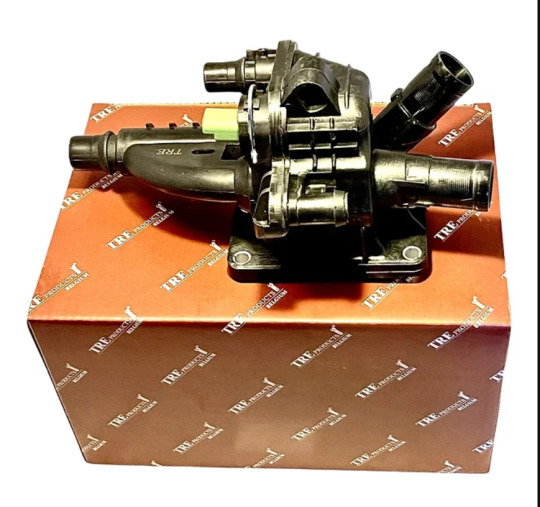

TRE Products has gained extensive experience in the Automotive Manufacturing Industry during the past 40 years and has established itself as an important manufacturer and provider of Automotive Cooling Products, Pressure caps and Cooling Solutions with certification to ISO 9001 : 2000. Temperature is at the Heart of every working and moving engine, whether it be in Cars, Trucks, Agricultural Tractors Industrial or Off-Road Machinery. Our focus on Quality and Manufacturing Standards and combined with International Certification has made Excellence a bi-word for our Products and Services regardless of the application or environment. For more details visit us @ https://www.treproductsdirect.co.uk/

Don't wanna be here? Send us removal request.

Text

What is a Truck Thermostats used for?

The heated coolant then flows into the radiator, where it releases heat and cools down before being recirculated back into the engine. This circulation process continues until the engine reaches an optimal operating temperature. By regulating the flow of coolant, the thermostat helps maintain consistent engine temperatures, which is critical for engine efficiency and longevity.

Several signs can indicate a faulty truck thermostat. Engine overheating is one of the most common symptoms. If the temperature gauge suddenly rises to the red zone or if steam is visible under the hood, a malfunctioning thermostat could be the culprit. Other symptoms include reduced fuel efficiency, rough idling, poor heater performance, and even potential engine damage.

The design of truck thermostats often involves a wax pellet chamber. This chamber contains a wax pellet that melts at a specific temperature, typically between 175 and 200 degrees Fahrenheit. When the wax melts, it releases a spring that operates a rod, which in turn opens the valve, allowing hot coolant to flow into the radiator for cooling. The temperature at which the wax melts determines the thermostat’s operating temperature.

In the event of a malfunctioning thermostat, it’s crucial to diagnose and address the issue promptly. An overheating engine can lead to serious damage, and a thermostat replacement might be necessary. Ensuring the cooling system is full of coolant, checking the functionality of the electric fan and water pump, and consulting guides for thermostat replacement on specific vehicle models are recommended steps to take.

Ultimately, a properly functioning truck thermostat is vital for maintaining the engine’s efficiency and preventing overheating. It’s a component that exemplifies the synergy of engineering and physics in modern vehicles. By regulating coolant flow and ensuring optimal operating temperatures, the truck thermostat contributes to the overall performance and longevity of the engine. Visit us @ TRE Products UK LTD

0 notes

Text

Cars Engine Cooling Products: A Comprehensive Overview

Cars Engine Cooling Products

The Cooling System’s Functionality: At the core of every vehicle’s cooling system lies a fundamental objective: preventing the engine from overheating. The cooling system performs this task through a well-orchestrated process that involves a combination of components working in harmony.

The cooling system essentially circulates a liquid coolant through the engine and a radiator. This coolant absorbs the engine’s excess heat, which is then transferred to the radiator. A cooling fan aids in dissipating this heat by blowing air through the radiator. As the coolant releases heat into the air, it returns to the engine to continue the cycle.

Key Components of the Cooling System:

Radiator: The radiator acts as a heat exchanger. It cools the hot coolant as air passes through its fins, releasing heat into the atmosphere.

Thermostat: This component regulates the flow of coolant to the radiator. It opens when the engine reaches a certain temperature, allowing coolant to flow and cool the engine.

Water Pump: The water pump drives the circulation of coolant throughout the system, ensuring a steady flow and efficient heat transfer.

Cooling Fan: The cooling fan enhances the heat exchange process by blowing air across the radiator’s fins. It can be mechanically driven or electrically operated.

Fan Clutch: In some vehicles, the fan clutch adjusts the fan’s speed based on temperature, enhancing efficiency and reducing unnecessary power consumption.

Coolant: The coolant itself is a crucial component. It’s a mixture of water and antifreeze, designed not only to prevent overheating but also to prevent freezing in cold temperatures.

Choosing the Right Engine Cooling Products: Selecting appropriate cooling products is vital for maintaining a vehicle’s optimal performance and longevity. Various products cater to different aspects of the cooling system, each contributing to the overall efficiency of the engine’s temperature management. Here are a few notable cooling products that can make a difference:

Prestone Coolant/Antifreeze: Known for its performance and versatility, Prestone Coolant/Antifreeze offers corrosion protection for extended periods. With a wide temperature range, it suits various climates and can be safely added to existing coolant without causing damage.

Evans Waterless Engine Coolant: Ideal for high-performance vehicles, Evans Waterless Coolant eliminates many issues associated with water-based coolants. It offers a wider temperature range and reduces strain on engine components.

Comma Xstream: The Comma Xstream coolant boasts advanced organic additive technology that provides year-round protection against corrosion, overheating, and freezing. It caters to both petrol and diesel engines.

Valvoline Zerex G05: This popular engine coolant offers exceptional protection against corrosion, leaking, and deposits. Its formulation is designed to keep various cooling system parts clean and functioning properly.

CarPlan Premium Red Antifreeze & Coolant: Offering prolonged corrosion resistance and adaptability to different dilution ratios, this antifreeze and coolant solution is both versatile and cost-effective.

Conclusion: Engine cooling products play a pivotal role in maintaining the health and efficiency of a vehicle’s engine. The cooling system’s intricate design, encompassing components such as the radiator, thermostat, water pump, and cooling fan, ensures that the engine operates at optimal temperatures. Proper maintenance and the use of quality cooling products are essential to prevent overheating, extend engine life, and enhance overall vehicle performance. By understanding the significance of these components and products, vehicle owners can make informed decisions to ensure their vehicles remain reliable and efficient for years to come. To buy Cars Engine Cooling Products Visit us @ TRE Products UK LTD

0 notes

Text

Thermostat Cooling System for vehicle engine cooling

A thermostat cooling system is an essential component in a vehicle’s engine cooling system, responsible for regulating the engine’s temperature to ensure optimal performance and efficiency. It plays a vital role in preventing the engine from overheating or operating at too low a temperature. In this comprehensive explanation, we will delve into the working principles, components, functions, and benefits of a thermostat cooling system based on the provided information.

Working Principle: The thermostat is a temperature-sensing device located between the engine and the radiator in a liquid-cooled car engine. Its primary function is to control the flow of coolant to the radiator based on the engine’s temperature. When the engine is cold, the thermostat remains closed, preventing coolant flow to the radiator. As the engine warms up and reaches its operating temperature (usually around 200 degrees F or 95 degrees C), the thermostat opens, allowing coolant to flow to the radiator for cooling.

The working principle of the thermostat relies on a charge cylinder filled with a wax-like material that has a specific melting temperature (commonly around 180–80 degrees F or 82–90 degrees C). When the engine’s coolant temperature rises to this melting point, the wax expands significantly, pushing a connected rod. The movement of this rod opens the thermostat valve, allowing coolant circulation to the radiator.

Components of the Thermostat Cooling System: The thermostat cooling system consists of several components that work together to control the flow of coolant:

Main Valve / Primary Valve: Controls the flow of engine cooling water to the radiator.

By-Pass Valve / Secondary Valve: Allows coolant to bypass the radiator and circulate within a closed circuit.

Charge Cylinder: Contains wax that expands when heated, causing the thermostat valve to open.

Seal / Gasket: Prevents unwanted flow past the main valve.

Spring: Returns the main valve to the closed position when the cooling water temperature decreases.

Secondary Spring: Controls the movement of the rod connected to the charge cylinder.

Air Bleed: Used to remove air from the cooling water system.

Functions of the Thermostat Cooling System: The thermostat cooling system has several critical functions in the engine cooling process:

Control Working Temperature: The primary function of the thermostat is to regulate the engine’s working temperature. It ensures that the engine operates within the desired temperature range, typically between 194 to 221 degrees Fahrenheit (90 to 105 degrees Celsius).

Prevent Overheating: By controlling the coolant flow, the thermostat prevents the engine from overheating, which can lead to irreversible damage.

Efficient Warm-up: At cold starts, the thermostat blocks coolant flow, helping the engine reach its working temperature quickly and efficiently.

Optimize Cooling: The thermostat ensures that the coolant absorbs sufficient heat from the engine before circulating to the radiator for cooling.

Benefits and Importance of a Thermostat Cooling System: The presence of a properly functioning thermostat cooling system is crucial for the following reasons:

Engine Protection: The thermostat helps maintain the engine’s temperature within the optimal range, reducing the risk of damage due to overheating or excessive cooling.

Enhanced Efficiency: Operating the engine within the recommended temperature range ensures optimal fuel combustion and overall engine efficiency.

Reduced Emissions: A well-regulated engine produces fewer emissions, contributing to environmental protection.

Improved Performance: Keeping the engine at the right temperature allows it to perform at its best and extends the engine’s lifespan.

In conclusion, the thermostat cooling system is a critical component in a vehicle’s engine cooling system. Its role in regulating the engine’s temperature is vital for engine protection, efficiency, and performance. By controlling the flow of coolant based on the engine’s temperature, the thermostat ensures the engine operates at the desired temperature range, preventing overheating and excessive cooling. Understanding how the thermostat works and its components helps vehicle users appreciate its importance in maintaining the engine’s health and prolonging its lifespan. To find the thermostat cooling system for vehicle engine cooling Visit us @ TRE Products UK LTD

0 notes

Text

What is a cooling thermostat car?

The cooling thermostat car in a liquid-cooled car engine is a small device located between the engine and the radiator. Its main purpose is to control the flow of coolant to the radiator until the engine reaches its operating temperature. When the engine is cold, the thermostat remains closed, blocking the flow of coolant to the radiator. This ensures that the engine warms up quickly, reducing engine wear, deposits, and emissions. Once the engine reaches its designated operating temperature, typically around 200 degrees F (95 degrees C), the thermostat opens, allowing coolant to flow through the radiator and maintain the engine at its optimal temperature.

The working principle of a car’s thermostat involves a small cylinder filled with a wax that starts melting at a specific temperature, usually around 180 degrees F (82 degrees C). Connected to the valve, a rod presses into the wax. As the wax melts and expands, it pushes the rod out of the cylinder, opening the valve. The expansion of the wax occurs because it changes from a solid to a liquid, causing it to expand further due to the heat. This ingenious mechanism allows the thermostat to control the flow of coolant effectively.

There are several types of automotive thermostats available in the market:

Conventional Wax Thermostats: These thermostats utilize a wax element to regulate coolant flow based on temperature changes. They are proven products with high volume production, and their opening temperature is pre-defined.

Electrically Heated Wax Thermostats: These thermostats provide improved operating ranges through variable opening temperatures. They have a quick response time due to optional current feed and work well with advanced engine management systems to reduce emissions and improve fuel consumption. They are also compatible with conventional thermostats.

Electrically Actuated Thermostats: These thermostats offer full control without temperature dependency, providing the maximum possible operating range. They are adaptable to modern temperature management requirements.

Maintaining the thermostat’s functionality is essential to prevent engine overheating and potential damage. Signs of a failing car thermostat include very high temperature readings on the dashboard, an overheating engine, leaking coolant, erratic temperature fluctuations, and poor engine performance. A malfunctioning thermostat can lead to engine damage and increased fuel consumption.

Regular maintenance of the cooling system, using high-quality antifreeze, and avoiding mixing or pouring water into the coolant circuit can extend the engine’s durability and reduce fuel consumption and pollutant emissions.

In conclusion, a cooling thermostat in a car’s cooling system is a critical component that helps regulate the engine’s temperature and ensures it operates efficiently. By understanding its working principle and importance, as well as recognizing signs of malfunction, drivers can take appropriate measures to keep their vehicles running smoothly and avoid potential engine issues. For more details visit us @ TRE Products UK LTD

0 notes

Text

Comprehensive Guide to Truck Engine Cooling Products

Introduction

Truck engine cooling product is a critical aspect of maintaining a vehicle's performance and longevity. Proper engine cooling ensures that the engine operates at an optimal temperature, preventing overheating and potential damage. This comprehensive guide will explore various aftermarket accessories and products designed to cool truck engines, with a focus on those offered by AmericanTrucks, a trusted supplier of truck parts, and other reputable sources. We will also discuss the importance of maintaining an efficient cooling system and highlight key components that can enhance cooling capabilities.

Understanding the Importance of Engine Cooling:

The engine is the heart of any vehicle, and trucks are no exception. A well-maintained engine cooling system is vital to ensure the engine operates within its ideal temperature range. Overheating can lead to various issues, such as reduced performance, engine damage, and even total engine failure. To prevent these problems, truck owners should pay close attention to their cooling systems and opt for quality cooling products when necessary.

Truck Engine Cooling Products from AmericanTrucks:

AmericanTrucks is a reputable online store dedicated to providing truck owners with a wide range of high-quality aftermarket parts and accessories. Within their engine cooling category, they offer products like radiators, intercoolers, and other cooling system components.

The following are some of the key products offered by AmericanTrucks:

a. Performance Radiators:

AmericanTrucks provides performance radiators made from lightweight aluminum. These radiators offer increased surface area and coolant capacity, compensating for the reduction in thermal conductivity compared to traditional copper and brass radiators. Some models are designed with a dual-pass, horizontal-flow configuration, which enhances cooling efficiency by allowing coolant to make two passes through the radiator. Upgrading to an aluminum radiator may require adjustments to the water pump to accommodate higher coolant flow rates.

b. Electric Fans:

Electric fans are an excellent addition to the cooling system, especially when dealing with stop-and-go traffic or idling situations. Unlike engine-driven fans, electric fans provide consistent airflow regardless of engine RPM, contributing to better cooling performance. AmericanTrucks offers dual-fan setups that ensure the entire radiator surface receives cooling airflow.

Additional Aftermarket Accessories for Enhanced Cooling:

Apart from the specific products offered by AmericanTrucks, other aftermarket accessories can help improve a truck's engine cooling capabilities. These include:

a. Thermostats:

Upgrading to a performance thermostat can improve temperature control and ensure the engine operates at the optimal temperature range. Performance thermostats open at lower temperatures, allowing coolant to flow through the engine earlier, resulting in quicker warm-up and improved cooling efficiency.

b. Coolant Additives:

Certain coolant additives can enhance the cooling system's heat transfer properties and prevent corrosion, contributing to overall cooling system efficiency.

The Importance of Regular Cooling System Maintenance:

While aftermarket accessories can significantly enhance engine cooling, regular maintenance remains crucial for optimal performance. Truck owners should follow manufacturer-recommended maintenance schedules and perform routine checks for coolant leaks, damaged hoses, and other potential cooling system issues.

Conclusion

Proper engine cooling is essential for maintaining a truck's performance and preventing engine damage. AmericanTrucks offers a range of high-quality aftermarket cooling products, including performance radiators and electric fans, to enhance cooling capabilities. Additionally, investing in performance thermostats and coolant additives can further improve cooling system efficiency. However, regular maintenance and timely replacement of worn-out components are equally critical for ensuring the longevity and reliability of a truck's engine cooling system. By prioritizing proper cooling, truck owners can enjoy smooth drives, better engine performance, and increased vehicle longevity. For more details visit us @ TRE Products UK LTD

0 notes

Text

Truck Thermostats: Understanding their Function and Importance

Truck thermostats play a crucial role in maintaining optimal engine temperature and ensuring the efficient operation of trucks. Understanding how a truck thermostat works is essential for proper maintenance and preventing issues that can lead to engine overheating or poor performance. In this comprehensive guide, we will explore the functioning of truck thermostats, their components, signs of a faulty thermostat, and the importance of regular maintenance.

How a Truck Thermostat Works

A truck thermostat is a valve that controls the flow of coolant within the engine's cooling system. It is typically located between the engine and the radiator, connected to the upper or lower radiator hose. The thermostat remains closed when the engine is cold to prevent coolant from flowing through the radiator. This allows the engine to heat up quickly and reach its optimal operating temperature, reducing wear and enhancing heat dispersion.

As the engine warms up, the thermostat gradually opens, allowing coolant to circulate between the engine and the radiator. This process is crucial for maintaining a consistent operating temperature. The coolant absorbs heat generated by the engine and carries it to the radiator, where it is cooled down before returning to the engine. The thermostat continues to regulate the coolant flow to maintain the engine temperature within the desired range.

Components of a Truck Thermostat

A truck thermostat typically consists of multiple layers and components. The top layer, often made of glass, prevents water from evaporating from the engine block. The bottom layer is composed of a ceramic or metal plate. Additionally, a fan connected to a sensor may regulate the temperature of the air entering the fuel cell. The sensor monitors the air temperature and controls the fan accordingly to maintain optimal conditions.

Signs of a Faulty Thermostat

Identifying signs of a faulty truck thermostat is essential for timely maintenance and avoiding potential engine damage. Some common indications of a malfunctioning thermostat include:

Engine Overheating: If the thermostat gets stuck in the closed position, coolant flow to the radiator is blocked, resulting in engine overheating. Signs of engine overheating include temperature gauge readings in the red zone, steam coming from under the hood, or a warning light on the dashboard.

Insufficient Engine Warm-up: A faulty thermostat that remains open continuously can lead to longer engine warm-up times. If your engine takes longer than usual to reach its optimal operating temperature or fails to reach it entirely, it may indicate a problem with the thermostat.

Poor Engine Power and Fuel Efficiency: A malfunctioning thermostat can affect engine performance and fuel efficiency. If your truck experiences decreased power, reduced fuel economy, or struggles to operate efficiently, it could be a result of an inefficient cooling system caused by a faulty thermostat.

Coolant Leak: Leaking coolant around the thermostat housing or visible puddles of coolant under the truck may suggest a problem with the thermostat. It is important to address coolant leaks promptly to prevent engine damage and maintain the cooling system's integrity.

Importance of Regular Maintenance

Regular maintenance of truck thermostats is crucial for optimal engine performance and longevity. It is recommended to follow the manufacturer's guidelines for maintenance intervals and have the thermostat inspected during routine service visits. A skilled mechanic can check the thermostat's operation, test its opening and closing temperatures, and replace it if necessary.

Conclusion

Truck thermostats are essential components of the cooling system, responsible for regulating engine temperature and ensuring efficient operation. Understanding how a truck thermostat works and recognizing signs of a faulty thermostat is vital for maintaining optimal engine performance, preventing overheating, and avoiding potential damage. Regular maintenance, including thermostat inspections, helps ensure the proper functioning of the cooling system, contributing to the overall reliability and longevity of trucks. For more details Visit us @ TRE Products UK LTD

0 notes

Text

Agricultural Tractor Thermostats is used for?

Agricultural tractors play a crucial role in modern farming practices, providing power and efficiency for various tasks in the field. One essential component of these tractors is the thermostat, which helps regulate the engine's temperature and ensures optimal performance. In this discussion, we will explore the function of agricultural tractor thermostats, their types, and their importance in maintaining the engine's operating conditions.

A thermostat's primary purpose is to reduce engine warm-up time, maintain an optimal running temperature, and assist in heater output, if equipped. When an engine is cold, it experiences several undesirable effects, such as increased wear on internal parts due to poor lubrication and friction. Additionally, fuel vaporization is inefficient when the engine is cold, leading to oil dilution and decreased performance. The thermostat helps mitigate these issues by regulating coolant flow within the engine.

There are different types of thermostats used in agricultural engines, including aneroid and hydrostatic (wax poppet) thermostats. The aneroid thermostat, which is less commonly used in modern tractors, utilizes a vapor-metal bellows to control coolant flow based on the pressure differential between the bellows and the system. On the other hand, hydrostatic thermostats feature a wax substance with a high coefficient of thermal expansion. As the engine's temperature rises, the wax melts and compresses a rubber insert, allowing coolant flow to begin.

In the agricultural context, thermostats are crucial for maintaining proper operating temperatures. They prevent the engine from overheating or running too cold, which could lead to inefficient combustion, decreased performance, and potential engine damage. Thermostats help optimize fuel efficiency and reduce emissions by ensuring the engine operates within its recommended temperature range.

When selecting a thermostat for agricultural tractors, several key features should be considered. These features include:

Digital Display: A thermostat with a digital display is recommended, as it provides real-time information about the actual temperature (present value, PV) being measured and the setpoint (SP) temperature. This feature allows for accurate temperature control and troubleshooting of the overall system operation.

Output Indicator: The thermostat should have an output indicator, such as a light, that indicates whether the load is being turned on or off. This feature helps monitor the status of the thermostat switch, whether it is closed (ON) or open (OFF).

Remote Probe: A thermostat with a remote probe provides flexibility in temperature measurement. It allows the control unit to be placed conveniently for reading and use while the probe measures the temperature at the desired location. This feature is particularly useful in agricultural applications where temperature conditions may vary across different areas.

Accurate Measurement: The thermostat should offer accurate temperature measurement over a wide range, ideally with the ability to calibrate it in the field. A tolerance of +/- 2°F accuracy within the range of 32°F to 212°F is achievable for many thermostats.

Low Differential Ability: The thermostat's differential ability refers to the temperature difference at which it turns the load on or off. A thermostat with a low differential, such as 1°F, allows for precise temperature control.

Ability to Change Mode: It is beneficial to select a thermostat that can be easily switched from cooling use to heating use. This feature enables standardization of thermostats on the farm and in processing plants and allows for the thermostat to be used in different applications depending on the season or specific needs.

Other considerations when choosing an agricultural tractor thermostat include ensuring compatibility with the intended load's voltage and amperage, or allowing for the use of a relay if necessary. It is essential to check the current ratings to ensure the thermostat can handle the load capacity. In some cases, an external relay can be added to increase the load capacity.

In conclusion, agricultural tractor thermostats are vital components that help regulate the engine's temperature, ensuring optimal performance and efficiency. They assist in reducing engine warm-up time, maintaining the ideal running temperature, and supporting heater output. When choosing a thermostat, features such as digital display, output indicator, remote probe, accurate measurement, low differential ability, and mode change capability should be considered. By selecting the right thermostat, farmers can ensure their agricultural tractors operate reliably and efficiently, contributing to successful farming operations.

0 notes

Text

Alfa romeo thermostat housing Uses?

The Alfa Romeo thermostat housing is a crucial component of the vehicle's cooling system. It is responsible for housing the thermostat, which regulates the flow of coolant through the engine to maintain optimal operating temperatures. The thermostat housing plays a vital role in ensuring the efficient operation of the engine and preventing overheating or damage.

When it comes to replacing the thermostat housing in an Alfa Romeo, there are several options available on the market. Various manufacturers offer replacement thermostats and components designed to meet the OEM specifications and provide a reliable solution for Alfa Romeo owners. Some notable brands in the market include iD Select, Gates, MotoRad, Beck Arnley, Mopar, and DIY Solutions.

iD Select offers engine coolant thermostats and failsafe engine coolant thermostats as direct OEM replacements. These products are built to OEM specifications and ensure the same fit, form, and function as the original factory part. They are designed to deliver excellent quality, reliability, and value.

Gates provides engine coolant OE type thermostats and premium thermostats. Their thermostats are developed with meticulous attention to detail and manufactured from high-quality materials. Gates emphasizes the importance of quality control and factory calibration to ensure the accuracy of opening and closing, regardless of pressure changes. Their premium thermostats are known for their great design, function, and durability.

MotoRad offers engine coolant thermostats that are designed to provide precise pressure control and ensure the proper fit. These thermostats undergo state-of-the-art equipment, strict quality control, and functional testing to ensure high-quality performance and reliability.

Beck Arnley has been a trusted provider of OE quality parts for vehicles for over a hundred years. They offer engine coolant thermostats that meet OE quality standards. Their products are made from top-quality materials and are known for their reliability and durability.

Mopar, a renowned brand in the automotive industry, provides engine coolant thermostats and cooling thermostat kits. Their thermostats are carefully crafted from premium materials and offer excellent corrosion and wear resistance. Mopar products are specifically designed to maintain engine efficiency and performance.

DIY Solutions offers an engine coolant thermostat kit that is designed to help restore vehicles to their former glory. The kit provides a quick replacement solution for Alfa Romeo owners looking to bring their vehicles back to optimal condition. The focus is on quality and ensuring customer satisfaction.

It is important to select the appropriate thermostat housing for your specific Alfa Romeo model and engine variant. Compatibility and fitment should be confirmed to ensure proper installation and optimal performance. Consulting with a qualified mechanic or referring to the vehicle's service manual can help in identifying the correct thermostat housing for your Alfa Romeo.

In addition to the information obtained from the internet, it is worth noting that the thermostat housing mentioned in another online discussion forum specifically relates to the Alfa Romeo 164 model. The discussion indicates that the housing provided in the forum is not suitable for a 164 engine in a 164 chassis. Therefore, it is essential to ensure the compatibility of the thermostat housing with the specific Alfa Romeo model and engine configuration.

In summary, the Alfa Romeo thermostat housing is a critical component of the cooling system. Several reputable manufacturers offer replacement thermostats and components designed to meet OEM specifications. It is crucial to choose a compatible housing for your Alfa Romeo model and engine variant to ensure proper fitment and optimal performance. Consulting with a professional or referring to the vehicle's service manual can help in selecting the appropriate thermostat housing for your specific Alfa Romeo model.

0 notes

Text

What Is A Thermostat Cooling System Used For?

The primary function of a thermostat is to help the engine warm up quickly and maintain the engine temperature within a specified range. The thermostat accomplishes this by controlling the flow of coolant through the engine and the radiator. When the engine is cold, the thermostat remains closed, blocking the flow of coolant to the radiator. This allows the engine to heat up more rapidly, reaching its optimal operating temperature.

The thermostat contains a small cylinder filled with a wax-like substance that begins to melt at a predetermined temperature, typically around 180°F (82°C). As the engine temperature rises, the wax expands, pushing a rod connected to the valve. Once the wax melts completely, the valve opens, allowing coolant to flow through the radiator. This process helps maintain the engine temperature within the desired range, typically between 194°F (90°C) and 221°F (105°C).

The radiator, which is an essential part of the cooling system, is responsible for dissipating heat from the coolant. It consists of flat aluminum tubes surrounded by fins. As the coolant flows through these tubes, air passing through the radiator cools it down, reducing its temperature. To enhance cooling, one or two electric fans are attached to the back of the radiator. These fans activate when additional airflow is needed, such as during slow or idle conditions, to prevent the engine from overheating.

A water pump plays a crucial role in the cooling system by circulating the coolant. It pulls the coolant out of the radiator and pushes it back into the engine, ensuring a continuous flow to maintain proper cooling.

A properly functioning thermostat is essential for the cooling system’s effectiveness. If the thermostat becomes faulty, it can cause various symptoms. A thermostat stuck open may result in the engine running below the optimal temperature, leading to poor fuel efficiency, lack of heat from the heating system, and potential triggering of the Check Engine light. On the other hand, a thermostat stuck closed can cause the engine to overheat, leading to potential damage.

Replacing a thermostat is necessary if it malfunctions or if the thermostat housing is leaking coolant. Symptoms of a failing thermostat may include high temperature readings, an overheating engine, coolant leaks, and erratic temperature changes .

In summary, a thermostat cooling system is a crucial component of an engine’s cooling system that regulates the engine’s temperature. By controlling the flow of coolant, the thermostat helps the engine warm up quickly and maintains it within the desired temperature range. This contributes to optimal engine performance, reduces wear and deposits, and minimizes emissions. For more details visit us @ TRE Products UK LTD

0 notes

Text

What Are The Uses Of An Oil Cooler Thermostat?

Function and Benefits of an Oil Cooler Thermostat: The primary function of an oil cooler thermostat is to control the flow of engine oil to an oil cooler based on the operating temperature of the oil. It helps maintain the oil within a specific temperature range, optimizing its viscosity and ensuring proper lubrication and cooling of the engine components. Here are some key benefits of an oil cooler thermostat:

a. Heat Dissipation: An oil cooler is designed to dissipate excess heat from the engine oil, preventing it from becoming too hot and losing its lubricating properties. The thermostat ensures that the oil is sent to the cooler when it reaches a certain temperature threshold, allowing it to be cooled down before returning to the engine.

b. Engine Protection: By regulating the oil temperature, an oil cooler thermostat helps protect the engine from overheating. It ensures that the oil remains within the optimal temperature range, preventing excessive wear and tear on engine components, such as bearings, pistons, and cylinders.

c. Enhanced Performance: Maintaining the proper oil temperature is crucial for optimal engine performance. An oil cooler thermostat helps prevent oil from becoming too thin or too viscous, ensuring consistent lubrication and optimal engine efficiency.

d. Extended Oil Life: Excessive heat can degrade the quality and longevity of engine oil. By cooling the oil and keeping it within the recommended temperature range, an oil cooler thermostat helps extend the life of the oil, reducing the frequency of oil changes and associated maintenance costs.

Working Principles of an Oil Cooler Thermostat: An oil cooler thermostat typically consists of a valve mechanism, a temperature-sensitive element, and a bypass circuit. The temperature-sensitive element, usually a wax-filled or bimetallic sensor, is designed to respond to changes in oil temperature. Here’s a breakdown of how the oil cooler thermostat works:

a. Closed Position: When the engine is cold, the thermostat remains in a closed position. In this state, the valve blocks the flow of oil to the oil cooler. The oil circulates within the engine, allowing it to warm up quickly.

b. Opening Phase: As the engine oil reaches the predetermined temperature threshold, the temperature-sensitive element in the thermostat responds to the heat. This causes the element to expand or contract, initiating the opening of the valve.

c. Open Position: Once the valve opens, the oil is directed towards the oil cooler. The oil cooler dissipates excess heat, cooling the oil before it returns to the engine. This process helps maintain the oil within the desired temperature range.

d. Closing Phase: When the oil temperature decreases below the threshold, the temperature-sensitive element contracts or expands, causing the valve to close. This prevents the oil from flowing through the oil cooler and allows it to warm up again within the engine.

Potential Issues and Maintenance: Like any automotive component, an oil cooler thermostat can experience issues over time. Here are some common problems that may arise:

a. Stuck Closed: If the thermostat gets stuck in the closed position, it will prevent oil from reaching the oil cooler. This can result in increased oil temperatures, reduced lubrication efficiency, and potential engine damage.

b. Stuck Open: Conversely, if the thermostat gets stuck in the open position, it will constantly direct oil to the oil cooler, even when the oil is not at an optimal temperature. This can lead to overcooling, longer warm-up times, and decreased fuel efficiency.

c. Leaks or Blockages: The valve mechanism or the coolant passages in the thermostat can develop leaks or blockages due to wear or debris accumulation. This can disrupt the proper functioning of the thermostat and result in inefficient oil cooling.

d. Regular Maintenance: To ensure the proper functioning of the oil cooler thermostat, it is important to follow the vehicle manufacturer’s recommended maintenance schedule. This typically includes regular inspections, cleaning, and replacement of the thermostat if necessary.

In conclusion, an oil cooler thermostat plays a vital role in maintaining the optimal operating temperature of engine oil. By regulating the flow of oil to an oil cooler, it helps dissipate excess heat, protects the engine from overheating, and ensures efficient lubrication. Understanding the function, benefits, and potential issues of an oil cooler thermostat can assist vehicle owners and mechanics in maintaining the cooling system’s integrity and optimizing engine performance. To find the best Oil cooler thermostat Visit us @ TRE Products UK LTD

0 notes

Text

Where To Choose The Car Engine Cooling Products?

Engine cooling is a critical aspect of maintaining the optimal performance and longevity of a car's engine. The engine produces a significant amount of heat during operation, and a cooling system is necessary to prevent overheating and potential damage. In addition to regular maintenance, there are various Cars engine cooling products available in the market that can help enhance cooling efficiency and protect the engine. This article will provide an overview of these products, including coolant/antifreeze, radiator additives, and cooling system cleaners.

Coolant/Antifreeze: Coolant, also known as antifreeze, is a liquid substance that circulates through the engine cooling system to regulate temperature and prevent freezing or boiling. It is typically a mixture of water and ethylene glycol or propylene glycol, along with additives to enhance its performance. Here are some key points about coolant/antifreeze:

Types of coolant: There are different types of coolant available, including conventional green coolant, extended-life coolant (usually orange or red), and hybrid coolants. It is essential to use the coolant recommended by the vehicle manufacturer to ensure compatibility and optimal performance.

Coolant ratio: Coolant should be mixed with water before use, following the manufacturer's recommendations for the correct ratio. This ensures the right balance of freeze and boil protection, as well as adequate corrosion inhibition.

Coolant maintenance: Regular coolant maintenance is crucial to maintain its effectiveness. Over time, coolant can degrade and lose its protective properties. It is recommended to flush and replace coolant according to the vehicle manufacturer's guidelines or at specified intervals.

Radiator Additives: Radiator additives are products designed to enhance the performance and efficiency of the cooling system. They are typically added to the coolant or directly to the radiator. Here are some common types of radiator additives:

Radiator stop leak: These additives are formulated to seal small leaks in the radiator or cooling system. They contain particles that can flow to the leak point and form a seal, reducing or stopping coolant loss. However, it is important to note that radiator stop leaks are temporary solutions, and proper repair should be conducted for significant leaks.

Water wetter: Water wetter additives are designed to improve heat transfer within the cooling system. They help reduce coolant temperature by improving the wetting and spreading properties of the coolant. Water wetter additives can be beneficial in high-performance or heavy-duty applications, but their effectiveness may vary depending on the specific vehicle and cooling system design.

Radiator cleaner: Radiator cleaning additives are used to remove deposits, rust, and scale that can accumulate in the cooling system over time. They help improve heat transfer and restore cooling system efficiency. These additives are typically added to the coolant and circulated through the system before being flushed out.

Cooling System Cleaners: Cooling system cleaners are products specifically formulated to clean and remove contaminants from the cooling system. They are typically used during coolant flushes or as part of cooling system maintenance. Here are some key points about cooling system cleaners:

Contaminant removal: Cooling system cleaners are designed to dissolve and remove deposits, rust, scale, and other contaminants that can accumulate in the radiator, engine block, and other components of the cooling system. This improves heat transfer and prevents clogging or blockages.

Flush and drain: Cooling system cleaners are usually added to the coolant, and the engine is run for a specified period. Afterward, the coolant is drained along with the dissolved contaminants. It is important to follow the product instructions carefully to ensure effective cleaning and complete removal of the cleaner.

Compatibility: It is essential to choose a cooling system cleaner that is compatible with the type of coolant used in the vehicle. Some cleaners are specifically formulated for certain coolant types, while others are designed to work with a wide range of coolants. Using an incompatible cleaner can lead to chemical reactions or damage to cooling system components.

In conclusion, Cars engine cooling products play a crucial role in maintaining the optimal performance and longevity of a car's engine. Coolant/antifreeze is a primary component of the cooling system, regulating temperature and preventing freezing or boiling. Radiator additives can enhance cooling system performance and address specific concerns like leaks or heat transfer. Cooling system cleaners are used to remove deposits and contaminants, improving overall system efficiency. It is important to follow the manufacturer's recommendations and guidelines when using these products to ensure compatibility, proper usage, and optimal results. Regular maintenance, including coolant flushes and replacements, is also necessary to keep the cooling system in top condition.

0 notes

Text

Mini thermostat housing | TRE Products UK LTD

A mini thermostat housing is a component used in the automotive industry to house the thermostat in a compact manner. The thermostat is a crucial part of a vehicle's cooling system, regulating the flow of coolant to maintain optimal engine temperature. The mini thermostat housing is designed to accommodate a smaller-sized thermostat, typically used in compact or lightweight vehicles.

The primary function of the thermostat housing is to provide a secure and leak-proof enclosure for the thermostat. It is usually made of metal or plastic, chosen for its durability, heat resistance, and cost-effectiveness. The housing is designed to withstand the high temperatures and pressures experienced within the engine compartment. Additionally, it must be compatible with the coolant and other fluids present in the cooling system.

The mini thermostat housing is engineered to be compact in size to fit within the limited space constraints of smaller vehicles. This allows for efficient packaging and integration into the engine assembly. The compact design ensures that the housing does not interfere with other engine components or impede the overall performance of the vehicle.

The mini thermostat housing consists of several key components. The main body of the housing encloses the thermostat and serves as a connection point for the coolant hoses. It has inlet and outlet ports through which the coolant flows in and out of the housing. These ports are strategically positioned to facilitate the proper circulation of coolant within the engine.

The housing also features a gasket or seal to ensure a tight and secure connection between the housing and the engine block. This prevents coolant leaks and maintains the system's integrity. The gasket is typically made of rubber or silicone, chosen for its flexibility and ability to withstand temperature variations.

Inside the mini thermostat housing, the thermostat is located. The thermostat is a heat-sensitive valve that opens and closes based on the engine's temperature. It is responsible for regulating the flow of coolant to maintain the engine within its optimal temperature range. When the engine is cold, the thermostat remains closed, preventing coolant from circulating through the radiator. As the engine warms up, the thermostat gradually opens, allowing coolant to flow and dissipate heat. This process continues to maintain a consistent operating temperature.

The mini thermostat housing is designed to facilitate easy installation and replacement of the thermostat. It often includes mounting points or brackets to secure it to the engine block. These mounting provisions ensure that the housing remains firmly in place, even under the vibrations and stresses generated by the engine's operation.

In addition to its primary function of housing the thermostat, the mini thermostat housing may incorporate other features to enhance its performance and functionality. For example, some housings have integrated coolant temperature sensors. These sensors provide feedback to the engine control unit (ECU) regarding the engine's temperature, allowing the ECU to adjust fuel injection and ignition timing for optimal performance and efficiency.

Furthermore, the mini thermostat housing may include bypass valves or passages. These features enable the coolant to bypass the thermostat under specific conditions, such as during engine warm-up. Bypassing the thermostat allows the engine to reach its operating temperature more quickly, reducing emissions and improving fuel efficiency.

Manufacturers of mini thermostat housings conduct rigorous testing to ensure their performance and reliability. These tests include assessments of the housing's durability, resistance to high temperatures and pressures, and compatibility with various coolants and fluids. The housing must meet stringent quality standards to ensure it can withstand the harsh conditions of the engine compartment and operate effectively over the vehicle's lifespan.

In conclusion, a mini thermostat housing is a compact and essential component in a vehicle's cooling system. It provides a secure enclosure for the thermostat, allowing it to regulate the flow of coolant and maintain the engine at its optimal temperature. The mini thermostat housing is designed to be small in size to accommodate compact vehicles while still providing the necessary functionality and durability. It incorporates features such as coolant ports, gaskets, and mounting provisions to facilitate proper coolant circulation.

1 note

·

View note