Don't wanna be here? Send us removal request.

Text

From Straw to Gold: A New Opportunity in Organic Fertilizer Production?

In the wave of global agricultural sustainable development, crop straw as raw material for organic fertilizer is attracting increasing attention. How can straw from crops like corn, wheat, and rice be transformed into high-value organic fertilizer? What conditions must be met in this process? And what challenges does it face? Let's explore this important aspect of the green circular economy in depth.

Basic Requirements for Straw as Organic Fertilizer Raw Material

Not all straw is suitable for direct use in organic fertilizer production. Ideal straw raw materials should meet the following conditions:

Moisture content controlled between 30-50% - too high may lead to anaerobic fermentation, too low affects microbial activity

Optimal length of 3-5 cm - too long affects subsequent processing efficiency

Free from serious pest and disease contamination to avoid pathogen transmission

Heavy metal content compliant with local organic fertilizer standards

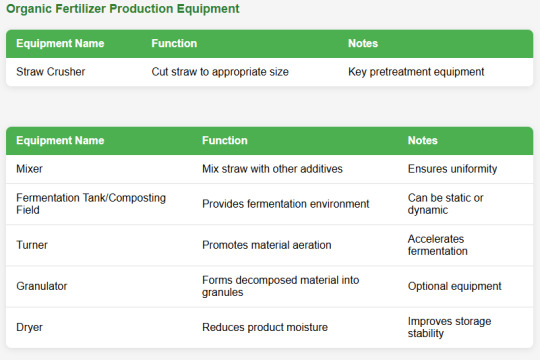

Key Equipment and Process Flow

Transforming straw into high-quality organic fertilizer requires a series of specialized equipment:

Advantages and Limitations of Straw Organic Fertilizer

Advantages:

Improves soil structure and increases organic matter content

Reduces environmental pollution from agricultural waste burning

Relatively low cost with wide availability of raw materials

Promotes nutrient recycling, aligning with sustainable development principles

Limitations:

High C/N ratio (typically 60-80:1), requiring nitrogen source adjustment

High lignin content results in slow decomposition

Bulky volume increases transportation and storage costs

Seasonal supply requires careful production planning

Microbial Inoculants: Necessity and Selection

Adding appropriate microbial inoculants can significantly improve straw decomposition efficiency. Commonly used strains include:

Cellulose-decomposing bacteria: Such as Trichoderma and Aspergillus

Lignin-decomposing fungi: Such as Phanerochaete chrysosporium

Nitrogen-fixing bacteria: Such as Rhizobium and Azospirillum

Compound inoculants: Mixtures of multiple functional strains

The typical addition rate is 0.1-0.5% of raw material weight, depending on product activity and environmental conditions.

Cost-Benefit Analysis

The cost structure of straw organic fertilizer production mainly includes:

Raw material collection and transportation (30-40%)

Equipment investment and maintenance (20-30%)

Labor and energy consumption (15-25%)

Inoculants and other additives (5-10%)

Conclusion

Using crop straw to produce organic fertilizer not only solves the problem of agricultural waste disposal but also creates economic value. Despite some technical challenges, with process improvements and increased market recognition, straw organic fertilizer is expected to become an important component of circular agriculture. For fertilizer producers, the key lies in optimizing production processes, controlling costs, and developing differentiated products to meet diverse customer needs.

Note: Data in this article is based on general conditions, specific parameters may vary by region and production conditions.

0 notes

Text

The production process of granular organic fertilizer mainly includes the following key steps: 1. Preliminary preparation.Raw material collection and pretreatment: Collect organic waste such as livestock and poultry manure and crop straw as raw materials. The raw materials need to be pretreated, such as adjusting the moisture content (generally controlled at 55%65%) and the carbon-nitrogen ratio (usually adjusted to 2530) to ensure the fermentation effect. 2. Fermentation and maturity.Aerobic fermentation: Add an appropriate amount of fermentation bacteria to the pretreated raw materials and perform aerobic fermentation through a turning machine. During the fermentation process, the temperature of the pile should be controlled at around 65°C to kill parasite eggs, pathogens and weed seeds to achieve harmless standards. The fermentation time depends on the type of raw materials and temperature conditions, and generally takes several weeks to several months. Aeration and turning: During the fermentation process, aeration is performed as needed to increase the oxygen content and improve the fermentation effect. At the same time, the turning machine is used to turn the pile regularly to promote uniform fermentation of the material. Composting and aging: After fermentation, the material needs to enter the composting stage to further decompose the macromolecular organic matter into small molecular structures to improve the fertilizer efficiency. This stage can be achieved by natural stacking or turning over again. 3. Crushing and screening.Crushing: Crushing the composted material to remove large impurities and refine the particles for subsequent granulation. Screening: The crushed material is graded by screening equipment to remove fine particles and impurities that do not meet the requirements. 4. Batching and mixing.Batching: Batching the raw materials according to product standards and market demand to ensure that the nutrient content of the finished organic fertilizer meets the relevant standards. Mixing: Use a mixer to fully mix the batched raw materials to ensure that the nutrient distribution of the finished organic fertilizer is consistent. 5. Granulation and drying.Granulation: Use equipment such as a drum granulator or a disc granulator to granulate the evenly mixed materials to form granular organic fertilizer. During the granulation process, an appropriate amount of water can be added as needed to increase the particle forming rate. Drying: The moisture content of organic fertilizer granules after granulation is high (generally 35%~45%), and the moisture content needs to be reduced to less than 20% through drying equipment (bio-organic fertilizer needs to be reduced to less than 15%). The temperature and time should be controlled during the drying process to avoid carbonization of organic matter and nitrogen evaporation loss.

6. Cooling and screening.Cooling: The dried organic fertilizer granules need to be cooled to reduce the temperature and prevent agglomeration. Screening: The cooled granules need to be screened again to remove broken granules and impurities to ensure the quality of the finished product. 7. Coating and microbial agent addition (optional).Coating: To improve the appearance and color of the finished granules, coating can be performed. Bacterial agent addition: If bio-organic fertilizer is produced, various microbial agents can be added during the coating process to enhance the fertilizer effect. 8. Packaging and storage.The processed granular organic fertilizer is packaged and sent to the finished product warehouse for storage or directly loaded and sold. In summary, the production process of granular organic fertilizer includes the steps of raw material collection and pretreatment, fermentation and decomposition, crushing and screening, batching and mixing, granulation and drying, cooling and screening, coating and bacterial agent addition (optional), etc. These steps together ensure the quality and fertilizer efficiency of granular organic fertilizer.

0 notes

Text

Organic fertilizer extrusion granulation equipment is an important equipment used to convert organic waste (such as chicken manure, cow manure, etc.) into organic fertilizer particles. The following is a detailed introduction to organic fertilizer extrusion granulation equipment: 1. Equipment type Organic fertilizer extrusion granulation equipment is mainly divided into two types: double-roll extrusion granulator and flat die extrusion granulator. Double-roll extrusion granulator: Principle: The powdered material is quantitatively and evenly added to the hopper through the feeder, and then evenly added to the arc-shaped notch of the roller after degassing and pre-pressing through the forced feeder. The surface of the roller is opened with mold holes arranged according to certain specifications. After the material enters the bite area, it is gradually bitten by the roller. With the continuous rotation of the roller, the material is compressed and formed, and then automatically demolded to become the required particles. Composition: Generally composed of a feeder, a roller, a crushing chamber (granulator), a screening device, etc. Advantages: Simple structure, easy operation, suitable for processing a variety of organic waste.

2. Flat die extrusion granulator: Principle: Similar to the roller extrusion granulator, but the material is mainly formed by the rotation and extrusion of the flat die. Model and output: There are many models of flat die extrusion granulators, and the output and performance parameters of different models are different. Advantages: high production efficiency, uniform particle shape, suitable for large-scale production. In summary, organic fertilizer extrusion granulation equipment is one of the important equipment for producing organic fertilizers. Users should choose and use it according to their actual needs and budget, and pay attention to the performance, price, after-sales service and other aspects of the equipment.

0 notes

Text

The biological organic fertilizer production process mainly includes three main stages: pre-treatment, primary fermentation and post-treatment. Today, Huaqiang Heavy Industry will briefly introduce the post-processing stage. Biological organic fertilizer production process – screening and granulation: After fermentation, the finished compost is screened to remove impurities and organic matter that is difficult to decompose. The screened materials are treated separately according to the moisture content. The materials with high moisture content need to be dried, and then various additives (such as nutrients such as nitrogen, phosphorus and potassium) are added in proportion and stirred and mixed. The materials are granulated by a granulator to make finished granular fertilizer. Biological organic fertilizer production process – inspection and packaging: The finished fertilizer is inspected for quality, including indicators such as appearance, odor, and nutrient content. The finished fertilizer that passes the inspection is quantitatively packaged and then put into storage for sale.

Note: During the entire production process, key parameters such as the moisture content, C/N ratio, and fermentation temperature of the raw materials must be strictly controlled. During the fermentation process, the compost must be turned regularly to ensure the uniformity and stability of the fermentation. In the post-processing stage, the finished fertilizer must be strictly inspected and packaged to ensure product quality. Through the above process, bio-organic fertilizer manufacturers can produce high-quality, safe and environmentally friendly bio-organic fertilizer products, making positive contributions to agricultural production and the protection of land resources. The above is the post-processing stage of the bio-organic fertilizer production process. If you want to know more, please contact Huaqiang Heavy Industry.

0 notes

Text

Blended fertilizer is also called BB fertilizer, soil-tested formula fertilizer. Because the formula and content are relatively flexible and the adjustment is relatively arbitrary, it is now used in many places. So what equipment does a blended fertilizer production line usually include?

1. Crusher: used to crush large block raw materials into powders of appropriate size. 2. Fully automatic quantitative batching system: can automatically measure various raw materials according to the formula requirements and send them into the mixer. 3. Mixer: used to fully mix and evenly distribute various raw materials. 4. Granulator: granulate the mixed raw materials. 5. Dryer: dry the formed granular products to remove excess moisture. 6. Cooler: cool the dried products to prevent deformation or damage. 7. Packaging machine: package the finished products for storage and sale. The above blended fertilizer equipment is suitable for production lines where the raw materials are powders and the finished products are granules. If the raw materials and finished products are both powders or granules, the equipment configuration is relatively simple, and the specific configuration varies depending on the actual situation of the blended fertilizer production line.

0 notes

Text

1. Plant construction and equipment purchase of organic fertilizer production line Plant construction: According to the scale and demand of organic fertilizer production project, select appropriate plant construction plan and comply with relevant construction specifications and environmental protection requirements. Ensure the safety and environmental protection of the plant to meet production needs. Equipment purchase: Organic fertilizer production equipment is divided into three categories: pretreatment equipment, fermentation equipment and deep processing production line. Pretreatment equipment includes solid-liquid separator, mixer, etc.; fermentation equipment includes fermentation tank, turner, compost fermentation film, etc.; deep processing production line includes crusher, mixer, screening machine, granulator, dryer, cooler, packaging machine, etc. According to the production scale and process requirements, select the appropriate model and quantity of organic fertilizer production equipment, and purchase corresponding accessories and consumables.

2. Production operation Raw material procurement and pretreatment: Purchase organic waste such as livestock and poultry manure and crop straw as raw materials. Pretreat the raw materials, such as solid-liquid separation and uniform mixing, to reduce the difficulty of fermentation and improve product quality. Fermentation and decomposition: Use fermentation equipment to ferment the pretreated raw materials. Control temperature, humidity, oxygen and other conditions according to process requirements to promote the reproduction of microorganisms and the decomposition of organic matter. After a certain period of fermentation and decomposition, the raw materials are converted into organic fertilizers. Deep processing and packaging: The fermented organic fertilizers are deep processed, such as crushing, screening, granulation, etc., to increase the added value and market competitiveness of the products. The finished products are packaged and labeled for sale and transportation. Quality control and environmental management: Establish a complete quality control system and environmental management system to ensure that product quality and environmental protection requirements meet relevant standards and regulatory requirements. Regularly inspect and maintain organic fertilizer production equipment to ensure the normal operation of organic fertilizer production equipment and the stable improvement of production efficiency.

0 notes

Text

https://fertilizerproductionprocess.com/how-do-organic-fertilizer-manufacturers-post-process-fermented-compost/

When the compost raw materials are fermented, organic fertilizer manufacturers also need to post-process them, which mainly includes the following steps. 1. Screening and granulation: After fermentation is completed, the finished compost is screened to remove impurities and organic matter that is difficult to decompose. The screened materials are processed separately according to the moisture content. The materials with high moisture content need to be dried, and then various additives (such as nutrients such as nitrogen, phosphorus and potassium) are added in proportion and mixed. The materials are granulated by a granulator to make finished granular fertilizer.

2. Inspection and packaging: The organic fertilizer manufacturer conducts quality inspection on the finished fertilizer, including indicators such as appearance, odor, and nutrient content. The finished fertilizer that passes the inspection is quantitatively packaged and then put into storage for sale. 3. Precautions: During the entire production process, key parameters such as the moisture content, C/N ratio, and fermentation temperature of the raw materials need to be strictly controlled. During the fermentation process, the compost needs to be turned regularly to ensure the uniformity and stability of the fermentation. During the post-processing stage, the finished fertilizer needs to be strictly inspected and packaged to ensure product quality. Through the above process flow, bio-organic fertilizer manufacturers can produce high-quality, safe and environmentally friendly bio-organic fertilizer products, making positive contributions to agricultural production and the protection of land resources.

0 notes

Text

The granular fertilizer production line mainly involves a series of equipment that work together to complete the entire process from raw material processing to finished granules. The following are the main equipment that may be needed in a granular fertilizer production line and their brief descriptions: 1. Raw material processing equipment: Crusher: used to crush large pieces of raw materials into a particle size suitable for subsequent processing. Mixer: Mix various raw materials and additives in a certain proportion to ensure the quality of the finished granules. 2. Granulation equipment: Disc granulator: The mixed material is squeezed into small spherical particles through a rotating disc. This granulator is widely used in the production of granular fertilizers such as organic fertilizers and compound fertilizers. Double-roll extrusion granulator: It uses two relatively rotating rollers to squeeze the material into granules, which is suitable for the granulation of a variety of materials. Spheronizing machine: The initially formed granules are rounded to improve the roundness and appearance quality of the granules.

3. Drying equipment: Dryer: Dry the wet granules after granulation to remove excess moisture and meet the specified moisture content requirements. Common drying machines include hot air circulation ovens, boiling dryers, etc. 4. Cooling equipment: Cooler: Cool the dried particles to prevent the particles from deteriorating due to high temperature during subsequent packaging or storage. 5. Screening and grading equipment: Vibrating screen: Screen the particles according to size to separate unqualified particles and impurities. Grading machine: Further grade the particles to meet the needs of different customers. 6. Packaging equipment: Automatic packaging machine: Automatically measure, package and seal qualified particles to improve production efficiency and packaging quality. In addition, other auxiliary equipment may be required, such as conveyor belts, storage bins, dust removal equipment, etc., depending on the specific needs and scale of the production line. It should be noted that the equipment configuration of the spherical granulation production line for different industries and products may vary. Therefore, when selecting equipment, it is necessary to customize and configure it according to the production needs and product characteristics of the granular fertilizer production line.

0 notes

Text

After granulation, the organic fertilizer production line still has the following processes to be completed. 1. Drying section. The dryer adopts the method of cylinder edge transmission, flange connection, and direct heat transfer, which is suitable for drying organic fertilizer after granulation. The material to be dried enters the copying plate drying area with a special combination. Due to the tilting and rotating movement of the machine body and the copying plate, the material is constantly carried by the copying plate to be fully scattered and move longitudinally. At the same time, it is fully heat exchanged with the high-temperature furnace gas from the hot air furnace to evaporate the water and dry the material. The material and flue gas to be dried are operated in a downstream and slightly negative pressure manner. There is a secondary granulation area in the dryer, which can be used to perform secondary granulation on some ungranulated materials, which is conducive to improving the granulation rate of the system. During the drying process, it is necessary to monitor at any time and adjust the temperature of the dryer furnace head and furnace tail by adjusting the hot air furnace temperature and the exhaust fan air volume according to the process requirements to achieve the drying index of the dried material. The materials that have completed the drying operation are transported to the next section of the organic fertilizer production line by a belt conveyor.

2. Cooling section. The rotary cooler is mainly used for cooling organic fertilizer products after drying, and can directly cool the hot granular fertilizer to near room temperature. The materials entering the cooler continue to move forward under the rotation and tilting of the machine body. At the same time, the induced draft fan draws air from the tail of the cooler to the head to meet the counterflow of the materials and take away the heat of the materials. During the cooling process, the cold air also takes away some moisture. The cooled materials are easy to pack in time and quickly to prevent agglomeration during storage. The machine adopts micro-negative pressure operation, which reduces pollution and improves the working environment. It has the characteristics of reasonable structure, stable operation and strong adaptability. The cooled materials are transported to the next section of the organic fertilizer production line by a belt conveyor. 3. Screening and large particle crushing section. The screening section is mainly used to separate fine powder, finished products and large particles in the materials. First, the fine powder in the semi-finished products is separated, and then the large particles are separated. The separated large particles are crushed by the large particle crusher and then enter the return belt together with the separated fine powder, and return to the granulator for granulation. The finished product enters the next section of the organic fertilizer production line. 4. Packaging section. The finished product is lifted by the skin elevator to the silo on the packaging machine, unloaded into the metering scale body, and automatically weighed according to the set weighing weight. The weighed material enters the sewing section through the conveyor, and is sewn and packed into the finished product warehouse.

0 notes

Text

Selecting equipment for a granular organic fertilizer production line is a complex process that requires comprehensive consideration of multiple factors to ensure the smooth operation of the production line and the quality and stability of the product. The following are the main factors to consider: 1. Production capacity Annual or daily output: First of all, it is necessary to clarify the production capacity of the production line, such as how many tons of granular organic fertilizer can be produced annually or how many tons of granular organic fertilizer can be produced per day. This directly determines the scale and quantity of equipment required. Production efficiency: The production efficiency of the equipment is also an important consideration. It determines how much fertilizer can be produced per unit time, thus affecting the overall production capacity of the production line.

2. Product type Granular shape: Determine what shape of granular organic fertilizer is produced, such as standard spherical, cylindrical, oblate, etc. Different shapes may require different types of granulators. Fertilizer type: Is it pure organic fertilizer, organic-inorganic compound fertilizer, biological organic fertilizer or compound microbial fertilizer? Different types of fertilizers also have different requirements for equipment. 3. Equipment selection Granulator: Select a suitable granulator according to the shape of the particles and production requirements, such as disc granulator, drum granulator, wet granulator, flat die granulator, ring film granulator, etc. Fermentation equipment: Select suitable fermentation equipment, such as trough compost turner, chain plate compost turner or self-propelled compost turner, etc., to ensure that the raw materials are fully fermented and mature. Pulverizer: Select a pulverizer suitable for processing fermented materials to crush them into fine powder for subsequent granulation. Drying and cooling equipment: Configure dryers and coolers to remove excess moisture from the particles and reduce the temperature. Screening equipment: Use a sieving machine to grade and screen the particles to ensure the uniformity and quality of the product. Packaging equipment: Select a fully automatic packaging machine to quantitatively weigh and package the finished products.

0 notes

Text

The granular fertilizer production line mainly involves a series of equipment that work together to complete the entire process from raw material processing to finished granules. The following are the main equipment that may be needed in a granular fertilizer production line and their brief descriptions: 1. Raw material processing equipment: Crusher: used to crush large pieces of raw materials into a particle size suitable for subsequent processing. Mixer: Mix various raw materials and additives in a certain proportion to ensure the quality of the finished granules. 2. Granulation equipment: Disc granulator: The mixed material is squeezed into small spherical particles through a rotating disc. This granulator is widely used in the production of granular fertilizers such as organic fertilizers and compound fertilizers. Double-roll extrusion granulator: It uses two relatively rotating rollers to squeeze the material into granules, which is suitable for the granulation of a variety of materials. Spheronizing machine: The initially formed granules are rounded to improve the roundness and appearance quality of the granules.

3. Drying equipment: Dryer: Dry the wet granules after granulation to remove excess moisture and meet the specified moisture content requirements. Common drying machines include hot air circulation ovens, boiling dryers, etc. 4. Cooling equipment: Cooler: Cool the dried particles to prevent the particles from deteriorating due to high temperature during subsequent packaging or storage. 5. Screening and grading equipment: Vibrating screen: Screen the particles according to size to separate unqualified particles and impurities. Grading machine: Further grade the particles to meet the needs of different customers. 6. Packaging equipment: Automatic packaging machine: Automatically measure, package and seal qualified particles to improve production efficiency and packaging quality. In addition, other auxiliary equipment may be required, such as conveyor belts, storage bins, dust removal equipment, etc., depending on the specific needs and scale of the production line. It should be noted that the equipment configuration of the spherical granulation production line for different industries and products may vary. Therefore, when selecting equipment, it is necessary to customize and configure it according to the production needs and product characteristics of the granular fertilizer production line.

0 notes

Text

After granulation, the organic fertilizer production line still has the following processes to be completed. 1. Drying section. The dryer adopts the method of cylinder edge transmission, flange connection, and direct heat transfer, which is suitable for drying organic fertilizer after granulation. The material to be dried enters the copying plate drying area with a special combination. Due to the tilting and rotating movement of the machine body and the copying plate, the material is constantly carried by the copying plate to be fully scattered and move longitudinally. At the same time, it is fully heat exchanged with the high-temperature furnace gas from the hot air furnace to evaporate the water and dry the material. The material and flue gas to be dried are operated in a downstream and slightly negative pressure manner. There is a secondary granulation area in the dryer, which can be used to perform secondary granulation on some ungranulated materials, which is conducive to improving the granulation rate of the system. During the drying process, it is necessary to monitor at any time and adjust the temperature of the dryer furnace head and furnace tail by adjusting the hot air furnace temperature and the exhaust fan air volume according to the process requirements to achieve the drying index of the dried material. The materials that have completed the drying operation are transported to the next section of the organic fertilizer production line by a belt conveyor.

2. Cooling section. The rotary cooler is mainly used for cooling organic fertilizer products after drying, and can directly cool the hot granular fertilizer to near room temperature. The materials entering the cooler continue to move forward under the rotation and tilting of the machine body. At the same time, the induced draft fan draws air from the tail of the cooler to the head to meet the counterflow of the materials and take away the heat of the materials. During the cooling process, the cold air also takes away some moisture. The cooled materials are easy to pack in time and quickly to prevent agglomeration during storage. The machine adopts micro-negative pressure operation, which reduces pollution and improves the working environment. It has the characteristics of reasonable structure, stable operation and strong adaptability. The cooled materials are transported to the next section of the organic fertilizer production line by a belt conveyor. 3. Screening and large particle crushing section. The screening section is mainly used to separate fine powder, finished products and large particles in the materials. First, the fine powder in the semi-finished products is separated, and then the large particles are separated. The separated large particles are crushed by the large particle crusher and then enter the return belt together with the separated fine powder, and return to the granulator for granulation. The finished product enters the next section of the organic fertilizer production line. 4. Packaging section. The finished product is lifted by the skin elevator to the silo on the packaging machine, unloaded into the metering scale body, and automatically weighed according to the set weighing weight. The weighed material enters the sewing section through the conveyor, and is sewn and packed into the finished product warehouse.

0 notes

Text

https://fertilizerproductionprocess.com/what-factors-should-be-considered-when-selecting-equipment-for-a-granular-organic-fertilizer-production-line/

Selecting equipment for a granular organic fertilizer production line is a complex process that requires comprehensive consideration of multiple factors to ensure the smooth operation of the production line and the quality and stability of the product. The following are the main factors to consider: 1. Production capacity Annual or daily output: First of all, it is necessary to clarify the production capacity of the production line, such as how many tons of granular organic fertilizer can be produced annually or how many tons of granular organic fertilizer can be produced per day. This directly determines the scale and quantity of equipment required. Production efficiency: The production efficiency of the equipment is also an important consideration. It determines how much fertilizer can be produced per unit time, thus affecting the overall production capacity of the production line.

2. Product type Granular shape: Determine what shape of granular organic fertilizer is produced, such as standard spherical, cylindrical, oblate, etc. Different shapes may require different types of granulators. Fertilizer type: Is it pure organic fertilizer, organic-inorganic compound fertilizer, biological organic fertilizer or compound microbial fertilizer? Different types of fertilizers also have different requirements for equipment. 3. Equipment selection Granulator: Select a suitable granulator according to the shape of the particles and production requirements, such as disc granulator, drum granulator, wet granulator, flat die granulator, ring film granulator, etc. Fermentation equipment: Select suitable fermentation equipment, such as trough compost turner, chain plate compost turner or self-propelled compost turner, etc., to ensure that the raw materials are fully fermented and mature. Pulverizer: Select a pulverizer suitable for processing fermented materials to crush them into fine powder for subsequent granulation. Drying and cooling equipment: Configure dryers and coolers to remove excess moisture from the particles and reduce the temperature. Screening equipment: Use a sieving machine to grade and screen the particles to ensure the uniformity and quality of the product. Packaging equipment: Select a fully automatic packaging machine to quantitatively weigh and package the finished products.

0 notes

Text

Under the great historical background, organic fertilizers with livestock and poultry manure, kitchen waste, etc. as raw materials and straw and garden waste as auxiliary materials have emerged and shouldered the responsibility of protecting hundreds of millions of acres of grain fields. The country’s vigorous promotion and the hot market have made the call for organic fertilizers higher and higher, and the prospects are broader. Many people are very confident in the prospects of organic fertilizers and want to invest in organic fertilizer production line, but they don’t know much about the production costs: 01 Raw material costs The main materials of organic fertilizers are usually livestock and poultry manure, kitchen waste, etc., and the auxiliary materials are straw, garden waste, mushroom residue, etc. Since the main and auxiliary materials are “garbage” in our usual sense, the price is very cheap, and the cost is almost negligible. Although the cost of raw materials is very low, before deciding to go into production, it is necessary to first determine whether the supply of raw materials is stable, so as not to affect production due to shortage of raw materials. 02 Fermentation bacteria cost The high-quality fermentation bacteria cost about 60 yuan per kilogram. We usually buy the original bacteria, which need to be expanded with brown sugar water and cornmeal. 1 kilogram of bacteria can be expanded to 10 kilograms.

03 Electricity cost For small organic fertilizer production lines, the power is generally around 70 kilowatts. According to the energy consumption ratio of 80%, it consumes 60 degrees of electricity per hour and can produce 3 tons of organic fertilizer per hour. The cost of electricity is 20 yuan/ton. 04 Packaging cost Since organic fertilizer is sold to the outside, it needs to be packaged, and the packaging cost is about 50 yuan/ton. 05 Labor cost The factory generally needs to be equipped with 1 forklift operator, 1 fermentation agent blender, 2 packers, 1 mechanic, and 1 electrician. According to the salary of 200 yuan per person per day, the labor cost of 1 day is 1,200 yuan, which is 50 yuan/ton for organic fertilizer. 06 Plant cost Organic fertilizer does not require high plant requirements, only basic civil engineering is needed, and the cost is about 300,000 (conservative estimate, different in different places), but the service life can reach 20 years or even longer, and the cost per ton of organic fertilizer is very low. 07 Equipment cost Depending on the shape of the finished product, the equipment can be divided into powdered organic fertilizer production line and granular organic fertilizer production line.

0 notes

Text

Many people do not breed a single type of livestock, so do we need to buy a granulator for each type of livestock? The answer is no. There is actually no clear boundary in the distinction between pellet machines. We generally refer to chicken feed granulator machines or fish feed granulator machines according to the user’s use. The manufacture and design of granulator machines are actually similar, and they are all suitable for the processing of various livestock feeds and fertilizers. Therefore, the granulator machines used for chicken farming are also suitable for fish farming, sheep farming, pig farming, rabbit farming, etc.

0 notes

Text

During the production process, edible oil processing plants will produce various raw material residues, such as rapeseed cake, bean cake, peanut bran, etc. These are not only high-quality feed, but also high-quality organic fertilizer raw materials. However, in order for cake fertilizer to become usable organic fertilizer, it needs to be fermented. So, how do edible oil processing plants use compost turning machines to ferment cake fertilizer?

First, soak various cake fertilizers with a small amount of water, or chop or smash them, and then adjust the water content to about 60%. If there is too much water, dry it in the sun before fermenting. Pay attention to fermenting solid fertilizers. Do not add too much water, otherwise it will easily stink. Method to judge the water content: stir evenly after adding water, grab a handful with your hand and squeeze it hard. There is water between your fingers but it does not drip. It can automatically disperse when it falls gently on the ground. This is the standard. If conditions permit, you can add organic fertilizer fermentation agent during fermentation, stir it evenly and put it in a place with high temperature and no sunlight, avoid rain and sunlight, for about 2-3 days, when the middle temperature reaches above 50 degrees, use a compost turning machine to turn the compost, turn it every few days until the temperature drops and the fermentation is complete. The fermented cake fertilizer is dark brown, with a slight fragrance or fermentation smell, and can be used as fertilizer. Although cake fertilizer is a good natural organic fertilizer, the price is relatively high. If you only use cake fertilizer to grow vegetables, it will not have much effect if you use less, and the cost is a bit too high if you use more. If you use cake fertilizer mixed with other organic fertilizers, it can save costs, nourish the land, and play a good effect. In general, the compost turning machine helps to speed up the fermentation of cake fertilizer and promote its even and full fermentation.

0 notes

Text

A large number of discarded mushroom residues will not only pollute the environment, but also cause a lot of waste. In recent years, some people have proposed to use discarded mushroom residues to make organic fertilizers, so as to achieve the purpose of waste utilization, reduce resource waste, and improve the environment. Because mushroom residues are rich in nutrients required by organisms, fermented organic fertilizers have good effects on various vegetable plantings and fruit tree plantings. Therefore, many mushroom farms choose to build their own mushroom residue organic fertilizer plants.

How much does it cost to invest in a mushroom residue organic fertilizer plant? Small organic fertilizer production lines require little investment, but the organic fertilizers produced can still be sold on the market, solving the current situation of many customers who want to invest in this industry but have little funds, and are favored by many customers. Since each customer has different raw materials and specific requirements for equipment, no specific price is provided here. It should be noted here that a complete mushroom residue organic fertilizer production line is generally not composed of one device, but usually a combination of multiple devices, so its price is even more difficult to determine. It depends on the actual situation. As long as the equipment is reasonably matched and the manufacturer is selected, it can ensure that the user’s investment is small and the profit in the later stage is higher. If you are interested in the mushroom residue organic fertilizer plant, please contact Huaqiang Heavy Industry to obtain the plant design plan.

0 notes