Text

WON'T YOU FLYYY HIIIGH, FREE BIRD, YEAAAH!

13 notes

·

View notes

Text

im stacking extension cords on each other like theyre tinker toys. constructing a tower of babel in the name of the god of electricity. there'll be at least 100 outlets when ive hooked these boys up nice and good. ill never run out again

92K notes

·

View notes

Note

explain to me how gears are machined!

wohaohowhao. gears are impossibly difficult to fabricate. way, way beyond what people might expect looking at them. “oh, it is just a shape, it is simple” - imbeciles. morons

this will be VERY LONG and i am doing most of you idiots a favor by putting this here:

i’m not going to go over what a gear is or what it does, but i will be making some assumptions:

pinions are not gears

gears are made out of metal (steel)

hobs don’t exist (they’re cheating and rob you of a nuanced understanding of what goes into a proper gear)

if you tried to machine some gears “freehand” you would never actually end up creating something that can truthfully called a gear -- the best you could do is a spoked wheel with maybe 5-7% efficiency

gears are complicated to machine for 3 primary reasons

geometrical limits -- gears are circles (squat cylinders if we’re being precise) with a finite number of equally-spaced teeth at their peripheries. in order for two gears to mate (mesh, “come together”, etc) they must have exactly the same tooth geometry (e.g. exactly the same size) and exactly the same spacing between the teeth

it’s not apparent at first, but this is a pretty limiting set of requirements. remember, two identical meshed gears are not very useful; a 1:1 gear ratio just sort of transfers power from over here to over there. you usually want a big gear driving a small gear, or vice versa. since your gear tooth size and spacing is fixed, you have a greatly reduced set of gear diameters you can work with, since in order to fit one extra tooth on a gear, you have to jump up a corresponding diameter increment, and can’t use any diameters in-between. you are also restricted by a tooth/diameter minimum, i.e., you can’t have a 1 or 2 tooth gear, which is something that a computer scientists might not realize at first glance

so, this isn’t too bad altogether, you just have to do your homework before cutting some gears. don’t worry, it gets worse

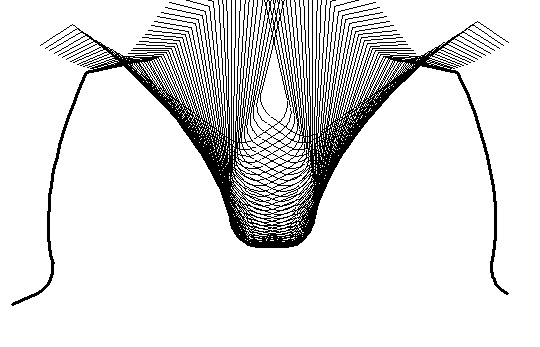

tooth geometry - you might think that there are all sorts of different tooth shapes you can employ to get all sorts of results, but you’d be wrong (idiot), there is only one tooth shape:

the involute of a circle, two pictured above. don’t worry about what that means. yes i know what this shape resembles.

if you don’t cut your teeth to exactly this shape (which, btw, changes according to the diameter of the gear they’re cut into) you will not evenly transmit power between gears, which is to say your gears won’t spin at a steady RPM. this is because your fucked up wrongteeth will be slamming into each other & knocking each other into free space that should be filled by goodteeth. look:

the blue dot and red dot (respectively) in the above images represent the point of contact (thus the point of power transmission) between the two gears at any given point in time. remember, gears are metal, metal is hard, the total area of surface contact between two pieces of metal is usually hilarious small (because metal does not “give” or “soften” to normalize a traveling path of contact, and due to all of this, the point of contact between two meshed gear teeth has to travel evenly and without interruption -- just as the blue and red dots above. why? i need to digress for a second.

gear teeth can’t just whack into each other. this isn’t carpentry. gears are used to transmit power up to the order thousands of tons per revolution. they’re made out of extremely hard martensitic steel that doesn’t handle large impluse shocks very well. if you slam martensite around hard enough, it will shatter (not “bend”, or more precisely deform elastically/plastically) and if slammed around under load, it will fucking explode. again, consider the colossal amount of power being transmitted, divided by the minimal area of surface contact between two gear teeth, and you get pressures sometimes several times what exists in the core of the earth. when the tooth that is holding this pressure suddenly shatters, all that energy is released into bits of broken gear tooth that’ll cut through you like a knife through butter, that will cut through a cast iron chassis like a knife through butter, not even noticing it

but not only that -- even with indestructible handwavium gears your teeth can’t slam into each other because that scenario requires there to be uneven empty space between gear teeth, allowing unmitigated travel in, possibly, the wrong fricken direction. this kills your efficiency incredibly quickly: sudden changes in a gear’s rotational speed oppose that gear’s nominal momentum, i.e., gears that don’t spin at a constant RPM require energy to slow down/speed up as they deviate. that energy comes from your input power, which should be transferred to the driven gear, but instead is powering zero-sum deviations in spin rate. additionally, incidences of tooth contact following a period of no contact between two gears (e.g. tooth contact beginning at any point in time other than the last moment the previous two gear teeth were in contact) (e.g. two teeth slamming into each other) see a massive reduction in power transfer as most of that energy goes into friction between the teeth instead of transmitting power mechanically -- instead of the two teeth coming together steadily, you have the driving gear tooth speed up during the period of no contact only to slam into the driven gear tooth, spalling off metal from the tooth surface and heating it from the friction (sparks). these two things will drop your efficiency to less than 10%, usually on the lower side of that, but that doesn’t matter, because if your gear teeth are slamming together they’re about to explode anyway

but ok, first we solved the issue of “how do i even design working gears considering the geometrical limits”, and now we’ve solved the issue of “what extremely weird and specific shape do i make the gear teeth so my gear train does anything other than explode spectacularly/immediately” and now we can move on to

rotational compounding error, machining precision, offset -- this is the real killer, what makes machining gears truly difficult.

let’s digress again

gears are made out of metal, and people who make things out of metal are machinists, and do so using machines. when you’re machining metal, and you’re in america, you operate using two units: the mil (1/1000th of an inch which is about the smallest discrete movement a professional [piano player, diemaker, anything that requires precise small hand movements] can make with their hands consciously. the tip of a needle is around 100 mils) and the tenth (one tenth of one mil, or 1/10,000th of an inch). these are inconceivably & imperceptibly small units.

the first step to machining a gear involves cutting a perfect circle. you start with barstock, that is, a rod of metal whose diameter is a bit above what the final gear diameter should be. stock that comes out of the steel mill may look round, but it’s not, remember, we’re working in thousands of an inch here, just appearing round won’t cut it.

we stick the stock in the lathe and turn it concentric (into a perfect circle) and cut off a “slice” with a thickness as close to the design as possible without going under. we now have a squat cylinder whose edges are perfectly circular but whose faces aren’t flat enough nor square enough with the round edges. easy -- we stick it face down onto the surface grinder, grind a side flat, flip it over, grind the other side flat and then until its the right thickness. now, we have a perfectly circular, perfectly square cylinder of the right dimensions. now to cut the teeth!

here is where things get tricky and you need special hardware. you cut involute teeth using a special mill tool which you move the workpiece through axially at it’s periphery as to machine the void between two teeth -- on your second pass, you will have machined two voids leaving a perfect tooth between them. but, once you’ve made your first pass, you have to rotate the workpiece, and holy shit. you cannot be off by even 1/100th of a degree. these are perhaps the most sensitive and crucial cuts you’ll be doing, because your error adds up and if it’s too high, you’ll go to cut that last tooth and realize you still have extra surface space, or go to cut the last tooth and realize you don’t have enough space. either of these will result in a totally useless gear that won’t complete a single rotation before exploding. the solution is to mount the gear in a dividing head which allows for extremely precise, but more importantly, extremely repeatable rotations in the workpiece

machining gears requires precision on the level of mils & tenths described above, and this is due to how error compounds in a unidirectionally rotating system -- gears. normal gears rotate in one direction, clockwise or counterclockwise, continuously, without reversing. during one rotation, any error, any deviation from the design model incurred during machining translates to some positive or negative “extra” rotation. that is to say, as the first rotation of the gear occurs there is some “extra” force that causes the gear to “want” to rotate a little more or a little less than one full rotation. but here’s the kicker:

upon the beginning of the second rotation, that erroneous “extra” force remains. upon the completion of the second rotation, that “extra” force has now doubled. the error forces accrue, constructively because the gear is always spinning in the same direction, never reversing, and the error (geometric deviations from design model) is unchanging. gear trains that explode after maybe a dozen or so rotations aren’t very useful,

so what do we do ? hell, why does it even matter that we fabricate the gears to such tight tolerances if any deviation/error whatsoever leads to a functionally useless, doomed gear ?

the answer is simply to machine perfectly with no error wait no that is impossible. we need some slip space to allow accrued error force vectors to dissipate, but this is extremely precarious, as slip space both causes gear teeth to slam into each other as the point of contact between teeth doesn’t move evenly and also reduces the total tooth-contact travel distance meaning that all the force that is transferred now occurs over a shorter distance, multiplying the pressure between the teeth accordingly

“but wait ian you said that the teeth can’t slam into each other ever” -- yes, you’re right. how do we provide empty slip space between teeth without disrupting a continuous & even power transmission surface? the answer is fricken extremely calculated error analysis & gear offset

imagine you have two compatible gears and you mesh them together as hard as possible such that the teeth engage with each other as deeply as possible -- no empty space whatsoever -- this is zero gear offset. now lets say you pull them apart, to some arbitrarily large degree, but not so much that the teeth no longer engage with each other -- this is too much gear offset -- the teeth slam together and explode. but what if we very arduously and scientifically analyze and test our machining equipment as to accurately quantify the error they will impart to gears they machine and use that figure to calculate a gear offset that perfectly opposes erroneous forces ?

something beautiful happens

your slip space is perfectly large enough to dissipate all the error-borne forces, not a hair too big and not a hair too small. the gear teeth stay in contact evenly, they don’t slam into each other, and no error forces compound and cause the gears to explode. finally, a working gear: a monumental achievement that can only be properly appreciated when looked at through an engineer’s lens. proper gear trains can achieve up to like 99% efficiency (!!!) which is unheard of -- wings on a 747 commercial passenger jet are like 10% efficient, your car’s internal combustion engine is about 37% efficient.

8K notes

·

View notes

Text

Check out This awesome artist!! Featuring Rusty, Vic, DialTone, and some other dudes!

Artfight Attacks! Part 1

I finally got around to finding my groove again for drawing! Just something about drawing for others really gets me motivated to draw and experiment :D

Rusty Green for @icarusk

Vic and Dialtone for @vic-sinclair-96

Sunflora for Cookiecat141 on Toyhouse

Jamie Rosepetal for @rizzoto-whump

Roderick Ruthenburg for @reinarandraw

Zima for tenebrion on Toyhouse

Levhi for @nyoaeuikhoudu

Julian Briar for combatcat on Toyhouse

Tema for @thebestusernamepossible

Puipui Molecar oc for Aimtec on Toyhouse

10 notes

·

View notes

Text

Nobody will care but I need the old bastards from Top Gear to drive across the Arctic and retrace the path of the Erebus and Terror in a batshit insane special episode. They make Richard sail in a historically accurate recreation of one of the vessels, while James and Jeremy are in some sick ass off road Jeep or whatever suited up for the weather. Richard gets lead poisoning and Jeremy laughs at him.

93 notes

·

View notes

Text

Here's my first attack!

It's Rusty Green, @icarusk 's newest character!

WOAH, ARTFIGHT?

That's right! We're artfighting this bitch. Find me on the website!

5 notes

·

View notes

Text

WOAH, ARTFIGHT?

That's right! We're artfighting this bitch. Find me on the website!

5 notes

·

View notes

Text

Reasons why computer problems seem to mysteriously vanish as soon as a technician shows up:

You were spacing out and skipping a step somewhere without realising it, and you can’t reproduce it when you try to demonstrate it because now you’re paying attention to what you’re doing

It’s an intermittent electrical connection fault that’s being aggravated by movement/vibrations in your desk; you need to check your cables

The act of explaining the problem to someone caused you to figure out what you were doing wrong

The real cause of the problem was somewhere upstream of your terminal device – for example, at the network service provider – and it got fixed at the source while you were waiting

Your computer is in a location with poor airflow and is overheating; waiting for the technician to arrive gave it a chance to cool off

Despite all appearances to the contrary, modern computers actually have very good fault recovery, and most minor problems will sort themselves out on their own if you give it a minute

Magic

56K notes

·

View notes

Text

Bottom image looks like an album cover i swear

I still don’t have anything to play on his screen, but I enjoy powering him on when I can

130 notes

·

View notes

Text

LIL GUY POSTING

This is the Canadian market Nissan Micra!

The Micra is the smallest car made by Nissan that doesn't fall into the kei class of Japanese microcars. This makes it, adorable and determined. A zippy boi who was born smol but doesn't let that stop him!

Most Micras were sold in Asian markets, but Nissan had an assembly plant for these cars in Mexico. Because of the Mexican plant, some genius working for Nissan Canada realized they could purchase and import Micras for so little money that they could sell the least expensive new car in the *country*! Brand-new, the CDM Micra cost just $9,998.

Did i mention the Micra is a race car?

To promote the Micra, Nissan of Canada set up a spec racing series using exclusively Nissan Micras with stock engines. The Micra had a, frankly oversized 1.6 liter 4 cylinder which made it leagues more powerful than it's more expensive rivals, the 3 cylinder Mitsubishi Mirage and the Chevy spark. The Micra was also very light. Barely tipping the scale at 2,300 pounds, which is about the same as a Miata.

All this comes together to make a car that was brilliantly affordable, super fun to drive, and of fairly high quality!

The Micra is, a top tier Lil guy, and one that Americans never got.

8 notes

·

View notes

Text

Everyone needs to look at this art by my epic boyfriend @icarusk

More Rusty doodles :)

Vic and Dialtone are my partners: @vic-sinclair-96

6 notes

·

View notes

Note

Reblog if you're a carkisser

I dont think there's enough car objectum content. Computers and plushies and inflatables and all the other little inanimate friends are lovely, but we really really need to awaken the carkissing community

There are cars of all shapes and sizes and specialties, and some of them like different terrains, and some of them like different kinds of fuel, and that means theres so much personality to each and every make and model of car. Manual transmissions specifically got me acting up, especially because it's like the car is holding your hand and telling you when to change gears. also, the sound of the car is so nice you dont even need music to drive because listening to the car is already so nice. Also, the car has so many safety features to protect you because it loves you so much, and it wants you safe. I also love how it asks you so nicely for fuel and sometimes i like to picture a car low on gas as like. its thirsty and wants a little drink. I can go on and on about how much i love cars and driving and also fixing cars and mechanics but my point is

i dont see enough people who want a car carnally like i do and i hope this ask reaches all the carkissers like me

this ask is sponsored by my 1999 toyota tacoma named tuesday. shes my wife

47 notes

·

View notes

Photo

How to fix a Volvo

Percussive maintenance

Almond’s repair methods can be a bit.. questionable

8K notes

·

View notes

Photo

How to fix a Volvo

Percussive maintenance

Almond’s repair methods can be a bit.. questionable

8K notes

·

View notes

Text

Woo! Rusty reveal! Everyone go check out the art created by my brilliantly skilled boyfriend @icarusk

And now for something completely different :)

This is Rusty, he's an oc for a post apocalyptic story created by my awesome partner @vic-sinclair-96

He and my BPRD ocs will be on artfight this year! You can find me there as IcarusK

7 notes

·

View notes

Text

Holla to all my digital claustrophobics out there

going from 2 monitors to 1 is so weird i have like a fantom monitor in my brain thats just always blank in real life. its like i lost brain capacity, the connections and insticts to utilize and look at the other monitor for tasks is all still there in my mind but the actual monitor itself isn't. transhumanist-phantom-limb-syndrome or something

6K notes

·

View notes