Don't wanna be here? Send us removal request.

Text

TEWATT Diesel Driven Oil Free Air Compressors

What is a Diesel Driven Oil Free air compressor?

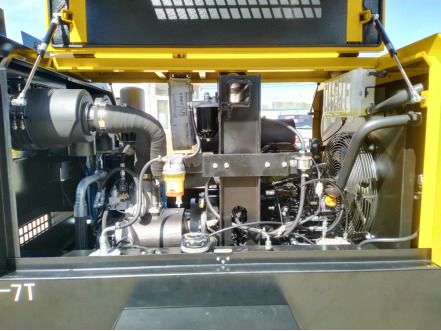

Diesel driven oil free air compressor is an air compressor driven by a diesel engine to drive a dry oil-free screw air-end. It mainly consists of a Cummins X15 diesel engine that complies with the U.S. EPA T3 and T4 standards, a German GHH 100% Oil Free screw main unit, as well as TEWATT heat exchange system, TEWATT unit chassis system, TEWATT traction system, TEWATT electrical control system, TEWATT intake filtration system, TEWATT pneumatic control system, and TEWATT hydraulic control system. In 2023, TEWATT completed the production of the first Diesel Driven Oil Free air compressor equipment.

Technical Specifications of TEWATT Diesel Driven Oil Free Air Compressor

Performance Features of TEWATT Diesel Driven Oil Free Air Compressor

1) Optional Parts:

Engine Water Heater,Spark Arrestor,Automatic Fuel Refueling System.

2)Global Market:

Meet global emission standards, environmental protection standards, and global warranty.

3) Working Environment:

Meet the requirements of -25 ℃ to 45 ℃ environment.

4) Intelligent Control System:

Standard remote GPS,GPRS monitoring system, multi-machine parallel system.

5)Stable & Reliable Design:

All parts are made of famous brands in the industry to ensure stable performance and long-lasting durability.

6)Efficient Air-end:

Germany GHH two-stage Oil Free air-end,each pair of rotors is finely processed in 20 steps,the added coating optimizes the performance and corrosion resistance of the rotor.

7)Efficient & Continuous Operation Guarantee:

Advanced fuel system and lubricating oil system can ensure that the machine runs continuously for 500 hours.

Applications of TEWATT Diesel Driven Oil Free Air Compressor

1)Equipment maintenance and testing in oil refineries.

2)Equipment maintenance and testing in nuclear power plants.

3)Equipment maintenance and testing in the petroleum, petrochemical, and natural gas industries.

4)Equipment maintenance and emergency use in the electronics and semiconductor industries.

5)Equipment maintenance and emergency use in the food and medical industries.

1 note

·

View note

Text

Advantages And Features Of Portable 100% Oil Free Air Compressor

Due to the lubricating oil used for cooling and lubrication of rotors during operation, ordinary screw air compressors produce compressed air containing oil. This oil adheres to valves, instruments, and pipes of the equipment, causing permanent damage and pollution. These severe damages can lead to instrument malfunctions and even production accidents. Additionally, oil contamination during the production process can result in a decline in product quality. 100% oil-free compressed air can save costs in two aspects: firstly, it improves production capacity under stable product conditions, and secondly, oil-contaminated compressed air increases maintenance work and the possibility of equipment downtime downstream. Therefore, 100% oil-free compressed air brings low usage costs, low maintenance costs, and ensures high product quality and increased production capacity.

With the development trends in various fields, the demand for oil-free air compressors is increasing. For example, in industries such as pharmaceuticals, food factories, and knitting mills, there are strict regulations on oil content in the air. If compressed air contains oil, it can increase the rate of non-compliance of goods and continue to damage air-consuming machinery and equipment. In such cases, the use of oil-free screw air compressors is necessary to boost production.

TEWATT 1250 CFM & 8.6/10.3 BAR mobilair portable oil free screw air compressors are equipped with high efficiency TEWATT two stage air-end, powered by CUMMINS heavy duty industrial engine with ultra low fuel consumption and global warranty. Tewatt oil free screw air compressors always meet the operation requirements in extremely high & low temperature, heavy dust, high altitude environment. Suitable for water well drilling, geothermal air drilling,oil & gas exploration, mining & DTH drilling etc.

1 note

·

View note

Text

Market Applications And Advantages Of Oil-Free Air Compressors

Oil-free air compressors are efficient, environmentally friendly, and low-noise devices suitable for a variety of applications. First and foremost, they are ideal for industries such as healthcare, pharmaceuticals, and food processing that require high-quality compressed air. Since they do not require lubricating oil, they avoid oil and odor contamination, ensuring the purity and hygiene of the compressed air.

Secondly, oil-free air compressors find extensive use in the automotive repair and painting industries. Oil contamination can potentially damage vehicle coatings, a problem circumvented by the use of oil-free air compressors.

Furthermore, oil-free air compressors are employed in industries such as electronics, textiles, construction, and chemicals. For example, the electronics industry demands high-quality, oil-free, and moisture-free compressed air, making oil-free air compressors the preferred choice. In summary, oil-free air compressors have a wide range of applications, providing high-quality, environmentally friendly, and low-noise compressed air, making them highly practical industrial equipment.

Compared to traditional oil-lubricated compressors, oil-free air compressors have several advantages:

Environmental Friendliness: Oil-free air compressors do not require oil lubrication, thus avoiding the generation of pollutants and meeting environmental standards.

Low Maintenance Costs: Since oil lubrication and filter replacements are not required frequently, maintenance costs are low.

Wide Applicability: Oil-free air compressors can be applied across various industries, including food, healthcare, electronics, chemicals, and pharmaceuticals.

Compressed Air Drying: Oil-free air compressors can use dryers to treat compressed air, reducing or eliminating moisture and oil vapor in the air.

However, most oil-free air compressors in the market also have some drawbacks:

High Cost: Due to their technical complexity, oil-free air compressors are more expensive than traditional oil-lubricated compressors.

Higher Noise Levels: Because of their structural characteristics, oil-free air compressors tend to be louder than traditional oil-lubricated compressors.

High Maintenance Requirements: Oil-free air compressors have higher maintenance demands than traditional oil-lubricated compressors, requiring regular cleaning and upkeep.

In conclusion, oil-free air compressors offer numerous advantages along with some disadvantages. Choosing and using them should be based on specific needs and circumstances.

1 note

·

View note

Text

What Are The Advantages Of Oil-Free Air Compressors In Use?

Firstly, the machine itself is made of materials that are free from oily substances. During operation, there is no need to add any lubricating oil. This significantly enhances the quality of the discharged air and ensures the safety of the user's associated equipment. In contrast to oil-lubricated air compressors, which emit gases containing a large amount of oil molecules that can cause varying degrees of corrosion to the user's associated equipment, choosing an oil-free, silent air compressor is essential for ensuring air quality.

Secondly, the maintenance of oil-free, silent air compressors is more convenient and straightforward compared to oil-lubricated compressors. As is well known, some oil-lubricated compressors require regular oil changes, and some may experience oil spraying or leakage, causing pollution to the surrounding environment. This necessitates users to spend time on cleaning, which increases the workload, contradicting people's desire to use machinery and equipment to improve work efficiency.

In comparison, oil-free, silent air compressors basically require no user maintenance time since they don't use a drop of oil. The fully automatic pressure sensing switch starts or stops the compressor based on the user's air consumption, making it both hassle-free and energy-efficient. The automated drainage device also adds to user convenience, making it extremely user-friendly. Moreover, the lifespan of oil-free, silent air compressors is longer than that of oil-lubricated silent compressors!

Through surveys, users who have used silent oil-free air compressors have expressed their willingness to recommend such compressors to friends!

With the rapid development of industry and the improvement of people's living standards, there is a significant increase in society's demand for required products. Simultaneously, the increased precision of pneumatic components has led to higher requirements for compressed air, demanding that it be free from oil and water. In the past, the extensive use of new oil-free air compressors was greatly restricted due to quality issues. However, with the improvement in the quality of oil-free air compressors, their fundamental improvement has fully met the needs of modern industrial production. The superiorities of oil-free air compressors during use are reflected as follows:

1.Due to the high viscosity of lubricating oil, oil removal equipment cannot completely remove it. Therefore, the characteristic of oil-free compressed air produced by oil-free air compressors becomes irreplaceable.

2.Oil-removal equipment such as refrigerated dryers, heatless regenerative dryers, and micro-heat regenerative dryers lose their dew point reduction function due to the presence of oil in compressed air. In contrast, the clean, oil-free gas compressed by oil-free compressors fully protects dew point reduction equipment, reducing additional funds required for maintaining dew point reduction equipment.

3.Using oil-free air compressors to supply compressed gases externally does not incur pressure loss due to oil removal equipment, significantly reducing the motor load and achieving energy-saving effects. High-quality three-stage oil removal devices generate 1 to 1.2 kilograms of pressure loss during use. For example, a 7.5KW air compressor will expend an additional 600W of power consumption for every 1 kg increase in pressure. Over a day's work (taking 10 hours as an example), this translates to 6 degrees of electricity consumption, representing a long-term invisible expense.

4.Using oil-lubricated air compressors significantly wastes lubricating oil. For a 7.5KW high-quality oil-lubricated air compressor, the minimum monthly consumption is 5 kilograms of lubricating oil. Over a year, this results in an additional cost of 60 kilograms of lubricating oil. Additionally, to remove oil from compressed gases, efficient oil filters must be used, requiring multiple replacements of filter cores, which is also a considerable expense.

0 notes

Text

The Application Of Diesel Mobile Air Compressor In Pipeline Sandblasting

Mobile air compressor can provide compressed air to support sandblasting of pipe surfaces. Sandblasting on the surface of a pipeline is a common cleaning and roughening treatment method, which can increase the surface area of the pipeline to better adhere to anti-corrosion materials, or remove the oxide layer on the surface of the pipeline to improve the welding quality of the pipeline.

Diesel mobile air compressors can provide stable air pressure on site to support the normal operation of sandblasting equipment. Sandblasting equipment usually requires a certain pressure of compressed air to drive sand blasting and ensure the blasting effect and uniform distribution of sand.

Diesel mobile air compressors can also be used with other equipment, such as pipeline cleaning equipment, anti-corrosion spraying equipment, etc. These equipment also require compressed air as a power source or auxiliary equipment to ensure the smooth progress of pipeline construction.

It should be noted that the following points need to be paid attention to when using diesel mobile air compressor in pipeline sandblasting applications:

Ensure that the power and air pressure of the air compressor can meet the needs of the sandblasting equipment to avoid insufficient or unstable pressure from affecting the sandblasting effect.

According to different pipeline materials and surface treatment requirements, select appropriate sandblasting materials and air compressor pressure to avoid excessive damage or insufficient treatment to the pipeline surface.

Pay attention to safety during use and avoid dangers caused by sandblasting equipment or air compressors during operation. Especially when handling flammable and explosive substances, appropriate safety measures need to be taken.

In short, diesel mobile air compressors are widely used in pipeline sandblasting, which can improve the quality of pipeline surfaces and ensure the smooth progress of pipeline construction. During use, you need to pay attention to safety and equipment selection and matching.

0 notes

Text

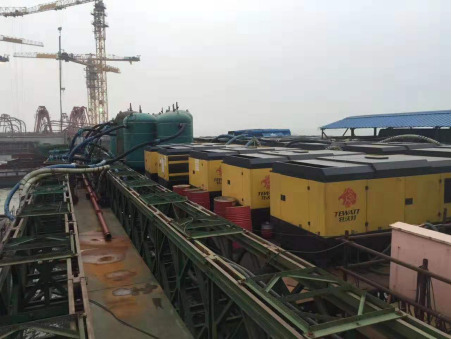

Diesel Air Compressor In Shipyards Sandblasting

The diesel air compressor plays an important role in shipyards sandblasting. Sandblasting is a common surface treatment method in shipyards and improves the adhesion and corrosion resistance of the steel. Mainly by removing rust, oxide scale, old paint films, etc. on the surface of steel materials. In this process, diesel air compressor provides stable and powerful power to drive the sandblasting equipment, which sprays sand particles at high speed onto the steel surface, achieving the purpose of cleaning and roughening the surface through impact and cutting.

Specifically, the diesel-driven air compressor generates high-temperature and high-pressure gas by burning diesel, and these gases are compressed and cooled to form stable compressed air, which is then transported to the sandblasting equipment. The sandblasting equipment uses these compressed air to accelerate the sand particles to high speed and spray them onto the steel surface, impacting and cutting the surface to remove rust and oxide scale.

Diesel air compressor has the advantages of high reliability, powerful power, and convenient maintenance in the sandblasting application in shipyards, and can adapt to the harsh working environment and diverse work requirements of shipyards. At the same time, diesel air compressor can be flexibly moved and adjusted according to work needs, meeting the needs of different workstations in shipyards, improving work efficiency and processing quality.

Generally, the pressure of air compressors for sandblasting is usually around 5-7bar, in order to generate sufficient sandblasting energy and create the desired grinding effect. The air volume needs to be determined according to factors such as the diameter of the sandblasting nozzle, the sandblasting distance, and the sandblasting time.

In summary, diesel air compressor plays a vital role in providing stable and powerful power and driving the sandblasting equipment to complete the surface treatment of steel materials in the sandblasting application of shipyards.

0 notes

Text

The Role Of Portable Diesel Air Compressors In Shipyard And Pipeline Sandblasting

In shipyards and during pipeline construction, the process of sandblasting plays a pivotal role in preparing surfaces for coating and maintenance. At the heart of this abrasive process is the portable diesel air compressor, which serves several critical functions in these industrial applications.

Surface Preparation: In shipyards, the first step in any significant maintenance or construction project is often the preparation of the vessel's surface. This involves removing rust, old paint, and contaminants. Portable diesel air compressors provide the high-pressure air necessary to propel abrasive materials, such as sand or grit, at the surface. This abrasive action effectively cleans and roughens the surface, ensuring optimal adhesion of coatings and paint.

Mobility and Flexibility: Shipyards and pipeline construction sites can be vast and complex, often requiring work at various locations. Portable diesel air compressors offer the flexibility and mobility required to reach different parts of a ship or pipeline without the need for extensive setup and infrastructure. This mobility minimizes downtime and speeds up the overall project.

High-Pressure Air Supply: The success of sandblasting relies heavily on a consistent and high-pressure air supply. Portable diesel air compressors are capable of delivering the required high-pressure air, enabling the effective removal of contaminants and coatings from the surfaces being prepared. This high pressure ensures efficient and uniform results, which are essential for proper surface preparation.

Reliability in Demanding Environments: Shipyards and pipeline construction sites can be challenging environments with harsh weather conditions, temperature extremes, and exposure to saltwater. Portable diesel air compressors are known for their robustness and reliability in such demanding settings. They can operate consistently in challenging conditions, ensuring the sandblasting process proceeds smoothly.

Versatility: Beyond sandblasting, these portable compressors often have multiple applications in shipyards and pipeline construction. They can power a range of pneumatic tools used in various aspects of the projects, from drilling and welding to bolting and painting.

In conclusion, portable diesel air compressors are indispensable tools in shipyards and pipeline construction, primarily in the critical process of sandblasting. Their mobility, high-pressure air supply, reliability in tough environments, and versatility make them essential for achieving efficient surface preparation, ultimately contributing to the success of shipbuilding and pipeline construction projects.

For more inquiry please feel free to contact us.

0 notes

Text

Portable Air Compressor For Shipyard And Pipeline Sandblasting Industry

Shipyard sandblasting is the process of treating and maintaining the surfaces of vessels, typically involving the removal of rust, old coatings, deposits, and preparing the surface for painting or corrosion protection work. This complicated process requires the use of high-power, high-volume sandblasting equipment. A sandblasting setup usually consists of three different parts: the abrasive itself, a sandblasting gun with blaster nozzle, and compressed air source (an air compressor).

Selecting the right air compressor for sandblasting is crucial to ensure efficient and effective sandblasting operations. Normally, the sand blasting machine requires the working pressure of portable air compressor is 7~12bar, the air capacity will be based on the air consumption of the gun which is equipped with sand blasting machine, usually, one sandblast machine can be equipped with one or two spray guns, the air consumption of the spray gun have 1m3/min, 2m3/min, 3m3/min and 6m3/min, for TEWATT portable air compressor, the suitable model for this area have TWT185D-7T, TWT375D-10T, TWT375D-12T, TWT406D-7T, TWT406D-10T & TWT605D-7T.

TEWATT Smaller portable air compressor is the affordable solution for Shipyard sandblasting, pipeline sandblasting projects and heavy-duty applications. With an impressive 185-605 CFM output, it can power a wide range of tools and equipment with ease. Whether you need it for construction, mining, or industrial work, this compressor delivers reliable and consistent performance, day in and day out.

0 notes

Text

Portable Diesel Air Compressor Specific Configuration In Offshore Application Industry

For air compressors used at offshore platform, there are some specific configuration changes that need to be taken into account.

Firstly, More efficient cooling system. Offshore environments always means high temperatures and humidity, so an efficient cooling system is crucial to maintain the normal operation of air compressor.

Secondly, considering that ships may encounter various severe weather and sea conditions at sea, the protection level of the air compressor should be improved to ensure normal operation in harsh environments.

In addition, the space on board may be relatively small, smaller and more efficient air compressor can be selected to save valuable space. At the same time, it is recommended to choose an air compressor with remote monitoring and fault diagnosis functions to facilitate timely discovery and troubleshooting.

Finally, the energy efficiency of the equipment should be fully considered. On the premise of ensuring the normal operation of the equipment, energy-efficient and low-power air compressors should be selected as much as possible to reduce operating costs.

In general, offshore air compressor need to be paid attention to configuration like improving cooling efficiency, enhancing protection level, selecting efficient and small air compressors, and improving the energy efficiency of the equipment.

0 notes

Text

Usage, Industries, And Environments Of High-Pressure Portable Mobile Air Compressors In Chile

In Chile, high-pressure portable mobile air compressors find extensive application across various industries owing to the diverse and challenging environmental conditions present in the country. These compressors are crucial for several key sectors and are adapted to perform effectively in Chile's unique settings.

Usage and Industries:

Mining Industry: Chile is a significant global producer of copper and other minerals. High-pressure portable mobile air compressors are extensively used in mining operations. They power essential tools, such as pneumatic drills, for excavation, tunneling, and ore extraction.

Construction Sector: The growing construction industry in Chile relies heavily on high-pressure portable air compressors. They power pneumatic tools used in construction projects, including jackhammers, concrete breakers, and sandblasting equipment.

Oil and Gas Industry: The oil and gas sector in Chile utilizes high-pressure portable air compressors for various purposes, including well drilling and maintenance activities. These compressors help power drilling equipment, providing the necessary force to penetrate the earth's surface.

Agriculture and Irrigation: In the agricultural sector, high-pressure portable air compressors are utilized for tasks such as powering pneumatic seeders, providing air to clean and maintain farm equipment, and assisting in irrigation systems.

Usage Environment:

Remote Locations: Many applications of high-pressure portable air compressors in Chile are in remote or off-grid areas where a reliable power supply is not available. These compressors, often powered by diesel engines, offer the flexibility to operate in diverse geographical settings.

High Altitudes: Parts of Chile, especially in the Andean region, experience high altitudes. Portable air compressors are engineered to function efficiently in these conditions, ensuring optimal performance despite reduced oxygen levels.

Harsh Climatic Conditions: Chile has a wide range of climates, from the Atacama Desert to the Patagonian region. High-pressure portable air compressors are designed to withstand extreme temperatures and varying weather conditions, making them suitable for use throughout the country.

In conclusion, high-pressure portable mobile air compressors in Chile serve as crucial tools in various sectors, including mining, construction, oil and gas, and agriculture. Their adaptability to remote and challenging environments, combined with their mobility, plays a pivotal role in sustaining key industries and infrastructure development within the country.

For more inquiry please feel free to contact us.

0 notes

Text

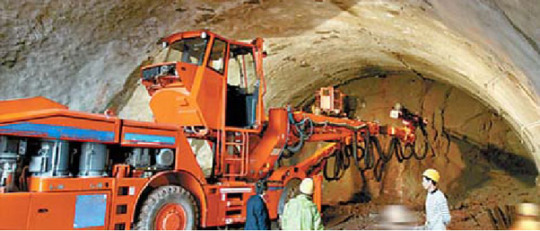

Why Portable Diesel Air Compressors Are Essential In Mining Blasting?

Mining operations are complex and require a wide array of equipment to extract valuable minerals and ores from the earth. Among the essential tools used in mining, portable diesel air compressors play a critical role, particularly in the context of blasting operations. Here's why these compressors are indispensable in mining blasting:

Remote Locations: Many mining sites are situated in remote and rugged terrains, far from the grid. Portable diesel air compressors provide a reliable source of compressed air where electricity may not be readily available, ensuring that blasting operations can proceed unhindered.

Mobility: Mining activities often occur in multiple locations within a single site. Portable diesel compressors can be easily transported to different areas, eliminating the need for fixed, stationary compressors at each location. This mobility improves cost-efficiency by reducing equipment duplication.

High-Pressure Air: Blasting requires a consistent and high-pressure air supply to propel explosives into the desired areas. Portable diesel air compressors are capable of delivering the necessary high-pressure air, ensuring the precision and effectiveness of the blasting process.

Safety: Diesel compressors are known for their robustness and reliability in harsh conditions. In mining, where safety is paramount, having a dependable power source for tools and equipment is crucial. Diesel air compressors operate reliably, even in extreme environments.

Versatility: Beyond blasting, portable diesel compressors in mining serve multiple functions. They can power a range of pneumatic tools used in drilling, excavation, and construction activities, contributing to improved efficiency and versatility.

Cost-Effective: Despite the initial investment, portable diesel air compressors offer long-term cost savings. They have lower operational costs in areas where diesel fuel is more economical than electricity. Their durability and longevity also contribute to a high return on investment.

In conclusion, portable diesel air compressors are integral to mining blasting operations due to their mobility, reliability, and capability to deliver high-pressure air in remote and demanding environments. They enhance safety, versatility, and cost-effectiveness in mining, making them a vital tool in the industry's pursuit of extracting valuable resources efficiently and safely.

For more inquiry please feel free to contact us.

0 notes

Text

For Higher Pressure And Flow, Tewatt Choose Two-Stage Compression Screw Air-End

For applications requiring higher pressure and flow, TEWATT compressors utilize a dual-stage compression process. The dual-stage compression involves two screw elements that perform primary and final compression. The air undergoes initial compression in the first stage and then enters the second stage for final compression, ultimately achieving the target pressure.

Twin-screw compressors with dual-stage compression can achieve higher compression ratios, making them suitable for applications with higher pressure and flow rate requirements. The compression process is divided into two stages, and each stage requires less power, which enhances the system's energy efficiency and overall performance. Additionally, it aids in reducing temperatures and improving equipment stability.

During this process, the lower power requirements for each stage mean:

1. Energy Savings: Compared to single-stage compression, each stage's compression process is relatively more efficient, resulting in achieving the same compression effect with lower energy consumption overall.

2. Improved System Efficiency: Since each stage requires less power, the overall system efficiency is increased. This means that twin-screw compressors with dual-stage compression are more energy-efficient and effective than single-stage compressors when operating at the same output pressure and flow rate.

3. Temperature Reduction: As the compression process is divided into two stages with smaller compression ratios for each stage, the temperature rise during compression is relatively lower. This helps to reduce air temperatures, decrease cooling requirements, and prolong the equipment's lifespan.

Therefore, TEWATT twin-screw compressors with dual-stage compression offer superior performance, energy efficiency, and temperature management for demanding applications with higher pressure and flow rate needs.

0 notes

Text

Main Features And Applications Of Diesel Portable Air Compressors

One of the key features of an air compressor is its ability to generate high-pressure air. It takes in atmospheric air and compresses it to a higher pressure, which can be adjusted according to the specific requirements of the application. This compressed air can then be used to power pneumatic tools, machinery, and equipment.

The advantages of using an air compressor are manifold. Firstly, it provides a clean and reliable source of power. Unlike other energy sources, such as hydraulic or electrical systems, compressed air does not produce harmful emissions or require complex cooling mechanisms. It is also unaffected by fluctuations in the power supply, ensuring uninterrupted operation.

Additionally, air compressors are versatile and flexible. They can be used in a wide range of industries, including manufacturing, construction, automotive, and pharmaceuticals. Air-powered tools, such as impact wrenches, nail guns, and paint sprayers, benefit from the consistent and controlled airflow provided by compressors.

Air compressors are also known for their efficiency. They are designed to minimize energy wastage and optimize performance. Modern compressors often incorporate advanced technologies like variable speed drives and energy recovery systems, further enhancing their energy efficiency and reducing operational costs.

Furthermore, air compressors contribute to a safer working environment. With the use of compressed air, operators can keep a safe distance from potentially hazardous processes or materials, reducing the risk of accidents and injuries.

In summary, air compressors are indispensable in many industries, offering high-pressure air, reliability, versatility, efficiency, and safety. Their applications range from powering tools and equipment to providing essential services in manufacturing processes. With ongoing advancements in technology, air compressors continue to evolve, delivering improved performance and meeting the ever-growing demands of diverse industries.

For more inquiry please feel free to contact us.

(https://www.tewatt.com/)

0 notes

Text

Mobile Air Compressor Maintenance And Precautions

Maintenance:

After approximately 500 hours of operation, the screw oil of the new air compressor needs to be replaced. Under normal operating conditions, the lubricating oil should be replaced every 2 to 3 months, depending on its cleanliness.

There should be no air leak, water, oil leakage, or looseness at the various connections of the air compressor.

Check the intake and exhaust valves, inspect their quality, springs, bolts, etc., for any signs of damage 1 to 2 times per month.

Clean the air filter, connecting rod big end bushing, and small end bushing 1 to 2 times every six months. Inspect the condition of the cylinder, piston, and piston rings once, and also check the pressure gauge and safety valve.

Perform annual maintenance on the air compressor, clean the cooler, measure the wear condition of its friction parts, and make proper records.

Precautions:

1) If the unit is using synthetic oil, maintenance should be carried out every 2000 hours under normal operating conditions, with only the oil filter and air filter requiring replacement.

2) When changing compressor oil, it is advisable to do so about 30 minutes after the unit has been turned off; try to drain all the dirty oil thoroughly, including from the machine head, gearbox, oil barrel, cooler, all oil valves, oil pipes, etc. When draining the dirty oil from the machine head, it is necessary to do so while turning the crankshaft.

3) Notes on adding new oil: Ensure that all oil outlets are properly closed; do not overfill the oil (allow the unit to run for a few minutes before adding to the normal oil level); a proper amount of oil must be added to the machine head (it's best to add oil while turning the crankshaft).

4) When removing the old oil filter, be careful to avoid letting any dirt or debris fall into the filter seat cavity. When installing, apply a layer of grease to the sealing surface of the oil filter and its seat. Tighten with appropriate torque.

(来源:https://www.tewatt.com/info/mobile-air-compressor-maintenance-and-precauti-86432953.html)

0 notes

Text

Large Diameter DTH Hammer Challenges Construction Difficulties, Accelerating Project Progress

Recently, a domestic waste incineration fly ash resource utilization project utilized the large diameter Down-The-Hole (DTH) hammer construction method. This not only tackled complex construction challenges but also accelerated the project's progress, earning high praise from the construction entity. The project's stratum is mainly comprised of waste deposits, with a significant thickness. The lower section consists of a rock-soil structure with intricate geology and hard rock. Given the unique geological structure and ecological environment, the project team boldly adopted the large diameter DTH drilling method with a pile diameter of 800mm and a drilling depth of over 30 meters, achieving hole creation in one go. This method not only ensured the construction quality of the pile foundation but also greatly improved work efficiency, yielding excellent economic and social benefits.

Features of the Large Diameter DTH Hammer Method:

01 Efficient Rock Penetration Solves the technical challenge of efficient rock penetration for large diameter piles: Capable of creating holes in complex geological formations like cobblestone layers and hard rock layers, ensuring high-quality piles and efficient construction.

02 Energy-saving and Emission-reducing Process Addresses the severe environmental pollution caused by mud wall protection in pile holes: Eliminates the need for mud wall protection, reducing pollution from mud production and discharge, and maintaining a clean worksite. It represents a new environmentally-friendly piling machinery product and process, offering both economic and societal benefits and vast market potential.

03 Tackling the Mud Issue Resolves the common problem of mud inclusion during concrete casting: The top and bottom power heads rotate in opposite directions during drilling, and the high-frequency DTH hammer impacts help in rock fragmentation. The full protective tube advances alongside the drilling process, preventing wall collapse and eliminating the risk of mud inclusion in the concrete.

04 Applicable to Various Complex Geological Formations Suitable for various unique geological conditions like fine sand layers, cobblestone layers, quicksand, underground rivers, plastic mud, caverns, hard rock layers, and high groundwater conditions, greatly enhancing project progress and construction quality.

05 Multi-functional Machine A multifunctional drill offers versatility: The machine features multi-functionality, adaptability, and diverse construction capabilities. This reduces equipment investment and increases equipment utilization, generating higher equipment value and economic benefits. Moreover, it also results in significant societal benefits.

Tewatt's mobile air compressor is stable in performance and highly reliable, providing comprehensive support for large diameter DTH hammer construction and other major projects, aiding these projects to achieve new heights!

1 note

·

View note

Text

Application Of Tewatt Mobile Air Compressors In The Mining Blasting Industry

With the continuous development of urban construction, the demand and excavation of mineral resources are increasing. In the process of mining, we encounter many complex construction problems. Among them, air compressors play a vital role in mining and blasting, making significant contributions to mineral resource extraction.

Product Requirements and Features:

Mining typically involves quarries, iron mines, copper mines, coal mines, etc. The primary use of diesel mobile air compressors is for hole blasting.

Working conditions: Operations are generally in remote mountain areas, with much dust and poor fuel quality. The cold weather in the north lasts longer, and some areas are at high altitudes, where standard diesel engines often struggle to adapt.

For directional blasting in mines using small holes, the exhaust pressure of the air compressor is generally 10kg/cm2-14kg/cm2 with an exhaust volume of 21m3/min. This model facilitates multi-drilling, with hole diameters ranging from 50-80mm. For large diameter mountain blasting in mines, the compressor operates at 24kg/cm2, 30m3/min, supporting two hydraulic drills with diameters between 115-120mm. For shale hardness, one shift can complete 1,000 meters, while limestone hardness can achieve 300 meters.

Solutions:

Given the mining industry's requirements for diesel mobile air compressors to operate in extreme conditions such as high temperatures, cold weather, high altitudes, and high dust environments, our company uses imported Swedish VOLVO heavy-duty industrial engines, adopting high-end configurations to meet all these stringent requirements.

VOLVO is globally recognized as the most advantageous engine in high cold and high-altitude regions, meeting the rigorous environmental requirements of temperatures from -40℃ to +50℃ and altitudes up to 4500 meters.

For high temperatures and high dust, we are equipped with a special heat exchanger and a high-efficiency two-stage cyclone air filtration system.

In the engine's fuel system, we designed four stages of filtration, effectively preventing damages to the engine from fuel impurities like water and sulfur.

Our walking and towing system adopts a double axle sulfuric structure, ensuring smooth operation even on rough mountain roads.

Tewatt mobile air compressors provide continuous and stable power to mining equipment, extensively used in the mining blasting industry. With its continually improving performance, it will be applied to even more fields in the future, playing an even more significant role.

1 note

·

View note

Text

What Are Applications Of Air Compressors?

Air compressors are now widely used in industries related to petroleum exploration and extraction, mining, geothermal drilling projects, shipbuilding, and infrastructure construction.

Petroleum Exploration and Extraction:

The air compressors required by the petroleum industry are generally for petroleum exploration, drilling, powering drilling equipment, pipeline cleaning, well cementing, pipeline sweeping, optical cable transport, and pipeline pressure testing.

Air compressors needed in petroleum exploration and drilling require high pressure, large exhaust volume, equipment that is moisture-resistant, corrosion-resistant, stable in performance, and leak-free.

Mining:

Mining generally includes quarries, iron mines, copper mines, coal mines, etc., mainly using diesel mobile air compressors for hole blasting or mountaintop removal.

Working conditions: They are typically remote mountain operations, dusty, with poor fuel quality. In some places, the cold weather lasts longer, and some are at high altitudes, demanding high performance from the compressors.

(blasting site)

Geothermal Drilling Projects:

Air compressors are often used in bedrock structured wells and geothermal projects. Air drilling is significantly more efficient than traditional water drilling, representing the inevitable trend for the drilling industry's long-term development.

The air compressors have a large exhaust volume, high pressure, mobility, and a greater drilling depth to meet the needs of structured wells and geothermal wells. Some use multiple machines in parallel to achieve even greater drilling depths.

Shipbuilding:

The shipbuilding industry mainly uses air compressors for sandblasting and rust removal of the ship's hull and cabins, pressure testing of ship hull pipes, and ship hull tightness tests.

Due to operations being conducted seaside, the humidity is high, it's corrosive, and dusty. Therefore, most air compressors are diesel mobile types, but with the continuous rise in fuel prices, many shipyards have switched to electric mobile compressors.

Infrastructure Construction:

The subway, tunnel, bridge, and hydropower and other infrastructure construction industries have a high demand for air compressors. The commonly used types are electric fixed type, electric mobile type, and diesel mobile type, with exhaust pressures ranging from 8kg/cm2 to 18kg/cm2 and exhaust volumes from 10m3/min to 180m3/min.

Due to the harsh construction environment of basic engineering, the equipment runs continuously for extended periods, hence the requirements for the performance and cost-effectiveness of the air compressor are high.

0 notes