#yingkou

Explore tagged Tumblr posts

Text

A seagull sits on the “red beach” created by clusters of suaeda salsa – also known as seepweed or seablite – in Yingkou, China

Photograph: VCG/Getty Images

#vcg#getty images#photographer#seagull#bird photography#suaeda salsa clusters#seepweed#seablite#yingkou#china#animal#nature#red beach

21 notes

·

View notes

Text

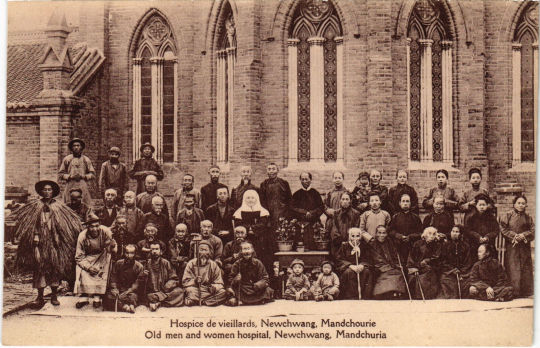

Retirement home in Yingkou, Lianoning province, China

French vintage postcard

#postkaart#china#carte postale#french#briefkaart#province#old#sepia#yingkou#postkarte#vintage#postal#lianoning#photography#ephemera#postcard#tarjeta#photo#home#ansichtskarte#lianoning province#retirement#historic

4 notes

·

View notes

Text

Um caminhão carregado com produtos químicos explodiu em frente ao Hospital Dashiqiao Nanlou em Yingkou, província de Liaoning, China (02.01.2025)

1 note

·

View note

Text

Hexagonal Boron Nitride Powder: Industrial Uses and Market Forecast

"Executive Summary Hexagonal Boron Nitride Powder Market :

CAGR Value

Global hexagonal boron nitride powder market size was valued at USD 2.68 billion in 2024 and is projected to reach USD 4.02 billion by 2032, with a CAGR of 5.20% during the forecast period of 2025 to 2032.

Systematic, objective and exhaustive study of the facts related to any subject in the field of marketing have been performed while formulating this Hexagonal Boron Nitride Powder Market report. Several steps are also carried out for gathering, analysing and recording of market data. The report helps businesses to take on the approach of systematic problem analysis, model building and fact-finding that ultimately aids in decision-making and managing marketing of goods and services. Not to mention, various purposes or objectives of market research are kept in mind while forming the Hexagonal Boron Nitride Powder Market report which helps client achieve success in the business.

The market research conducted in the Hexagonal Boron Nitride Powder Market report also makes out the response of consumers to an already existing product in the market and identifies the causes for failure of particular product already in the market. The report has potential to uncover the general market conditions and tendencies. It estimates the prospective market for a new product to be launched in the market. The report also measures or analyses the strength and weak points of the competitors. This Hexagonal Boron Nitride Powder Market research report is a resource which provides current as well as upcoming technical and financial details of the industry for the forecast period.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Hexagonal Boron Nitride Powder Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-hexagonal-boron-nitride-powder-market

Hexagonal Boron Nitride Powder Market Overview

**Segments**

- Based on grade, the global hexagonal boron nitride powder market can be segmented into industrial grade, and cosmetics grade. The industrial grade segment is expected to dominate the market due to its wide range of applications in industries such as electronics, ceramics, lubricants, and aerospace.

- By application, the market can be classified into advanced ceramics, paints & coatings, lubricants, thermal management, cosmetics, and others. The advanced ceramics segment is anticipated to hold a significant market share owing to the increasing demand for high-performance materials in various end-use industries.

- On the basis of region, the global hexagonal boron nitride powder market is segmented into North America, Europe, Asia-Pacific, South America, and Middle East & Africa. Asia-Pacific is projected to be the largest market for hexagonal boron nitride powder, driven by the growing manufacturing sector in countries like China, Japan, and South Korea.

**Market Players**

- Saint-Gobain - Momentive - 3M - H.C. Starck - UK Abrasives - Denka - Henze - Showa Denko Group - Xinfukang - Zibo Jonye Ceramic Technologies - YingKou Liaobin Fine Chemicals - Qingzhou Fangyuan - Dandong Rijin - Penglai Huaan Basaltic Products - Beihai Jinzhi - Zichuan Shenghe - QingZhouMaTeKeChang Materials

The global hexagonal boron nitride powder market is highly competitive with key players focusing on expanding their product portfolios, enhancing distribution networks, and strategic collaborations to gain a competitive edge. These market players are investing in research and development activities to introduce innovative products and cater to the evolving needs of end-use industries. The market is characterized by the presence of both multinational corporations and regional players, contributing to the overall growth and development of the industry.

The global hexagonal boron nitride powder market is witnessing significant growth driven by the increasing demand for high-performance materials across various industries. The industrial-grade segment is expected to dominate the market due to its diverse applications in electronics, ceramics, lubricants, and aerospace. The cosmetics grade segment is also gaining traction, driven by the rising demand for skincare and beauty products incorporating hexagonal boron nitride powder.

In terms of applications, the advanced ceramics segment is poised to hold a substantial market share due to the growing need for advanced materials with exceptional thermal and mechanical properties. The paints & coatings segment is also expected to witness steady growth, fueled by the increasing use of hexagonal boron nitride powder as a functional additive in coatings for enhanced performance. The market players are focusing on expanding their product portfolios to cater to the specific requirements of different applications and industries.

In terms of regional analysis, Asia-Pacific is projected to be the largest market for hexagonal boron nitride powder, driven by the rapid industrialization and manufacturing activities in countries like China, Japan, and South Korea. The presence of key market players in the region and the growing investments in research and development activities are further contributing to the market growth in Asia-Pacific. North America and Europe are also significant markets for hexagonal boron nitride powder, supported by the presence of advanced industries and favorable regulations promoting the adoption of advanced materials.

The competitive landscape of the global hexagonal boron nitride powder market is intense, with key players focusing on strategies such as product innovation, strategic collaborations, and geographic expansion to gain a competitive edge. Companies like Saint-Gobain, Momentive, and 3M are actively investing in R&D activities to introduce new products and enhance their market presence. The market is also characterized by the presence of regional players focusing on niche applications and customized solutions for specific industries.

Overall, the global hexagonal boron nitride powder market is poised for significant growth in the coming years, driven by the increasing demand for high-performance materials in various industries. The market players' focus on innovation and strategic partnerships will play a crucial role in shaping the market landscape and meeting the evolving needs of end-use industries.The global hexagonal boron nitride powder market is experiencing robust growth propelled by the escalating demand for high-performance materials across diverse industries. The industrial-grade segment is expected to maintain its dominance in the market due to its extensive applications in critical sectors such as electronics, ceramics, lubricants, and aerospace. Conversely, the cosmetics grade segment is gradually gaining traction driven by the increasing incorporation of hexagonal boron nitride powder in skincare and beauty products. This shift in consumer preferences towards beauty and personal care items formulated with advanced materials is opening up new avenues for market expansion and innovation.

In the realm of applications, the advanced ceramics sector is poised to secure a considerable market share owing to the escalating need for materials with exceptional thermal and mechanical properties. Additionally, the paints & coatings segment is anticipated to witness steady growth fuelled by the augmented utilization of hexagonal boron nitride powder as a functional additive in coatings to enhance performance characteristics. Market players are actively diversifying their product portfolios to cater to the distinct requirements of various applications and industries, reflecting the dynamic nature of the market and the continuous pursuit of technological advancements.

From a regional perspective, Asia-Pacific emerges as the frontrunner in the hexagonal boron nitride powder market, primarily fueled by the rapid industrialization and manufacturing activities in countries such as China, Japan, and South Korea. The region's strong foothold in the market is further strengthened by the presence of key market players and substantial investments in research and development endeavors, underscoring the region's strategic importance in the global market landscape. North America and Europe also represent significant markets for hexagonal boron nitride powder, bolstered by their advanced industries and favorable regulatory frameworks that encourage the adoption of cutting-edge materials.

The competitive landscape of the global hexagonal boron nitride powder market is marked by intense rivalry among key players who are adopting strategies such as product innovation, strategic collaborations, and geographical expansion to gain a competitive edge. Companies like Saint-Gobain, Momentive, and 3M are at the forefront of these efforts, channeling significant resources into research and development initiatives to drive product innovation and strengthen their market positioning. The market also accommodates regional players focusing on niche applications and tailored solutions for specific industries, contributing to the overall vibrancy and diversity of the market ecosystem.

In conclusion, the global hexagonal boron nitride powder market is poised for substantial growth in the foreseeable future, propelled by the rising demand for high-performance materials across a spectrum of industries. The concerted focus of market players on innovation and strategic partnerships is poised to be instrumental in reshaping the market landscape and meeting the evolving requirements of end-use industries. The market's trajectory underscores the pivotal role of technological advancement and market differentiation in driving sustainable growth and competitiveness in the hexagonal boron nitride powder sector.

The Hexagonal Boron Nitride Powder Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-hexagonal-boron-nitride-powder-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

The investment made in the study would provide you access to information such as:

Hexagonal Boron Nitride Powder Market [Global Hexagonal Boron Nitride Powder Market – Broken-down into regions]

Regional level split [North America, Europe, Asia Pacific, South America, Middle East & Africa]

Country wise Market Size Split [of important countries with major Hexagonal Boron Nitride Powder Market share]

Market Share and Revenue/Sales by leading players

Market Trends – Emerging Technologies/products/start-ups, PESTEL Analysis, SWOT Analysis, Porter's Five Forces, etc.

Market Size)

Market Size by application/industry verticals

Market Projections/Forecast

Browse More Reports:

Global Wafer Level Packaging Market Global Gusset Seal Market Global Tilt Sensor Market Global Central Vacuum Cleaner Market Middle East and Africa Healthcare Information Technology (IT) Market Global Emission Control Catalyst Market Global Breast Implants Market Global Dental Bonding Agents Market Europe Brain MRI Scan Market Global Delta Robots Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]"

#Hexagonal Boron Nitride Powder Market#Hexagonal Boron Nitride Powder Market size#Hexagonal Boron Nitride Powder Market share

0 notes

Text

Diaminomaleonitrile (DAMN) Market Report: Trends, Opportunities, and Forecast 2025-2031

Diaminomaleonitrile (DAMN) Market, Global Outlook and Forecast 2025-2032

The global Diaminomaleonitrile (DAMN) market is experiencing steady growth, with its valuation reaching USD 136.63 million in 2024. According to the latest industry analysis, the market is projected to grow at a CAGR of 3.6%, reaching approximately USD 174.04 million by 2032. This growth is primarily driven by increasing demand from the pharmaceutical industry, where DAMN serves as a critical intermediate in drug synthesis and chemical processes.

Diaminomaleonitrile (DAMN) is a crucial chemical compound used in pharmaceutical synthesis, agrochemical production, and fine chemical manufacturing. Its unique chemical structure makes it an essential component in the production of various active pharmaceutical ingredients (APIs) and specialty chemicals. The compound's versatility and importance in drug formulation processes have made it increasingly valuable in pharmaceutical research and development.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/292731/diaminomaleonitrile-market

Market Overview & Regional Analysis

North America currently leads the global DAMN market, accounting for approximately 38% of global consumption. The region's strong pharmaceutical sector and advanced chemical manufacturing capabilities drive demand for high-purity DAMN. The United States remains the largest consumer, with major pharmaceutical companies incorporating DAMN in their drug development processes.

Europe follows closely, with Germany, France, and Switzerland being key markets for DAMN. The region's stringent pharmaceutical regulations and focus on high-quality chemical intermediates support market growth. The Asia-Pacific region is emerging as the fastest-growing market, with China and India showing significant potential due to their expanding pharmaceutical manufacturing sectors and lower production costs.

Key Market Drivers and Opportunities

The DAMN market is primarily driven by the expanding pharmaceutical industry, particularly in emerging economies. The compound's role in synthesizing various pharmaceutical compounds and agrochemicals continues to create demand. Recent advancements in drug discovery and the increasing complexity of pharmaceutical formulations have further increased the importance of DAMN in the chemical synthesis process.

Opportunities exist in the development of more efficient production methods for DAMN, which could reduce costs and improve purity levels. The growing focus on specialty chemicals and the increasing investment in pharmaceutical R&D in developing countries present significant growth potential for DAMN manufacturers.

Challenges & Restraints

The DAMN market faces challenges including the high cost of production and the need for specialized manufacturing facilities. Regulatory compliance in pharmaceutical applications requires high purity levels, which can increase production costs. The market is also affected by fluctuations in raw material prices and the need for specialized handling and storage of the compound.

Environmental regulations regarding chemical manufacturing processes and waste disposal present additional challenges for DAMN producers. The specialized nature of DAMN production also creates barriers to entry for new market participants.

Market Segmentation

The DAMN market can be segmented by application and end-use industry:

Pharmaceutical intermediates

Agrochemical production

Fine chemical synthesis

Research and development

Key end-use industries include:

Pharmaceutical manufacturing

Agrochemical production

Chemical research

Specialty chemical manufacturing

Competitive Landscape

The DAMN market features several key players, including:

Nippon Soda Co., Ltd.

Yingkou Derui Chemical Co., Ltd.

Hangzhou Dayangchem Co., Ltd.

Shanghai Sunway Pharmaceutical Technology Co., Ltd.

Hubei Jusheng Technology Co., Ltd.

These companies compete on factors such as product purity, production capacity, and technical support services. The market is characterized by ongoing research into more efficient production methods and applications for DAMN.

Future Outlook

The DAMN market is expected to maintain steady growth through 2032, driven by the expanding pharmaceutical industry and increasing demand for specialized chemical intermediates. Technological advancements in chemical synthesis and purification processes are expected to improve production efficiency and reduce costs.

Emerging markets in Asia and Latin America are expected to show the highest growth rates, while established markets in North America and Europe will continue to drive demand for high-purity DAMN for pharmaceutical applications.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/292731/diaminomaleonitrile-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscape.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

The Evolution of Cable Making Machines: Top Manufacturers in the Market

The cable manufacturing industry has undergone significant transformation over the decades, driven by advancements in technology, increasing demand for high-quality cables, and the need for efficient production processes. At the heart of this evolution are cable making machines, which have evolved from simple mechanical devices to highly sophisticated, automated systems. This blog explores the journey of cable making machines and highlights some of the top manufacturers leading the market today.

The Evolution of Cable Making Machines

Early Beginnings: Manual and Semi-Automated Systems

In the early days, cable production relied heavily on manual labor and basic mechanical tools. These systems were slow, labor-intensive, and prone to inconsistencies.

Semi-automated machines emerged in the mid-20th century, introducing basic automation for processes like wire drawing, stranding, and insulation.

The Rise of Automation

With the advent of computer technology in the 1970s and 1980s, cable making machines became more automated. Programmable Logic Controllers (PLCs) allowed for precise control over production processes, improving efficiency and product quality.

Machines began to integrate multiple functions, such as twisting, shielding, and jacketing, into a single system.

Modern Innovations: Smart and High-Speed Machines

Today, cable making machines are equipped with advanced features like IoT connectivity, real-time monitoring, and AI-driven quality control. These innovations enable manufacturers to produce cables with minimal waste and maximum precision.

High-speed machines can now produce thousands of meters of cable per hour, catering to industries like telecommunications, automotive, and renewable energy.

Sustainability and Eco-Friendly Manufacturing

As environmental concerns grow, manufacturers are developing energy-efficient machines that reduce carbon footprints. Recyclable materials and waste reduction technologies are also being integrated into modern cable making systems.

Cable Making Machine Manufacturers

Top Manufacturers in the Cable Making Machine Market

The global market for cable making machines is highly competitive, with several key players dominating the industry. Here are some of the top manufacturers:

Nokia-Maillefer (Part of Bekaert)

A pioneer in the cable manufacturing industry, Nokia-Maillefer is known for its high-quality extrusion and cabling solutions. The company offers a wide range of machines for fiber optic, power, and telecommunication cables.

Sikora AG

Sikora is a leading provider of precision measurement and control systems for cable production. Their machines are renowned for their accuracy and reliability, particularly in the wire and cable industry.

Troester GmbH & Co. KG

With over 130 years of experience, Troester specializes in extrusion technology for cable production. Their machines are widely used in the automotive and energy sectors.

Nextrom Technologies

A subsidiary of Rosendahl Nextrom, this company offers cutting-edge solutions for optical fiber, wire, and cable production. Their machines are known for their flexibility and high performance.

Davis-Standard

Davis-Standard is a global leader in extrusion technology, providing innovative solutions for cable and wire production. Their machines are designed for efficiency and durability.

Niehoff GmbH

Niehoff is a trusted name in the wire and cable industry, offering advanced machines for drawing, stranding, and twisting. Their systems are widely used in the production of fine and ultra-fine wires.

Yingkou Jinchen Machinery Co., Ltd.

Based in China, Jinchen Machinery is a rising star in the cable making machine market. They offer cost-effective solutions for wire drawing, stranding, and insulation.

Maillefer (Part of Bekaert)

Maillefer is another key player, known for its innovative extrusion and cabling solutions. Their machines are used in the production of power cables, communication cables, and more.

Wire Machine Manufacturers

Future Trends in Cable Making Machines

Integration of AI and Machine Learning

AI-powered systems will enable predictive maintenance, reducing downtime and improving machine longevity.

Increased Focus on Customization

As industries demand specialized cables, manufacturers will develop machines capable of producing custom designs with minimal setup time.

Sustainability-Driven Innovations

Eco-friendly materials and energy-efficient processes will become standard in cable production.

Expansion of Fiber Optic Cable Production

With the rise of 5G and high-speed internet, the demand for fiber optic cables will drive advancements in related machinery.

Conclusion

The evolution of cable making machines reflects the broader trends in manufacturing: a shift toward automation, precision, and sustainability. As the demand for high-performance cables continues to grow, manufacturers are investing in cutting-edge technologies to stay ahead of the curve. Companies like Nokia-Maillefer, Sikora, and Troester are leading the charge, setting new standards for quality and efficiency in the industry.

Horizontal Pay Off Machine Manufacturers in Tamil Nadu

Whether you're a cable manufacturer or an industry enthusiast, staying informed about these advancements is crucial to understanding the future of cable production. The next decade promises even more exciting developments, as smart technologies and sustainable practices reshape the landscape of cable making machines.

#Cable Making Machine Manufacturers#Wire Machine Manufacturers#Horizontal Pay Off Machine Manufacturers in Tamil Nadu

0 notes

Text

Electronic Circuit Board Level Underfill Materials: Enhancing Reliability in Consumer Electronics and Automotive Applications

Market Overview: Electronic Circuit Board Level Underfill Material Market

The electronic circuit board level underfill material market involves the use of specialized materials, known as underfills, to protect and enhance the reliability of semiconductor packages, particularly for advanced electronic circuits such as flip-chip packages. These materials are applied at the board level, filling the gaps between the chip and the substrate to improve mechanical stability, reduce thermal stress, and enhance the overall performance of electronic devices. Underfill materials are essential for ensuring the durability of electronic components, especially in high-reliability applications such as smartphones, automotive electronics, telecommunications, and consumer electronics.

The Electronic Circuit Board Level Underfill Material Market CAGR (growth rate) is expected to be around 5.25% during the forecast period (2024 - 2032).

For In depth Information Get Free Sample Copy of this Report@

Electronic Circuit Board Level Underfill Material Market Companies Are:

AIM Metals and Alloys, Dow Chemical, Epoxy Technology, Sumitomo Bakelite, Yingkou Nanshan, Lord Corporation, Kester, Henkel, Huitian New Materials, Nordson, Jiangsu Shunfeng, AIM Solder, Hysol, EQ Chem, Shenzhen DAP Technology

Underfill materials play a critical role in modern electronics by providing electrical insulation and mechanical support to sensitive components like flip chips, ball grid array (BGA) packages, and chip-on-board (COB) technologies. These materials help prevent the formation of cracks, corrosion, and other damage that can result from thermal cycling and mechanical stress, which are common in high-performance devices. With the growing demand for smaller, faster, and more durable electronic devices, the market for electronic circuit board level underfill materials is experiencing growth, driven by advancements in semiconductor packaging technologies and the expanding electronics industry.

Market Drivers, Restraints, Opportunities, and Challenges (DROC Analysis)

Drivers:

Growing Demand for Miniaturized Electronics: As consumer electronics, such as smartphones, tablets, and wearables, become smaller and more complex, the need for advanced packaging solutions to support these miniaturized devices increases. Underfill materials are essential in ensuring the reliability of high-density packages used in these compact devices.

Increase in Automotive Electronics: The automotive industry is adopting more electronic components in vehicles, particularly for applications like infotainment systems, autonomous driving, and electric vehicles (EVs). These automotive systems require high-reliability packaging, which is driving the demand for underfill materials to protect electronic circuits under harsh conditions.

Advancements in Semiconductor Packaging: New semiconductor packaging technologies, such as 3D ICs, system-in-package (SiP), and flip-chip packages, are pushing the demand for effective underfill materials. These technologies require underfills that can withstand high thermal and mechanical stress to ensure long-term functionality and reliability.

Demand for High-Performance Electronics: As the demand for high-performance computing, telecommunications, and consumer electronics continues to rise, there is a greater need for reliable underfill materials that can provide thermal management and protect against mechanical failures, ensuring the performance and longevity of electronic products.

Opportunities:

Innovation in Eco-Friendly Materials: The development of environmentally friendly underfill materials, such as water-based or bio-based resins, presents an opportunity to cater to the growing demand for sustainable electronics. This could help manufacturers meet stricter environmental regulations and attract customers who prioritize eco-friendly products.

Emerging Markets and IoT: The expansion of the Internet of Things (IoT) and the increasing use of electronics in industrial automation, smart homes, and healthcare devices are creating new opportunities for underfill materials. These devices often require compact, durable, and reliable electronic circuits, driving the need for effective underfill solutions.

Growth of Wearable Electronics: The rise of wearable technologies, such as fitness trackers, smartwatches, and augmented reality devices, is generating demand for smaller, more efficient packaging solutions. As these devices become more prevalent, the need for underfill materials to protect their miniaturized components will continue to grow.

Technological Advancements in Underfill Materials: Research and development into new underfill materials with superior thermal and mechanical properties, such as flexible and high-temperature-resistant materials, presents an opportunity to meet the increasing demands of next-generation electronics, particularly in automotive and aerospace sectors.

Challenges:

Material Compatibility Issues: The use of underfill materials must be compatible with the substrate, components, and other materials in the electronic package. Ensuring that the underfill material does not negatively affect the performance or reliability of the overall assembly can be challenging, especially as packaging technologies become more complex.

Pressure to Reduce Cycle Time: The application of underfill materials can add time to the production process due to the curing time required. With increasing pressure on manufacturers to speed up production cycles and meet short delivery deadlines, underfill materials that require long curing times or complex application methods can hinder the overall production efficiency.

Supply Chain and Raw Material Availability: The supply chain for raw materials used in the production of underfill materials can be vulnerable to disruptions, such as shortages of specific chemicals or fluctuations in material prices. These supply chain issues can impact the availability and cost-effectiveness of underfill materials.

Global Regulatory Challenges: As the demand for underfill materials grows globally, manufacturers must navigate a range of regulatory standards and certifications in different regions. Adhering to these regulations while maintaining consistent product quality can be challenging, especially when markets are adopting increasingly stringent environmental and safety standards.

The electronic circuit board level underfill material market is experiencing steady growth, driven by increasing demand for miniaturized, high-performance, and reliable electronic devices across industries such as consumer electronics, automotive, telecommunications, and industrial automation. While challenges such as high costs, manufacturing complexity, and environmental concerns exist, the market offers opportunities through innovations in eco-friendly materials, advancements in semiconductor packaging technologies, and the growth of emerging markets like IoT and wearables.

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071 Email: [email protected] Website: https://www.marketresearchfuture.com

0 notes

Text

Top 15 Market Players in Global Zinc Borate (smoke suppression and afterglow reduction) Market

Top 15 Market Players in Global Zinc Borate (smoke suppression and afterglow reduction) Market

Zinc borate plays a vital role as a multifunctional additive in industries such as plastics, rubber, and coatings. Its ability to enhance flame retardancy, suppress smoke, and reduce afterglow has made it a critical component in fire protection. The following 15 companies are driving innovation and market growth in the zinc borate sector:

Borax (part of Rio Tinto Group) A global leader in boron-based chemicals, Borax provides high-quality zinc borate for fire protection and other industrial uses.

Zhejiang Xusen Flame Retardants Co., Ltd. A major supplier in Asia, Xusen focuses on producing cost-effective and high-performance zinc borate for flame retardant applications.

U.S. Borax Inc. Known for its premium boron products, U.S. Borax delivers zinc borate solutions that meet stringent industry standards.

Shandong Taixing Advanced Materials Co., Ltd. This Chinese company specializes in zinc borate production for smoke suppression in polymers and coatings.

Chemtura Corporation (now part of Lanxess) A key player in specialty chemicals, Chemtura offers advanced zinc borate formulations tailored for industrial applications.

China Zibo Borate Co., Ltd. Recognized for its high-quality zinc borate products, Zibo Borate serves the growing demand in Asia-Pacific markets.

Borochemie International Pte. Ltd. Headquartered in Singapore, Borochemie delivers specialized borate chemicals, including zinc borate, for global industries.

Shenzhen Jinhongda Flame Retardant Materials Co., Ltd. This company focuses on zinc borate additives for advanced flame-retardant solutions in construction and electronics.

Russian Bor As a leading supplier of boron products in Eastern Europe, Russian Bor provides zinc borate for smoke suppression and fire safety applications.

Yingkou Tanyun Chemical Research Institute Co., Ltd. A pioneer in flame-retardant materials, Tanyun offers zinc borate with applications in rubber, plastics, and textiles.

The Shepherd Chemical Company Known for its expertise in specialty chemicals, Shepherd Chemical develops zinc borate formulations for high-performance applications.

MCC Corporation MCC produces high-quality zinc borate, targeting sectors such as automotive, construction, and consumer electronics.

Quiborax Based in South America, Quiborax is a significant producer of boron-based chemicals, including zinc borate, for industrial applications.

Firebrake ZB by ICL Group A renowned product line under ICL, Firebrake ZB is widely used for smoke suppression and afterglow reduction in flame-retardant systems.

Guangdong Hongkai Flame Retardant Co., Ltd. A key player in the Chinese market, Hongkai focuses on innovative zinc borate solutions for polymers and textiles.

Request report sample at https://datavagyanik.com/reports/global-zinc-borate-smoke-suppression-and-afterglow-reduction-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Zinc Borate (smoke suppression and afterglow reduction) Market

To remain competitive, companies in the zinc borate market are adopting innovative and customer-centric approaches. Below are the top strategies propelling growth in the sector:

Focus on Sustainability Companies are developing eco-friendly zinc borate products that comply with global environmental standards.

Expansion in Emerging Markets Targeting high-growth regions, such as Asia-Pacific and Latin America, is helping companies capture new customer bases.

Customization of Products Tailored zinc borate formulations are gaining traction, as industries demand solutions that meet specific performance criteria.

Strengthening Supply Chains Ensuring a steady supply of raw materials and minimizing logistics disruptions is a key priority for market leaders.

Collaborative R&D Companies are partnering with academic institutions and research organizations to develop next-generation zinc borate products.

Integration of Advanced Manufacturing Technologies Automation and AI-driven processes are enabling cost-efficient production while maintaining high product quality.

Regulatory Compliance Adhering to regional and international fire safety standards is essential for gaining customer trust and expanding market reach.

Strategic Partnerships Collaborating with polymer, rubber, and coating manufacturers helps in promoting zinc borate applications across diverse industries.

Expanding Product Portfolios Companies are diversifying their offerings to include zinc borate products with enhanced properties, such as improved thermal stability.

Investment in Marketing and Branding Building brand recognition through strategic marketing efforts is helping companies increase their visibility in the competitive market.

Adoption of Circular Economy Principles Recycling and reusing materials in zinc borate production processes align with global sustainability trends.

Enhancing Technical Support Services Providing robust technical guidance and post-sale support ensures long-term customer relationships.

Leveraging Digital Tools Utilizing data analytics and digital platforms helps in identifying customer needs and predicting market trends.

Competitor Benchmarking Regularly analyzing competitor strategies allows companies to fine-tune their own approaches and stay ahead.

Vertical Integration By integrating raw material extraction and production processes, companies achieve cost savings and ensure consistent quality.

Request a free sample copy at https://datavagyanik.com/reports/global-zinc-borate-smoke-suppression-and-afterglow-reduction-market-size-production-sales-average-product-price-market-share/

#Zinc Borate (smoke suppression and afterglow reduction) Market#Zinc Borate (smoke suppression and afterglow reduction) Production#market players#market size#market share#top trends#revenue#average price

0 notes

Text

Carbonato de etilo y metilo, previsión del tamaño del mercado mundial, clasificación y cuota de mercado de las 13 principales empresas

Según el nuevo informe de investigación de mercado “Informe del Mercado Global del Carbonato de etilo y metilo 2024-2030”, publicado por QYResearch, se prevé que el tamaño del mercado mundial del Carbonato de etilo y metilo alcance 1.74 mil millones de USD en 2030, con una tasa de crecimiento anual constante del 21.0% durante el período de previsión.

Figure 1. Tamaño del mercado de Carbonato de etilo y metilo global (US$ Millión), 2019-2030

Según QYResearch, los principales fabricantes mundiales de Carbonato de etilo y metilo incluyen Shinghwa Advanced Material Group, Fushun Dongke Fine Chemical, Haike Group, Liaoyang Best Group, Yingkou Hengyang New Energy Chemical, Shandong Hualu-Hengsheng Chemical, Liaoning Ganglong Chemical, Liaoyang Dongchang Chemical, Mitsui Fine Chemicals, Ruihai Group, etc. En 2023, las cinco principales entidades mundiales tenían una cuota de aproximadamente 65.0% en términos de ingresos.

Figure 2. Clasificación y cuota de mercado de las 13 principales entidades globales de Carbonato de etilo y metilo (la clasificación se basa en los ingresos de 2023, actualizados continuamente)

The demand for ethyl methyl carbonate (EMC) is influenced by several market drivers, including:

1. Growing Demand in Lithium-ion Battery Production: EMC is used as a solvent and electrolyte additive in the production of lithium-ion batteries. The expanding market for electric vehicles (EVs) and the increasing use of portable electronic devices are driving the demand for lithium-ion batteries, consequently bolstering the need for EMC.

2. Shift Towards Environmentally Friendly Solvents: As the global emphasis on environmental sustainability increases, there is a growing demand for green solvents that offer reduced toxicity and environmental impact. EMC, as a green and environmentally benign solvent, has found applications across various industries, including electronics, pharmaceuticals, and chemicals.

3. Rising Application in Pharmaceuticals: EMC is utilized as a solvent in pharmaceutical manufacturing for various applications, including in the production of drug formulations and as a reaction medium. With a growing pharmaceutical industry, especially in emerging markets, the demand for EMC in this sector is witnessing an uplift.

4. Government Regulations and Environmental Policies: Stringent regulations regarding the use of traditional solvents, particularly those with high volatile organic compound (VOC) content, are encouraging the adoption of greener alternatives such as EMC. This regulatory environment is steering industries towards the use of environmentally friendly solvents, which includes a market driver for EMC.

5. Shift Towards Cleaner Energy Storage Solutions: The transition towards cleaner energy, including renewable energy sources and energy storage systems, is propelling the demand for lithium-ion batteries. EMC's role in improving the performance and safety of these batteries positions it favorably to benefit from this industry trend.

6. Increasing Demand in Electronics Manufacturing: EMC is used in the electronics industry as a solvent in various processes, such as in the production of capacitors, which are vital components in electronic devices. As the demand for consumer electronics continues to grow, the market for EMC also experiences a corresponding increase.

7. Focus on Energy Efficiency and Energy Storage: With a global focus on energy efficiency and the need for effective energy storage solutions, technologies such as lithium-ion batteries are being increasingly integrated into various applications, including renewable energy systems, grid stabilization, and portable electronics. This trend fuels the demand for EMC used in the production of these batteries.

These market drivers collectively contribute to the growing demand for ethyl methyl carbonate across various industries, positioning it as an important solvent and electrolyte additive in the production of lithium-ion batteries, electronics manufacturing, pharmaceuticals, and other applications.

Sobre QYResearch

QYResearch se fundó en California (EE.UU.) en 2007 y es una empresa líder mundial en consultoría e investigación de mercados. Con más de 17 años de experiencia y un equipo de investigación profesional en varias ciudades del mundo, QY Research se centra en la consultoría de gestión, los servicios de bases de datos y seminarios, la consultoría de OPI, la investigación de la cadena industrial y la investigación personalizada para ayudar a nuestros clientes a proporcionar un modelo de ingresos no lineal y hacer que tengan éxito. Gozamos de reconocimiento mundial por nuestra amplia cartera de servicios, nuestra buena ciudadanía corporativa y nuestro firme compromiso con la sostenibilidad. Hasta ahora, hemos colaborado con más de 60.000 clientes en los cinco continentes. Trabajemos estrechamente con usted y construyamos un futuro audaz y mejor.

QYResearch es una empresa de consultoría a gran escala de renombre mundial. La industria cubre varios segmentos de mercado de la cadena de la industria de alta tecnología, que abarca la cadena de la industria de semiconductores (equipos y piezas de semiconductores, materiales semiconductores, circuitos integrados, fundición, embalaje y pruebas, dispositivos discretos, sensores, dispositivos optoelectrónicos), cadena de la industria fotovoltaica (equipos, células, módulos, soportes de materiales auxiliares, inversores, terminales de centrales eléctricas), nueva cadena de la industria del automóvil de energía (baterías y materiales, piezas de automóviles, baterías, motores, control electrónico, semiconductores de automoción, etc.. ), cadena de la industria de la comunicación (equipos de sistemas de comunicación, equipos terminales, componentes electrónicos, front-end de RF, módulos ópticos, 4G/5G/6G, banda ancha, IoT, economía digital, IA), cadena de la industria de materiales avanzados (materiales metálicos, materiales poliméricos, materiales cerámicos, nanomateriales, etc.), cadena de la industria de fabricación de maquinaria (máquinas herramienta CNC, maquinaria de construcción, maquinaria eléctrica, automatización 3C, robots industriales, láser, control industrial, drones), alimentación, bebidas y productos farmacéuticos, equipos médicos, agricultura, etc.

0 notes

Text

Dreamworld - by Zhang Guochen Yingkou, China

#night sky#under the milky way#milky way#night scape#celestial enrichment#constellations#celestial ceiling#under starry skies#under the starry skies#under the milkyway#starry skies#nightscape#starry night#starry sky#celestial#celestial odyssey#the celestial odyssey

1 note

·

View note

Text

The world’s largest wheeled crane installs a wind turbine in China [Video]

0 notes

Text

Global Phenoxyethanol Market Is Estimated To Witness High Growth Owing To Increasing Demand for Preservatives in Cosmetics and Personal Care Products

The global Phenoxyethanol market is estimated to be valued at US$ 167.5 million in 2021 and is expected to exhibit a CAGR of 5.9% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Phenoxyethanol is a colorless and odorless organic compound widely used as a preservative in cosmetics and personal care products. It helps in preventing the growth of bacteria and fungi, thereby extending the shelf life of these products. The increasing demand for preservatives in skincare, haircare, and makeup products is driving the growth of the Phenoxyethanol market. Moreover, its non-irritating and low sensitization properties make it a preferred choice among manufacturers. Market Key Trends: One key trend driving the Phenoxyethanol market is the growing demand for natural and organic preservatives. With the rising consumer awareness regarding the potential harmful effects of synthetic preservatives, there is a shift towards natural and plant-based ingredients. This trend has pushed manufacturers to develop phenoxyethanol derived from natural sources such as green tea or fermented rice bran. For example, Zhejiang Weishi Biotechnology Co., Ltd. offers a natural version of phenoxyethanol derived from green tea extract, which is gaining popularity in the market. PEST Analysis: Political: The tightening regulations on the use of preservatives in cosmetics and personal care products by regulatory bodies such as the European Union and the U.S. Food and Drug Administration (FDA) are key political factors impacting the market. Economic: The growing consumer spending on skincare and personal care products, coupled with the increasing demand for premium and high-quality products, is boosting the market growth. Social: The changing consumer preferences towards natural and organic products, driven by concerns over health and the environment, are driving the demand for natural preservatives like phenoxyethanol. Technological: Advancements in technology have led to the development of innovative and efficient extraction methods for natural phenoxyethanol. This has enabled manufacturers to produce natural variants and cater to the growing demand for eco-friendly products. Key Takeaways: 1. The Global Phenyoxyethanol Market Size is expected to witness high growth, exhibiting a CAGR of 5.9% over the forecast period. This growth is primarily attributed to the increasing demand for preservatives in cosmetics and personal care products. 2. The Asia-Pacific region is projected to be the fastest-growing and dominating region in the Phenoxyethanol market, owing to the rapid expansion of the cosmetics and personal care industry in countries like China, India, and Japan. 3. Key players operating in the global Phenoxyethanol market include Zhejiang Weishi Biotechnology Co., Ltd., E. I. du Pont de Nemours and Company, Dow Chemical Company, Eastman Chemical Company, Liaoning Kelong Fine Chemical Co., Ltd, N V Organics Pvt. Ltd, Triveni Interchem Private Limited, BASF SE, Yingkou Tanyun Chemical Research Institute Corporation, and Hangzhou Uniwise International Co., Ltd. In conclusion, the global Phenoxyethanol market is witnessing significant growth due to the increasing demand for preservatives in cosmetics and personal care products. The shift towards natural and organic ingredients presents opportunities for manufacturers to develop innovative and eco-friendly alternatives. The Asia-Pacific region is expected to be a lucrative market for Phenoxyethanol, driven by the expanding cosmetics industry. Key players in the market are focusing on product innovation and strategic collaborations to gain a competitive edge in the market.

#Phenoxyethanol Market#Phenoxyethanol Market Insights#Phenoxyethanol Market Growth#Phenoxyethanol Market Forecast#Phenoxyethanol Market Outlook#Coherent Market Insights

0 notes

Text

Global Sodium Cyanide Market Research Report 2024(Status and Outlook)

Global Sodium Cyanide Market Research Report 2024(Status and Outlook)

The Global Sodium Cyanide Market was valued at USD 2.39 billion in 2023 and is projected to expand at a CAGR of 4.9%, reaching USD 3.18 billion by 2029. This growth trajectory reflects the compound's critical role in gold mining operations, where it remains indispensable for metal extraction despite increasing environmental scrutiny. The market evolution demonstrates complex dynamics between industrial demand and regulatory pressures across key regions.

Sodium cyanide (NaCN), while notorious for its toxicity, maintains irreplaceable functionality in ore processing - particularly in the increasingly important gold mining sector. Recent advances in transportation safety protocols and cyanide recycling technologies are helping mitigate environmental concerns while ensuring continued industrial adoption.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/259925/global-sodium-cyanide-market-2024-339

Market Overview & Regional Analysis

Asia-Pacific dominates sodium cyanide consumption, accounting for 58% of global demand, driven by China's massive gold mining operations and Indonesia's expanding mineral processing sector. Australia's strict "Cyanide Code" implementation sets regional benchmarks for responsible usage, influencing operational standards across Southeast Asia.

North America shows steady growth, particularly in Nevada's goldfields, where operators are investing heavily in closed-loop cyanide recycling systems. Europe's market remains constrained by REACH regulations, while Latin America presents growth opportunities in Peru and Brazil, where new mining concessions are being awarded under tighter environmental oversight.

Key Market Drivers and Opportunities

The market's primary driver remains gold mining, consuming 78% of global production. Emerging applications in chemical synthesis (12%) and electroplating (7%) show promising growth as manufacturers develop safer handling formulations. The shift toward heap leaching techniques over traditional tank leaching creates new demand patterns, requiring different cyanide solution specifications.

Innovation opportunities exist in cyanide detoxification systems and alternative reagent development. The African gold mining sector - particularly Ghana and Burkina Faso - presents untapped potential, though infrastructure limitations and regulatory uncertainty currently constrain market expansion across the continent.

Challenges & Restraints

Stringent environmental regulations pose significant challenges, with the International Cyanide Management Code now adopted by 90% of global gold producers. Transportation restrictions increase logistical costs, while community opposition to cyanide usage has delayed several mining projects. The industry also faces competition from non-cyanide extraction methods, though these alternatives currently lack cost-effectiveness for large-scale operations. Market Segmentation by Type

Solid Sodium Cyanide

Liquid Sodium Cyanide

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/259925/global-sodium-cyanide-market-2024-339 Market Segmentation by Application

Mining Industry

Chemical Industry

Electroplating

Others

Market Segmentation and Key Players

Cyanco

Chemours

Orica

Australian Gold Reagent

Hebei Chengxin

Anhui Shuguang Chemical Group

Tongsuh Petrochemical

Taekwang Industrial

Tiande Chemical

Lukoil

CyPlus (Evonik)

Korund Group

Yingkou Sanzheng

Jincheng Hongsheng Chemical

Changsha Hekang Chemical

Report Scope

This comprehensive market analysis provides granular insights into the sodium cyanide industry landscape from 2024 through 2029. The report delivers critical intelligence on:

Market sizing and growth projections

Application-specific demand patterns

Pricing trends and raw material dynamics

Our research methodology combines:

Primary interviews with industry stakeholders

Plant capacity audits of major producers

Regulatory impact analysis across jurisdictions

The report evaluates the complete competitive landscape, including:

Market share analysis of top producers

Production capacity expansions

Technological developments in cyanide management

Strategic partnerships across the value chain

Regional analysis covers:

North America: US and Canadian market dynamics

Europe: Regulatory constraints and compliance costs

Asia-Pacific: China's dominance and regional growth hotspots

Latin America: Emerging mining opportunities

MEA: Infrastructure challenges and potential

Get Full Report Here: https://www.24chemicalresearch.com/reports/259925/global-sodium-cyanide-market-2024-339

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

BEIJING (AP) — An explosion at a steel mill in China’s northeast killed four people and left five hospitalized with injuries, the city government said Friday.

A blast furnace exploded Thursday morning at the Yingkou Iron and Steel Co., Ltd. in Yingkou, east of Beijing in Liaoning province, the city’s Emergency Management Bureau said in a statement.

The cause was under investigation, but experts believe an equipment malfunction was to blame, the announcement said.

Phone calls to the Yingkou government Friday weren’t answered.

The disaster occurred less than 12 hours after an explosion Wednesday evening blamed on cooking gas killed 31 people in a barbecue restaurant in Yinchuan, a city in China’s northwest.

1 note

·

View note