#working for 2D barcodes

Explore tagged Tumblr posts

Text

Mixed Materials in 3D. I experimented with moving from 2D to 3D. It wasn’t easy because I wanted to make something interesting and relevant to my project. I also found myself shifting focus from barcodes to transmission towers (which I explored a few weeks ago and decided to continue with).

Building the transmission tower with willow sticks and wires of different thicknesses was quite challenging. If I had more time, I would have studied the tower in more detail and tried to make it more precise. I know it doesn’t look perfect—it actually looks quite rough—but maybe that’s part of the idea: to work quickly without aiming for perfection.

5 notes

·

View notes

Text

Understanding Barcode Definitions: A Quick Guide 2025

1. What Is a Barcode? Simple Barcode Definitions Explained

In 2025, barcodes continue to play a vital role in modern business operations. To begin, let’s explore the Barcode Definitions in the simplest terms. A barcode is a visual representation of data using parallel lines (in 1D barcodes) or squares and patterns (in 2D barcodes like QR codes). This code is scanned using machines to retrieve the encoded information instantly.

The purpose of Barcode Definitions is to explain what barcodes are and how they enable businesses to streamline tracking, inventory, and point-of-sale systems. Barcodes are now used in retail, healthcare, logistics, catering, and countless other sectors.

2. How Barcodes Work: A Quick Technical Breakdown

Understanding how barcodes function helps bring clarity to Barcode Definitions. Each barcode is designed to hold specific data such as a product ID, location, batch number, or price. A scanner uses light sensors to read the code and instantly translate it into readable data for a computer system.

The scanner decodes the reflected light from the barcode and converts it into digital signals. These signals are matched with backend systems to identify the item or data linked to the code. This makes barcodes a fast and efficient solution for real-time tracking and management.

3. Common Types of Barcodes Used in 2025

When looking at Barcode Definitions, it’s important to know the various types available today:

1D Barcodes (like UPC or EAN): These are linear and used mainly in retail.

2D Barcodes (like QR Codes and Data Matrix): These carry more data in less space.

PDF417: Used in official documents like driving licenses or airline boarding passes.

GS1 Barcodes: Global standards for supply chains and retail.

Each of these fits under the umbrella of modern Barcode Definitions and helps businesses choose the best format for their needs.

4. Importance of Barcodes in Retail, Logistics, and Healthcare

Barcodes play a huge role in various industries. The Barcode Definitions used in retail involve product labeling, price management, and automated checkout systems. In logistics, barcodes help in tracking goods from warehouse to delivery. In healthcare, patient IDs, medication labels, and equipment tags rely on barcodes for accuracy and safety.

These definitions reflect the growing demand for error-free, data-driven systems that barcodes continue to fulfill in 2025.

5. Barcode Definitions in Inventory Management Systems

One of the key applications of Barcode Definitions is in inventory control. Businesses use barcodes to keep accurate track of stock levels, shipments, and usage trends. Barcode systems eliminate manual entry and reduce errors significantly.

For example, catering businesses like Jaffer Bhai’s use barcodes to track ingredient usage, kitchen supplies, and packaging materials. Each item can be tagged, scanned, and updated in real-time, helping with order accuracy and planning.

6. Advantages of Using Barcodes in Modern Business Operations

There are many advantages associated with Barcode Definitions in daily business use:

Speed: Scan hundreds of items in minutes.

Accuracy: Reduce human errors in data entry.

Cost-effective: Affordable to print and implement.

Scalability: Suitable for businesses of all sizes.

These benefits show why Barcode Definitions are essential for businesses that value efficiency and precision in 2025.

7. Barcode vs QR Code: What's the Difference in 2025?

Many people confuse barcodes with QR codes, so understanding their differences is part of clear Barcode Definitions. A barcode (1D) holds limited information and requires line-of-sight scanning. A QR code (2D) can hold more data and can be scanned from any angle, even with mobile phones.

In catering, barcodes might be used to label utensils, while QR codes can direct customers to digital menus or feedback forms. Knowing when to use each format helps businesses make the most of their barcoding systems.

8. Smart Packaging and Barcode Innovation Trends for 2025

Barcode Definitions have evolved with the rise of smart packaging. In 2025, businesses use barcodes combined with cloud systems and mobile apps to manage inventory automatically. Products can be tracked from production to customer delivery using advanced barcode systems.

Smart labels also include features like temperature tracking, expiry alerts, and tamper evidence, making barcode solutions smarter and more secure than ever.

9. How to Implement a Barcode System for Your Business

Implementing barcode systems starts with understanding Barcode Definitions and identifying your tracking needs. Here are basic steps:

Choose the right barcode type for your industry.

Invest in barcode software and printers.

Label all inventory or equipment clearly.

Train staff on how to scan and manage barcoded items.

Connect scanning data to your inventory or POS software.

Once set up, barcodes will begin improving accuracy and accountability immediately.

10. The Future of Barcode Technology: What's Next Beyond 2025?

The Barcode Definitions of the future include integration with AI, IoT (Internet of Things), and blockchain. These technologies will help verify the origin of goods, automate reordering, and improve transparency in the supply chain.

Barcodes will also evolve in design, using invisible ink or nano printing for added security. Mobile apps will continue making barcode scanning easier for businesses and consumers alike.

Call to Action:

Want to implement barcode tracking in your business? Contact AIDC Technologies India today to discover cutting-edge solutions built on reliable Barcode Definitions and smart automation.

#BarcodeDefinitions#BarcodeTechnology2025#SmartInventory#RetailAutomation#BarcodeSystem#InventorySolutions#AIDCIndia

0 notes

Text

The Ultimate Guide to Choosing the Best Zebra Barcode Scanner and 2D Barcode Scanner

In today's digital world, businesses rely heavily on barcode scanning technology to streamline operations, improve efficiency, and reduce errors. Whether you run a retail store, warehouse, healthcare facility, or logistics company, investing in a high-quality Zebra barcode scanner or 2D barcode scanner can significantly enhance your workflow. This guide will help you understand the key benefits of these scanners and how to choose the best one for your business needs.

Why Barcode Scanners Are Essential for Businesses

Barcode scanners play a crucial role in improving inventory management, tracking shipments, and enhancing customer service. With advancements in scanning technology, modern barcode scanners offer faster processing, better accuracy, and improved durability. Among the top brands, Zebra barcode scanners stand out for their reliability and performance.

A 2D barcode scanner is particularly useful as it can read both traditional 1D barcodes and more complex 2D barcodes, such as QR codes and Data Matrix codes. These scanners are widely used in retail, healthcare, and logistics industries where high-speed and high-accuracy scanning is required.

Understanding Zebra Barcode Scanners

Zebra is one of the leading manufacturers of barcode scanning technology. Their barcode scanners are known for their durability, precision, and ease of use. Here’s why a Zebra barcode scanner could be the right choice for your business:

1. High Performance and Speed

Zebra scanners offer rapid scanning speeds, reducing wait times at checkout counters or inventory processing.

They can scan barcodes even if they are damaged or poorly printed.

2. Durability and Rugged Design

Many Zebra barcode scanners are designed to withstand tough environments, making them ideal for warehouses and industrial use.

They are built to survive drops, dust, and water exposure.

3. Versatile Connectivity Options

Zebra scanners offer various connectivity options, including USB, Bluetooth, and Wi-Fi, to integrate seamlessly with existing systems.

Wireless options provide mobility and flexibility for workers who need to scan items on the go.

4. User-Friendly Operation

Zebra scanners come with intuitive designs and easy-to-use interfaces, reducing training time for employees.

Many models include plug-and-play functionality for quick setup.

The Advantages of Using a 2D Barcode Scanner

A 2D barcode scanner is a step up from traditional 1D scanners. It is capable of reading more complex barcode formats and offers several benefits:

1. Reads Multiple Barcode Types

Unlike 1D scanners, which only read linear barcodes, 2D scanners can read QR codes, Data Matrix codes, and Aztec codes.

This versatility makes them suitable for industries like healthcare, ticketing, and logistics.

2. Omni-Directional Scanning

A 2D barcode scanner can read barcodes from any angle, eliminating the need for precise alignment.

This speeds up the scanning process and reduces errors in high-volume environments.

3. Scans from Screens

Many businesses now use digital barcodes displayed on mobile screens.

A 2D barcode scanner can easily scan barcodes from smartphones, tablets, and computer screens, making it ideal for contactless transactions and digital ticketing.

4. Enhanced Data Storage

2D barcodes can store more information than traditional barcodes, allowing businesses to embed more details in each scan.

This is especially useful for tracking product history, expiration dates, and batch numbers.

Choosing the Best Zebra Barcode Scanner or 2D Barcode Scanner

When selecting a barcode scanner, consider the following factors:

1. Intended Use

If you need a scanner for a retail checkout, a compact and wireless Zebra barcode scanner is a great choice.

For warehouse and industrial environments, choose a rugged model that can withstand harsh conditions.

2. Scanning Distance

Standard scanners work well for close-range scanning, while long-range Zebra scanners can capture barcodes from several feet away.

3. Connectivity Options

Decide whether you need a wired or wireless scanner based on your workflow requirements.

Wireless scanners provide greater mobility, while wired scanners offer reliability for stationary use.

4. Budget and Features

Compare different models and their features to find the best value for your business.

Consider additional features like hands-free scanning, multi-code reading, and real-time data integration.

Popular Industries Using Zebra Barcode Scanners and 2D Barcode Scanners

Retail and E-Commerce

Speeds up checkout processes and improves customer service.

Scans digital coupons and mobile payment barcodes efficiently.

Warehousing and Logistics

Tracks shipments and manages inventory more accurately.

Ensures real-time data synchronization with inventory management systems.

Healthcare and Pharmaceuticals

Helps track medications and patient records with precision.

Reduces human errors by scanning patient wristbands and prescription labels.

Manufacturing and Industrial Use

Assists in product labeling and tracking throughout the production process.

Enhances quality control and ensures compliance with safety regulations.

Future Trends in Barcode Scanning Technology

Barcode scanning technology continues to evolve, with innovations improving speed, accuracy, and connectivity. Here are some emerging trends:

AI-Powered Scanning: Enhances scanning accuracy and automates data processing.

Cloud-Based Barcode Management: Allows remote access to barcode data from anywhere.

Integration with IoT: Smart barcode scanners connected to IoT networks improve efficiency in warehouses and supply chains.

Conclusion

Investing in a Zebra barcode scanner or a 2D barcode scanner can significantly enhance your business operations by improving efficiency, reducing errors, and optimizing workflow. Whether you're in retail, logistics, healthcare, or manufacturing, these scanners offer the reliability and performance needed to stay competitive. By understanding the different types, features, and use cases, you can choose the best scanner for your specific needs. Upgrade your scanning solutions today and take your business to the next level!

0 notes

Text

0 notes

Text

GTIN Barcode

Understanding GTIN Barcodes: What They Are and How They Work

In today’s fast-paced and highly interconnected global market, efficient product identification and tracking are critical. One of the most effective ways to achieve this is through the use of GTIN barcodes. These barcodes are essential for businesses to streamline operations, improve inventory management, and ensure smooth transactions across various sales channels.

This article will explore what GTIN barcodes are, how they work, and why they are an essential tool for modern businesses.

What is a GTIN Barcode?

A GTIN barcode is a machine-readable representation of a Global Trade Item Number (GTIN), a unique identifier used to track and manage products. The GTIN itself is a numeric code that identifies a product or trade item, while the barcode is the visual representation of that code. The barcode can be scanned by barcode readers or mobile devices to quickly retrieve product information, such as the product’s description, price, stock level, and more.

A GTIN barcode is typically printed on product packaging or labels, making it easy for retailers, distributors, and suppliers to scan and track items throughout the supply chain.

How Does a GTIN Barcode Work?

The GTIN barcode works by encoding the unique GTIN into a machine-readable format. Here's a breakdown of the process:

GTIN Creation: The first step is the creation of a GTIN (such as GTIN-12, GTIN-13, or GTIN-14) for the product. This code can be assigned by the manufacturer or business when the product is created and registered with GS1, the global standards organization.

Barcode Generation: Once the GTIN is assigned, a GTIN barcode is generated. The barcode is a visual pattern of bars and spaces that represent the GTIN number. It can be a 1D (one-dimensional) barcode (like UPC or EAN) or a 2D (two-dimensional) barcode (such as QR codes, though less commonly used for GTINs in retail).

Barcode Printing: The generated barcode is printed on the product packaging, label, or tag. This barcode can now be scanned by devices to retrieve the product information embedded in the GTIN.

Scanning the Barcode: At the point of sale or during inventory management, the barcode is scanned. A scanner or mobile device reads the barcode and decodes the GTIN, which retrieves the relevant product data from the database, such as the product name, price, and stock level.

Types of GTIN Barcodes

There are various types of GTIN barcodes, each corresponding to a different GTIN format. The most common types of GTIN barcodes are:

UPC Barcode (GTIN-12): A 12-digit barcode used in North America. It is commonly used for retail products and is one of the most recognizable barcode formats in the world. This barcode is used for individual products that are sold directly to consumers.

EAN Barcode (GTIN-13): A 13-digit barcode primarily used outside of North America, including Europe and Asia. The GTIN-13 is used for individual consumer products, similar to the GTIN-12 but with an additional digit to accommodate international identification.

ITF-14 Barcode (GTIN-14): A 14-digit barcode used to identify trade items that are sold in bulk or in larger packaging, such as cartons or pallets. The GTIN-14 barcode is used to track large shipments and bulk products.

Why are GTIN Barcodes Important?

GTIN barcodes provide a range of benefits for businesses, retailers, and consumers:

Increased Efficiency: The use of GTIN barcodes significantly speeds up product scanning and checkout processes. Instead of manually entering product codes or prices, the barcode can be scanned, instantly retrieving product details and speeding up the entire transaction.

Accurate Product Tracking: Barcodes make it easy to track products throughout the supply chain. Each product’s barcode can be scanned at multiple points, from warehouse management to point-of-sale, ensuring accurate tracking of inventory levels, shipments, and stock.

Reduced Errors: By automating data entry through barcode scanning, the risk of human error is minimized. This ensures that the correct product details, pricing, and stock levels are always captured and updated in real time.

Global Compatibility: GTIN barcodes are recognized worldwide. Regardless of where a product is sold or distributed, a GTIN barcode ensures the product can be scanned and identified internationally. This makes it easier for businesses to sell products globally and for consumers to purchase products from different regions.

Improved Inventory Management: Businesses can use GTIN barcodes to efficiently manage inventory. Scanning barcodes allows real-time updates of stock levels, helping businesses avoid overstocking or stockouts and optimize their supply chain operations.

E-commerce Integration: Many e-commerce platforms, such as Amazon, require GTIN barcodes for product listings. Having a GTIN barcode ensures that products are properly listed and searchable on these platforms, improving visibility and sales potential.

Better Consumer Experience: For consumers, GTIN barcodes ensure faster checkouts and more accurate product information. Whether shopping in-store or online, the consistent use of GTIN barcodes helps to improve the overall shopping experience.

How to Generate and Print GTIN Barcodes

To create and print GTIN barcodes, businesses must first obtain GTINs for their products by registering with GS1. Once a GTIN is assigned to a product, businesses can generate the corresponding barcode using barcode generation software. These barcodes can be printed on product packaging, labels, or tags.

There are many online tools available, including websites like gtin.info, that can guide businesses through the process of generating GTIN barcodes and printing them correctly for their products.

Conclusion

GTIN barcodes are an essential tool for modern businesses that want to streamline operations, reduce errors, and ensure smooth product tracking throughout the supply chain. By using these barcodes, businesses can efficiently manage inventory, speed up transactions, and expand their reach in global markets. Whether you are a small retailer or a large multinational business, adopting GTIN barcodes will improve operational efficiency and enhance the customer experience. If you're ready to get started, websites like gtin.info offer valuable resources to help businesses register their products and create barcodes.

0 notes

Text

The Honeywell 1250: A Game-Changer for Barcode Scanning

In today’s fast-paced retail and industrial environments, barcode scanning technology is critical for enhancing efficiency and accuracy. One of the latest innovations in the market, the Honeywell 1250 Barcode Scanner, is making waves with its advanced features and reliability. Whether you're managing inventory, processing sales, or tracking assets, this scanner is designed to streamline operations and boost productivity.

Key Features of the Honeywell 1250 Barcode Scanner

The Honeywell 1250 Barcode Scanner is packed with features that make it a top choice for businesses looking to improve their barcode scanning capabilities. Here are some of the standout features:

Versatile Scanning Capabilities: The Honeywell 1250 excels in scanning a wide range of barcodes, including 1D and 2D barcodes, making it ideal for diverse applications across various industries.

Enhanced Durability: Built to withstand tough environments, the 1250 is rugged and resistant to drops, dust, and water, ensuring it performs reliably in demanding conditions.

Ergonomic Design: The scanner’s lightweight and ergonomic design reduce hand fatigue, making it comfortable to use for extended periods.

Fast Scanning Speed: With high-speed scanning capabilities, the Honeywell 1250 significantly reduces wait times and improves overall efficiency in your workflow.

Advanced Imaging Technology: The built-in imaging technology ensures accurate and reliable scans even for damaged or poorly printed barcodes.

Why Choose the Honeywell 1250 Barcode Scanner?

The Honeywell 1250 Barcode Scanner is a game-changer for businesses in various sectors, including retail, logistics, and healthcare. Its adaptability to scan both 1D and 2D barcodes, combined with its robust features, makes it the ideal tool for businesses looking to optimize their operations. Whether you need to speed up checkout processes, manage inventory, or improve asset tracking, the Honeywell 1250 offers the perfect solution.

Partnering with PrimePOS: Your Trusted Dealer for the Honeywell 1250

When purchasing the Honeywell 1250 Barcode Scanner, it’s important to work with a reliable and experienced dealer. PrimePOS is your go-to source for top-quality barcode scanners, including the Honeywell 1250. As a trusted dealer, PrimePOS provides expert advice, excellent customer service, and competitive pricing.

Here’s why PrimePOS is the right choice for your barcode scanning needs:

Expert Guidance: The team at PrimePOS understands the unique needs of each business and can help you select the best barcode scanner solution.

Competitive Pricing: With PrimePOS, you get the best value for your investment. Their competitive pricing ensures you can afford top-tier technology without breaking the bank.

Ongoing Support: PrimePOS offers excellent after-sales support, ensuring your equipment remains in top condition and performs as expected.

Wide Selection: In addition to the Honeywell 1250, PrimePOS carries a wide range of barcode scanning solutions tailored to your specific needs.

Conclusion

The Honeywell 1250 Barcode Scanner is indeed a game-changer in the world of barcode scanning. Its combination of speed, accuracy, durability, and versatility makes it an excellent investment for businesses looking to stay ahead of the curve. Partnering with a trusted dealer like PrimePOS ensures you receive the best product and service to help streamline your operations and improve efficiency. Don't wait – invest in the Honeywell 1250 and see the difference it can make for your business today!

For More Products

Visit : www.primepos.in

Contact : 9849032655/8008333163

0 notes

Text

Barcode

The Significance of Barcodes in Modern Business

Barcodes have revolutionized the way businesses track products, manage inventory, and streamline operations. A barcode is a pattern of parallel lines and spaces, typically in black and white, which can be scanned and decoded by a machine. The simplicity of a barcode hides its remarkable efficiency in managing vast amounts of information.

What Exactly is a Barcode?

At its core, a barcode is a visual representation of data that can be read by a machine. It consists of a series of vertical lines that vary in width, along with spaces between them. These lines and spaces represent numerical or alphanumeric characters that a barcode scanner can interpret. There are different types of barcodes, each designed for specific purposes. Some are one-dimensional (1D), while others are two-dimensional (2D), which can store much more information in the same space.

How Barcodes Work

The function of a barcode is simple yet powerful. When a barcode is scanned, the scanner shines light on the barcode. The black lines absorb light, and the white spaces reflect it back. The scanner detects the variations in light and translates the data into a readable format for the system to process. This technology allows for quick data entry and minimizes human error, ensuring accurate records and faster transactions.

Uses of Barcodes in Business

Barcodes are widely used in retail environments to streamline sales transactions. When a product is scanned at the checkout, the barcode provides essential information about the item, such as its price and stock number. This system speeds up the purchasing process, making it more efficient for both the customer and the business.

In warehouses and distribution centers, barcodes play a critical role in managing inventory. Each item is assigned a unique barcode, and as it moves through the supply chain, the barcode allows for quick tracking. This leads to better stock management, reduces the risk of lost goods, and minimizes the time spent searching for products.

Barcodes also help improve accuracy in data collection and reduce human error. In industries like healthcare, pharmaceuticals, and logistics, where precision is essential, barcodes help ensure that the right products are delivered to the right places.

Benefits of Using Barcodes

Efficiency: Barcodes speed up processes by allowing quick scanning and data entry.

Accuracy: They minimize human error by automating data collection.

Cost-Effective: Implementing barcode systems is relatively inexpensive compared to other data entry methods.

Inventory Control: They help businesses track inventory levels in real-time, improving stock management and reducing waste.

Improved Customer Experience: Faster checkout and fewer errors lead to better customer satisfaction.

Future of Barcodes

As technology advances, barcodes continue to evolve. With the rise of mobile devices and smartphones, we see a shift toward using mobile apps that can scan barcodes, giving businesses the flexibility to manage operations on the go. Additionally, newer types of barcodes, such as QR codes, are becoming more popular for marketing and customer engagement purposes, allowing businesses to provide additional information or promotions through a simple scan.

In conclusion, barcodes are a small but mighty tool that businesses rely on for accurate, efficient, and cost-effective operations. From inventory management to enhancing customer experience, barcodes will continue to be an essential part of the modern business landscape for years to come.

0 notes

Text

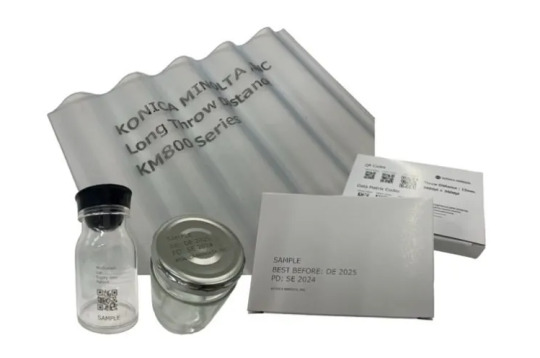

Konica Minolta launches KM800H-MR industrial inkjet printhead

Konica Minolta has launched the KM800H-MR, which supports various inks with an internal heater, as a new product of the industrial inkjet printhead KM800 series featuring a long throw distance.

In the logistics industry, there is growing need for higher productivity due to an increase in cargo volumes. Compared to the method of attaching printed labels, direct printing using inkjet technology on industrial products, such as metals and wood, and other target objects, such as pharmaceuticals, food packaging, and corrugated cardboard, can increase the efficiency by reducing the downtime due to replacement of label rolls, and contributes to a lower environmental impact by reducing waste.

Inkjet printing is also characterized by ease of design changes and production adjustments because the information to be printed can be changed flexibly. It is applicable to small lots, helping reduce inventory losses. Notably, piezo inkjet is suitable for high-resolution printing in small areas and printing of complex designs, such as 2D barcodes, because of its printing capabilities and high image quality.

Konica Minolta has been working on 'Improving fulfillment in work and corporate dynamism,' 'Addressing climate change,' and 'Using limited resources effectively' as its material issues through expansion of the inkjet printhead business, which contributes to higher efficiency of work processes and a lower environmental impact. Because this business can help reduce processes and handle small lots through direct printing on target objects in the logistics industry, Konica Minolta will further strengthen its capabilities to make proposals that contribute to higher productivity.

Values provided by the KM800H-MR

The KM800 series is characterized by long throw distance performance, which enables printing with high image quality on target objects 20 mm away from the printhead, and the ink jetting stability. The long throw distance enables printing even on base materials where the distance from the nozzles to the printing surface varies, such as curved and rough surfaces. The distance between printhead and material should be enough to reduce the chance of head strike or material collision with the printhead.

Equipped with an internal heater, the KM800H-MR achieves a long throw distance even for UV inks, which are more viscous than water-based inks at normal temperature. The ability to support UV inks enables printing on non-absorbing base materials, such as plastics, films, and paper containers, expanding the coding and marking applications to bottles, packages, pharmaceutical packaging, and medical supplies.

Inkjet jetting technology of KM800 Series

High-resolution printing on curved and rough surfaces realized by superb long throw distance performance

In general, the throw distance is about 1 mm to 3 mm. The greater the distance, the lower the likelihood of inks being placed accurately on positions, resulting in low image quality. Konica Minolta’s long throw distance technology realizes excellent high-resolution printing of 2D barcodes and other designs even when the nozzles and target object are 20 mm apart. It is also suitable for textile printing because the distance between the printhead and the printing surface can be maintained to avoid interference by fuzz. It is also expected to be applied to DTS for direct printing on three-dimensional objects because the narrow width between nozzle rows enhances the printing performance on curved and rough surfaces.

Usability in various usage environments by vertical placement and color printing

In general, an inkjet printhead is placed horizontally to print in the direction perpendicular to the target object. When printing on the side of a target object in the transfer process, it is desirable to place an inkjet printhead vertically in some cases. However, vertical placement causes the jetting characteristics to vary between nozzles in the upper positions and those in the lower positions, resulting in lower image quality. The KM800 series can perform printing while maintaining the image quality through stable ink jetting even in the vertical placement by applying Konica Minolta’s nano-fabrication and driving technologies. The inkjet printhead also supports color printing and can be used for various applications, including embellishment. The series also features a compact product design to facilitate installation in printing equipment.

0 notes

Text

Barcode Definition: 5 Types & Common Applications You Should Know

In today’s digital-first business landscape, speed and accuracy are no longer optional—they're essential. Barcodes are one of the simplest yet most powerful technologies that help companies track, manage, and optimize inventory. Understanding the barcode definition in 2025 is vital for businesses aiming to boost productivity, streamline processes, and reduce errors. At AIDC Technologies India, we empower businesses with the right barcode solutions that fit industry-specific needs.

What is a Barcode? A Simple Barcode Definition

The barcode definition refers to a machine-readable visual representation of data that is typically used to identify and manage products, items, or assets. A barcode is made up of a series of black and white lines or patterns that store information such as product codes, serial numbers, or pricing.

When scanned using a barcode reader, the information is instantly retrieved and processed by a software system. This simple yet powerful technology is used in everything from grocery billing to industrial warehouse management. At AIDC Technologies India, we help businesses apply the barcode definition in real-world environments with customized solutions.

Components of a Barcode System: From Scanners to Software

To understand the practical application of the barcode definition, you need to know the main components of a barcode system:

Barcode Labels – Printed tags or stickers containing barcodes.

Barcode Scanners – Devices that read the barcode and capture the information.

Software – Systems that process and organize barcode data.

Printers – Tools used to generate barcode labels for different items.

AIDC Technologies India provides complete barcode systems—integrating hardware and software to create end-to-end tracking and identification solutions. Our offerings ensure seamless operation and high accuracy.

5 Types of Barcodes You Should Know

Understanding the barcode definition means recognizing the different types of barcodes and their specific uses. Here are five popular barcode types used widely in 2025:

UPC (Universal Product Code): One of the most recognized barcode types, used mainly in retail for identifying products at checkout.

QR Code (Quick Response Code): A 2D barcode that stores more data, including URLs, contact details, and payment info—commonly used in marketing and mobile apps.

Data Matrix: A compact 2D barcode used in healthcare, electronics, and manufacturing for marking small items and components.

PDF417: A stacked linear barcode that can store large amounts of data, often used in identification cards and travel documents.

Code 128: A high-density barcode ideal for logistics and shipping labels where space is limited but data needs to be precise.

AIDC Technologies India helps clients choose the most appropriate barcode type based on their industry, product, and operational needs.

Real-World Applications of Barcodes Across Industries

The barcode definition is best understood when you see how it works in real business environments. Here are key industry applications:

Retail: Barcodes enable fast checkout, accurate billing, and real-time inventory updates.

Healthcare: Used for patient ID, tracking medication, and managing medical supplies.

Logistics and Warehousing: Ensures precise inventory control, package tracking, and delivery verification.

Manufacturing: Tracks raw materials, components, and final products across the supply chain.

Education and Libraries: Helps track books, student materials, and assets in schools and universities.

At AIDC Technologies India, we design barcode systems to fit each industry’s specific requirements, ensuring compliance, accuracy, and operational ease.

Benefits of Barcode Technology for Businesses

Adopting the barcode definition into daily operations comes with multiple advantages:

Accuracy: Reduces manual errors during data entry.

Speed: Instant scanning improves customer service and operational efficiency.

Inventory Control: Provides real-time visibility into stock levels.

Cost Savings: Minimizes waste, reduces losses, and saves on labor.

Traceability: Enables complete tracking of products from source to delivery.

Our clients at AIDC India experience these benefits firsthand through custom-tailored barcode implementation strategies that enhance both scalability and efficiency.

How AIDC Technologies India Powers Barcode Solutions

AIDC Technologies India provides end-to-end support for barcode implementation, including system consultation, hardware deployment, software integration, training, and post-sale support.

We ensure that our clients not only understand the barcode definition but also experience its full power in their daily workflows. Whether you need barcode printers for product labels or scanners integrated with your ERP system, we make the process seamless. Our industry experience allows us to handle barcode projects for retail, warehousing, manufacturing, and more with high precision and scalability.

Barcode Technology Trends to Watch in 2025

The barcode definition continues to expand as technology evolves. In 2025, several key trends are influencing the future of barcode use:

Mobile Scanning: Smartphones are increasingly used for reading barcodes in retail and field operations.

Cloud Integration: Barcode systems are now cloud-enabled for real-time data access across locations.

Sustainable Labeling: Eco-friendly label materials are gaining popularity.

AI Integration: Barcode data is used to train AI for predictive analytics and smart inventory planning.

Hybrid Tracking: Combining barcodes with RFID for layered tracking and better asset management.

AIDC India stays updated with these trends to ensure our clients are equipped with future-ready barcode solutions.

Conclusion: Unlock Efficiency with AIDC's Barcode Solutions

The barcode definition may seem basic, but its impact is powerful and far-reaching. With the right barcode system in place, businesses can achieve better control, faster processes, and increased customer satisfaction. From small retail stores to massive industrial operations, barcodes play a key role in digital transformation.

AIDC Technologies India is here to support you in your barcode journey. We offer professional-grade hardware, custom software integration, and expert consulting to ensure your business gets the best results from barcode technology.

Call to Action

Looking to boost your business with barcode technology? Partner with AIDC Technologies India for reliable, scalable, and industry-specific barcode systems.

#BarcodeDefinition2025#TypesOfBarcodes#BarcodeApplications#BarcodeTechnology#BarcodeSolutions#SmartBarcodeUses#BarcodeInBusiness#AIDCBarcode

0 notes

Text

Barcode

Understanding Barcodes: The Key to Modern Inventory and Retail Management

Barcodes have become an indispensable part of our daily lives, revolutionizing how products are tracked, managed, and sold globally. From retail stores to warehouses, and healthcare facilities to logistics operations, barcodes simplify product identification, improve inventory accuracy, and enhance operational efficiency. This article dives into the fundamentals of barcodes, their types, uses, and why they remain a critical tool in modern business operations.

What is a Barcode?

A barcode is a method of representing data in a visual, machine-readable format using a combination of parallel lines, spaces, or dots. Scanners or mobile devices equipped with barcode readers decode this data and convert it into readable information, such as product details, pricing, or inventory levels.

Barcodes primarily consist of two elements:

Black Bars (or Patterns): Represent data.

White Spaces: Separate the black bars for clarity.

Each barcode contains a unique identifier that links to a database, providing details about the product, including its price, stock status, and origin.

History of Barcodes

The concept of barcoding was introduced in the 1940s by Norman Joseph Woodland and Bernard Silver. However, it wasn’t until 1974 that the first barcode was scanned on a Wrigley’s gum pack in an Ohio supermarket, marking the beginning of a technological revolution in retail and inventory management.

Types of Barcodes

There are two primary categories of barcodes: 1D (Linear Barcodes) and 2D Barcodes.

1. 1D (Linear) Barcodes:

These are the traditional barcodes with vertical black and white lines. Examples include:

UPC (Universal Product Code): Commonly used in retail stores.

EAN (European Article Number): International retail barcode.

Code 39: Used in manufacturing and military applications.

Code 128: Often found in logistics and shipping.

2. 2D Barcodes:

These barcodes store more data in both horizontal and vertical patterns. Examples include:

QR Codes (Quick Response Codes): Used in marketing, payments, and product information.

DataMatrix Codes: Common in healthcare and electronics.

PDF417: Found in shipping labels and ID cards.

How Do Barcodes Work?

Barcode Creation: A unique identification number is encoded into a barcode format.

Printing: The barcode is printed on labels or product packaging.

Scanning: A barcode scanner reads the black and white patterns.

Decoding: The scanner translates the barcode into digital data.

Database Lookup: The system retrieves product or asset details from the database.

This seamless process ensures accurate and instant information retrieval, reducing manual errors and improving efficiency.

Applications of Barcodes

Barcodes are widely used across various industries:

1. Retail:

Quick and accurate billing at checkout counters.

Improved inventory management and stock tracking.

2. Healthcare:

Tracking patient medications.

Managing medical equipment and supplies.

3. Logistics and Warehousing:

Real-time tracking of shipments.

Efficient warehouse inventory control.

4. Manufacturing:

Monitoring production lines.

Ensuring quality control through traceability.

5. Event Management:

Ticket scanning for concerts, sports events, and conferences.

Benefits of Barcodes

Accuracy: Reduces human errors in data entry.

Speed: Speeds up processes like billing, inventory checks, and shipping.

Cost-Effective: Affordable technology with significant ROI.

Inventory Control: Real-time visibility into stock levels.

Improved Traceability: Enhances product tracking across supply chains.

Data Insights: Provides accurate data for business analysis and forecasting.

Barcode Scanning Technology

Barcode scanners are devices designed to read and decode barcode information. Common types include:

Laser Scanners: Fast and accurate, commonly used in retail.

CCD Scanners (Charge-Coupled Device): Best for short-range scanning.

2D Image Scanners: Can read both 1D and 2D barcodes.

Mobile Scanners: Smartphones with barcode scanner apps for flexible use.

Barcodes vs RFID

While barcodes are widely used, RFID (Radio Frequency Identification) is emerging as an alternative technology.

Feature

Barcode

RFID

Cost

Low

Higher

Range

Short-range scanning

Long-range reading

Line of Sight

Required

Not required

Data Storage

Limited

Extensive

Both technologies have their advantages, but barcodes remain the preferred choice for cost-sensitive applications.

Challenges with Barcodes

Despite their advantages, barcodes face certain challenges:

Damage or Smudging: Barcodes may become unreadable if damaged.

Limited Data Storage: 1D barcodes can only store minimal information.

Dependency on Line of Sight: Direct scanning is necessary.

The Future of Barcodes

The future of barcoding technology is promising:

Smart Barcodes: Embedded with enhanced data storage.

Integration with IoT (Internet of Things): Enabling smarter inventory systems.

AI Integration: Improving predictive analytics for supply chains.

Blockchain Integration: Ensuring immutable traceability records.

With the rise of e-commerce and digital logistics, barcodes are evolving to meet the demands of modern supply chains.

How to Get a Barcode for Your Business

Register with GS1: GS1 is the global authority for barcode standards.

Obtain a GTIN (Global Trade Item Number): A unique identifier for your product.

Generate the Barcode: Use GS1-approved barcode creation tools.

Print and Apply: Ensure high-quality printing for accurate scanning.

Investing in barcoding systems ensures smooth operations and enhances scalability for businesses of all sizes.

Conclusion

Barcodes are far more than black lines on product packaging—they are a gateway to efficiency, accuracy, and global connectivity. From simplifying retail checkouts to ensuring supply chain transparency, barcodes have proven their value across industries.

As technology continues to advance, barcodes remain a cornerstone of effective product identification and data management, offering unparalleled benefits in a world driven by speed and precision.

0 notes

Text

Understanding the Technology Behind Barcode Scanners in Supermarkets

Barcode scanners are an essential tool in modern supermarkets. They have transformed how stores operate, making processes faster, more efficient, and remarkably accurate. But have you ever wondered how this seemingly simple device works or why it’s a cornerstone of retail operations? Let’s dive into the fascinating technology behind barcode scanners and explore their pivotal role in supermarkets.

What is a Barcode Scanner?

A barcode scanner is a device that reads barcodes and converts the data into a format a computer system can understand. Barcodes themselves are machine-readable codes consisting of black and white lines or patterns, each representing specific information. In a supermarket, barcodes typically contain details about a product, such as its name, price, and inventory code.

The magic happens when a scanner decodes this information in a fraction of a second, making checkout and inventory processes seamless.

How Does Barcode Scanning Technology Work?

The process may seem effortless, but behind the scenes, it involves some impressive technology:

Light Source: Barcode scanners use a light source (commonly a laser or LED) to illuminate the barcode.

Sensor: The scanner’s sensor detects the light reflected off the barcode’s black and white lines. Black lines absorb more light, while white lines reflect it, creating a pattern.

Decoder: The scanner’s decoder processes the pattern and translates it into digital data. This data is sent to a computer system, which identifies the product and retrieves its information.

Barcode scanners can use different technologies, such as laser, CCD (Charge-Coupled Device), and 2D image scanners. Each type has its strengths and is chosen based on specific supermarket needs.

The Role of Barcode Scanners in Supermarkets

Barcode scanners are indispensable in supermarkets, thanks to their versatility and efficiency. Here’s how they impact daily operations:

1. Faster Checkout

Barcode scanners significantly speed up the checkout process. Instead of manually entering product details, cashiers simply scan the barcode, and the system instantly retrieves the price and product information. This method saves time and minimizes the chances of making errors.

2. Accurate Pricing

Scanners ensure accurate pricing by pulling data directly from the store’s database. This eliminates discrepancies caused by manual entry and ensures customers are charged the correct amount.

3. Inventory Management

Supermarkets rely on barcode scanners to track inventory in real time. Each scan updates the inventory system, ensuring the stock levels are always accurate. This helps stores avoid overstocking or running out of popular items.

4. Data Insights

The data collected through barcode scanning provides valuable insights into customer buying habits. Supermarkets can analyze which products are selling well, identify trends, and make informed decisions about restocking and promotions.

Types of Barcode Scanners Used in Supermarkets

Depending on their specific needs, supermarkets use different types of barcode scanners. Here are some common types:

Handheld Scanners: Lightweight and portable, these are ideal for scanning bulky or heavy items.

Flatbed Scanners: Found at most checkout counters, flatbed scanners are designed for high-speed scanning.

Wireless Scanners: These scanners provide flexibility by allowing staff to move around freely while scanning.

2D Scanners: Capable of reading both 1D (linear) and 2D (matrix) barcodes, these scanners are increasingly popular for their versatility.

Emerging Technologies in Barcode Scanning

The technology behind barcode scanners continues to evolve, offering even more efficiency and innovation. Some of the latest advancements include:

Mobile Barcode Scanning: With the rise of smartphone apps, customers can now scan barcodes themselves, creating a seamless shopping experience.

QR Code Integration: QR codes are gaining popularity in retail for their ability to store more information than traditional barcodes.

AI-Powered Scanners: Artificial intelligence is integrated into barcode scanning to improve accuracy and adaptability in dynamic retail environments.

The Benefits of Barcode Scanners for Supermarkets

Barcode scanners offer numerous advantages for supermarkets, such as:

Improved Efficiency: Automating checkout and inventory management saves time and labor costs.

Enhanced Customer Experience: Faster checkout lines and accurate pricing contribute to customer satisfaction.

Reduced Errors: By eliminating manual entry, barcode scanners minimize human errors.

Cost Savings: Streamlined operations lead to significant cost savings in the long run.

Conclusion

Barcode scanners are more than just tools for scanning products; they’re the backbone of modern supermarket operations. By understanding the technology behind these devices, we gain insight into how supermarkets operate so efficiently, ensuring customers have a seamless shopping experience.

As technology advances, barcode scanners will only become more sophisticated, playing an even greater role in shaping the future of retail. Whether you’re a tech enthusiast or simply a curious shopper, the next time you’re at the checkout counter, you’ll have a newfound appreciation for the humble barcode scanner.

#rfid technology#Barcode Scanner#Barcode Reader#inventory management#Retail#supermarket#retail solutions

0 notes

Text

0 notes

Text

Asset Tracking Systems: Revolutionizing Business Efficiency and Accountability

In today’s competitive business environment, managing resources efficiently is crucial to staying ahead. Companies across industries—whether it’s a small business or a global corporation—are constantly seeking ways to streamline operations and improve the accuracy of their asset management processes. Asset tracking systems are at the forefront of these efforts, providing businesses with a powerful solution to keep track of valuable resources.

An asset tracking system utilizes a blend of technology to monitor the location, condition, and utilization of physical assets. From tools and equipment to vehicles and IT infrastructure, the goal of asset tracking is to ensure that businesses know where their assets are, how they’re being used, and when they need maintenance or replacement.

This blog explores the ins and outs of asset tracking systems, their benefits, and how they are transforming how companies manage their resources.

What Is an Asset Tracking System?

An asset tracking system is a technology solution designed to help businesses monitor and manage physical assets, often in real-time. The system typically consists of tags or labels placed on assets, scanning devices (such as barcodes or RFID), and a software platform that compiles and analyzes the data.

The system works by providing detailed visibility into the asset’s location, condition, and usage history. Whether you’re tracking tools in a warehouse, office equipment, or machinery on a construction site, these systems help ensure your assets are being optimally utilized and not misplaced or underused.

How Asset Tracking Systems Work

At the heart of asset tracking systems is the technology used to tag and track assets. Let’s break down the main components:

1. Tagging and Labeling Assets

The first step in asset tracking is assigning a unique identifier to each asset. This identifier can be a QR code, barcode, or RFID tag. These tags are attached to the assets and serve as their "ID card."

Barcodes are scanned manually using a handheld scanner. Barcodes are best suited for stationary assets, and they require direct line-of-sight to be scanned.

RFID tags are more advanced and allow for automatic and remote scanning. RFID is great for tracking high-value or high-mobility assets. It doesn’t require direct line-of-sight and can scan multiple items at once.

QR codes, a form of 2D barcodes, can also be scanned using mobile devices, making them more versatile in terms of access and use.

2. Tracking the Assets

Once an asset is tagged, it is tracked using various technologies, including RFID readers, GPS devices, and mobile applications.

RFID readers and scanners capture information from the tags, while GPS tracking devices provide real-time location updates for mobile assets, such as vehicles and equipment.

For stationary items, tracking systems may rely on manual scans when assets are moved or checked.

3. Software Integration and Data Management

The data collected by the RFID readers, GPS devices, and barcode scanners is sent to an asset management platform. This platform stores all the information related to the assets, including location, usage, maintenance schedules, and more.

The software often integrates with existing business management systems (like Enterprise Resource Planning (ERP) or Inventory Management Software) to ensure a seamless flow of data across departments.

It also provides advanced features like real-time tracking, data analysis, alerts, and reporting, which allow businesses to make informed decisions about asset allocation, maintenance, and purchases.

The Benefits of Asset Tracking Systems

Implementing an asset tracking system brings several key advantages to businesses, regardless of size or industry. Here’s why an asset tracking system is a game-changer:

1. Enhanced Accuracy and Visibility

One of the primary challenges of traditional asset management is the risk of human error. Manual tracking methods—like spreadsheets or physical logs—are prone to mistakes, leading to inaccurate asset records.

An automated asset tracking system ensures accuracy by providing real-time updates on asset status and location. This visibility allows businesses to make data-driven decisions on resource allocation and maintenance, reducing errors and improving overall operations.

2. Improved Security and Theft Prevention

Asset theft and misplacement can be costly for businesses, especially in industries that rely on high-value or mobile assets. An asset tracking system provides real-time alerts when an asset is moved outside a designated area or is no longer where it should be.

Geofencing technology, a feature of many asset tracking systems, allows companies to define virtual boundaries. When an asset enters or exits this boundary, the system triggers an alert, reducing the risk of theft and loss.

3. Cost Savings and Resource Optimization

Many businesses are unaware of how underutilized their assets are. By tracking the usage patterns of assets, businesses can determine which ones are being overused or underused, allowing them to reallocate resources more effectively.

This optimization reduces the need for purchasing additional assets or renting equipment unnecessarily, saving businesses money in the long run.

Furthermore, knowing when assets need maintenance or replacement helps prevent costly repairs or downtime, which can disrupt operations and incur additional expenses.

4. Improved Maintenance and Longevity of Assets

Regular maintenance is key to prolonging the life of assets and preventing unexpected breakdowns. An asset tracking system can track the age, usage, and maintenance history of each asset, triggering automated alerts when maintenance is due.

This ensures that assets are serviced on time, reducing the risk of unexpected failures and increasing their lifespan.

5. Streamlined Compliance and Reporting

For many industries, asset tracking is not just a best practice—it’s a requirement. In industries like healthcare, construction, and manufacturing, strict regulatory requirements dictate how assets must be maintained and tracked.

An asset tracking system makes it easy to keep accurate records of asset movements and maintenance, simplifying compliance with industry regulations. Additionally, the system generates detailed reports that can be used for audits, helping companies stay compliant with minimal effort.

Applications of Asset Tracking Systems

Asset tracking systems have a wide range of applications across industries. Below are some examples of how different sectors benefit from asset tracking:

1. Healthcare

In hospitals and healthcare facilities, tracking medical equipment is essential for providing efficient care. Asset tracking systems ensure that critical devices, such as wheelchairs, infusion pumps, and diagnostic tools, are easy to locate when needed. Additionally, these systems help track maintenance schedules for sensitive medical equipment, ensuring it remains in working order.

2. Construction

Construction companies often operate with a wide variety of equipment and machinery spread across different job sites. Asset tracking systems provide visibility into the location and status of tools, vehicles, and heavy machinery, ensuring they are used effectively and not lost or stolen.

GPS tracking is particularly useful for monitoring large equipment across multiple sites, improving logistics, and reducing downtime.

3. Logistics and Supply Chain

In the logistics industry, asset tracking helps businesses manage their fleet of vehicles, containers, and inventory in real time. Companies can track the movement of goods, monitor the performance of delivery vehicles, and ensure that assets are properly maintained.

This level of oversight boosts operational efficiency and improves customer satisfaction by providing accurate delivery timelines.

4. Retail

Retailers use asset tracking systems to manage their inventory and stock levels. By tagging products and stock with barcodes or RFID tags, businesses can automate inventory counts and minimize human error.

The system also allows for better stock replenishment, ensuring that high-demand items are always available for customers, reducing lost sales due to out-of-stock situations.

Conclusion: The Future of Asset Management

Asset tracking systems are more than just a tool—they’re a transformative technology that helps businesses optimize their resources, improve operational efficiency, and reduce costs. As industries continue to evolve and businesses become increasingly data-driven, having a system in place to manage and track assets is essential for staying competitive.

By providing real-time visibility, improving asset security, and ensuring assets are maintained properly, these systems empower businesses to make smarter, more informed decisions. Whether you��re in healthcare, logistics, construction, or retail, an asset tracking system is a must-have solution that pays dividends in the form of reduced costs, improved productivity, and long-term asset durability.

In the ever-changing landscape of modern business, an investment in an asset tracking system is an investment in the future success of your organization.

0 notes

Text

Discover the Best Label Manufacturers for Your Business Needs with Barspell Technology

In today's fast-paced business environment, the demand for high-quality labels is at an all-time high. Whether you're looking for pre-printed label manufacturers or a barcode label manufacturer, finding the right supplier can make all the difference in ensuring your products are well-branded and easily identifiable. At Barspell Technology, we specialize in providing top-tier label solutions that cater to various business needs, enhancing both efficiency and branding. This article delves into the importance of labels, the different types of label manufacturers, and how Barspell Technology can help you choose the best supplier for your specific requirements.

Why Labels Matter: An Overview

Labels are not just for identification; they play a vital role in marketing, branding, and logistics. From barcode labels used for inventory tracking to pre-printed labels that showcase your brand, choosing the right label manufacturer can enhance product presentation, improve supply chain management, and streamline operations. Whether you are in retail, manufacturing, or e-commerce, the quality and design of your labels can influence both customer perception and operational efficiency. Barspell Technology is committed to delivering high-quality, durable labels that help businesses like yours thrive.

What to Look for in Label Manufacturers

When searching for the best label manufacturers, several factors should be taken into consideration. Quality, durability, customization options, and cost-effectiveness are crucial for any business, regardless of industry. A reliable label manufacturer, such as Barspell Technology, will offer:

1. Customization Options: Labels can be tailored to fit the specific needs of your products, whether it’s pre-printed or featuring barcode technology.

2. Durability: High-quality labels that withstand various environmental conditions, from heat to moisture, are essential for long-term product labeling.

3. Fast Turnaround Times: Depending on the urgency of your business needs, Barspell Technology provides quick and efficient label production services.

4. Competitive Pricing: Choose manufacturers that offer a good balance of quality and cost, providing you with value for money.

Pre-Printed Label Manufacturers: Streamlining the Process with Barspell Technology

For many businesses, pre-printed label manufacturers offer a simple solution for efficient labeling. These labels come with your design already printed, which can save time in your production process. Pre-printed labels are ideal for products that have fixed information, such as barcodes, ingredients, or brand logos.

By working with experienced pre-printed label manufacturers like Barspell Technology, you ensure that each label is consistent, professionally designed, and printed with high-quality materials that can withstand wear and tear.

Barcode Label Manufacturers: Essential for Inventory and Logistics

Barcode labels are essential for inventory control, shipping logistics, and point-of-sale systems. A barcode label manufacturer such as Barspell Technology can provide you with high-quality labels that are scannable, durable, and customized to fit your product's needs. These labels enable fast, accurate tracking of products throughout the supply chain, which can significantly reduce human error and improve efficiency.

Whether you need standard 1D or advanced 2D barcode labels, Barspell Technology ensures that your barcodes are printed, scannable, and resistant to fading, ensuring smooth operations.

Choosing the Right Label Manufacturer for Your Business

With so many options available, choosing the right label manufacturer can feel overwhelming. Here are a few tips to help you make an informed decision:

1. Reputation and Reviews: Look for manufacturers with a proven track record of delivering high-quality labels. Barspell Technology has earned a reputation for quality and customer satisfaction in the labeling industry.

2. Industry Experience: A manufacturer experienced in your industry will understand your unique labeling needs and offer expert advice.

3. Technological Capabilities: Ensure the manufacturer uses the latest printing technology to deliver precise, high-quality labels. At Barspell Technology, we leverage cutting-edge technology to provide labels that meet your exact specifications.

Conclusion: Find Your Perfect Label Manufacturer with Barspell Technology

Whether you're looking for barcode label manufacturers or pre-printed label manufacturers, it’s important to work with a company that understands the nuances of labeling and meets your business’s unique requirements. By considering factors such as customization options, quality, and industry experience, you can find a label supplier to support your product labeling needs and help streamline your operations.

Labels are more than just a necessity they are an essential part of your brand’s identity and functionality. Partnering with Barspell Technology ensures you get the best labels to elevate your brand and optimize your business processes.

1 note

·

View note

Text

How Do You Optimize Barcode Reading Performance?

When it comes to barcode scanning, speed and accuracy are paramount. But what if your barcode reader isn't keeping up? Issues like slow scan times, inconsistent reads, and challenging lighting conditions are common pain points that can lead to lost time and frustration. Whether you’re optimizing a POS system in retail, managing logistics in a warehouse, or simply ensuring better control over inventory, having a reliable barcode reading setup can make all the difference. But what exactly do you need to enhance performance, and how can a USB camera be the key to achieving these improvements?

Understanding the Challenges of Barcode Reading Performance

Before diving into solutions, it’s essential to understand the common hurdles that many businesses face with barcode scanning. From poor image quality to lighting variations and unreadable codes, these challenges can significantly impact efficiency. Here are some frequent pain points:

Inconsistent Scans: A barcode scanner that only works some of the time or requires multiple attempts can disrupt workflows and lead to employee frustration.

Poor Lighting Conditions: Many barcode readers struggle to capture clear images in low or overly bright lighting, leading to missed scans.

Small or damaged barcodes: Whether the barcodes are worn, scratched, or printed too small, these issues can make scanning challenging.

Incompatibility with Newer Systems: Older scanning systems may not work seamlessly with modern POS or inventory software, slowing down operations.

Complex Setup and Calibration: Some barcode scanners require extensive setup and calibration, consuming time and technical resources.

Why a USB Camera Can Improve Barcode Reading Performance

USB cameras are gaining popularity as flexible, affordable solutions for barcode reading. These cameras offer high-quality imaging, are easy to integrate into existing systems, and can be customized for various industrial or retail applications. Let’s look at some of the advantages of using a USB camera specifically for barcode reading.

Enhanced Image Quality: USB cameras provide high-definition images that make reading both linear and 2D barcodes easier and faster.

Wide Compatibility: Unlike specialized scanners that may only work with certain systems, USB cameras are typically compatible with multiple platforms, from POS systems to inventory management software.

Customizable Field of View: Depending on your application, USB cameras can be set up to capture images within a specific range, optimizing the camera’s ability to scan small or large barcodes accurately.

Flexible Integration Options: USB cameras can be mounted in a variety of ways, from handheld to fixed-mount options, offering greater flexibility for both stationary and mobile applications.

Steps to Optimize Barcode Reading Performance with a USB Camera

1. Choose the Right Camera Specifications

The performance of a USB camera in reading barcodes depends on various specifications such as resolution, field of view, and frame rate. High-resolution cameras capture finer details, making it easier to read small or damaged barcodes. For fast-moving environments, a higher frame rate is essential to ensure smooth captures without lag.

Resolution: Look for USB cameras with a resolution of at least 720p or higher, depending on your specific requirements.

Field of View: Ensure the camera’s field of view covers the intended barcode area. A wide field of view may be necessary for larger barcodes, while a narrower one can be sufficient for small or close-up scanning.

2. Adjust lighting for optimal image capture.

Lighting is crucial for accurate barcode reading. Poor lighting can result in unclear or incomplete scans. Here’s how to manage lighting conditions effectively:

Install Proper Lighting: Consider LED lights that can be easily adjusted to reduce glare or shadows. Some USB cameras come with built-in lighting, which can simplify setup.

Minimize Reflection and Glare: If you’re scanning barcodes on shiny surfaces, avoid direct light that can cause glare. Instead, angle the lighting or use diffused lighting to minimize reflections.

3. Calibrate the camera’s focus and exposure.

Proper calibration of focus and exposure settings is vital for achieving the best barcode reading performance. Many USB cameras come with manual and auto-focus options, so choose the one that best suits your application:

Auto-Focus for Dynamic Environments: If your application involves scanning barcodes at varying distances, use a USB camera with auto-focus to ensure sharp images.

Adjust Exposure Settings: If your camera’s exposure settings are adjustable, optimize them to prevent under or over-exposed images, which can interfere with the barcode reader’s ability to detect codes.

4. Utilize image processing software.

For industries that require rapid or bulk scanning, integrating image processing software with your USB camera can streamline operations. Many software solutions include features that enhance barcode reading performance, such as image correction and contrast enhancement.

Real-Time Image Processing: Use software that can enhance images in real time, correcting lighting, sharpening details, and even adjusting for barcode orientation.

Barcode Decoding Tools: Some USB cameras can be paired with barcode-decoding software, which automatically reads and records barcode data, making the entire process faster and more efficient.

5. Implement automation for consistent scanning.

If your application allows for a fixed camera setup, you can automate barcode scanning to reduce manual handling. Automated setups are beneficial in industrial and warehouse environments where high-volume scanning is required.

Fixed-Mount Scanning: Install the USB camera at a fixed position and let conveyor systems bring the items into view. This ensures that each item is scanned without requiring human intervention.

Motion Detection and Triggers: Some USB cameras come with motion detection, which can trigger the camera to scan as soon as an item is in view, saving time and reducing errors.

6. Regularly Test and Maintain the USB Camera

Like any technology, USB cameras benefit from regular testing and maintenance to ensure optimal performance. Check the following regularly:

Clean the Lens: Dust or smudges on the camera lens can interfere with barcode clarity, so clean it frequently.

Firmware Updates: Check for firmware updates from the camera manufacturer, as these can improve functionality and compatibility with barcode-reading software.

Calibration Checks: Periodically check and recalibrate focus and exposure settings to ensure the camera continues to perform as expected.

Benefits of Optimizing Barcode Reading with USB Cameras

By implementing these optimizations, you can significantly improve your barcode reading performance, leading to a range of benefits:

Reduced Errors: Accurate scans mean fewer errors in data entry, which helps keep inventory and sales data accurate.

Improved Workflow Efficiency: Faster, more reliable scans save time, allowing employees to focus on other tasks.

Cost-Effective Solution: USB cameras often provide a more affordable solution compared to dedicated barcode scanners, especially when optimized correctly.

Greater Flexibility: USB cameras can be repurposed for other image capture tasks when not in use for barcode reading, making them versatile tools in retail and industrial settings.

Key Takeaways

Optimizing barcode reading performance with a USB camera is both an effective and cost-efficient solution for businesses. By focusing on key aspects like camera specifications, lighting, calibration, and automation, you can turn a USB camera into a powerful barcode-reading tool that enhances efficiency and accuracy. In an era where speed and reliability are essential, taking the time to optimize your barcode scanning setup can make a big difference to your bottom line.

Every second matters in the hectic commercial world of today, and every scan is no exception. Whether you work in warehouse, logistics, or retail, maximizing your barcode scanning performance with the correct USB camera configuration can revolutionize your business operations by making procedures more precise, seamless, and productive.

0 notes