Don't wanna be here? Send us removal request.

Text

MAINTAINANCE AND IMPORTANCE OF CORRECT RUBBER ROLLERS

Rubber rollers for gravure printing and transfer rollers for solventless lamination

In order to save small amount of money some end-users orders and uses, bigger width rollers for smaller jobs.

Which damages the rubber surface from the edges and directly affects the printing and laminating quality when used again for bigger width jobs.

That is why; our expert team at Vintex Rubber Industries highly recommends buyers and users not to use big rubber rollers for small width jobs.

To extend the life of rubber coverings, the rubber rollers should be send for grinding on regular intervals, which removes the oxidation and maintain the dimensional accuracy on the rubber surface.

Using Wrong or Defective Rubber Rollers causes:

Decrease in Quality of Product = Risk of loosing customers, business and market reputation

Decrease in Rate of Production = Lower Cost Efficiency

Increase in Scrap Ratio = Less Profit

Increase in Machine Down-Time = High Cost of Production

Heavy "DOWN-TIME" of the machine is the most expensive thing in printing industry. It is due to defective printing, for this one of the reasons could be a faulty roller.

The type of roller required, varies by its function, customer’s or industrial requirements. The best roller varies with kind of ink, press speed, type of presses etc.

R & D team at Vintex Rubber Industries is continuously developing new rubber compounds and improved urethane compounds, to broaden the types of rubber rollers for gravure printing and transfer rollers for solventless lamination.

Thus it is very necessary for printers who strive for quality should understand the methodology of proper use and care of Rubber Rollers. Without proper care user’s can end up with spending a substantial amount of profit and many times it is not even recognized.

0 notes

Text

HOW TO TAKE CARE OF RUBBER ROLLERS

Improper care and maintenance leads to various problems and damages in Rubber Rollers like

DURING USAGE

One should be highly cautious while fitting the bearings, as it may bend or damage the journal ends by hammering or over forcing. Keep a regular check on the journal ends/bearing seats, sockets for any wear or damage.

It is always recommended to use a bearing puller to change the bearings, instead of using a hammer.

STORAGE AREA

Rubber rollers should be kept away from direct sunlight and extreme temperatures. Temperature between 60 and 90 degrees F is a standard preference.

The rubberized portion, of Rubber Rollers, should never be in contact with a Flat area or any other surface.

Certain rollers can be stored on a flat surface; other Rubber Rollers should be rested horizontally on the journals (end Shafts).

Improper handling or storage may cause cracks in rubber, their ends cracks, surface cracks or flex cracks, so proper precautions should be taken.

Many rollers become useless because of longtime and/or improper storage. This problem can be solved by Re-grinding the roller, only if the dimensional specification tolerances have not been exceeded.

If deterioration is too severe during storage or use, the roller should be taken out of service or replaced.

If the rubber rollers are stored for longer period of time on shop floor, shelf or flat surface, they should be placed on foam or bubble wrap and rotated repeatedly.

AFTER USAGE

The rubber rollers should be covered with black or brown paper.

Rubber Rollers, when kept on stands, should be rotated timely in order to protect them from ozone attack or oxidation. It releases the stress that gets built up in rubber rollers.

The replaced rubber rollers should be cleaned thoroughly after usage and dusting should be done with talcum powder.

After cleaning the rollers, they should be stored in their own boxes or on stands until; the rubber roller is put back into service or returned to the manufacturer for recovering.

The lifespan and durability of Rubber Rollers can be extended, just by following these simple measures, in a result which will lower the cost of frequent purchases, damages or recovering it.

0 notes

Text

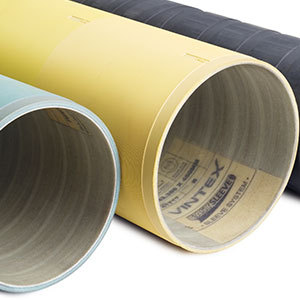

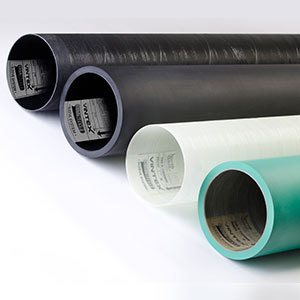

FIBER GLASS SLEEVES

To give maximum advantage to the Packaging Industry in India, Vintex Rubber Industries (INDIA) and North West Roller Services (United Kingdom) have come together with a world-class customized range of Fibre-glass Sleeves.

After years of proven success, Vintex Rollers has earned a renowned name in the market. With continuous product development, Vintex is serving the Packaging industry with best products and services.

Also with a complete focus on comprehensive and constantly updated sleeves range, North West Roller Services (United Kingdom) is recognized worldwide since 1990 for providing excellence in composite sleeve technology.

NWRS will manufacture customized Fiberglass Sleeves {“Easy Sleeves”} and the sleeves will be further rubber covered in India by Vintex Rubber Industries.

VINTEX ROLLERS & NORTH WEST WILL OFFER NUMBER OF BENEFITS TO

IMPRESSION SLEEVES FOR GRAVURE PRINTING M/C

ESA (ELECTRO-STATIC ASSIST) FOR PRINTING M/C

IMPRESSION SLEEVE FOR COATING M/C

IMPRESSION /NIP SLEEVE FOR SOLVENT BASE LAMINATION

TRANSFER / METERING SLEEVE FOR SOLVENTLESS LAMINATION

PLATE MOUNTING & PAD SLEEVES FOR FLEXO M/C

LASER ENGRAVED / ITR SLEEVES FOR CI FLEXO M/C

COATING SLEEVE S FOR HOT MELT M/C

COATING SLEEVE FOR UV COATING M/C

IMPRESSION SLEEVE FOR EMBOSSING M/C

INNUMERABLE ADVANTAGES OF “EASY SLEEVES”

Light in weight

Easy to handle and store

Fast on or off press changeovers

Guaranteed No Slip

Tough and Durable

Fully conductive throughout in comparison to the other suppliers

Consistent & reliable results and many more

NWRS IS THE ONLY MANUFACTURER TO GIVE

Non Slip Guarantee**

**Non-slip guarantee is applicable only if the mandrels are manufactured according to the Industrial Standards.

PRODUCTS OFFERED BY VINTEX ROLLERS & NWRS:

CONICAL / TAPER SLEEVE SYSTEM

Ranging Dia: 72mm-585, Length: 300mm-2500mm

PARALLEL / CYLINDRICAL SLEEVE SYSTEM

Ranging Dia: 50mm-400mm, Length: 100mm-2500mm

Tapered Base Sleeves

The Tapered Sleeves are primarily used in coating and printing industries where the sleeves are covered with rubber compounds to suit the process. To maintain the sleeve’s form, the Tapered Base Sleeves are manufactured from reinforced fiberglass and specially designed resins.

This gives necessary flexibility to expand the sleeve with air to ensure that non-slip performance is achieved. Wall thicknesses range from .060" to .080" depending on the diameter and air pressure available.

EASY Sleeve’s ~ Tapered Based Sleeves are recommended where a superior gripping pressure is needed and any sleeve slippage is unacceptable. Tapered base sleeves improve uptime with high tolerance.

Parallel Base Sleeves

Parallel Base Sleeves are manufactured from reinforced fiberglass and specially designed resins to give the same structural integrity, efficiency, and durability of any sleeve available.In Parallel Sleeves type, one of the most important Product Category is Plate Mounting Sleeves. These are ground to ensure a suitable mounting surface for printing plates. Sleeves will be grinded in-house by Vintex, to ensure the dimensions meet the exact needs of the flexographic printing process, ensuring more efficiency, perfect fit, and uptime along with durability.

A range of wall thicknesses is available to achieve various repeat sizes from one base mandrel. In addition, plate mount scribe lines can be added to assist with the positioning of printing plates.

SLEEVE MANDRELS

The Air Mandrels of Easy Sleeves are designed and manufactured to meet the exact specifications, to ensure the sleeves fit properly once in the field. The designed air system will ensure that sleeve loading and removal is achieved with ease and the sleeves will not slip from improper fit.

Easy Sleeve mandrels can be of nickel or chrome plated to protect them from harsh chemicals and all of our mandrels are dynamically balanced to ensure the best sleeves, the best performance in the world.

Laser Engraving / DIRECT LASER ENGRAVING (DLE)

What is direct laser engraving?

A process where the surface of the sleeve is modeled by means of ablation, using a high-energy laser beam to create a raised image. This process requires high-power laser because – in contrast to the very thin layer on a digital photopolymer form that is only a few microns thick – it is necessary to remove material to a depth of several tenths of a millimeter.

As an alternative to conventional printing plates, the rubber-covered sleeve can be laser engraved for a continuous printing pattern.

Laser Engraving also eliminates the cost of plate mounting. We offer complete digital laser-engraved sleeve production solutions that combine the flexibility, speed and efficiency of flexo-printing with the advanced ink transfer benefits of rubber to ensure long run, printing of continuous designs. Further cost savings can be achieved through the lower ink consumption.

DLE is also called "In the Round" (ITR) Technology, can now exceed the detail quality of photopolymer for all sleeves used in the flexographic printing process. Our laser engraving produces the sharpest dot and best image possible.

Continuous (ITR) sleeves and cylinders offer long, trouble-free cost-effective print runs without the inconvenience of plate lift and press downtime.After approval of digital artwork, the designs are separated and electronically engraved on CO2 lasers. Our Laser can engrave till 170-180 LPI, which give an extraordinary Print Results.

Our experts have the knowledge and years of experience to advice customers whether their requirement is related to sleeve technology, laser rubber engraving, flexographic laser elastomers, or laser plate making.

Applications:

Publications

Flexible Packaging

Aluminum foils

Shrink products

Folding Carton

Gift wrapping paper

Sanitary paper products

Wallcovering

Metal Decorating

Liquid Carton/Aseptic Packaging

Corrugated (Pre- and Post-Print)

Single Use (Tissue, Towel, Cups)

Benefits & Product Features of Direct Engraved Elastomer Sleeves

Tag and Labels

High Durability

High Ink Transfer

Uniform build thickness

Easy to Clean

No plate lift

Fully conductive

Reduced downtime

Optimal registration

Continuous print designs

Environmentally friendly

Excellent ink transfer

Available in Any Circumference

High resolution — up to 170-180 lpi

Higher Print Speed vs. Plates

High-Resolution Screening and Undercutting

Sleeves can be re-ground for use again

High Solvent Resistance (ethyl acetate, ethanol, MEK)

High level of resistance to light and ozone

Suitable for line, solid and halftone printing

Consistent print quality from start to finish

Good abrasion resistance to longevity and consistent print results

The combination of dpi quality, lower setup costs, superior rubber compounds, and years of expertise of NWRS and VINTEX ROLLERS has made us the best choice in the industry for engraving needs.

Vintex Rubber Industries will cover the manufactured sleeves by NWRS in India, with the best elastomer compounds and ship anywhere in the world.

0 notes