Don't wanna be here? Send us removal request.

Text

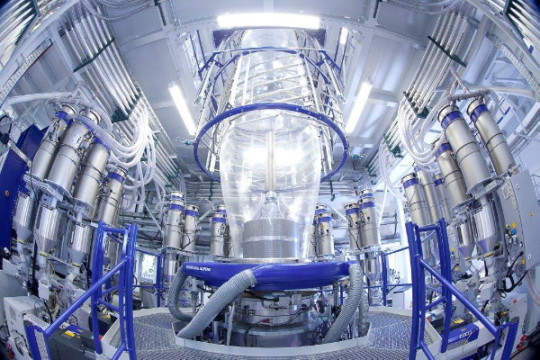

High-Quality Injection Moulding Machines for Prototypes and Mass Production

Quality is key when it comes to injection moulding machines. Our expert team ensures that all our moulding machines meet strict quality standards. Whether you're creating prototypes or scaling up for mass production, our plastic moulding solutions will meet your exact specifications. Let us help you find the right equipment for your business needs.

0 notes

Text

Plastic Injection Molding Machine: Revolutionizing Manufacturing Processes

A Plastic Injection Molding Machine is a pivotal tool in modern manufacturing, enabling the efficient and precise production of plastic components. This article delves into the intricate details of these machines, exploring their functionalities, types, applications, and the impact they have on various industries.

The Process of Plastic Injection Molding

The injection molding process is a complex sequence of events that transforms raw plastic material into a final product. Understanding the step-by-step guide to this process provides insights into the capabilities of Plastic Injection Molding Machines.

Types of Plastic Injection Molding Machines

Plastic molding is not a one-size-fits-all operation. There are various types of molding machines, each designed for specific applications. From hydraulic and electric machines to hybrid models, this section provides an overview of their features and best-use scenarios.

Key Components and Features

To comprehend the functioning of Plastic Injection Molding Machines, it's essential to dissect the machine's key components. This section offers a detailed analysis of components such as the injection unit, clamping unit, and the crucial role they play in the overall process.

Advantages of Plastic Injection Molding

Efficiency, precision, and cost-effectiveness are the cornerstones of plastic injection molding. This segment highlights the numerous advantages of utilizing these machines, from high production rates to minimal material wastage.

Applications in Various Industries

Plastic Injection Molding Machines find applications in diverse industries, including automotive, medical, consumer goods, and more. Their versatility and ability to produce intricate parts make them indispensable in the manufacturing sector.

Choosing the Right Machine for Your Needs

Selecting the appropriate molding machine is a critical decision. Factors such as material type, production volume, and part complexity play a role. This section guides manufacturers in making informed choices tailored to their specific requirements.

Maintenance and Troubleshooting

Proper maintenance is vital for the longevity and efficiency of Plastic Injection Molding Machines. This part offers practical tips on machine upkeep and addresses common issues that may arise during operation.

Industry Trends and Innovations

The plastic molding sector is dynamic, with continuous technological advancements. Explore emerging trends such as automation, 3D printing, and smart manufacturing, shaping the future landscape of plastic injection molding.

Environmental Impact

As sustainability becomes a global focus, understanding the environmental impact of manufacturing processes is crucial. Learn about sustainable practices in plastic injection molding and how these machines are adapting to reduce their ecological footprint.

FAQs about Plastic Injection Molding

Q: What is the typical cycle time for injection molding? The cycle time varies based on factors such as material, part complexity, and machine specifications. However, it typically ranges from a few seconds to a few minutes.

Q: Can one machine handle multiple materials? Some advanced machines support multiple materials through the use of dual injection units, allowing for versatility in production.

Q: How can I prevent defects in the molded parts? Proper machine calibration, quality material selection, and regular maintenance contribute to defect prevention. Attention to detail in the molding process is crucial.

Q: Are there size limitations for parts produced by injection molding? While there are size limitations, many machines can produce large and complex parts. It's essential to choose a machine that aligns with the size requirements of the intended products.

Q: What industries benefit the most from plastic injection molding? Industries such as automotive, healthcare, packaging, and consumer goods extensively benefit from the precision and efficiency of plastic injection molding.

Q: How do I choose between hydraulic and electric machines? Consider factors like energy efficiency, production volume, and initial cost. Hydraulic machines are robust and cost-effective for certain applications, while electric machines offer higher precision and energy efficiency.

Future Outlook

The future of plastic injection molding is marked by continuous innovation. Anticipate advancements in materials, automation, and sustainability, shaping a more efficient and environmentally conscious industry.

0 notes

Text

Pipe Extrusion Lines Manufacturers | Windsor International Sales: Revolutionizing the Pipe Manufacturing Industry

In today's rapidly evolving world, the demand for high-quality pipes is on the rise. From plumbing systems to industrial applications, pipes play a crucial role in various sectors. To meet this growing demand, pipe extrusion lines have emerged as a game-changer in the pipe manufacturing industry. Among the leading manufacturers in this field, Windsor International Sales stands out for its innovative solutions and commitment to excellence. In this blog post, we will explore the significance of pipe extrusion lines, the role of manufacturers like Windsor International Sales, and how they are revolutionizing the pipe manufacturing industry.

1. Understanding Pipe Extrusion Lines:

Pipe extrusion lines are advanced machinery used to manufacture pipes of various sizes and materials. These lines consist of multiple components, including an extruder, die head, cooling system, haul-off unit, and cutting system. The process begins with the extruder, which melts the raw material, typically plastic, and pushes it through the diehead to form the desired pipe shape. The cooling system then solidifies the molten material, and the haul-off unit pulls the pipe at a controlled speed. Finally, the cutting system trims the pipe to the required length. This seamless and efficient process ensures the production of high-quality pipes with consistent dimensions.

2. The Role of Pipe Extrusion Lines Manufacturers:

Pipe extrusion line manufacturers, such as Windsor International Sales, play a pivotal role in the pipe manufacturing industry. They design, develop, and produce state-of-the-art machinery that meets the diverse needs of pipe manufacturers worldwide. These manufacturers invest heavily in research and development to stay at the forefront of technological advancements. By continuously improving their products, they enable pipe manufacturers to enhance their production capabilities, reduce costs, and deliver superior quality pipes to their customers.

3. Windsor International Sales: A Leader in Pipe Extrusion Lines:

Windsor International Sales has established itself as a leader in the field of pipe extrusion line manufacturing. With decades of experience and a strong focus on innovation, Windsor International Sales has earned a reputation for delivering cutting-edge technology and unmatched quality. Their pipe extrusion lines are known for their precision, reliability, and efficiency. Whether it's PVC pipes, HDPE pipes, or any other type of plastic pipes, Windsor International Sales offers customized solutions to meet the specific requirements of their clients.

4. Advantages of Windsor International Sales' Pipe Extrusion Lines:

4.1. Enhanced Productivity: Windsor International Sales' pipe extrusion lines are designed to maximize productivity. With features like automatic control systems, high-speed extruders, and efficient cooling systems, these lines enable manufacturers to produce pipes at a faster rate without compromising on quality.

4.2. Cost Efficiency: By incorporating energy-saving technologies and optimizing the production process, Windsor International Sales' pipe extrusion lines help manufacturers reduce operational costs. The efficient use of raw materials and the elimination of manual labor-intensive tasks contribute to significant cost savings.

4.3. Superior Quality: The precision engineering and advanced technology used in Windsor International Sales' pipe extrusion lines ensure the production of pipes with consistent dimensions, smooth surfaces, and excellent mechanical properties. This results in pipes that meet the highest quality standards and exceed customer expectations.

5. The Future of Pipe Manufacturing:

As the demand for pipes continues to grow, the role of pipe extrusion line manufacturers like Windsor International Sales becomes even more critical. With ongoing advancements in technology, we can expect further innovations in pipe extrusion lines, such as improved automation, integration of artificial intelligence, and enhanced sustainability. These developments will not only streamline the manufacturing process but also contribute to a more sustainable and eco-friendly pipe manufacturing industry.

Conclusion:

Pipe extrusion lines have revolutionized the pipe manufacturing industry, enabling manufacturers to meet the increasing demand for high-quality pipes. Manufacturers like Windsor International Sales have played a significant role in this revolution by providing cutting-edge technology and unmatched quality in their pipe extrusion lines. With its commitment to innovation and customer satisfaction, Windsor International Sales continues to lead the way in the industry. As we look to the future, we can expect further advancements in pipe extrusion lines, shaping the pipe manufacturing industry for years to come.

0 notes

Text

Discover High-Quality Blown Film Extrusion Solutions at Windsor: Unveiling the Power of a Reliable Sales Network

Blown film extrusion is a widely used manufacturing process that involves the creation of plastic films for various applications. As the demand for high-quality films continues to rise, finding a reliable blown film extrusion manufacturer becomes crucial. In this blog post, we will explore the exceptional blown film extrusion solutions offered by Windsor, a leading manufacturer in the industry. We will also delve into the significance of their domestic sales network, which ensures top-notch products and reliable service.

Unleashing the Potential of Blown Film Extrusion: Windsor's Cutting-Edge Solutions

The Art of Blown Film Extrusion: Blown film extrusion is a versatile process that involves the transformation of plastic resins into thin films. These films find applications in packaging, agriculture, construction, and many other industries. Windsor, a renowned blown film extrusion manufacturer, has mastered this art and offers a wide range of solutions to meet diverse customer needs.

Unparalleled Quality and Innovation: Windsor takes pride in its commitment to delivering high-quality products. Their blown film extrusion solutions are designed to meet the most stringent industry standards. By leveraging advanced technology and innovative techniques, Windsor ensures that their films possess excellent strength, durability, and barrier properties. Whether it's for food packaging, medical applications, or industrial purposes, Windsor's films provide optimal performance and reliability.

The Windsor Advantage: What sets Windsor apart from other blown film extrusion manufacturers is their unwavering dedication to customer satisfaction. With decades of experience in the industry, Windsor understands the unique requirements of each customer. They work closely with clients to develop customized solutions that cater to their specific needs. From film thickness and width to color and printing options, Windsor offers a comprehensive range of choices to ensure customer satisfaction.

The Power of a Reliable Sales Network: Windsor's domestic sales network plays a pivotal role in their success. With a widespread network of sales representatives across the country, Windsor ensures that their products are easily accessible to customers. This network enables them to provide prompt and efficient service, addressing customer queries and concerns in a timely manner. By establishing strong relationships with their customers, Windsor builds trust and loyalty, making them the preferred choice for blown film extrusion solutions.

Unmatched Customer Support: Windsor's commitment to customer satisfaction extends beyond the sale of their products. Their dedicated customer support team is always ready to assist clients with any technical or operational issues. Whether it's troubleshooting, product recommendations, or after-sales service, Windsor goes the extra mile to ensure that their customers receive the support they need. This level of commitment has earned them a reputation for reliability and excellence in the industry.

Sustainability and Environmental Responsibility: In today's world, sustainability is a key consideration for businesses. Windsor recognizes the importance of environmental responsibility and strives to minimize their ecological footprint. They employ eco-friendly manufacturing practices, use recyclable materials, and invest in research and development to create films that are both high-performing and environmentally conscious. By choosing Windsor as your blown film extrusion manufacturer, you contribute to a greener future.

Conclusion: When it comes to blown film extrusion, Windsor stands out as a reliable and innovative manufacturer. Their commitment to quality, customer satisfaction, and environmental responsibility sets them apart from the competition. With a robust domestic sales network and unmatched customer support, Windsor ensures that their high-quality blown film extrusion solutions are readily available to customers across the country. Choose Windsor for your film extrusion needs and experience the power of a reliable sales network.

0 notes

Text

Plastic Injection Moulding Machine: The Secret Weapon Every Manufacturer Needs

1. Let's talk about Plastic Injection Moulding Machines!

Hey there, manufacturers! Looking for the secret weapon to boost your productivity and profits? Look no further than the plastic injection moulding machine. This amazing piece of technology has revolutionized the manufacturing industry, allowing for faster, more precise, and cost-effective production of plastic parts. Whether you're in the automotive, electronics, or consumer goods industry, a plastic injection moulding machine is your ticket to success. Don't believe us? Keep reading to discover the incredible benefits of this game-changing machine!

2. Why every manufacturer needs one!

Let's dive deeper into why every manufacturer needs a plastic injection moulding machine. Firstly, efficiency is the name of the game. With this machine, you can produce large quantities of plastic parts in a short period of time, eliminating the need for time-consuming manual labor. Not only does this save you time, but it also reduces costs and increases overall productivity.

Secondly, the precision of the plastic injection moulding machine cannot be underestimated. It ensures that every part produced is consistent in shape, size, and quality, resulting in satisfied customers and fewer product defects. This level of precision is crucial, especially in industries where accuracy is paramount, like the medical or aerospace sectors.

Lastly, purchasing a plastic injection moulding machine is a long-term investment that pays off in the long run. Not only does it offer a significant return on investment, but it also provides manufacturers with a competitive edge, enabling them to meet customer demands efficiently and stay ahead of the competition.

So, if you're a manufacturer looking to boost your productivity, lower costs, and enhance the quality of your products, a plastic injection moulding machine is your secret weapon! Say goodbye to traditional manufacturing methods and say hello to the future of production.

3. The benefits of a Plastic Injection Moulding Machine

The benefits of a plastic injection moulding machine are numerous and go beyond just efficiency and precision. Let's explore some of the additional advantages that make this machine a must-have for manufacturers.

One benefit is flexibility. Plastic injection moulding machines are highly versatile and can be used to produce a wide range of products in different shapes, sizes, and materials. This means that manufacturers can easily adapt to changing market demands and produce customized products to meet their customers' unique requirements.

Another advantage is waste reduction. With traditional manufacturing methods, there is often a significant amount of material waste. However, with a plastic injection moulding machine, the process is carefully controlled, and the amount of material used can be optimized, leading to minimal waste. This not only saves costs but also reduces the environmental impact of production.

Furthermore, the automated nature of the plastic injection moulding machine leads to consistent quality control. Each part produced is subjected to the same controlled process, ensuring that the final product meets the highest standards. This consistent quality builds customer trust and leads to improved brand reputation.

In the next section, we will delve into the different types of plastic injection moulding machines available in the market and how to choose the right one for your manufacturing needs. Stay tuned!

4. Where to find the best machines in town!

Now that we have established the advantages of a plastic injection moulding machine, the next step is to find the best machines in town. With numerous manufacturers and suppliers in the market, it can be overwhelming to make the right choice.

One option is to explore local suppliers who specialize in plastic injection moulding machines. These suppliers often have a wide range of machines available, catering to different production needs and budgets. You can visit their showrooms, discuss your requirements with their experts, and even witness a demonstration to get a better understanding of the machine's capabilities.

Another option is to research online suppliers. Many reputable companies offer plastic injection moulding machines on their websites. You can browse through their catalogue, compare different models, and read customer reviews to make an informed decision.

Additionally, attending industry trade shows and exhibitions can also provide valuable insights into the latest machines available in the market. You can network with experts, gather information, and even witness live demonstrations.

In the next section, we will discuss the key factors to consider while choosing a plastic injection moulding machine. Stay tuned to discover how to make the best investment for your manufacturing needs!

5. Let's get started with Plastic Injection Moulding!

Now that you have found some options for purchasing a plastic injection moulding machine, it's time to dive into the process of actually using one. In this section, we will cover the basics of plastic injection moulding to get you started on your manufacturing journey.

Firstly, it's important to understand the core components of a plastic injection moulding machine. These include the hopper, barrel, screw, nozzle, mould, and clamping unit. Each component plays a crucial role in the injection moulding process, from melting and injecting the plastic material to shaping it within the mould.

Before you begin using the machine, it's essential to select the right material for your product. The choice of material will depend on factors such as the desired properties of the final product, its intended use, and the manufacturing cost. Common materials used in plastic injection moulding include polyethylene, polypropylene, polystyrene, and PVC.

Once you have selected the material, it's time to set up the machine. This involves adjusting the temperature and pressure settings to achieve the desired melt and injection conditions for the chosen material. It's important to follow the manufacturer's guidelines and refer to any technical documentation provided with the machine.

Now, you're ready to start the plastic injection moulding process. The machine will melt the plastic material in the barrel, then inject it into the mould under high pressure. The mould, which is designed to shape the final product, will then cool down and solidify the plastic.

Keep in mind that the success of the injection moulding process depends on several factors, such as the quality of the machine, the expertise of the operator, and the design of the mould. It may take some trial and error to achieve the desired results, but with practice and experience, you will be able to produce high-quality plastic products efficiently.

In the next section, we will delve deeper into troubleshooting common issues that may arise during plastic injection moulding. Stay tuned to learn how to overcome challenges and optimize your production process.

6. Wrap it up and start producing!

Now that you have a basic understanding of the plastic injection moulding process, it's time to wrap it up and start producing! With the right knowledge and equipment, you can now turn your ideas into reality.

Before you begin production, it's important to ensure that all the necessary safety precautions are in place. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety goggles. Remember, working with a plastic injection moulding machine involves high temperatures and pressures, so safety should always be a top priority.

Once you have taken the necessary safety measures, it's time to set up the mould and prepare for production. Ensure that the mould is properly secured in the clamping unit and that it is clean and free from any debris or contaminants. This will help to ensure that your final product is of high quality.

Next, it's time to load the chosen plastic material into the hopper. The material will then be fed into the barrel, where it will undergo the melting process. Make sure to monitor the temperature and pressure settings closely to maintain optimal conditions for the material.

Once the plastic material is melted, it will be injected into the mould under high pressure. The mould will then cool down and solidify the plastic, shaping it into the desired product. It's important to monitor the injection pressure and cycle time to ensure consistent and accurate results.

As you start producing, it's normal to encounter some challenges and issues along the way. This could include issues such as air bubbles, warping, or inconsistent dimensions. Don't be discouraged! Troubleshooting is a part of the learning process, and with time and experience, you will become more adept at identifying and resolving these issues.

Remember to keep good records of your production runs, including settings, materials used, and any troubleshooting steps taken. This will help you track your progress and make improvements over time.

So, with your plastic injection moulding machine ready and your skills honed, it's time to unleash your creativity and start manufacturing. Whether you're producing small components or large-scale products, the possibilities are endless. Embrace the challenges, learn from your mistakes, and enjoy the satisfaction of seeing your products come to life. Happy moulding!

7. Happy Manufacturing!

Now that you have all the necessary information and tools, it's time to get down to business and start manufacturing! With your plastic injection moulding machine at your disposal, the possibilities are endless. Whether you're producing small components or large-scale products, this is your chance to unleash your creativity and bring your ideas to life.

As you embark on this manufacturing journey, remember that challenges may arise along the way. From air bubbles to warping and inconsistent dimensions, troubleshooting is a normal part of the learning process. Don't be discouraged! With time and experience, you will become more adept at identifying and resolving these issues.

To keep track of your progress and make improvements over time, it's important to maintain good records. Keep a detailed log of your production runs, including settings, materials used, and any troubleshooting steps taken. This will help you understand your process better and make necessary adjustments.

So, roll up your sleeves, put on your gloves and safety goggles, and get ready to experience the satisfaction of seeing your products come to life. Happy manufacturing!

1 note

·

View note

Text

Plastic Injection Molding Machine: The Coolest Thing You Never Knew You Needed

1. Hey there, let's talk about something super cool!

Hey there, ever heard of a plastic injection molding machine? If not, get ready to have your mind blown. This incredible device is the secret behind the production of so many items in our everyday lives, from toys to car parts. It's like a magic box that turns molten plastic into any shape you can imagine. Trust me, once you learn about the wonders of plastic injection molding, you'll wonder how you ever lived without it. So, buckle up and prepare to be amazed!

2. What on earth is a plastic injection molding machine?

Well, let me break it down for you. A plastic injection molding machine is like a magician's workshop. It's a fantastic piece of technology that enables manufacturers to create products with precision and efficiency.

So, how does it work? Here's the lowdown: First, the machine heats up plastic pellets until they melt into a molten liquid. Then, it injects this liquid into a mold, which is like a custom-made container that determines the shape of the final product. Once the plastic cools and hardens inside the mold, it's ejected, and voila - you have a perfectly molded item!

It's mind-boggling how versatile these machines are. They can produce anything from tiny components to large-scale products. Plus, they're incredibly fast, capable of churning out thousands of items in a matter of hours.

Trust me, once you see a plastic injection molding machine in action, you'll be in awe of its capabilities. Stay tuned to find out more fascinating facts about this amazing invention!

3. The insane uses and benefits of having one

Now that you know how a plastic injection molding machine works, you'll be amazed to learn about the insane uses and benefits of having one.

First off, these machines have revolutionized the manufacturing industry. They have made it possible to create complex and intricate shapes that were once difficult or impossible to produce. From automotive parts to household appliances, the possibilities are endless.

One of the biggest benefits of using a plastic injection molding machine is the efficiency it offers. With its high-speed production capabilities, manufacturers can produce large quantities of items in a short amount of time. This not only increases productivity but also reduces production costs, making it a cost-effective solution for businesses.

Another benefit is the consistency and precision these machines offer. The molds used in the process ensure uniformity in the final products, eliminating any variations or defects. This means you can expect high-quality and reliable items every time.

Furthermore, these machines are environmentally friendly. The ability to recycle and reuse plastic materials reduces waste and promotes sustainability. Additionally, the energy-efficient nature of these machines reduces energy consumption and lowers carbon emissions.

In conclusion, a plastic injection molding machine is not only a cool invention, but it also has numerous uses and benefits. From enabling complex shapes to increasing production efficiency, these machines have transformed the manufacturing industry. Stay tuned for the next section where we'll dive deeper into the fascinating world of plastic injection molding machines.

4. Where can you get your hands on one? (Spoiler alert: they're not as expensive as you think!)

Where can you get your hands on one? (Spoiler alert: they're not as expensive as you think!)

Now that you're sold on the idea of owning a plastic injection molding machine, you're probably wondering where you can find one. The good news is, these machines are more accessible than ever before.

You may be surprised to learn that there are many companies that specialize in selling plastic injection molding machines. These companies offer a wide range of options to suit different budgets and production needs. From small desktop machines for hobbyists to large industrial machines for mass production, there's something for everyone.

If you're just starting out or have a limited budget, you can consider buying a used machine. Many manufacturers and businesses sell their old machines at a fraction of the cost of a new one. Just make sure to do your research and inspect the machine thoroughly to ensure it's in good working condition.

Another option to consider is leasing or renting a machine. This can be a cost-effective solution, especially if you only need the machine for a specific project or a short period of time.

In conclusion, getting your hands on a plastic injection molding machine is easier and more affordable than you might think. Whether you choose to buy a new machine, find a used one, or explore leasing options, you'll be able to bring your manufacturing dreams to life. In the next section, we'll discuss some tips and considerations to keep in mind when purchasing a plastic injection molding machine. So stay tuned!

5. Saying goodbye to "I wish I had a plastic injection molding machine" dreams

Ah, the satisfaction of turning dreams into reality! In this next section, we'll dive into some tips and considerations to keep in mind when purchasing a plastic injection molding machine. Because let's face it, when you finally have one in your possession, you'll want to make the most of it.

First things first, it's important to assess your production needs. Ask yourself how often you'll be using the machine and what kind of products you'll be manufacturing. This will help you determine the size and capabilities you require.

Next, make sure to do your research on different machine manufacturers. Look for reputable brands with a track record of producing high-quality machines. Reading reviews and asking for recommendations from other users can also be a valuable source of information.

Budget is always a consideration, so take the time to compare prices and features. Remember, the cheapest machine might not always be the best investment in the long run. Look for machines that offer a balance between affordability and functionality.

Lastly, don't forget about maintenance and support. Find out if the manufacturer offers technical support and if replacement parts are readily available. A machine that is well-supported will ensure smooth operation and minimal downtime.

By following these tips, you'll be well on your way to making your plastic injection molding dreams a reality. Stay tuned for the next section, where we'll explore some exciting applications of plastic injection molding that might surprise you. Until then, happy molding!

6. Seriously, you need to check this out!

I know, I know, you're probably thinking "Why do I need a plastic injection molding machine anyway?" Well, my friend, let me tell you, this machine is seriously cool and can open up a world of possibilities for you.

Think about it - with a plastic injection molding machine, you can create all sorts of products right at home. From custom-made phone cases to personalized keychains, the possibilities are endless. And the best part? You have complete control over the design and production process.

Imagine the satisfaction of seeing your ideas come to life, right in front of your eyes. It's like being a magician, turning raw materials into something amazing. Plus, with advancements in technology, these machines are becoming more user-friendly and affordable, making them accessible to everyday hobbyists and professionals alike.

So, if you've ever had a creative itch or a desire to bring your own products to the market, a plastic injection molding machine is definitely something you should consider. Trust me, once you have one, you'll wonder how you ever lived without it.

In the next section, we'll explore some mind-blowing examples of what can be achieved with a plastic injection molding machine. Get ready to be inspired and amazed by the incredible things people are creating. See you there!

7. So, what are you waiting for? Get your hands on a plastic injection molding machine and start creating!

So, what are you waiting for? It's time to dive deeper into the world of plastic injection molding and explore the amazing things you can create with this incredible machine. From intricate jewelry pieces to functional household items, the possibilities are truly endless.

Imagine being able to design your own unique phone cases, perfectly tailored to your style and preferences. Or how about creating custom keychains to give as personal and thoughtful gifts? With a plastic injection molding machine, you have the power to bring your ideas to life and make them a reality.

Not only is the process of using a plastic injection molding machine incredibly rewarding, but it's also surprisingly simple. As technology has advanced, these machines have become more user-friendly, so even if you're a beginner, you'll be able to create professional-quality products.

Whether you're a hobbyist looking to explore your creative side or an entrepreneur wanting to bring your own products to market, a plastic injection molding machine is the perfect tool for you. It's time to unleash your creativity and start bringing your ideas to life. So, what are you waiting for? Get your hands on a plastic injection molding machine and start creating!

0 notes

Text

The Ultimate Guide to Choosing the Perfect Injection Moulding Machine for Your Manufacturing Process

Introduction

Selecting the right injection moulding machine is a critical decision for manufacturers. With so many options available, finding the perfect machine for your manufacturing process can be overwhelming. The wrong choice can result in wasted time, money, and resources. That is why it is crucial to have a comprehensive understanding of the different types of injection moulding machines and their capabilities. This ultimate guide will walk you through the key factors to consider when choosing an injection moulding machine, ensuring you make the best decision for your manufacturing needs.

Factors to consider when choosing an injection moulding machine

Factors to Consider When Choosing an Injection Moulding Machine

When selecting an injection moulding machine for your manufacturing process, there are several important factors to consider. These factors will help you narrow down your options and make an informed decision.

1. Production Requirements: Determine the quantity and type of products you need to produce. Consider factors such as production volume, cycle time, and desired output rate. This will help you choose a machine with the appropriate clamping force, shot capacity, and injection speed for your specific needs.

2. Materials: Identify the type of materials you will be using in your manufacturing process. Different injection moulding machines are designed for specific materials such as plastic, rubber, or metal. Ensure that the machine you choose is compatible with the materials you will be working with.

3. Size and Space: Assess the available space in your facility and consider the size of the machine. Make sure you have enough space for installation, maintenance, and proper operation.

4. Budget: Consider your budget constraints and the overall cost of the machine, including installation, maintenance, and operational expenses. Choose a machine that offers the best value for your investment.

By carefully considering these factors, you can confidently choose the perfect injection moulding machine that meets your manufacturing requirements and helps you achieve your production goals. In the next section, we will discuss the different types of injection moulding machines available in the market.

Understanding the different types of injection moulding machines

Understanding the different types of injection moulding machines

Now that we have discussed the important factors to consider when choosing an injection moulding machine, let's delve into the different types of machines available in the market.

1. Hydraulic Injection Moulding Machines: These machines use hydraulic systems to operate. They are known for their ability to provide high clamping force and precise control over the injection process. Hydraulic machines are versatile and can handle a wide range of materials.

2. Electric Injection Moulding Machines: As the name suggests, these machines are powered by electricity. They offer excellent precision and repeatability, making them ideal for producing high-quality products. Electric machines are energy-efficient and have a fast cycle time.

3. Hybrid Injection Moulding Machines: Hybrid machines combine the best features of both hydraulic and electric machines. They provide the high clamping force of hydraulic machines and the precision of electric machines. Hybrid machines are energy-efficient and offer excellent performance.

4. All-electric Injection Moulding Machines: These machines are entirely electric-powered, eliminating the need for hydraulic components. They provide precise control over the injection process and are highly energy-efficient. All-electric machines are ideal for producing small, intricate parts.

By understanding the different types of injection moulding machines, you can choose the one that best suits your production needs, materials, and budget. In the next section, we will discuss the important features to look for in an injection moulding machine.

Assessing your manufacturing needs and requirements

Assessing your manufacturing needs and requirements

Now that you have a good understanding of the different types of injection moulding machines, it's time to assess your manufacturing needs and requirements. This step is crucial in choosing the perfect machine for your specific production process.

One of the first things to consider is the size and complexity of the parts you will be producing. Different machines have different capabilities in terms of clamping force, shot size, and mold size. You need to ensure that the machine you choose can handle the size and complexity of your parts.

Next, consider the production volume. Are you planning to produce small batches or large quantities of items? Some machines are designed for high-volume production, while others are more suitable for low-volume production. It's important to choose a machine that can meet your desired production capacity.

Another important consideration is the type of material you will be working with. Different machines have different capabilities when it comes to processing various types of materials, such as thermoplastics, thermosetting plastics, or elastomers. Make sure the machine you choose is compatible with the materials you will be using.

Additionally, consider factors such as cycle time, automation options, energy efficiency, and maintenance requirements. These factors can greatly impact the overall efficiency and cost-effectiveness of your manufacturing process.

By carefully assessing your manufacturing needs and requirements, you can narrow down your options and choose the perfect injection moulding machine that will optimize your production process. In the next section, we will discuss the important features to look for in an injection moulding machine to further aid you in your decision-making process.

Key features to look for in an injection moulding machine

Now that you have assessed your manufacturing needs and requirements, it's time to dive into the key features to look for in an injection moulding machine. These features will greatly impact the performance, efficiency, and versatility of the machine.

1. Clamping force: This refers to the machine's ability to hold the mold closed during the injection process. It is crucial to choose a machine with sufficient clamping force to handle the size and complexity of your parts.

2. Shot size and volume: The shot size determines the maximum amount of material that can be injected into the mold at once. It is important to choose a machine with a shot size that aligns with your production requirements.

3. Control system: A user-friendly and intuitive control system is essential for efficient and precise operation. Look for machines with advanced control systems that allow for easy programming, monitoring, and troubleshooting.

4. Cooling system: Efficient cooling is vital to ensure proper solidification of the injected material. Look for machines with effective cooling systems that can maintain consistent cycle times and minimize production defects.

5. Energy efficiency: Choosing an energy-efficient machine not only reduces operating costs but also contributes to environmental sustainability. Look for machines with energy-saving features such as variable pump motors and high-efficiency heaters.

By considering these key features, you can make a well-informed decision and choose the perfect injection moulding machine that meets your manufacturing needs and boosts your production process. In the next section, we will delve into the different types of injection moulding machine technologies available in the market.

Evaluating the reputation and reliability of machine manufacturers

When choosing the perfect injection moulding machine, it is crucial to consider the reputation and reliability of the manufacturers you are considering. A reputable manufacturer will not only provide you with a high-quality machine but also offer excellent customer support and after-sales service.

Start by researching the background and history of the manufacturers. Look for companies with a strong track record in the industry and positive customer reviews. This will give you an idea of their reputation and the satisfaction level of their customers.

Additionally, consider the manufacturer's expertise and experience. Look for manufacturers that specialize in injection moulding machines and have extensive knowledge in the field. This expertise ensures that the machines are designed and built to meet industry standards and specific manufacturing requirements.

Another aspect to evaluate is the manufacturer's support and service network. A reliable manufacturer should have a well-established network of service centers and technicians who can provide prompt assistance when needed. This will minimize downtime and ensure that your production process runs smoothly.

By thoroughly evaluating the reputation and reliability of machine manufacturers, you can make an informed decision and choose a trusted partner that will provide you with a durable and efficient injection moulding machine. In the next section, we will explore the importance of considering your budget and cost-effectiveness when selecting a machine.

Comparing costs and return on investment

After considering the reputation and reliability of injection moulding machine manufacturers, the next crucial factor to evaluate is the cost and return on investment (ROI) of the machines you are considering. While quality and reliability are important, it is equally essential to ensure that the machine you choose fits within your budget and offers a good ROI.

Start by determining your budget and the maximum amount you are willing to invest in an injection moulding machine. This will help narrow down your options and prevent you from overspending. Remember to consider not just the initial purchase cost but also the ongoing operational and maintenance expenses.

Next, carefully assess the cost-effectiveness of each machine. Look beyond the purchase price and consider factors such as energy efficiency, production capacity, and lifecycle costs. A machine that may seem expensive upfront might actually save you more money in the long run due to its higher productivity, lower energy consumption, and reduced maintenance requirements.

Additionally, consider the potential return on investment. Determine how quickly the machine will pay for itself through increased production efficiency and reduced scrap rates. Calculate the payback period and evaluate whether it aligns with your business goals and timeline.

By comparing costs and ROI, you can make a well-informed decision that considers both your budget constraints and long-term profitability. In the next section, we will delve into the importance of selecting a machine that meets your specific manufacturing requirements.

Seeking expert advice and recommendations

When it comes to choosing the perfect injection moulding machine, seeking expert advice and recommendations can be invaluable. While you may have done extensive research on your own, consulting professionals in the industry can provide you with valuable insights and guidance.

Reach out to manufacturers, suppliers, and industry experts who have deep knowledge and experience in injection moulding machines. They can help you understand the latest advancements in technology, identify the best machines for your specific manufacturing needs, and provide valuable recommendations based on their expertise.

In addition to seeking advice, consider visiting trade shows, exhibitions, and conferences related to the manufacturing industry. These events provide a platform to interact with industry professionals, view demonstrations of different machines, and gain a better understanding of the latest trends and innovations in injection moulding machines.

Remember, the opinions and recommendations of experts can help streamline your decision-making process and ensure that you choose a machine that maximizes efficiency and productivity in your manufacturing process. In the next section, we will explore the importance of evaluating the features and specifications of the machines you are considering.

Making an informed decision for your manufacturing process

Making an informed decision for your manufacturing process

Once you have gathered expert advice and recommendations, it is time to evaluate the features and specifications of the injection moulding machines you are considering. This step plays a crucial role in ensuring that the machine you choose is the perfect fit for your manufacturing process.

Start by defining your specific requirements and objectives. Consider factors such as the size and complexity of the products you will be manufacturing, the desired production speed, and the materials you will be using. Understanding these requirements will help you narrow down your options and focus on machines that meet your needs.

Next, carefully review the technical specifications of each machine. Look for key features such as injection volume, clamping force, and mould thickness capacity. Assess whether these specifications align with your production requirements. Additionally, consider the machine's energy efficiency, automation capabilities, and maintenance requirements.

It is also important to consider the reputation and track record of the manufacturer. Research their history, customer reviews, and reliability. Look for a manufacturer that has a proven track record of producing high-quality machines with excellent customer support.

By thoroughly evaluating the features and specifications of the injection moulding machines you are considering, you can make an informed decision that will ultimately contribute to the success of your manufacturing process. In the next section, we will discuss the importance of considering the cost and return on investment of the machine.

Conclusion: Investing in the right injection moulding machine for success.

In conclusion, choosing the perfect injection moulding machine for your manufacturing process requires careful consideration of various factors. By defining your specific requirements and objectives, reviewing technical specifications, and researching the reputation of manufacturers, you can make an informed decision that will benefit your business in the long run.

However, it is important to note that the cost and return on investment of the machine should also be taken into account. While it may be tempting to focus solely on the upfront cost, it is crucial to consider the overall value the machine will bring to your production process. This includes factors such as productivity, efficiency, and durability.

Taking the time to thoroughly assess all aspects of the injection moulding machine will help ensure that you make a wise investment that will contribute to the success of your manufacturing process. So, before making a final decision, make sure to evaluate the cost and return on investment in the next section.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

1 note

·

View note