Welink Medical was set up for worldwide turnkey project for different ranges disposable products, such as syringe, hypodermic needle, infusion set, IV cannula, blood collection needles, scalp vein sets, insulin syringes and so on. Besides we are also supplying workshop design guide, technical support, production suggestion and after service. https://www.welink-med.com/

Don't wanna be here? Send us removal request.

Text

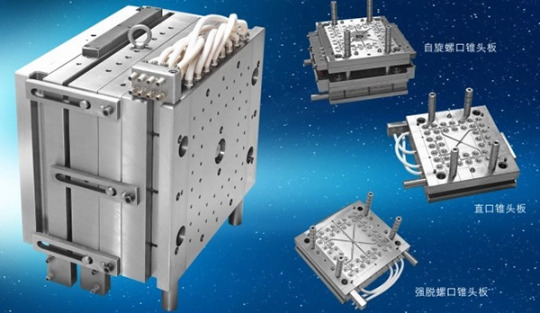

HYPODERMIC NEEDLE MOLD

Welinktech Hypodermic Needle Molds are specifically designed to produce needles for syringes that are used for various medical applications. These molds come in different shapes and sizes, ensuring precision and accuracy in the manufacturing process to guarantee that the needles are safe for medical use.

TYPES OF HYPODERMIC NEEDLE MOLD

Hypodermic Needle Hub Mold (14G, 16G, 17G, 18G, 19G, 20G, 21G, 22G, 23G, 24G, 25G, 26G, 27G, 28G, 29G, 30G, 31G)

ADVANTAGES OF HYPODERMIC NEEDLE MOLD

1. Precision and Accuracy: Hypodermic needle molds are intended to manufacture needles with specific dimensions and properties, assuring manufacturing precision.

2. Increased Efficiency: Using hypodermic needle molds may improve the efficiency and speed of the manufacturing process, lowering labor costs and turnaround time.

3. Cost-effective: The capacity of needle molds to manufacture a high volume of needles in a short length of time decreases manufacturing costs, making the production process more cost-effective.

4. Consistency: Hypodermic needle molds are designed to produce needles with uniform dimensions, resulting in consistent products that fulfill the requisite safety and quality criteria for medical applications.

5. Customizable: Needle molds can be customized to meet specific requirements for unique needles, ensuring that the final product meets the demands of the medical sector.

6. Quality Assurance: The use of needle molds in needle production ensures that the needles are of high quality and meet the necessary safety and quality standards.

UNDERSTANDING THE DIFFERENCES AMONG HYPODERMIC NEEDLE MOLDS

1

The flow rate of the liquid being injected is affected by the gauge of the needle. Flow rates will be slower with smaller gauge needles than with larger gauge needles.

2

Patients are often more comfortable with smaller gauge needles since they produce less discomfort and bleeding. Bigger gauge needles cause greater discomfort and may result in more bleeding.

3

The needle gauge used will also be determined by the application. A 14G needle, for example, may be utilized for heavier fluids, but a 30G needle may be appropriate for administering insulin.

4

The design of different gauge needles can vary based on the manufacturing process. For example, thinner needles may require more precise molds and additional steps in the manufacturing process.

0 notes

Text

DRIP CHAMBER ASSEMBLY MACHINE

The Welinktech Drip Chamber Assemble Machine is a state-of-the-art piece of equipment used for precisely assembling IV drip chambers. These machines automate the assembly process by using robotic arms to perform various operations, including ultrasonic welding, cutting, and assembly of drip chamber components such as the drip chamber, air vent, spike, and fluid filter.

To ensure efficient and reliable production, the Welinktech Drip Chamber Assemble Machine is equipped with sensors and cameras that detect any faults in the assembled drip chambers. The machine can produce a large number of high-quality drip chambers quickly and accurately, while maintaining strict quality control standards for medical device manufacturing.

SPECIFICATION OF DRIP CHAMBER ASSEMBLY MACHINE

Assembly speed

5500-6000pcs/h

Input power

220V50HZ

Machine Size

340*390*165cm

Full machine power

2.3w

Weight

2000kg

Atmospheric pressure

0.45-0.6MPa

WHAT IS A DRIP CHAMBER ASSEMBLY MACHINE USED FOR?

A drip chamber assemble machine is used in the assembly of IV drip chambers. The machine automates the process of assembling various components that form the drip chamber, including the air vent, spike, fluid filter, and drip chamber itself. The machine utilizes robotic arms, ultrasonic welding, and cutting to guarantee an efficient, consistent, and high-quality assembly process.

Additionally, it is equipped with sensors and cameras that inspect the final product to ensure there are no defects, and guarantee a perfect product is produced. These machines are essential in the medical device manufacturing industry as they guarantee an efficient and accurate production of IV drip chambers.

WHAT ARE THE BENEFITS OF USING A DRIP CHAMBER ASSEMBLY MACHINE?

The machines' automation of the assembly process results in higher productivity and an increased capacity for output.

Using these machines ensures a uniform assembly process, creating quality products consistently.

By detecting defects in assembled drip chambers, these machines ensure that only flawless products are delivered.

These machines reduce labor costs, resulting in an efficient production process and reduced per-unit cost.

These machines minimize rejected products by ensuring proper assembly of components.

Robotic arms used in these machines allow for precision assembly, ensuring that drip chambers are exactingly made.

The strict healthcare standards met in building these machines guarantee the production of safe, regulatory-compliant final products.

These machines can be tailored to produce various types of drip chambers suited for different medical applications.

0 notes

Text

DISPOSABLE SYRINGE MOLD

Welinktech Disposable Syringe Mold is a high quality and precise injection mold that meets the needs of medical and healthcare applications. It has a unique design that is easy to use and allows for accurate and efficient production. The mold is crafted from durable materials and is safe and reliable for use.

ADVANTAGES OF DISPOSABLE SYRINGE MOLD

Disposable syringe molds offer several advantages compared to their reusable counterparts: they are more cost effective, require less maintenance, and are easier to use. Additionally, disposable molds can be quickly cleaned and sterilized, eliminating the need for manual cleaning and reducing the risk of cross-contamination. Finally, due to their single-use nature, the risk of spreading disease or infection through multiple uses is greatly reduced, making them a much safer option for medical and healthcare settings.

HOW TO STORE DISPOSABLE SYRINGE MOLD?

1

Disposable Syringe Mold should be stored in a clean, dry and well-ventilated environment.

2

Ensure that the temperature and humidity of the storage environment are suitable and it is away from direct sunlight.

3

Place the mold in a flat position and keep it away from sharp objects and corrosive chemicals.

4

Wrap the mold in a protective material such as cloth or plastic to prevent dust or other contaminants from affecting the mold.

0 notes

Text

CONNECTOR MOLD (LUER SLIP AND LUER LOCK TYPE)

A connector mold, also known as a connector tooling, is a type of injection mold that is specifically designed to produce connectors or cable assembly components. Connectors are widely used in different industries, such as telecommunications, automotive, consumer electronics, and many others, so connector molds are in high demand.

Connector molds can range in complexity from simple single cavity molds to complex multi-cavity molds to produce multiple parts at once. Some molds may feature specialty inserts, such as inserts for over-molding, in-mold labels, or other functional features. There are many different types and sizes of connector molds to accommodate different connector designs and production quantities.

HOW IS A CONNECTOR MOLD MADE?

Connector molds are typically made through a process called injection molding. This process involves the following steps:

Mold design: The first step in making a connector mold involves designing the mold according to the specifications of the connector being manufactured. This includes determining the shape, size, and other attributes of the mold.

Material selection: Once the mold is designed, the appropriate material for the mold is selected. Connector molds are typically made of high-grade steel or aluminum.

Mold creation: After the material is selected, the mold is created through a series of machining and fabrication processes, including milling, drilling, and cutting.

Injection molding: Once the mold is created, it is loaded into an injection molding machine. The machine melts the raw materials, which are then injected into the mold cavity through a nozzle.

Cool and solidify: As soon as the material is injected into the mold, the mold is cooled and solidified. This process is crucial in ensuring that the finished connector has the desired shape, size, and other attributes.

Eject the connector: Once the material has completely solidified, the connector is ejected from the mold using a special ejector pin system.

Finishing: Finally, the connector is subjected to further treatment, such as surface finishing, painting, or polishing, to enhance its appearance and functionality.

CAN A CONNECTOR MOLD BE REUSED?

Yes, a connector mold can be reused multiple times. Connector molds are designed to withstand multiple injection molding cycles, and it is common for a single mold to produce thousands or even millions of connectors over its lifetime. However, the lifespan of a connector mold may vary depending on a number of factors, including the materials used in the mold, the injection molding process, and the maintenance and cleaning practices implemented by the manufacturer.

Regular maintenance and cleaning of connector molds can help ensure consistent quality and reliability of the connectors produced. By reusing molds, manufacturers can save time and cost in the production process while still producing high-quality products.

0 notes

Text

CONNECTOR ASSEMBLY MACHINE

The Welinktech Connector Assemble Machine is a cutting-edge device designed to create a range of connectors for various industrial applications, including electrical, coaxial, and fiber optics. The machine uses automated processes to combine components like pins, sleeves, and sockets, producing the finished connector device with a high degree of precision and replication.

The Welinktech Connector Assemble Machine employs various operations like cutting, crimping, soldering, and testing to ensure the finished product meets quality control standards. The use of this machine provides high-precision and superior connector assembly processes, reducing production time and the cost of production. These machines are widely used in the electronics and telecommunications industries as they can produce a diverse range of connectors that meet specific requirements, ensuring high-quality and reliable connections.

SPECIFICATION OF CONNECTOR ASSEMBLY MACHINE

Assembling area

Single head assembly

Double head assembly

Assembling speed

5800-6300PCS/h

Input

220V50HZ

Machine size

7150x150x150cm

200x200x160cm

Power

1.8kw

Weight

650kg

Air pressure

0.5-0.65MPa

WHAT MATERIALS ARE USED TO MAKE CONNECTOR ASSEMBLY MACHINE?

Connector assemble machines typically consist of several key materials to ensure their proper functioning. The frame of the machine is typically made from a strong and durable metal such as aluminum, steel or stainless steel. The machine's internal components usually are crafted from high-grade plastics, stainless steel, or other materials that can withstand high temperatures and mechanical stresses.

The machine may have electronic parts such as microcontrollers and touchscreens, which require PCB boards, wires, and cables for their functioning. The materials used to manufacture connector assemble machines should have high durability, heat resistance, and conductivity to meet the requirements of the electrical and electronic industries.

HOW TO USE CONNECTOR ASSEMBLY MACHINE?

Check all required components and make sure the machine is in good working order before using it.

Gather all the cables, connection parts, and equipment required.

Follow the manufacturer's directions for installing the connector parts into the device.

Prepare the wires by stripping them to the proper length before using.

Insert the prepared wires into the connector components that are fixed in the machine.

Start the machine and select the appropriate settings for the type of connector to be assembled.

Watch the machine carefully as it assembles the connectors and ensure there are no errors or issues.

Once the connectors are completed, remove them from the machine and test their functionality using a testing tool or a device.

0 notes

Text

CLAMP BODY MOLD

A Clamp Body Mold is a type of injection mold that is designed to produce the clamp body component used in clamping systems. The clamp body is a type of device used to hold two or more components together, commonly used in the automotive and electrical industry. The mold produces the clamp body component in the desired shape and size, which can vary based on the specific requirements of the end-use application. The clamp body mold is typically made of high-quality materials such as steel or aluminum, and it undergoes precision machining to produce accurate and consistent parts.

WHAT ARE THE FEATURES OF A CLAMP BODY MOLD?

A standard Clamp Body Mold typically has an efficient design, with one or more cavities and runners for accurate molten material flow. It provides a tight tolerance fit between mold halves to maintain the accuracy of the final product. The mold is often designed with cooling channels to ensure even cooling and reduce cycle times.

WHAT MATERIALS ARE USED TO MAKE CLAMP BODY MOLD?

The materials used to manufacture Clamp Body Mold are often high-quality and durable, such as steel, aluminum, or other high-strength alloys. The material used is dependent on the specific requirements of the end-use product, the rate of production required, and the complexity of the mold.

0 notes

Text

CANNULA MAKING MACHINE

The Welinktech Cannula Making Machine is a specialized equipment used to produce medical-grade cannulas used in procedures such as venipuncture and surgery. It employs advanced technology to produce precise, sterile, and high-quality cannulas.

PRECISION AND ACCURACY IN CANNULA MANUFACTURING

1. Material Selection: The choice of material plays a critical role in determining the precision and accuracy of a cannula.

2. Extrusion Process: Advanced extrusion techniques produce cannulas with high levels of accuracy, including improved tolerances and surface finish.

3. Machining Techniques: The use of precision machining for cutting, grinding, and polishing ensures that the cannula has a smooth surface finish and the correct dimensions.

4. Quality Control: Consistent quality control protocols and statistical analysis ensure the accurate measurement of cannula dimensions and tolerances.

5. Sterilization and Packaging: The sterilization and packaging of cannulas must also be carried out with high levels of precision to guarantee the final product's uniformity

MAINTENANCE TIPS FOR CANNULA MAKING MACHINES

1

It is important to clean and maintain the cannula making machine regularly to avoid any blockages or damages. The debris or dust that accumulates on the machine parts can cause issues in the production process.

2

Lubrication of the machine parts is important as it helps in reducing friction and wear and tear, thus increasing the lifespan of the machine.

3

Regular checking of the machine parts for any wear and tear is crucial as it helps in replacing the worn-out parts and improving the overall functioning of the machine.

4

The electrical components of the machine should be checked regularly to ensure that they are in good condition and functioning properly.

5

The machine should be calibrated regularly to ensure accurate measurements and consistent production.

6

Hiring a professional technician for regular maintenance checkups can help in identifying any potential problems and addressing the same before they cause any major issues.

7

Proper storage of the machine is crucial to avoid any damages caused by environmental factors such as heat, moisture, or dust.

0 notes

Text

CANNULA DIAMETER REDUCING MACHINE

The Welinktech Cannula Diameter Reducing Machine is a high-precision device used to accurately reduce the diameter of cannulas quickly. It is widely used in medical device manufacturing facilities for producing cannulas of different sizes to meet various application requirements. The machine features a computer-controlled system that permits accurate adjustment of the cannula diameter.

The Welinktech Cannula Diameter Reducing Machine comes with a robust clamping device that holds the cannula in place while a rotary cutting tool reduces the diameter to the required specifications. It also features a control panel with a user-friendly interface that allows the operator to input specific parameters needed for the task at hand, increasing production efficiency and precise quality control of the final product.

SPECIFICATION OF CANNULA DIAMETER REDUCING MACHINE

Rated power

6kw

Driving motor

4kw

Cooling water

2L/hour

Working specification

Ф1.6-Ф4mm

Work efficiency

6-22m/min

Machine size (LxWxH)

3000x1500x1200mm

Weight

600kg

HOW DOES A CANNULA DIAMETER REDUCING MACHINE WORK?

A rotary cutting tool is used by a cannula diameter reducing machine to trim the cannula's diameter to the desired size. A computer-controlled system drives the machine, which modifies the diameter to meet the required criteria. The cannula is initially inserted into the device by the operator, who then clamps it in place.

HOW TO CHOOSE CANNULA DIAMETER REDUCING MACHINE ?

Precision: Ensure the machine offers precise control in reducing the cannula diameter to the desired size, guaranteeing that the final product meets quality standards.

Output capacity: Choose a machine that meets the production capacity requirements, taking into account the necessary production speed without affecting quality.

User-friendly: Look for a machine with a user-friendly interface that enables quick parameter programming and easy operation.

Endurance: Choose a machine made from durable materials that can withstand heavy usage while maintaining efficiency. It's also best to opt for machines that come with a warranty and adequate support for maintenance and repairs.

1 note

·

View note