attempt and contain the refrigerant. When you unwrap the area, put in the refrigerant leak detector and check whether you get a reading. Keep in mind, refrigerant is heavier than air and it will sink to the ground. It is best to sniff under tubing and compartments when looking for it.

These are state of the art leak detectors and are the most current tool to find refrigerant leaks. They operate on the principle of sound detection. Instead of sniffing for refrigerant gas they tune in for the sound it makes as Freon escapes the system. To utilize a ultrasonic leak detector the system ought to be influenced all together for the refrigerant to leak out and make clamor. Also, the work area must be totally quiet.

Recollect that it is looking for sound and no background commotion is imperative. This is the main drawback to using a ultrasonic leak detector. Not very many auto shops are sufficiently calm to utilize it effectively. Most electronic detectors adequately detect leaks. The working of such detectors must be confirmed by the technician before its usage. There are a few detectors whose sensors should be changed after a certain season of usage. Their working must be tried periodically so that the technician don’t waste their time by using a faulty detector to search the leak.

Refrigerant dyes:

Certain dyes can be utilized to detect refrigerant leaks by injecting them into the system. The dye gets blended with the refrigerant oil and the leakage point builds up a dye stain. The area of leak can be located via searching for the dye stained area. Generally, fluorescent and red dyes are utilized.

Ultrasonic detectors:

A sound, having recurrence somewhat higher than normal is discharged when there is a leak of refrigerant. These sound waves can be detected with the assistance of ultrasonic detectors. This strategy gives accurate outcomes the length of there are no different sources within the area of the system that discharge same recurrence sound waves.

Ultraviolet Dye Leak Detectors

This strategy ultraviolet dye is injected into the air conditioning system and in principle ought to escape with the refrigerant. Regularly, an auto shops have a ultraviolet leak detection pack that has all of the tools necessary to finish this task. Generally these packs accompany ultraviolet lamp or ultraviolet flashlight, a dye injector, safety glasses and ultraviolet dye. This technique is the most technically complex of the three and is the messiest. You have to inject the ultraviolet dye into the system and wait for it to leak out. The dye can be muddled and get all over the place. It gets in you’re A/C system, your refrigerant manifold gages and you. However once you shine your ultraviolet flashlight and detect the leak, you usually can see exactly where it is.

Conclusion

Regulations on refrigerant leak detection depicts and administers the correct repair of a leak and appropriate disposal of any refrigerant system which can’t be repaired. These broad prerequisites are in constrain in the United States, as well as several outside nations. The treaties put forward an overall reaction to improving and protecting the planet.

Fast action of refrigerant leak detection is a great importance to the earth. Refrigerant contains gasses that have been distinguished as damaging to the ozone layer and demonstrate a high potential for causing global warming. To agree to environmental standards, many companies are investing in a refrigerant management program to monitor and track hardware usage.

Because of environmental and cost concerns related to refrigerant leak detection, many facilities with systems that utilization refrigerants are relying on refrigerant tracker applications. A refrigerant tracker monitors refrigeration and air-conditioning (RAC) systems and heating, ventilation and air conditioning (HVAC) systems around the clock and instantly detects the location of any leaks. Various reviews affirm that industrial and commercial facilities will have the capacity to save cash each year by using leak detection monitoring systems.

Author bio:

Alva is considered as one of the most prestigious experts in terms of driving. with more than 10 years of experience in working for the driving organization, he is good at understanding all the driving equipment as well as the equipment which is mainly used in order to protect the safety for all the users. That is a reason why we suggest all of you guys should get on well with the following website in order to update the newest information about the drivinglife.net or find him on Twitter here: @alva_russel1984.

0 notes

Text

Basic Methods for Refrigerant Leak Detection

Introduction

Each administration technician who is environmentally cognizant must know ways and methods to check for leaks in air conditioners and refrigerators. The increasing expenses of refrigerants, global warming and ozone exhaustion have brought about technicians becoming better leak detectors.

Leakage can happen in all sealed systems. This is because flaws are available at each weld, seam or joint fitting. Indeed, even the best gear of leak detection can fail to detect to a great degree small flaws. In any case, given environmental anxiety, temperature, vibration and time, even these flaws get to be distinctly detectable. This article will reveal insight into some ways and methods to detect leaks in refrigerators.

The vapors of refrigerant are able to stream under layers of pipe insulation, slag, rust, flux and paint. Habitually, the site of the leak is away from the point where the refrigerant gas appears. This is the reason for the importance of cleaning the site of the leak by removing rust, flux, slag and free paint. Grease and oil ought to also be expelled from the leak site since they may contaminate the tips of electronic detectors, which are very delicate.

Diagnosing a refrigerant leak issue is straight-forward, however locating the leak source is troublesome. There are several methods that can be utilized by technicians to find these leaks. Each strategy has its own upsides and downsides. A few methods may function admirably in the location of a leak in certain conditions, yet may not function admirably in another system in altogether unique conditions.

There are certain circumstances when it is advantageous to utilize more than one leak detection technique while searching the leak – one to locate the general leakage area and the other to pinpoint the exact location of the leak.

Following are a few methods to detect leaks of refrigerants.

Visual inspection:

In a system, when the refrigerant leaks, the refrigeration oil also leaks. The area surrounding the location of the leak gets stained by this oil. A basic way to detect a leak is to inspect visually the fittings and lines for indications of oil. It may give the general idea about the area of the leak.

Using Soap bubbles:

For locating leaks in a system, a typical strategy is to utilize a soap arrangement. The arrangement will begin to rise in case a leak is available. This technique is helpful if there is adequate weight in the system or if the area where the leak is available is known. It is ideal to utilize a soapy arrangement that is purchased from a supply house. Homemade arrangements can also be utilized. They will function the length of they don’t solidify onto the fittings or tubing and they don’t cause consumption.

Electronic detectors:

Electronic Refrigerant Leak Detectors are the snappiest and easiest to utilization of the three methods. More often than not you will have no idea where the refrigerant is leaking and have to narrow down the conceivable areas. An electronic refrigerant leak detector can get you near the location of the leak and from that point you can get more exact. A portion of the better models will allow to crank up the affectability once you get the area found.

For small leaks you can wrap the speculated area in cling wrap or a rag to attempt and contain the refrigerant. When you unwrap the area, put in the refrigerant leak detector and check whether you get a reading. Keep in mind, refrigerant is heavier than air and it will sink to the ground. It is best to sniff under tubing and compartments when looking for it.

These are state of the art leak detectors and are the most current tool to find refrigerant leaks. They operate on the principle of sound detection. Instead of sniffing for refrigerant gas they tune in for the sound it makes as Freon escapes the system. To utilize a ultrasonic leak detector the system ought to be influenced all together for the refrigerant to leak out and make clamor. Also, the work area must be totally quiet.

Recollect that it is looking for sound and no background commotion is imperative. This is the main drawback to using a ultrasonic leak detector. Not very many auto shops are sufficiently calm to utilize it effectively. Most electronic detectors adequately detect leaks. The working of such detectors must be confirmed by the technician before its usage. There are a few detectors whose sensors should be changed after a certain season of usage. Their working must be tried periodically so that the technician don’t waste their time by using a faulty detector to search the leak.

Refrigerant dyes:

Certain dyes can be utilized to detect refrigerant leaks by injecting them into the system. The dye gets blended with the refrigerant oil and the leakage point builds up a dye stain. The area of leak can be located via searching for the dye stained area. Generally, fluorescent and red dyes are utilized.

Ultrasonic detectors:

A sound, having recurrence somewhat higher than normal is discharged when there is a leak of refrigerant. These sound waves can be detected with the assistance of ultrasonic detectors. This strategy gives accurate outcomes the length of there are no different sources within the area of the system that discharge same recurrence sound waves.

Ultraviolet Dye Leak Detectors

This strategy ultraviolet dye is injected into the air conditioning system and in principle ought to escape with the refrigerant. Regularly, an auto shops have a ultraviolet leak detection pack that has all of the tools necessary to finish this task. Generally these packs accompany ultraviolet lamp or ultraviolet flashlight, a dye injector, safety glasses and ultraviolet dye. This technique is the most technically complex of the three and is the messiest. You have to inject the ultraviolet dye into the system and wait for it to leak out. The dye can be muddled and get all over the place. It gets in you’re A/C system, your refrigerant manifold gages and you. However once you shine your ultraviolet flashlight and detect the leak, you usually can see exactly where it is.

Conclusion

Regulations on refrigerant leak detection depicts and administers the correct repair of a leak and appropriate disposal of any refrigerant system which can’t be repaired. These broad prerequisites are in constrain in the United States, as well as several outside nations. The treaties put forward an overall reaction to improving and protecting the planet.

Fast action of refrigerant leak detection is a great importance to the earth. Refrigerant contains gasses that have been distinguished as damaging to the ozone layer and demonstrate a high potential for causing global warming. To agree to environmental standards, many companies are investing in a refrigerant management program to monitor and track hardware usage.

Because of environmental and cost concerns related to refrigerant leak detection, many facilities with systems that utilization refrigerants are relying on refrigerant tracker applications. A refrigerant tracker monitors refrigeration and air-conditioning (RAC) systems and heating, ventilation and air conditioning (HVAC) systems around the clock and instantly detects the location of any leaks. Various reviews affirm that industrial and commercial facilities will have the capacity to save cash each year by using leak detection monitoring systems.

Author bio:

Alva is considered as one of the most prestigious experts in terms of driving. with more than 10 years of experience in working for the driving organization, he is good at understanding all the driving equipment as well as the equipment which is mainly used in order to protect the safety for all the users. That is a reason why we suggest all of you guys should get on well with the following website in order to update the newest information about the drivinglife.net or find him on Twitter here: @alva_russel1984.

0 notes

Text

An elusive leak on the ISS has been narrowed down to 2 Russian modules

https://sciencespies.com/space/an-elusive-leak-on-the-iss-has-been-narrowed-down-to-2-russian-modules/

An elusive leak on the ISS has been narrowed down to 2 Russian modules

The International Space Station has been leaking for more than a year.

While the station is perpetually losing some air, officials first noticed an increase in that airflow last September. At the time the leak wasn’t major, but this summer they saw an uptick in that already higher-than-usual rate.

So in late August, the three crew members aboard the station – the NASA astronaut Chris Cassidy and the Roscosmos cosmonauts Anatoly Ivanishin and Ivan Vagner – hunkered down in one module of the station and sealed off the others. After closing the hatches, they conducted leak tests on each section.

But their data didn’t reveal leaks in those sections.

That leaves only two modules that could be leaking: the ones the crew didn’t test because they were inside them while monitoring the rest of the station.

One is the Zvezda Service Module, which provides life support for the station’s Russian side. The other is the Poisk Mini-Research Module 2, which serves as a port for docking spaceships and a place where crew members prepare for spacewalks.

“With the crew living and working in these modules, it was impossible to achieve the proper environmental conditions necessary for this test,” a NASA spokesman, Daniel Huot, told Business Insider.

NASA and Roscosmos, Russia’s space agency, are working to identify a “window of opportunity” to test those remaining modules for leaks, he added – either by finding a way for crew members to safely isolate the untested modules or by using specialised detectors that wouldn’t require sealing the sections off.

In the meantime, Huot said, “the crew is in no danger and the space station has ample consumables onboard to manage and maintain the nominal environment.” Consumables, in this case, refers to breathable air.

Zvezda isn’t the only life-support module on the station

NASA didn’t consider the leak it detected a year ago to be major. And other priorities, like spacewalks and crew exchanges, kept the agency and the ISS crew too busy to collect enough data about the problem.

But once the leak rate increased, the agency decided it was time to do something about it. If the leak were to quickly grow even bigger, the pressurised air-supply tanks that NASA sends up to the ISS on resupply missions might not be enough.

The Zvezda module, which launched in July 2000, was the first liveable part of the space station in orbit. It provides the Russian half of the station with oxygen and drinkable water, and it’s equipped with a machine that scrubs carbon dioxide from the air.

The module also contains the section’s sleeping quarters, dining room, refrigerator-freezer, and bathroom.

But Zvezda isn’t the only section of the orbiting laboratory that provides life support. The US side of the station has its own fully functioning life-support system, with oxygen generators, a kitchen, and drinkable-water systems.

So theoretically, crew members could stay on the US side while conducting further tests.

The problem, though, is that Zvezda connects directly to the Soyuz spacecraft that’s attached to the ISS and that the astronauts and cosmonauts need to use to get back to Earth.

Closing the module’s hatches and testing it for leaks would therefore make it tough for Ivanishin, Cassidy, and Vagner to access the Soyuz quickly in case of an emergency, should they have to make a quick getaway.

However, there’s a slim chance that earlier leak tests missed something. So on Thursday, crew members used an ultrasonic leak detector to examine several windows, valves, and seals within previously tested modules, just in case.

The tool measures noise caused by “turbulent airflow” – in this case, an air leak that’s too quiet for humans to hear.

The crew tested windows in the Kibo section on the US side, as well as several other windows on the Russian side. Engineers on Earth will analyse the data in the coming days.

And this isn’t the first leak on the International Space Station

This isn’t the first leak found on the space station’s Russian side, nor the most frightening.

In August 2018, crew members discovered a 2-millimetre drill hole in part of a Russian Soyuz MS-09 spaceship that was docked to the station at the time.

(NASA via Chris Bergin/Twitter)

Above: At left, a hole that appears drilled into part of a Soyuz spacecraft at the International Space Station. At right, a patch made by the crew using epoxy.

That hole seemed to indicate a manufacturing defect – it appeared that someone on Earth had attempted to plug the hole with paint, but that paint broke off after the Soyuz reached the space station.

So in December 2018, two cosmonauts donned spacesuits and floated to the outside of the Soyuz ship to study the hole in detail. They spent nearly eight hours hacking away at the insulation with a knife to find and document it.

After that, the crew patched up the hole with an epoxy sealant.

Roscosmos has stayed fairly quiet about that incident ever since.

“We know exactly what happened, but we will not tell you anything,” the head of Roscosmos, Dmitry Rogozin, said at a youth science conference in September 2019, according to the Russian state news agency Ria Novosti.

This article was originally published by Business Insider.

More from Business Insider:

#Space

0 notes