Who: Alexia van der Dys, Chloe Tondera, DeBorah Thomas, Luis Coyote

Don't wanna be here? Send us removal request.

Text

Project Blog Post #8

For the work period of March 23 - April 13, Team 17 tested and demonstrated the functions of the Active Body Hydration Sensor. For the initial demonstration, the device had been disassembled as the shell was too small for the internal components of the device. Another round of testing was completed once the internal components were united with the latest model of the device shell, but the results proved to be inconclusive. The copper electrodes chosen for our device were the wrong material for the device, and we have concluded that steel electrodes would be a better material for the needs of the Active Body Hydration Sensor. The steel electrodes are the better option moving forward as the copper corroded easier than expected with the test subjects' sweat.

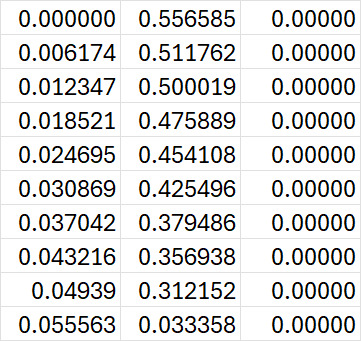

Due to the corrosion of the electrodes, Team 17 has determined that the Active Body Hydration is unsuccessful. During the initial testing for the demo and the most recent testing with the fully assembled device, the results displayed by the software returned inconclusive. The data points gathered during the later test runs can be seen numerically in Figure 1 and graphically in Figure 2. While the device does read and return hydration data, further adjustments must be made for it to be within the success threshold that Capstoners has established. The data gathered by the Active Body Hydration Sensor are not near the ±5% error when compared to the data provided by the Fit Track Dara 1. Team 17 has also concluded that it would be good to revise the code for the software and ensure that the proper data points are output.

For the remaining time before the final resting report, Captsonters has decided to continue the validation process to present valid data for the final report. Team 17 plans to complete all necessary validations during the week of April 14 and adjust the device as necessary.

Capstoners has also prepared a small sneak peek for their technical poster that will be presented on either April 24 or April 29.

The Results and Discussion section and the Conclusions section have been left blank for now as Capstoners plans to continue testing and adjusting the device prototype and software.

0 notes

Text

Project Blog Post #7

For the work period of March 9 - March 23, Team 17 has continued to make progress towards the assembly of the Active Body Hydration Sensor. All components of the device have been gathered save for the PCB component, which will be obtained and assembled before the testing period on March 24, 2024 at 8:20 AM. The design has also been finalized for the prototype testing, and has been updated further since the final progress report featuring an additional bottom layer to the main shell to aid with skin contact. The device is currently undergoing a series of troubleshooting to ensure its functionality, and more tests will be conducted upon the accusation of the PCB.

For the work period of March 24 - April 6, Team 17 plans on completing their demonstration to Dr. Chang and Dr. Agrawal, improving the final design of the device, and creating a user's manual for the completed prototype. The demonstration will take place on March 24, 2024 at the University of Houston Recreation Center and will last for a total of 30 minutes. However, more testing needs to be done in order to gather accurate information on the device. Therefore, Team 17 plans on doing additional tests after the demonstration period is over to gather several data sets and determine the team's satisfaction with the performance of the device. The tests may prove that the device needs an alternate design, so Team 17 is also keeping in mind the possibility for updates to the device's shell to improve functionality. Changes to the shell may still be made after the demonstration phase, and more testing will be done to improve the device's performance for future tests. Lastly, Team 17 has begun planning for their final deliverable, the instruction manual, and plans to complete a draft for their presentations.

For the next two weeks, Team 17 estimates that there could be obstacles during the demonstration and testing phases. While it is planned to have the test subject be well rested and restored for the testing phase to have a controlled experiment, Team 17 understands that life does not always go as planned and some variables can be out of control. While it would be ideal to have a fully recovered test subject for the demonstration, Team 17 understands that it might not be the case, and hopes for a data set that can still accurately estimate the subject's hydration. Team 17 will still do their best to ensure that the test subject can perform their best, and check in occasionally for 48 hours leading up to the testing time. Lastly, while several rounds of troubleshooting have already taken place, Team 17 understands that technology can perform differently when put under different environments. There is a chance that the data might not read properly every time during the demonstration and testing phases, and Team 17 must adjust the device between tests to get the best performance for the Active Body Hydration Sensor. Possible solutions for data transfer and readings would be to adjust the data storage methods and software for the device.

0 notes

Text

Project Blog Post #6

For the work period of February 4 - February 17, the Capstoners have chosen a final 3D printing pattern, ordered all internal device components, and finalized the code for the Active Body Hydration Sensor. Previously, the printing pattern selected for the outer shell of the Active Body Hydration sensor was too rough and had the possibility of irritating the skin when worn, but the new printing pattern is smoother and more stable in comparison. The new pattern is also less porous, allowing for a longer predicted lifespan as it does a better job at resisting moisture.

For the work period of February 17 - March 9, Team 17 plans on assembling the shell with all internal components. This also includes finalizing the connections between the Active Body Hydration Sensor's hardware and software, and troubleshooting the device once the connections are secure. Adjustments may need to be made to the internal components or code to ensure everything runs smoothly during testing. Once Team 17 is sure the device is on its way to running smoothly, they will move onto the testing phase of the device. Once the testing phase begins, Capstoners will continuously analyze the data collected by the device to ensure it is operating as intended. For the next two weeks, Team 17 estimates that the trouble shooting and testing and the security and stability of the device will be the most difficult challenges. For the testing and troubleshooting phase, Capstoners hopes that the device will function as intended and need little debugging. However, until the device has been assembled and connected to the software, it is difficult to predict just how much debugging and editing must be done to the code. As for the security and stability of the device, Team 17 hopes that their calculations for the thickness and seals of the device shell work with the chosen printing pattern to keep moisture away from the internal components. If the shell fails and water leaks in through the seams, Team 17 will get a better seal for the device ends, and likely some form of adhesive for any small cracks that might be on the shell walls. Finally, since the Active Body Hydration Sensor is meant to be used during a workout, the device will be moving around a significant amount. Team 17 hopes that this will not cause the internal components to move out of place and become damaged. Adhesive is also a solution to this issue as it would keep the components from moving once they are put in place.

0 notes

Text

Project Blog Post #5

For the work period of December 11 - February 3, Team 17, the Capstoners, has created a prototype shell for their device and gathered the screws necessary to keep the shell lid in place. However, the shell of the device does not yet meet the standards of the team. Currently, the device shell's 3D print pattern has resulted in a shell that is too rough and could irritate the skin when worn. Team 17 is now redesigning the filament pattern, infill, and overall print thickness to both speed up the printing process and make for a smoother device shell.

For the work period of February 4 - February 17, Capstoners plans to have a finalized version of the device shell and a full assembly of the shell with the internal components (motherboard, battery holder, battery, memory card, sensors). Once the full device prototype is complete, Team 17 will begin the testing phase of the device. For the future of this project, Team 17 estimates there will be some difficulty with ensuring that the software and motherboard can connect properly. Another obstacle could be with the software failing to display all data points, and that the device itself reads each data point for the one-minute intervals without skipping over any intervals. Another obstacle could be that the device fails to save the data points to the memory card. Should these issues arise, Team 17 plans to troubleshoot the device to be certain of where the issue lies (in the code or hardware), and address it so the device functions as intended. If any of these issues are too advanced for the collective experience of the team, they will seek the advice of more experienced engineers.

0 notes

Text

For this work period of November 11, 2023 to November 25, 2023, Team 17 has continued to refine the design of the Wearable Body Hydration Sensor. We have adjusted our material from a low carbon steel to a polymer-based material. Further material analysis must be conducted before a material is finalized, but PETG (polyethylene therephthalate glycol) seems to be our most promising choice. The overall design of our device has also undergone a few adjustments, including a lid that allows for access to the internal components of the device, making any necessary repairs or battery replacements easy. Lastly, we have made the decision that our device should be worn around the arm instead of around the chest as our sensors do not rely on a specific location of the body.

The final design of our device features a slot for our device to power the internal components. Lastly, we have adjusted our device to include the lid, as previously mentioned, so that the internal components can be accessed for necessary repairs and battery replacements. The device shell also includes two loops on the top and bottom edges shown in figures 2 and 3 where an elastic arm strap will slide through to secure the device in place.

At this point in time, we have determined that a 3D print of our device shell using PETG filament is a very likely candidate for the shell material, though final calculations must still be confirmed. With current calculations, a 3 mm wall thickness is ideal to ensure that the device will still be water resistant despite the porous nature of 3D printed structures. With the lid covering, we will also need to implement a rubber component similar to an o-ring around the edge of the lid so that no sweat can enter the device and ruin the internal hardware. Once the prototype is complete, we can conduct our IP rating tests to determine how water-resistant our device is and if it can withstand a full workout without sweat getting to the internal components.

In preparation for Capstone II, the Capstoners have found a facility to 3D print the device shell. We are also continuing to optimize our current code to cater to the needs of our specific device and its sensors. During winter break, we plan on gathering all components of our prototype and creating a functioning prototype that can be tested next semester during Capstone II.

0 notes

Text

For the work period of October 28 - November 11, we have begun material analysis for the shell of our device, created a basic code for the device and further advanced in our specifications table. The code still requires more adjustments to fit in with our specific device and only output hydration data. More adjustments will also be made once we have obtained the sensor and the memory chip. Team 17 has also created a preliminary CAD model.

As we have not yet completed our specifications table, team 17 plans to complete the specifications table and make further advancements to the device’s code. The new additions to the specifications table may also demand adjustments to the CAD model. By November 25, Team 17 plans to have a completed specifications table and a finalized CAD drawing of their device. We also hope to have completed a minimized toa chip.

Over the next two weeks, we predict that the largest obstacles will be putting the components of our research, code, specifications, and design together and ensure that all of our parameters are being met, and that the device functions well enough to be approved by Team 17. We plan on addressing any issues with trial and error — seeing what works with our device and what still needs improvement.

Photos of the current code progress are attached on this post.

0 notes

Text

Project Blog Post #2

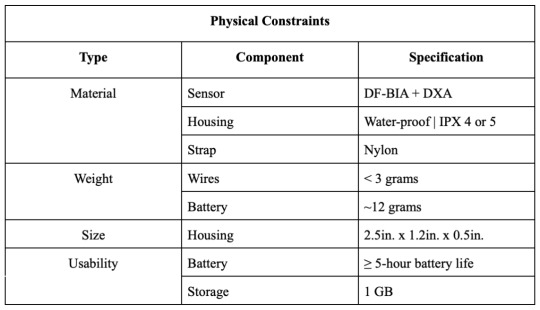

Our device consists of various physical constraints that can be challenging as the device comes together. One of these is weight, the weight of the device is essential since it allows for comfortable portability, including movement when in use. The weight is desired to be within 52 grams, as previously stated, the movement while in use can’t be great in such a manner that it interferes with data point collection. Consequently, the material chosen to hold the device needs to be comfortable to wear for an extended amount of time as well as having good structure to ensure a good hold around the body. Lastly, aside from the weight, size matters just as much, once again to offer portability to the user and not become a physical obstacle when in use.

The Technical Analysis Plan is initiated with research. The first round of research is focused on identifying any gaps in knowledge, and/or finding a starting ground for the basic 4 components: the sensor, battery, software/data storage, and housing unit. As well as market research to further find a niche that needs to be filled and narrow the project scope. With this knowledge we will use the near peer devices (such as the scale, the Nix sensor, Whoop, and Garmin chest strap) to focus our research and benchmark our conceptual design. Using the gathered research the next step is identifying ways our combined knowledge base applies to each parameter specifically. That experience will be used to eliminate any non-viable options and hone in on the options that progress towards the solution of the problem.

With the research portion of our Technical Analysis Plan complete next is the pre-fabrication execution portion. In this step is where most of the mathematical and engineering analysis will occur as the previous research is validated. Key parameters that will allow us to move forward to a digital prototype are the size dimensions and total weight with all the research components, the optimal shape, orientation of the sensors, and the proper materials to prevent damage and inaccuracy caused by sweat. Only then can we start drafting prototypes, looking for new challenges and optimizing the design.The corresponding milestone of this will be the completion of CAD drawing prototypes of the physical components, completed code, and a diagram of the electrical component layout.

Our potential project consists of 4 main parts, and so while analyzing the potential challenges we will be categorizing them accordingly.

Sensor

For the sensor, a few of our concerns circulate around the accuracy of the sensor. One concern is the effect sweat will have on the data as the device will be worn during exercise. So finding a way in the design or through external factors to limit, if not eliminate the contact that the device has with sweat on the outside if the body is crucial. Another challenge would be determining whether or not one sensor would be enough to obtain enough data points.

Battery

We want our design to be as lightweight as possible as it will increase the comfort for the wearer, so finding a battery that has a long life and light weight is important, also considering if we want to have a rechargeable one. Another consideration with the battery that is important is the corrosion resistance, what happens when the battery comes into contact with sweat, will damage the other components collecting data if so, how will we mitigate this. In conjunction with preventative measures, how we will prevent the battery from overheating and also damaging the components and causing discomfort to the wearer is of concern as well.

Software and Data Storage

Our biggest concern with software is securing the proper code, and also fine-tuning it with the wearer’s current body stats in order to isolate the water loss data. As for the hardware associated with the data collection, it all needs to be sweat-resistant and fit into the size constraints that we have specified.

The only challenges we foresee in the housing unit will be sealing it so no sweat gets into the components while it also holds the sensor securely in place and in contact with the skin.

0 notes

Text

Project Blog Post #1

With each year, the fitness industry becomes more advanced. Athletes from any and all experience levels continue to strive to be the best within their specialty, but one aspect of training has always been a guessing game: recovery. Recovery is arguably the most important part of the training process and can include fueling, nutrition, hydration, and eliminating any physical, emotional, and spiritual stressors that the athlete has in his or her life. This Capstone project will focus on the hydration portion of recovery, as many athletes will have significant water loss during the bulk of their training sessions, resulting in poor performance. With our device, athletes from beginner to elite can track their water retention during the training sessions so they know when to replenish their fluids and later predict when to replenish their fluids on the competition day.

Currently, the only measurement tools available to athletes who wish to know more about their hydration levels are body composition scales or going to a lab setting. The issue with these methods is that the user must stop all activity if they want to get a measurement, or measure their hydration only before and after the workout. Attending a lab session is also expensive so it is not an option available to a wide audience.

Team 17 will provide athletes with a wearable device that can track their hydration levels at predetermined intervals throughout the duration of a workout and store that data until it is uploaded to software that provides a graphical representation of the body’s water retention. The device should be small enough to wear comfortably during a workout and not hinder movement and have an adjustable elastic band that stays in place. The device also needs a minimum of a four-hour battery life to stay on for the entire duration of the user’s physical exertion. The device should have at least one gigabyte of storage to contain the data points gathered within the designated intervals. We have determined that a measuring interval of one minute would provide an accurate insight as to how the water levels change over time. We predict our device will have a 0%-5% error when compared to the results of current devices like body composition scales or pods.

Providing the necessary equipment for measurement such as the sensors necessary to measure the body’s water loss will not be as much of an obstacle as providing the materials that make up the shell and band of the device. As the test subject conducts their training session, their body heat will go up as they utilize the energy stored in their body. As humans are endothermic organisms — humans are able to generate heat — we maintain homeostasis within the body. In the case of exercise, humans sweat in order to cool the body down externally as the internal body temperature rises. As sweating is an involuntary and inevitable bodily function, our main obstacle will be making sure that, with whatever material we decide to outfit the device in, it is somewhat comfortable and user-friendly and resists any bodily fluids that it may come into contact with during the training session. Another obstacle that we will experience closer to the execution of this project is the possibility of certain materials being back-ordered and taking a while to ship.

0 notes