Don't wanna be here? Send us removal request.

Text

How to buy direct from china factory

When importing from overseas, finding the factory source can not only save a lot of negotiation time, but also save a lot of money.

Details

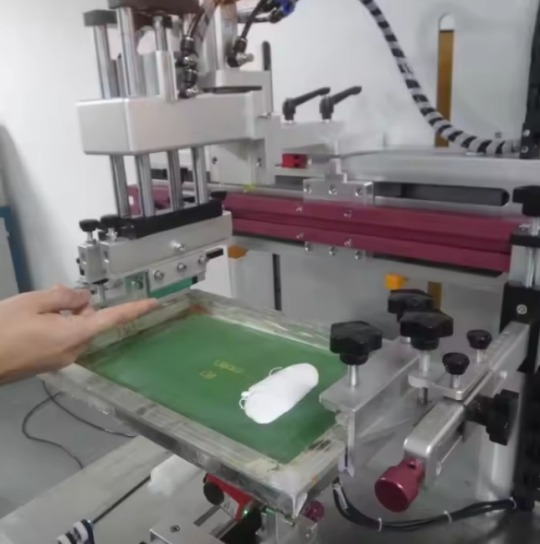

How to buy direct from china factory 1. Online B2B platform: such as Alibaba, Global Resources, Made in China, Yiwugou, etc. These platforms provide rich product information and supplier resources.

2. International trade fairs: Participating in international trade fairs is an effective way to obtain first-hand sources. At trade fairs, buyers can communicate with manufacturers face to face to learn about the latest product dynamics and market trends.

3. Search engines: Similar to Google, Bing, Yandex, etc., Chinese suppliers are gradually realizing the importance of self-built websites. More and more manufacturers are starting to take the route of independent brands and find corresponding manufacturers on search engine platforms through product keywords.

4. Social media platforms: Many manufacturers have established their own company's official homepages on social platforms such as FB, Linkedin, and Ig.

5. Intermediary buyers: Some intermediaries are more familiar with China, so they can contact domestic manufacturers.

When selecting suppliers, buyers should evaluate the supplier's strength and reputation. They should understand the supplier's production scale, quality management system, and after-sales service to ensure a long-term and stable cooperative relationship. In addition, buyers can also further judge the supplier's comprehensive strength by checking the supplier's operating conditions, service ratings, and historical sales on the platform.

Nanjing Weproving Inspection china leading third party inspection company. Not only provides you with professional product inspection, factory audit and import and export qualification certificates, but also helps you find reliable source manufacturers in China.

#buy direct from China factory#weproving inspection#third party inspection#factory audit#import from china#pre shipment inspection#quality control

0 notes

Text

Importance of Inspection

The importance of inspection for a company Inspection plays an important role for both manufacturers and buyers

The benefits of inspection for manufacturers 1.Inspection ensures production quality and safety. During the factory production process, inspection is the key to ensure that product quality meets design requirements and standards. Through strict inspection of raw materials, semi-finished products and finished products, problems can be discovered and solved in time to prevent unqualified products from entering the market.

2.Inspection helps prevent accidents and failures. In industrial production, strict inspection can prevent equipment failures and safety accidents. For example, regular inspection and maintenance of production equipment can ensure its normal operation and reduce production interruptions and potential safety hazards caused by equipment failure.

The importance of product inspection for buyers 1. Through inspection, buyers can ensure that the purchased goods meet the expected quality standards and avoid purchasing defective goods.

2. Raw material inspection and pre-shipment inspection can avoid defective products, reduce after-sales returns and exchanges, and avoid economic losses.

3. Inspection can improve consumer satisfaction and enhance brand loyalty. High-quality products also increase customer repurchase rate.

Examples of the importance of inspection In garment production, pre-production inspection, initial inspection, mid-term and final inspections ensure that each batch of clothes meets quality standards. Through the AQL sampling method, quality is guaranteed while reducing inspection costs.

Weproving Inspection has more than 16 years of experience in the inspection industry and has served thousands of overseas buyers. Through Weproving Inspection's professional product inspection, supplier audits, and import and export certificates, we ensure that customers buy the best products from China.

#supplier audit#third party inspection#quality inspection service#AQL Sampling#weproving inspection#goods inspection

1 note

·

View note

Text

Saa Approval

SAA certification is a certification service provided by SAA Approvals.

Details

SAA certification is officially known as Australian Safety Certification. It is a certification service provided by SAA Approvals, a third-party certification body approved by the Joint Certification Service of Australia and New Zealand (JAS-ANZ). It is responsible for issuing mandatory and non-mandatory electrical equipment certification certificates to ensure that electromechanical equipment meets the safety requirements specified in the standards of Australia and New Zealand.

Background of SAA Certification SAA certification is one of the standards established by the Standards Association of Australia (SAI). Although SAA Approval is the most certified institution, Australian safety certification is not limited to SAA. Other institutions such as Global-Mark and TUV Rheinland also provide similar certification services. SAA certification is a safety standard that must be met by electrical equipment in the Australian and New Zealand markets. It applies to products such as external power supplies, chargers, plugs, some home appliances and lamps.

SAA Certification Process Applying for SAA certification requires submitting detailed test reports and product photos. The certification process usually includes the following steps: 1. Submit test report: The product needs to be tested by a nationally recognized laboratory and submit a test report. 2. Audit test report: SAA Approvals audits the test report to ensure that the product meets the relevant standards. 3. Issue certificate: After the audit is passed, the SAA certification certificate will be issued, and the certification number and logo will be marked on the product.

Validity period of SAA certification The validity period of the SAA certification certificate is up to 5 years. The holder needs to be a local registered company or local agent, and the product needs to be marked with the certification number and logo on the label.

The importance of SAA certification to enterprises

1.Legal compliance: SAA certification is a mandatory requirement in Australia and New Zealand. All electrical products entering the market must comply with SAA certification standards. Uncertified products will be detained or confiscated.

2. Supply chain management: For enterprises that need to purchase SAA certified products, purchasing certified products can ensure the quality and safety of products, which is conducive to supply chain management and risk control.

3. Technical standard compliance: SAA certification follows strict technical standards, such as AS/NZS 3000 electrical installation standards and AS/NZS 3820 basic safety requirements for low-voltage electrical equipment.

Weproving Inspection one stop certification, audit and product quality control service. We ensure you find the best suppliers in China and get the best products.

#saa certification#saa approval#quality control#weproving inspection#australia safety certification#electrical equipment inspection

0 notes

Text

About SS 00259 you should know

SS 00259 is mainly used to manage and control environmental management substances.

Details

SS 00259 is a standard developed by Sony Corporation, mainly used to manage and control environmental management substances used in its products. The full name of this standard is Management regulations for the environment-related substances to be controlled which are included in parts and materials. It aims to prevent harmful substances from being mixed into Sony electronic products, while complying with the laws of various countries and reducing the impact on the ecosystem.

Update of SS 00259 The latest version of SS-00259 is the 22nd edition, which was released on May 1, 2024 and officially took effect on June 1, 2024. This version adjusts the control requirements for some substances, adds new material control requirements, adjusts the definition and limit values of controlled substances, etc.

Specific content of SS-00259 SS-00259 covers the environmental management material requirements of parts and materials used in the products designed and manufactured by Sony Group and its commissioned products. Specific requirements include:

1. New material control requirements: Added control of certain substances

2. Adjusted the definition and limit of controlled substances: For example, the controlled substance "perfluorooctane sulfonic acid and its derivatives (PFOS)" was adjusted to "perfluorooctane sulfonic acid (PFOS) and its salts" and "perfluorooctane sulfonic acid (PFOS) related substances", and reset the control limit

3. Added control objects and limits: Added control objects and limits for some substances

The impact of SS 00259 on enterprises

1. Enterprises need to ensure that all materials and components in their products meet the standards of SS-00259, otherwise they may face compliance issues and affect product sales.

2. Compliance with SS-00259 standards can help enterprises gain more competitive advantages in the international market. As consumers pay more attention to environmental protection and sustainability, products that meet environmental standards are more likely to gain market recognition, thereby enhancing the brand image of enterprises.

The SS-00259 standard is adjusted every year according to the latest international regulatory trends. Companies need to pay close attention to these changes and update their standards and operating procedures in a timely manner to avoid compliance issues caused by non-compliance with new standards.

Weproving Inspection one stop inspection, audit, certification supply. Contact us for a inspection, make your business better.

#weproving inspection#ss-00259#quality control inspection#supplier audit#pre shipment inspection#incoming inspection

0 notes

Text

Rapid inspection

Through rapid inspection, enterprises can promptly discover and deal with incoming material problems.

Details

Rapid inspection is defined as rapid inspection. Compared with traditional detection methods, it has the characteristics of short detection time, simple operation and low cost, and is suitable for rapid detection in non-laboratory environments.

Rapid inspection features:

1. Short detection time: Rapid inspection methods can complete detection in a shorter time, and are usually faster and easier to operate than traditional detection methods.

2. Easy operation:Rapid inspection methods are usually easy to operate manually or automatically, and do not require complex equipment and steps.

3. Low cost: Compared with traditional detection methods, rapid inspection methods have lower costs and are suitable for large-scale applications.

Importance of Rapid inspection:

1. Quality control: Rapid Inspection can help enterprises confirm the quality of raw materials and components before production, and inspect the quality by sampling, so as to control quality problems at the source, reduce the number of unqualified products entering the production process, and avoid unqualified final products.

2. Improve production efficiency: Through rapid inspection, enterprises can promptly discover and deal with incoming material problems, reduce production stagnation and rework caused by quality problems, thereby improving production efficiency and delivery on time.

3. Continuous improvement: Rapid inspection is not only the inspection of incoming materials, but also includes tracking and handling of quality problems found during the inspection process, and establishing preventive measures within the enterprise, participating in the optimization of related processes in the logistics control link, so as to achieve continuous improvement.

Weproving Inspection provides professional rapid inspection services. Through rapid inspection at the manufacturer's site, we ensure that your company obtains high-quality products.

#rapid inspection#weproving inspection#industrial inspection#incoming inspection#factory audit#equipment inspection

0 notes

Text

About astm f2413 11 you should know

ASTM F2413-11 is applicable to various work environments that require foot protection.

Details

ASTM F2413-11 is a standard published by the American Society for Testing and Materials (ASTM). The full name is "Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear. This standard is intended to define the performance requirements for protective (safety) toe cap footwear to ensure that the necessary protection is provided in the workplace to prevent possible injuries.

ASTM F2413-11 covers the minimum requirements for footwear performance and is applicable to various hazardous situations in the workplace. This standard is not intended to be a detailed manufacturing or procurement specification, but can be referenced in procurement contracts to ensure that minimum performance requirements are met. The standard does not apply to overshoes with safety toe caps or straps with safety toe devices, and any changes to the original components of safety toe shoes may invalidate the standard.

ASTM F2413-11 content 1. Impact resistance: The toe part must be able to withstand a certain impact force, divided into 75 and 50 levels, and the specific requirements vary according to gender and weight.

2. Metatarsal protection: The design, construction and manufacture of footwear should ensure that the metatarsal impact protection device is partially located above the protective toe and extends to cover the metatarsal area, also divided into 75 and 50 levels.

3. Static electricity Dissipative (SD) properties: Footwear should protect the wearer by conducting the charge to the ground while maintaining a high electrical resistance.

4. Protection against electric shock: Footwear should provide protection against electric shock at the heel and toes.

5. Dielectric insulation: Footwear design should provide insulation protection in the event of accidental contact with electrical conductors or circuits.

6. Chain saw cutting resistance: Footwear should protect the foot area between the toes and calf when operating a chain saw.

ASTM F2413-11 is applicable to various work environments that require foot protection, such as construction sites, manufacturing, etc. By meeting these standards, workers can be ensured to be adequately protected when using these footwear, reducing potential risks during work.

#ASTM F2413-11#footwear industry#footwear quality inspection#quality inspection#third party inspection company#import trade

0 notes

Text

3 Number Receiving Inspection System of AQL

Acceptance Quality Level (AQL) is widely used in clothing and textile inspection, raw materials, finished products and semi-finished products inspection, as well as electronic products, medical devices, etc.

Details

The three inspection methods of AQL (Acceptance Quality Level) include general inspection, key inspection and special inspection.

1. General inspection: This inspection is mainly aimed at the general performance of the product, including quality inspection, appearance inspection, size inspection, etc. As long as the product meets the minimum requirements, it can pass this inspection. General inspection is suitable for those scenarios where the product quality requirements are not high.

2. Key inspection: Key inspection targets the key performance of the product, involving safety inspection, performance inspection, reliability inspection, etc. These inspection results have an important impact on the use of the product, so they must meet specific standards. Key inspection is suitable for those scenarios with strict requirements on product quality, especially those involving safety performance.

3. Special inspection: Special inspection targets the special performance of the product, such as durability, corrosion resistance, and pollution resistance. This inspection is more complicated and more demanding than general inspection and key inspection. Special inspection is suitable for those scenarios with high unit price and special requirements for product quality.

Background history of AQL AQL standard is an important basis for product inspection, and the inspection standard is determined by probability. It is widely used in industrial production and quality control to ensure the stability of product quality.

Sampling inspection methods Sampling inspection methods include simple random sampling, systematic random sampling, stratified sampling and cluster sampling. These methods have detailed regulations and application scenarios in the AQL standard.

Weproving Inspection offer professional third party inspection for hard/soft/electronic/industrial goods. Best service with reasonable price.

0 notes

Text

Asian Homeware Inspection

Weproving Inspection provide professional hard/soft goods inspection service. Factory audit, certification and production inspect all available in Weproving Inspection.

Details

In the first 10 months of 2024, the export value of Asian homeware goods was 390.45 billion yuan, an increase of 8.8% year-on-year. Main export markets: The main export markets for Asian homeware goods include the United States, Australia, France, the United Kingdom, etc.

Main export asian homeware products: Bedroom wooden furniture and kitchen wooden furniture. For example, the export value of spring mattresses increased by 31.15%, the export value of bedroom wooden furniture increased by 28.57%, and the export value of kitchen wooden furniture increased by 19%.

Asian household goods include a wide variety of categories, mainly including the following categories: Bedding: including pillows, pillowcases, quilts, quilt covers, sheets, etc. Kitchen and bathroom: including rice cookers, shovels, knives, wine glasses, etc. Electrical appliances: air conditioners, microwave ovens, televisions, refrigerators, etc. Lamps and lighting equipment: including various lighting fixtures and power tools. Kitchen utensils: including pots, baking equipment, tableware, etc.

The reasons for inspecting asian homeware products mainly include the following aspects:

1. Ensure quality: Through inspection, it can be ensured that the materials, processes, structures and other aspects of household products meet the predetermined standards, so as to provide customers with safe, reliable and durable products.

2. Ensure consumer safety: The safety of homeware products is directly related to the safety of life and property of consumers. Inspection can find potential safety hazards, such as whether the formaldehyde content exceeds the standard, the stability of the furniture structure, etc., so as to avoid accidents during use and protect the interests of consumers.

3. Improve market competitiveness: In the fierce market competition, high-quality products are more likely to be recognized by consumers. Through testing, companies can demonstrate their product quality and safety, thereby winning the trust of consumers and improving market competitiveness.

4. Meet regulatory requirements: Many countries and regions have strict quality and safety standards for homeware products. Through testing, it can be ensured that the product meets the relevant regulatory requirements and avoids being punished for quality problems.

5. Daily sales needs: In sales channels such as e-commerce platforms, supermarkets, and stores, it is usually required to provide a quality inspection report that passes the national standards. Without a quality inspection report, the product may not be able to enter these channels.

Household Goods and Homeware Products Testing Laboratory Weproving Inspection provides professional asian homeware products testing services to ensure that your company's household products comply with ISO, RoHS industry standards. Including:

Odor Testing Material Testing Durability Testing

#homeware product inspection#inspection service#furniture inspection#qc inspection#weproving inspection#third party inspection

0 notes

Text

Dupro Inspection

During Production Inspection (DPI), also known as In-Process Inspection. During Production Inspection is widely used in the inspection process, especially as one important complementary solution of Pre-Shipment.

Details

Durpo Inspection refers to the inspection conducted when the production is 20% to 80% completed during the process production. The main purpose is to confirm whether the factory produces according to the initial production quality requirements and processes, and ensure that the finished products meet the customer's quality requirements.

DUPRO Inspection Process

1. Time point: Usually carried out when the production line is 20% to 80% completed

2. Inspection content: Randomly select products from the finished batch for sampling, including product functions, performance, appearance and size, etc.

3. Inspection standards: Statistical sampling procedures are carried out in accordance with internationally recognized standards such as ANSI/ASQC Z1.4

Dupro Inspection Importance

1. Quality control: Through DUPRO inspection, problems in the production process can be discovered as early as possible, and the factory can be given enough time to make adjustment solutions.

2. Ensure that the order meets the requirements: Confirm the quality of the ordered goods, ensure that the batch goods meet the customer's needs, and avoid defects in the quality of the goods due to the influence of people, machines and environment on the production line.

3. Customer satisfaction: Through durop inspection, problems in the production process can be discovered in time to achieve on-time delivery.

Scope of application of DUPRO inspection DUPRO inspection is applicable to a variety of industries, including food and agricultural products, textiles, clothing, shoes and bags, kitchen and home furnishings, children's toys, electronic appliances, industrial machinery and equipment and other products.

Weproving Inspection supply professional third party inspection. Our mainly services are pre shipment inspection, container loading check and factory audit.

#DUPRO inspection#Weproving Inspection#third party inspection#factory audit#during production inspection#qc inspection

0 notes

Text

Work Inspirational Quotes

When you feel confused and tired at work, you might want to take a look at the following blog of inspirational work quotes

Details

1.“Going with the flow doesn't mean that we don't know where we're going; it means that we are open to multiple ways of getting there.” - Madisyn Taylor

2. "Coming together is a beginning; keeping together is progress; working together is success.” - Henry Ford

3. “Common sense is genius dressed in its working clothes.” - Ralph Waldo Emerson

4.“When I am working on a problem, I never think about beauty, but when I have finished, if the solution is not beautiful, I know it is wrong.” - R. Buckminster Fuller

5.“Optimism is the one quality more associated with success and happiness than any other.” - Brian Tracy

6. "There is no way to happiness. Happiness is the way.” - Thich Nhat Hanh

7. “Do it with passion, or not at all.” - Rosa Nouchette Carey

8.“I never dream of success. I work for it."- Estée Lauder

9.“I'm a great believer in luck, and I find the harder I work, the more I have of it.” —Thomas Jefferson

10.“Your work is going to fill a large part of your life, and the only way to be truly satisfied is to do what you believe is great work. And the only way to do great work is to love what you do. If you haven't found it yet, keep looking. Don’t settle. As with all matters of the heart, you"ll know when you find it.” —Steve Jobs

No matter where you are in the workplace, 2025 is a new beginning for everyone. Find your own goals and work hard. Whether you are confused or tired, take a look at the above work inspirational quotes, which may give you a different feeling.

Weproving Inspection not only supply inspection, certification, factory audit service but also help you business better developing.

#weproving inspection#certification inspection#factory audit#supplier audit#qc inspection#import and export#trade

0 notes

Text

Sa8000 Audit

Introduction

SA8000 audit is also known as the International Standard for Social Accountability. (Social Accountability 8000 Standard)

Details

SA8000 audit is also known as the International Standard for Social Accountability. (Social Accountability 8000 Standard) audit is a set of international standards initiated and developed by Social Accountability International (SAI).

SA8000 audit is based on the United Nations Declaration of Human Rights. The International Labor Organization Convention and the provisions of national labor laws are intended to ensure that companies comply with social responsibility standards in the production process, covering aspects such as environment, safety, and management systems.

What SA8000 audit includes

1. Child labor and underage labor: Companies shall not use child labor or underage labor to engage in dangerous, illegal or low-income work.

2. Forced labor: Companies shall not use forced or compulsory labor.

3. Health and safety: Companies should provide a healthy and safe working environment, take adequate measures to reduce hazards at work, and prevent accidents or injuries.

4. Freedom of association: Companies should respect employees' freedom of association and collective bargaining rights.

5. Working hours: The enterprise should provide reasonable working hours, including overtime and rest time

6. Disciplinary measures: The enterprise shall not engage in or support disciplinary measures such as corporal punishment, mental or physical coercion, and verbal insults

7. Salary and benefits: The wages paid by the enterprise to employees should not be lower than the minimum standard of the law or industry, and must be sufficient to meet the basic needs of employees

8. Management system: The enterprise should establish a sound management system to ensure the implementation and continuous improvement of the SA8000 standard

Scope of application of the SA8000 standard The SA8000 standard applies to any industry and enterprises of different sizes around the world, including retail, consumer goods, traders and companies producing related products. It aims to monitor and promote the social responsibility performance of enterprises through continuous improvement of development policies.

One stop certification, production inspect and factory audit service in Weproving Inspection.

0 notes

Text

Mobile qc checklist

Mobile phones have become indispensable in people's daily lives, and in recent years our partners have been inspection more and more smartphones.

Details

2023 Smartphone Export Sales Ranking: China ranks first, Vietnam ranks second, and India ranks third.

The mobile phone inspection checklist includes the following main items:

1. Assembly inspection: Check the assembly of various parts of the mobile phone, including front and rear covers, battery cover, flip cover, lens, keyboard, side key, LCD, battery buckle, jack, socket, antenna, etc. The assembly gap should be uniform, without obvious deflection or looseness.

2. Appearance inspection: Check the appearance quality of the mobile phone, including lens, LCD, plastic parts, rubber parts, etc. The lens should not have defects such as stains, bubbles, scratches, etc.; plastic parts should not have insufficient filling, silver bars, flow lines, etc.; rubber parts should not have hard scratches, cracks, etc.

3. Functional inspection: Test the basic functions of the mobile phone, including camera, flash, WIFI, call function, Bluetooth connection, touch screen performance, etc. Ensure that all functions work properly.

4. Hardware inspection: Check the hardware status of the mobile phone, including whether the screws are loose, whether the label is torn, etc., to determine whether the mobile phone has been disassembled and repaired.

5. Communication performance test: Evaluate the communication performance of the mobile phone, including signal strength, call quality, network connection speed, etc., to ensure that the mobile phone performs well in communication.

6. Battery performance test: Test the battery capacity, charging speed and battery life to ensure that the battery performance meets the standards.

7. Screen performance test: Check the screen brightness, contrast, color accuracy, etc. to ensure that the screen performance is good.

8. Camera performance test: Test the camera resolution, focus speed and shooting effect to ensure that the camera performance meets the standards.

9. Operating system and software test: Evaluate the performance and stability of the mobile phone's operating system and pre-installed software.

10. Conformity assessment: Check whether the mobile phone meets the requirements of relevant standards, regulations and specifications, such as electromagnetic compatibility testing, etc.

Through the above mobile qc inspection, the quality and performance of the mobile phone can be fully evaluated to ensure that the purchased mobile phone meets the expected standards.

#electronics#qc check#product inspection#smartphone quality#mobile phone inspection#inspection company

0 notes

Text

Asia inspection service

With the frequent exchanges of international trade, overseas buyers have more and more demands for third-party inspection in Asia. Asian inspection companies have many natural advantages.

Details

In recent years, Asian manufacturing has played an important role in world trade, so overseas buyers have an increasing demand for third-party asia inspection.

Advantages of third-party asia inspection companies:

1. Strong market credibility: Third-party inspection agencies have high credibility in the trade process and can gain the trust of both buyers and sellers. Internationally renowned companies such as Carrefour and Nintendo require that suppliers' products must be tested by third-party inspection agencies, which further enhances the market credibility of third-party inspection agencies.

2. Mature technology and strong comprehensive technical service capabilities: Third-party inspection agencies are usually equipped with professional and technical personnel in various fields, and can provide comprehensive technical services to reduce the human resource costs of enterprises. For example, the electronics manufacturing industry requires electronic technical personnel, and product quality testing also requires professional technologies such as materials, machinery, and chemistry. Third-party inspection agencies can provide comprehensive technical services.

3. Market-oriented operation and wide range of services: Third-party inspection agencies adopt market-oriented operation methods, actively explore customers, and provide complete service content including technical consultation and one-stop testing. This market-oriented operation method enables third-party inspection agencies to respond quickly to market demand and expand the scope of services.

4. Cross-industry and cross-regional operations: Independent third-party testing agencies are not restricted by administrative regions and industries. They can set up branches in different regions and establish professional laboratories in different industries to achieve large-scale and rapid development. This enables third-party testing agencies to better serve customers in different industries and regions.

5. Rapid industry growth and broad development prospects: As people pay more attention to product quality and food and daily necessities safety, the third-party inspection industry is developing rapidly. Investors can seize this trend and achieve long-term and stable investment returns.

Well-known third-party asia inspection companies

1.SGS SGS is a leading global inspection. Mainly engaged in agriculture, food, mining testing, petroleum and chemical testing, consumption, certification, industrial testing, etc.

2.Bureau Veritas Founded in 1828, it mainly engages in certification, construction, agricultural products, food and other commodities, and industrial product testing.

3.Weproving Inspection Professional one stop inspection, certification, audit service. All inspectors are full-time and experienced. One day report, start from $168.

0 notes

Text

Crane Equipment Inspection

In recent years, as countries increase their investment in infrastructure construction, China's exports of excavators, cranes and other engineering equipment have also increased year by year. Overseas buyers attach great importance to the quality of mechanical equipment, so the demand for inspection of engineering equipment has also increased significantly.

Details

Key points to pay attention to in crane equipment inspection:

1. Foundation and track inspection: Check whether the gantry crane track foundation has settlement, fracture and cracking; Check the contact between the track and the track foundation to ensure that there is no hanging phenomenon; Check whether the track joints meet the requirements, generally 1-2mm, 4-6mm in cold areas; Check whether the longitudinal slope of the track meets the design requirements, generally required to be 1‰, and not more than 10mm throughout the whole process; Check whether the track gauge is over-deviation, requiring the deviation of the trolley track gauge to not exceed ±15mm.

2. Inspection of the steel structure: Check the tightness of the connection bolts of the gantry crane leg flange; Check the connection plane combination of the leg flange; Check whether the pin of the leg connection tie rod is normal, Check the tightness of the connection bolts between the lower cross beam and the leg and the connection bolts between the lower cross beams; Check the connection of the main beam connection, including the tightness of the pin or connection bolts, the deformation of the connection joint, and the condition of the welding welds at the connection joint.

3. Inspection of the trolley running part: Check the wear and cracking of the running wheels, whether there is severe deformation, whether there is severe wear or no wheel rim, whether the speed reducer lubricating oil is sufficient and the quality of the lubricating oil; check whether the reducer housing is cracked and whether there is oil leakage; check the brake clearance of the brake, the wear of the brake pads, and the wear of the brake wheel.

4. Inspection of the main lifting mechanism: Check the wear and cracking of the running wheels, whether there is severe deformation, and check the operation of the trolley running mechanism.

5. Inspection of other important components: including the performance and status of key components such as brakes, reducers, motors, couplings, etc.

Through detailed inspections in the above aspects, the safety and reliability of the crane equipment can be ensured to avoid accidents and failures during use.

Weproving Inspection not only provides 100% new mechanical engineering equipment inspection, but also provides inspection for second-hand excavators, cranes and other equipment needs.

#crane inspection#machine inspection#quality control of crane#second hand machine#inspection service#third party inspection

0 notes

Text

What is QMS?

Introduction

QMS (Quality Management System) plays an important role in enterprises. It helps enterprises improve product quality, reduce costs, enhance customer satisfaction, and ultimately improve their competitiveness and market position by standardizing, managing and improving all quality-related activities within the organization.

Details

QMS (Quality Management System) is a standard used to regulate the quality management behavior of an enterprise. It aims to improve the quality management level of the enterprise by establishing a quality management system, ensure that the quality of products and services meets the requirements, thereby winning customer trust and improving the competitiveness and reputation of the enterprise. The QMS system standard is designed based on the ISO/TS system management requirements. Its core value lies in the solidification of the continuous improvement mechanism of enterprise quality management.

QMS usually includes activities such as formulating quality policies, objectives, quality planning, quality control, quality assurance, and quality improvement. In order to effectively carry out various quality management activities, it is necessary to establish a corresponding management system, namely the quality management system. This includes a series of documents, procedures and processes that regulate and guide quality management activities within the organization.

Benefits of QMS to your company First, QMS can help enterprises better manage quality and ensure that the quality of products and services meets the expected level. Through standardized processes and standards, QMS can track quality indicators, record problems and improve processes, thereby identifying and solving potential quality problems and meeting customer needs.

Secondly, QMS also plays an important role in ensuring compliance. Many industries have specific quality standards and regulatory requirements, and QMS can help companies comply with these standards and requirements, ensure compliance in the market, and monitor the supply chain to ensure that suppliers and partners also meet relevant standards and requirements.

In addition, QMS can also improve efficiency and reduce costs. By identifying and eliminating quality problems, QMS can reduce the defect rate of products and services, reduce the cost of repair and recycling, and improve production efficiency and customer satisfaction.

Last but not least, QMS has a profound impact on the sustainable development and competitiveness of enterprises. By establishing standardized quality management processes and standards, QMS helps companies achieve quality improvements, reduce defects in products and services, and improve the consistency and reliability of delivery, thereby enhancing customer trust and satisfaction with the company and enhancing the company's competitiveness.

0 notes

Text

The importance of 2nd hand excavator inspection

As the market demand for second-hand excavators grows, the demand for second-hand excavator inspections is also increasing. Today I will introduce to you the necessity of 2nd hand excavator inspection and the relevant aspects that need attention.

Details

For start-ups or small and micro companies, choosing a second-hand excavator may be a good choice. 1. More economical Compared with new machines, the price of second-hand excavators is more advantageous, significantly reducing the initial investment cost of the company. It greatly reduces the financial pressure on individuals or start-ups. 2. Environmental protection and energy saving Using second-hand machinery can reduce resource waste and is in line with the concept of green environmental protection in the 21st century. 3. Market demand continues to expand Countries are increasing their investment in infrastructure construction, and the market demand for excavators is also increasing. In small and medium-sized engineering projects, second-hand excavators have also won more favor, providing a broad space for the sales of second-hand excavators.

Second-hand excavators have so many benefits, but companies must also pay special attention to their quality when purchasing, so it is necessary to choose a professional third-party inspection company.

The Importance of 2nd Hand Excavators 1. Ensure equipment performance and safety Through third-party inspections, ensure that the performance and safety of second-hand excavators are in compliance with regulations, and avoid safety accidents or performance deficiencies caused by equipment problems.

2. Extend equipment life Through inspections, potential problems can be discovered and solved in a timely manner, thereby extending the service life of the excavator.

3. Avoid financial losses If you buy a second-hand excavator with problems, additional repair costs will be required, which will increase costs. Through a professional inspection company, this situation can be avoided, while saving the cost of subsequent maintenance.

What to pay attention to when inspecting second-hand excavators 1. Appearance Pay attention to whether the excavator's arms, cylinders, four-wheel belts, etc. show signs of wear or damage.

2. Equipment use and maintenance history Make sure the equipment has been well maintained.

3. Engine performance inspection Listen to the engine for abnormal noise, check whether the exhaust is normal, and whether the power is strong.

4. Load test Check the performance of the excavator under load to ensure that it can meet the work requirements.

The inspection of second-hand excavators involves not only technical inspections, but also an understanding of the excavator's history and usage. Through comprehensive inspections, the purchase risk can be greatly reduced, ensuring that the purchased second-hand excavator can meet the expected use requirements and safety standards.

#production inspection#machine inspection#inspection service#qc#quality control#equipment inspection

0 notes

Text

What is 4 point system fabric inspection?

As the domestic textile industry becomes more and more developed, the amount of textile raw materials and finished products exported overseas is also increasing, and the demand for textile fabric testing is also increasing. Today I will introduce the 4-point system fabric inspection method to you.

Details

Fabric inspection, also known as fabric checking, is a comprehensive fabric evaluation that identifies fabric defects. Fabric inspection is done to understand the quality of standard aspects such as color, density, print, weight, size, etc. before mass production. Fabric inspection covers all stages of production, including intermediate and final stages. "Perching" is another term for fabric inspection.

Textile quality control is the process of checking if the materials produced meet the buyer's requirements. This usually includes the quality of the finished product as well as the yarn and fabric material. Fabric inspection is a visual inspection step in addition to performance standards; it helps to detect irregularities and flaws. Fabrics are generally graded based on quality level, fabric weight, shade color, number of flaws, and more. In addition to ensuring the quality of garments, fabric inspection can also help manufacturing companies reduce scrap accumulation and improve production efficiency.

Implementing The 4 Point System in Fabric Inspection The 4 Point System is a widely recognized and effective method for evaluating fabric defects during inspections. It provides a practical way to classify and quantify defects based on their size and severity. Here’s how to implement the 4 Point System fabric inspection:

1. Basics: The basic principle of the 4-point system. In this system, defects are mainly divided into four categories:

Category 1: Severe defects that make the fabric unusable. Category 2: Major defects that affect performance. Category 3: Minor defects. Category 4: Negligible defects that are almost invisible.

2.Tolerance Levels: Establish individual tolerance levels for defect categories based on industry standards.

3. Sampling: Select representative fabrics for inspection according to the systematic sampling. Ensure that the sample size is statistically significant.

4. Inspection process: Defects are divided into four categories according to their size and impact.

5. Calculate defect density: The total number of defects divided by the total inspection area gives the defect density value. Defect density is mainly used to evaluate the overall quality of the fabric.

6. Compare with tolerance level: Compare the defect density with the established tolerance level of the defect category. If it exceeds, it is judged as unqualified.

7. Report: Record the defect type, quantity and category in the inspection report. Attach sample photos.

8. Corrective measures: Communicate with the manufacturer to inspect the defects found in the fabric and take corrective measures.

4 point defect rating formula:

Defect rating = (total number of level 1 defects * 4) + (total number of level 2 defects * 3) + (total number of level 3 defects * 2) + (total number of level 4 defects * 1)

The higher the inspection quality of the fabric, the lower the rating.

#4 point fabric inspection#fabric check#fabric inspection#textile inspection#garment inspection#qc inspection#inspection services

0 notes