Don't wanna be here? Send us removal request.

Text

What Are The Product Types Made From Injection Molding?

What Is Injection Molding?

Injection molding is the process that produces high quality, cost-effective plastic parts for various applications. One of its famous processes to create products with molded plastics is known as injection molding.

Injection molding manufacturers in India use this manufacturing process to produce parts in a bigger volume. It can range from hundreds to millions. The resin, once melted, is injected inside a deep mold till it's filled with liquid polymers or molten plastic that are cooled and released as completed, discrete pieces of equipment. The versatile technique can be used on everything from small electronics cases to larger structures like homes depending on the customer needs, all while providing faster production times than many other processes. There isn't any need for post-production assembly product been created through this method.

The injection-moulded design also means you'll never have bubbles in your finished products!

Product Made Of Plastic Injection Moldings

One can say that plastic bottles are one of the vastly manufactured common product by the millions each year. It is produced in multiple sizes and shapes. Usually, these plastic bottles are made with polyethene terephthalate (PET) as it is lightweight and strong.

On the other hand, electronic housings can also be fabricated with the help of an injection molding service. It is used in many devices like computers, remote controls, or televisions, for example, that house many electronics components inside them, all of which use this process when they're created - including medical equipment too!

Read More : How do you choose the right plastic mold for your project?

0 notes

Text

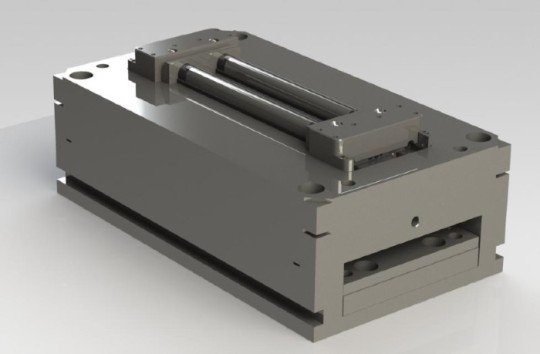

How do you choose the right plastic mold for your project?

Introduction:

Plastic is found in every facet of our daily lives, but did you know that there are different ways to form and mold it for commercial or industrial use? The India’s one of the best plastic moulding companies gives out the most common methods, along with some helpful considerations when deciding which one will work best.

Injection Molding

Injection molding is the process by which plastic products are created. When an injection machine heats up molten raw resin, it injects this material under great pressure into a die or "mold." The finished product emerges from the other side and every day we find them in our lives; most commonly as durable plastics like water bottles that can hold liquids without leaking out of them on their own accord.

PIM (Powder Injection Molding) is a process to make identical parts. The molds can be expensive and complex, depending on the geometry of the part being made. Careful engineering design will help prevent defects in your product as well as optimize quality and processing speed.

Rotation Molding :

Rotational molding is a cutting-edge manufacturing process that molds plastic into any shape you can imagine. A core and cavity tool are heated in an oven, rotated on two axes to create the perfect thickness of your desired product before being cooled with air or water at room temperature for full completion.

Extrusion Blow Molding :

In bead-making, a parison is created and manipulated into the desired shape. The oven heats up and the clamshell mold opens to allow molten plastic in the form of a large droplet called "parison" to be placed inside it. Once closed again with its counterpart half, this liquid is inflated until it fills an empty cavity within given walls; if water were cooled on these specific parts before hand - as well then they would quickly solidify enough for ejection from opening at peak time when pressure could not hold any longer.

Injection Blow Molding:

When you think of drinking bottles, the first thing that springs to mind is probably not a transparent PET or PEEK resin - but these are actually great materials for making them. They're durable and safe, they have excellent surface quality despite their transparency, and recycling rates in both countries where bottling companies reside can be upwards of 98%.

Reaction Injection Molding:

Scientists have developed a new process for manufacturing parts that are both lightweight and durable. This method is known as RIM (Reaction Injection Molding) which uses thermosetting plastics to produce delicate, yet strong car components such as dash boards, body panels or seats. Unlike conventional methods using thermoplastic polymers like ABS plastic in the same type of mold cavity creates weaker products because they cannot withstand high temperatures required by reaction injection molding processes without shrinking into unusable pieces before cooling down again; this requires specific molds with cavities designed specifically for each component being manufactured.

Vacuum Casting

Vacuum casting is a great option for making high-quality prototypes without the huge investment of tools and material. It's able to create small numbers with ease, but does require a 3D printed master pattern in order to work properly.

A sealed box (often made from silicone) that can be filled up with any rigid solid will allow you to make quick copies by removing it once air has been vacuumed out completely so there are no bubbles left inside the mold

Thermoforming

This process can be done with metal dies and simple basic equipment. It is often used for samples of the same type with thin-walled, hollow-bodied parts in industry.Thermoforming can be used to produce plastic products, such as cups and lids, as well car body panels from thicker materials.

Compression Molding

The molding process is a great way to create thin-walled parts that would otherwise be too expensive and impractical. It's relatively inexpensive, but controlling consistency can be difficult depending on the design of your initial mold.

Read More : Beginners guide to building a plastic mold

0 notes

Text

Beginners guide to building a plastic mold

We get asked all the time about how to make molds of things that you create. So we are plastic moulding manufacturers in india teaming up with The Plastic Surgery Workshop to give a little advice on some other ways for doing this!

1 - Mold Making Process:

- A mold is a negative impression used in the process of casting to produce, form or shape an object.

-The term 'mold' can be used for any material that creates this kind of pattern and we call it our "Master Model". An example would be using Sculpey clay as your Master Model (as I do).

- You want to start off with a simple 3D design such as coins or bunnies like my examples because they are easy shapes without undercuts which means you'll have less work. when you cast them into resin later on.

- Use minimal cut outs and limbs 10mm from the body so that when assembling your model, there will not be much leftover resin.

2 - Beginners Guide for Mold Making:

Squares are easy to use - you can make them as thick or thin (depending on the effect desired) and they're perfect for crafting a variety of objects, including jewelry boxes!

Cups save silicone material - there's no need to cut out squares from an expensive sheet of molding materials when these cups will do just fine with less waste all around!

They're readily available in supermarkets which makes it easier than ever before to get your hands on this wonderful product that is so useful at parties too where we want lots of people having fun.

The best way to make your own silicone mold is by using a master model. You can pour mixed silicone into the cup which makes the tool, and place it inside of an opening in the center with a small dab of super glue on its base. Once you have placed everything together be sure that there's at least 10 mm worth material over all parts so they don't move around when casting liquid resin later! Thinking about the cup make sure you have a good flat surface.

3 -Building a custom mold:

Silicone tool cases can be a great way to start shaping large shapes and you have the option of making your mold as big or small as you choose. I recommend leaving around 10 mm all the ways around on both sides, but feel free to make it whatever size is best for your Master Model. Both methods are good places to get started with silicone casting and will produce similar effects in the end product!

Read More: Reasons why your business should be using thermosetting material

0 notes

Text

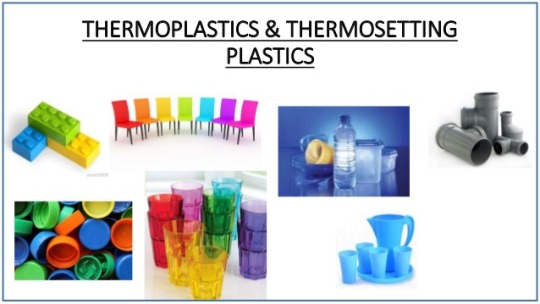

Reasons why your business should be using thermosetting material

Thermosetting plastics are synthetic resins that do not melt at high temperatures. Unlike thermoplastics, they retain the same characteristics even in heat and will only start to degrade (and produce smoke) when heated until it reaches a point where there is no possible way of fixing damage done by degradation;

hence why Thermoset materials such as particle boards have been used for exterior decking on homes with wood siding around windows or doors because you don't need to worry about them being damaged from sun exposure or rain leaking through cracks into your home's walls.

The chemical makeup of thermoplastics and thermosets affect their properties. Thermoplastics are made up of linear polymers that form in semi-crystalline or amorphous glass forms when they're solid, which makes the bonds weaker than those found within a thermoset.

The difference means that while you can melt plastic with heat (thermoplastic), it's not as easy to break down due to cross links between atoms (a trait exclusive to themerosets)

Here are some examples of Thermosets.

Silicone is the most common type of thermoset plastic, and it is used in many different products including kitchen utensils, electronic components and implants.

Silicone has a high resistance to heat without absorbing moisture which makes it ideal for these types of applications because they may be exposed to extreme temperature conditions on an ongoing basis.

Vulcanised rubber is created by cross-linking polymer and hardening it. It's often used in a variety of applications, such as footwear soles, hoses for water or other fluids with high pressure requirements, automobile tires made from synthetic materials like natural rubber reinforced with manmade fibers to improve traction on snow and ice surfaces - among others!

Thermosets are a type of polymer that is strong, durable and heat resistant. There are many different types such as polyurethane or PU in short which makes foam for furniture use to injection molding process popularly making the best thermoset plastics using heated moulds where cross-linking occurs.

Thermoplastics can be either thermoplastic elastomers (TPE) like latex rubber or thermoformable plastic materials used in 3D printing technology but all have one thing in common; they do not get damaged by temperature variations because their molecules remain unchanged when exposed to high temperatures unlike other properties like solvent resistance etc

https://www.techplaastic.com/ is one of the phenolic injection molding company who can extend help to manufacturers in thermosetting.

Read More : Compression Moulding (3D Animation)

0 notes

Text

Compression Moulding (3D Animation)

youtube

Read More : Reasons why your business should be using thermosetting material

1 note

·

View note