whthermal

24 posts

Don't wanna be here? Send us removal request.

Text

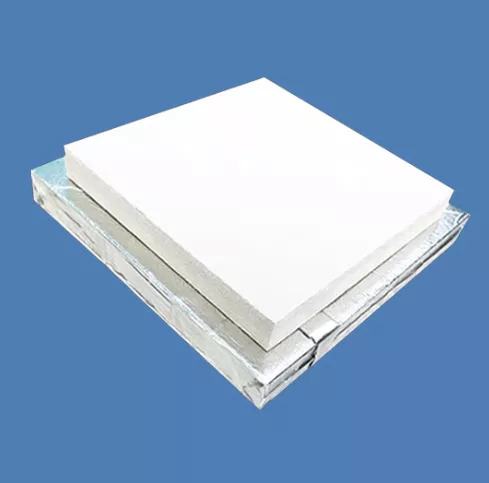

Foldable Microporous Insulation Panels – Innovative Solution Brings Thermal Protection to a Convenience

In modern industry and construction, thermal protection is of paramount importance. However, traditional insulation materials have some limitations, such as bulky, heavy and inconvenient installation. In order to break through these limitations and provide a more convenient thermal protection solution, foldable microporous insulation panels have emerged. This innovative insulation opens up new possibilities for thermal protection.

1. What is a collapsible microporous insulation board? The foldable microporous insulation panel is an innovative product made of high-performance microporous insulation materials. Its unique feature lies in its foldable design, which makes the installation and transportation process more convenient. This insulation board is composed of multiple microporous insulation blocks, which are connected together by flexible connectors to form a foldable whole.

2. Main features: Collapsible microporous insulation panels have a number of impressive features that make them ideal for thermal protection:

2.1 Lightweight and flexible: Compared with traditional insulation materials, the foldable microporous insulation board has lighter weight and flexible structure. It can be folded and unfolded according to actual needs to adapt to different installation environments and requirements.

2.2 Excellent thermal insulation performance: Although light and flexible, the foldable microporous insulation board is not inferior in thermal insulation performance. Microporous insulation material can effectively insulate heat and reduce thermal energy transfer, thus providing reliable thermal protection.

2.3 Durable and reliable: The foldable microporous insulation board is made of high-quality materials and has excellent durability and anti-aging performance. It can maintain effective thermal insulation effect for a long time and is not easily affected by the external environment.

2.4 Easy installation: Due to the foldable design, it becomes easier and faster to install the foldable microporous insulation board. By unfolding and connecting individual microporous insulation blocks, the installation process can be completed quickly, saving time and labor costs.

https://www.wh-heat-insulation.com/foldable-microporous-insulation-panels.html

0 notes

Text

Low temperature retaining material

Low temperature retaining materials are a type of material designed to effectively retain and insulate cold temperatures. These materials are used to minimize heat transfer between the low-temperature environment and the surrounding environment, thereby keeping the desired area cold and preventing heat from entering or escaping. This is particularly important in various industries and applications where temperature control is critical, such as in cold storage facilities, transportation of refrigerated goods, medical and scientific research, and even in some residential and commercial settings. The characteristics and properties of low temperature retaining materials make them highly effective in preserving cold temperatures. These materials often possess excellent thermal insulation capabilities, which help reduce heat conduction and radiation. They are also lightweight and flexible, allowing for easy installation and versatility in application. Furthermore, they are moisture-resistant and can withstand humid conditions, ensuring long-lasting insulation performance. In cold storage facilities, low temperature retaining materials are commonly used to insulate the walls, floors, and ceilings, as well as the doors and windows. These materials help maintain the desired low temperature inside the facility while reducing energy consumption by minimizing heat transfer. Similarly, in the transportation industry, such as in refrigerated trucks or containers, low temperature retaining materials are utilized to create a thermally insulated environment, preserving the cold chain and preventing the spoilage of perishable goods during transit. In the medical field, low temperature retaining materials are crucial for preserving temperature-sensitive medications, vaccines, and biological samples. Insulated containers or boxes made with these materials ensure that the contents remain at the desired low temperature, whether during storage or transportation, protecting their integrity and effectiveness. Additionally, low temperature retaining materials find applications in scientific research, particularly in laboratories and facilities that require controlled cold environments for experiments and storage of sensitive materials. They provide reliable insulation to maintain stable low temperatures, preventing undesired fluctuations that could affect the accuracy and reliability of scientific investigations. As technology advances, there is ongoing research and development in low temperature retaining materials to improve their performance and sustainability. Scientists and engineers are continually exploring new materials and designs to enhance thermal insulation properties while minimizing environmental impact. This includes designing materials that are recyclable, energy-efficient, and eco-friendly.

https://www.wh-heat-insulation.com/Low-temperature-retaining-material-id49970327.html

0 notes

Text

Ceramic Fiber Paper: Lightweight, Versatile, and High-Temperature Resistant

Ceramic fiber paper is a type of refractory material that is made from ceramic fibers and other raw materials. It is lightweight, versatile, and has excellent thermal insulation properties. Because of these characteristics, it has become an increasingly popular material in many high-temperature applications. One of the primary advantages of ceramic fiber paper is its lightweight nature. It is composed of ultrafine fibers that are woven together into a thin, flexible sheet. This makes it ideal for use in applications where weight is a concern, such as in aerospace and automotive industries. In addition to its lightweight, ceramic fiber paper is also extremely versatile. It is available in a range of thicknesses, densities, and sizes, making it suitable for use in a wide variety of applications. It can be cut, folded, and formed into various shapes and sizes, making it an excellent choice for insulation, gaskets, and seals. Finally, ceramic fiber paper is highly resistant to high temperatures. It can withstand temperatures up to 1,260°C (2,300°F) without any loss of performance. This makes it ideal for use in furnaces, kilns, boilers, and other high-temperature applications. Despite its many advantages, there are a few potential drawbacks to using ceramic fiber paper. It is relatively expensive compared to other thermal insulation materials, and it can be difficult to work with. It can also be fragile and prone to tearing, which can make it challenging to use in certain applications. In conclusion, ceramic fiber paper is a lightweight, versatile, and high-temperature resistant material that has become increasingly popular in many industrial applications. While there are some potential drawbacks to using it, its many advantages make it an excellent choice for those who require high-performance insulation products.

https://www.wh-heat-insulation.com/ceramic-fiber-paper.html

0 notes

Text

High-performance insulation materials: helping buildings save energy

In the field of construction, insulation materials play a very important role. Due to its ability to effectively insulate heat and reduce energy consumption, excellent thermal insulation materials have become representatives of technological progress and green buildings. With the development of new technologies, high-performance insulation materials have gradually become the mainstream choice in the market. Not only do they provide better thermal and thermal insulation properties, but they also contribute to building energy savings and even lower energy consumption.

High-performance insulation materials have the following characteristics:

First, they have high thermal conductivity values. High-performance insulation materials can insulate heat very effectively and minimize heat transfer, thereby greatly reducing energy consumption.

Second, they are highly compressible and ductile. Not only do these insulations adapt well to various building shapes, they can also withstand high levels of pressure and compression without losing their insulating properties. In addition, high-performance insulation materials also have good chemical stability and durability. They are resistant to all climatic conditions and environmental factors, providing long-lasting and stable thermal insulation.

In short, in terms of thermal insulation materials, high-performance thermal insulation materials are the leading trend of future building materials, which can contribute to energy saving and environmental protection of buildings.

https://www.wh-heat-insulation.com/high-performance-insulation-materials-helping-buildings-save-energy.html

0 notes

Text

Silicon heat shield: the best choice for protecting modern electronic equipment

The use of modern electronic equipment is becoming more and more extensive, and the problem of heat is becoming more and more prominent during the use of equipment. Excessive temperature will not only affect the performance of the equipment, but may also cause damage to the equipment, and even short circuit and other safety issues. Therefore, in order to better protect the equipment, people began to use various heat dissipation materials, among which Silicon heat shield was widely used and proved to be one of the best choices.

Silicon heat shield is a heat dissipation material with silicon as the main material, which has good thermal conductivity and high temperature resistance. Compared with other heat dissipation materials, Silicon heat shield has higher durability, and it is also very suitable for use in small, high-performance electronic devices, such as mobile phones, notebook computers, etc.

There are multiple benefits to using a Silicon heat shield. First of all, it can effectively reduce the temperature of the equipment and improve the stability and reliability of the equipment; secondly, it has good oxidation resistance and chemical stability, and will not produce oxidation and other phenomena that affect the performance of electronic equipment in high temperature environments ;Finally, the installation of Silicon heat shield is very simple and does not require special tools and professional skills.

Overall, Silicon heat shield is a powerful, cost-effective, and easy-to-use heat dissipation material that can effectively protect modern electronic devices and enhance their performance and reliability. Therefore, when purchasing and maintaining modern electronic equipment, we should give priority to Silicon heat shield to make our equipment work more efficiently and safely.

https://www.wh-heat-insulation.com/silicon-heat-shield-the-best-choice-for-protecting-modern-electronic-equipment.html

0 notes

Text

Ceramic Fiber Rope Specifications

Ceramic fiber rope is a high-temperature refractory material, which is widely used in various high-temperature equipment due to its excellent high-temperature resistance and chemical stability. There are many kinds of specifications of ceramic fiber rope, and the main content will be expanded below.

Specification classification

1. Diameter: The diameter of the ceramic fiber rope is usually between 1mm-50mm, and ropes with different diameters are suitable for different occasions.

2. Density: The density of the ceramic fiber rope is usually between 0.2g/cm3-0.8g/cm3, the higher the density the better the high temperature resistance.

3. Length: The length of the ceramic fiber rope can be customized according to customer needs, and the general length is between 10m-100m.

4. Shape: The shapes of ceramic fiber ropes are round, square, flat, etc. Ropes of different shapes are suitable for different occasions.

Material properties

1. High temperature resistance performance: ceramic fiber rope has excellent high temperature resistance performance and can withstand high temperatures up to 1600°C.

2. Chemical stability: Ceramic fiber rope has good chemical stability and can resist the erosion of most acids, alkalis, salts and other chemical substances.

3. Wear resistance: Ceramic fiber rope has very good wear resistance and can withstand long-term friction and wear.

4. Corrosion resistance: Ceramic fiber rope has good corrosion resistance and can resist the erosion of most corrosive substances.

Application field

1. Furnace seal: ceramic fiber rope can be used for the seal of furnace, which can effectively prevent gas leakage in the furnace.

2. Pipe insulation: ceramic fiber rope can be used for pipe insulation, which can effectively prevent heat loss.

3. Power equipment: ceramic fiber rope can be used for insulation of power equipment, which can effectively prevent electrical components from being affected by high temperature.

https://www.wh-heat-insulation.com/ceramic-fiber-rope-specifications.html

0 notes

Text

Insulating Materials for Pipes: A Comprehensive Guide

Insulating pipes is an essential part of any construction project. Not only does insulation improve energy efficiency, but it also helps to reduce noise and protect against heat loss. With so many different types of insulation materials available, it can be difficult to know which one is best for your particular application. This guide will provide you with an overview of the most common insulation materials used for pipes, to help you select the best option for your needs.

The most popular insulation material for pipes is fiberglass. Fiberglass is known for its excellent resistance to heat, and it's a popular choice for both industrial and residential applications. It's also relatively lightweight and easy to work with, making it a great option for insulating long runs of piping. Some downsides include the potential for fiberglass fibers to cause skin and eye irritation, as well as the limited ability to withstand high temperatures. Another popular insulation material for pipes is styrofoam. Styrofoam is lightweight and relatively easy to install, making it a great choice for residential applications. It can even be molded to fit the shape of your pipes, allowing you to get a snug fit. Unfortunately, it is not very resistant to high temperatures so it's not suitable for applications where pipes are exposed to extreme heat. Insulated metallic wraps are another great insulation material for pipes. These wraps are made out of a variety of materials, such as aluminum, steel, copper, or stainless steel, and they help to protect pipes from extreme temperatures. They're also extremely durable and can easily be cut to any desired size. The downside to these wraps is that they tend to be quite expensive compared to fiberglass and styrofoam.No matter what type of insulation material you choose for your pipes, it's important to ensure it is installed properly. Improper installation can result in an increase in energy usage, and it can also put the occupants of a building at risk of carbon monoxide emissions if the insulation is not fire-resistant. If you have any concerns about the installation process, it's best to consult a professional before proceeding.

Now that you know more about the different types of insulation materials available for pipes, you can make an informed decision for your particular application. Whether you choose fiberglass, styrofoam, or insulated metallic wraps, you can rest assured knowing that your pipes are properly protected.

https://www.wh-heat-insulation.com/insulating-materials-for-pipes.html

0 notes

Text

Insulation Material for Furnace

There are many insulation materials for furnace on the market, and each type has its own advantages and disadvantages.

The most popular types are fiberglass, rock wool, and cellulose.Fiberglass is made of tiny glass fibers and is the most popular type of insulation. It is available as loose-fill, batts, or blankets. It is easy to install and has a high R-value, but it can be a fire hazard.Rock wool is made of small rocks and is a good choice for people with allergies. It is available as batts or blankets and has a high R-value. It is not a fire hazard, but it can be a little difficult to install.

Cellulose is made of recycled paper and is a good choice for people who want to save money. It is available as loose-fill, batts, or blankets. It has a medium R-value, and it is not a fire hazard.

https://www.wh-heat-insulation.com/Insulation-Material-for-Furnace-id47030937.html

0 notes

Text

Ceramic Fiber Cloth – An Essential Material for High Temperature Applications

Ceramic fiber cloth is a high-temperature insulation material that is used for a wide range of applications in various industries such as aerospace, automotive, energy, and petrochemical. This material is composed of ceramic fibers that have been woven into a cloth-like material. It has the ability to resist temperatures up to 2300°F (1260°C). This makes it a great choice for applications that require high-temperature insulation.Ceramic fiber cloth is lightweight and flexible, making it easy to install in tight spaces. It is also resistant to most chemicals, including acids and alkalis. This makes it ideal for applications that require high levels of chemical resistance.Furthermore, it is non-combustible and has excellent thermal insulation properties.

Ceramic fiber cloth is available in a range of sizes and thicknesses, allowing it to be used in a variety of applications. It is often used as an insulation material in industrial ovens and furnaces, as well as in heat exchangers. It is also used in high-temperature gaskets, seals, and filters.Ceramic fiber cloth is also used for industrial insulation applications. It is often used as a protective jacketing material for pipes and vessels, as well as for insulation in boilers and other high-temperature equipment. It is also used as an acoustic insulation material in soundproofing applications.

Ceramic fiber cloth is an essential material for high-temperature applications. It is lightweight, flexible, and resistant to most chemicals. It also has excellent thermal insulation properties. This makes it a great choice for applications that require high-temperature insulation and chemical resistance.

https://www.wh-heat-insulation.com/ceramic-fiber-cloth.html

0 notes

Text

Ceramic Fiber Board: A Versatile Refractory Material

Ceramic fiber board is a general-purpose high-temperature refractory material. It is a kind of refractory material that is precisely mixed with various fibers. It is often used in high-temperature heat treatment, metallurgy and petroleum processing industries. It has good fire resistance and good thermal stability, can withstand high temperature, high pressure and corrosive environment, and can effectively protect equipment and facilities from damage.

The main feature of Ceramic fiber board is that it is suitable for high temperature environment, has good fire resistance and good thermal stability. Its fire-resistant temperature ranges from 1425°C to 1700°C, and its fire-resistant performance is very good. It has low moisture absorption rate and low thermal expansion coefficient, which can effectively reduce the temperature changes of equipment and facilities, making the equipment more stable and reliable. In addition, it has good heat insulation performance, can effectively hinder the transfer of heat energy, and protect metal equipment and pipelines from high temperature damage.

Ceramic fiber board also has good chemical stability, can withstand the erosion of various corrosive environments, has good corrosion resistance and water resistance, and can effectively prevent damage to equipment and facilities by corrosive media. Another advantage of ceramic fiber board is that it has good mechanical properties, can withstand various external forces, and prevent external forces from destroying equipment and facilities. It has a high surface hardness, is not easily damaged by external forces, has good wear resistance, and can effectively resist wear. It also has good insulation and flexibility, can withstand various impacts, and can effectively protect equipment and facilities from external damage. In conclusion, Ceramic fiber board is a multifunctional refractory material with good fire resistance, good thermal stability, good corrosion resistance and water resistance, good mechanical properties as well as good insulation and flexibility. Therefore, Ceramic fiber board is widely used in high-temperature heat treatment, metallurgy and petroleum processing industries, which can effectively protect equipment and facilities from damage.

https://www.wh-heat-insulation.com/Ceramic-Fiber-Board-A-Versatile-Refractory-Material-id44522137.html

0 notes

Text

Silica aerogels play a role in the preparation of thermally insulating coated fabrics

Thermal insulation coated fabric is a coating with thermal insulation effect on the surface of the fabric, by blocking, reflecting or radiating solar energy, to achieve the purpose of reducing the internal temperature of the fabric covering and reducing energy consumption, it has a wide range of applications in the textile industry prospect. According to the thermal insulation mechanism, fabric thermal insulation coatings can be divided into three types: barrier type, reflective type and radiation type. Barrier thermal insulation coating is a passive cooling coating that achieves thermal insulation through the resistance of heat transfer. In order to obtain good thermal insulation effect, it usually has the characteristics of relatively low bulk density, low thermal conductivity, and low dielectric constant. Reflective thermal insulation coating isolates sunlight energy through reflection. Commonly used reflective materials include ceramic micropowder, aluminum powder, titanium dioxide and ATO (antimony-doped tin dioxide) powder. Common barrier fabric thermal insulation coating agents are divided into chemical structures, mainly including polyvinyl chloride (PVC), polyacrylate (PA), polyurethane (PU), silicone, rubber emulsion and PTFE Ethylene, etc., among which PA and PU are widely used; according to the medium used, they can be divided into two types: solvent type and water dispersion type. As an amorphous nanoporous material, SiO2 aerogel has a controllable structure and a continuous three-dimensional network structure. And its density is adjustable between 3-500mg/cm3, it is a solid material with the lowest density in the world, the porosity can reach 80%-99.8%, the pore size is between 1-100nm, and the specific surface area can be as high as 1000m2/ g. Due to the unique nanoporous structure, its thermal conductivity is extremely low, and the thermal conductivity is as low as 0.017W/(m·K) under normal temperature and pressure, which is the lowest thermal conductivity of solid materials known so far. Since the structural units constituting the aerogel skeleton are smaller than the wavelength of visible light, it also has better light transmission properties. At the same time, it is an inorganic material with non-combustible or flame-retardant effect, and has wide application prospects in the field of thermal insulation. According to statistics, in recent years, the compound annual growth rate of the global aerogel market size is 36.4%, while the compound annual growth rate of the domestic aerogel market is as high as 61.1%. Its application in thermal insulation fabrics can not only reduce the weight of thermal protective clothing, make it lighter and thinner, but also greatly reduce work loss during use. For example, SiO2 aerogel can be added to PA or PU adhesives according to a certain proportion to obtain a thermal insulation coating agent, and the cotton fabric can be directly coated, and then the process of drying and baking can be carried out. Preparation of SiO2 Aerogel Thermal Insulation Coated Fabrics. Compared with the original fabric, the thermal insulation performance of the coated fabric with SiO2 aerogel is significantly improved, and when the amount of aerogel added in the coating agent is less than 10%, the thermal insulation effect of the fabric increases with the amount of SiO2 aerogel added. increases and gradually improves. In addition, glass fiber SiO2 aerogel felt can also be selected as the material of the fabric insulation layer. Its thermal protection performance is greater than 60, and it can withstand high temperature flame combustion at 450 ° C for 50s, which significantly improves the thermal protection performance of the fabric, and can resist firefighting. instantaneous high temperature. SiO2 aerogel has the characteristics of high porosity and low thermal conductivity, making it a new type of super insulating material. However, the flexibility and integrity of SiO2 aerogels are poor, and the thermal conductivity of aerogels prepared by drying at room temperature increases rapidly at high temperatures, which greatly limits the application of SiO2 aerogels. In recent years, SiO2 aerogel composite thermal insulation materials prepared by in-situ sol-gel method and molding method have improved their toughness, integrity and high-temperature thermal insulation performance to a certain extent, making SiO2 aerogels. It is possible as a single block insulation material.

https://www.wh-heat-insulation.com/thermally-insulating-coated-fabrics.html

0 notes

Text

What is Foldable Microporous Insulation Panel?

Foldable Microporous Insulation Panel is an insulation material made of microporous insulation foam. It is a lightweight, foldable and easy-to-install insulation panel. The microporous insulation foam is a closed-cell foam with millions of small pores. The small pores create a high insulation value and make the foam resistant to moisture and mold.

The foldable panel is made of a thin layer of insulation foam bonded to a rigid backer. The backer can be a sheet of plywood or a piece of extruded polystyrene foam. The panel can be folded to fit into a small space for storage and transportation. When it is time to install the panel, it can be unfolded and quickly attached to the wall or roof. The foldable microporous insulation panel is a great choice for insulating residential and commercial buildings. It is a quick, easy and affordable way to improve the energy efficiency of your home or office.

https://www.wh-heat-insulation.com/what-is-foldable-microporous-insulation-panel.html

0 notes

Text

The advantages of low temperature retaining material

Low temperature retaining material has the advantages of low temperature, small size and light weight. It can be used in a variety of fields, such as aerospace, military, medical and electronics.Low temperature retaining material can be used in aerospace to maintain the temperature of the aircraft and improve the efficiency of the aircraft. In the military, it can be used to maintain the temperature of the weapons and improve the accuracy of the weapons. In medical applications, it can be used to maintain the temperature of the body and improve the accuracy of the surgery. In the electronics field, it can be used to maintain the temperature of the chips and improve the efficiency of the chips.

Low temperature retaining material is a new and promising material with a variety of applications. It has the advantages of low temperature, small size and light weight, which makes it a promising material for a variety of applications.

https://www.wh-heat-insulation.com/The-advantages-of-low-temperature-retaining-material-id40271637.html

0 notes

Text

Matters need attention when use insulation sleeve for high temperature

Insulation sleeve for high temperature is a kind of insulation material which is mainly used to prevent the heat loss and heat radiation of equipments and pipelines. When using insulation sleeve for high temperature, we should pay attention to the following points: 1. The insulation sleeve for high temperature should be selected according to the requirements of the equipments and pipelines. 2. The installation of insulation sleeve for high temperature should be neat and tidy. 3. The insulation sleeve for high temperature should be kept clean and dry. 4. The insulation sleeve for high temperature should be regularly inspected and maintained.

https://www.wh-heat-insulation.com/Matters-need-attention-when-use-insulation-sleeve-for-high-temperature-id45089737.html

0 notes

Text

The features of silicon heat shield

Silicon heat shield is made of silicon, a very good heat conductor. It is a thin, flat, rectangular piece of silicon with a hole in the middle. The hole is the same size as the object that is to be protected.The silicon heat shield is placed between the object and the heat source. The heat is conducted through the silicon to the object, protecting it from the heat. The silicon heat shield can be used to protect objects from heat sources such as ovens, stoves, and fires.The silicon heat shield is very thin and lightweight, making it easy to use. It is also very durable and can be used over and over again.

https://www.wh-heat-insulation.com/The-features-of-silicon-heat-shield-id46867737.html

0 notes

Text

The advantages of aerogel insulation materials

Aerogel insulation materials have many advantages: 1. Low thermal conductivity: Aerogel insulation materials have the lowest thermal conductivity of any known insulation material. This means that they are very effective at preventing heat transfer, making them an ideal choice for insulation. 2. Lightweight: Aerogel insulation materials are very lightweight, making them easy to transport and install. 3. Durable: Aerogel insulation materials are highly durable and can withstand extreme temperatures and weather conditions. 4. Inexpensive: Aerogel insulation materials are relatively inexpensive compared to other insulation materials. 5. Non-toxic: Aerogel insulation materials are non-toxic and safe to use.

https://www.wh-heat-insulation.com/The-advantages-of-aerogel-insulation-materials-id43403947.html

0 notes

Text

What is flexible insulation panel

Flexible insulation panels are a type of insulation material that is designed to be flexible and easy to install. They are typically made from a combination of foam, plastic, and other materials, and can be used to insulate walls, floors, ceilings, and other areas of a home or building. Flexible insulation panels are often used in areas where traditional insulation materials may not be suitable, such as in tight spaces or around curved surfaces. They are also often used in areas where traditional insulation materials may not provide enough insulation, such as in attics or crawl spaces.

https://www.wh-heat-insulation.com/What-is-flexible-insulation-panel-id41914047.html

0 notes