Don't wanna be here? Send us removal request.

Text

They are essential for lifting, securing, towing, and moving loads of varying sizes and weights. While chains are widely regarded for their strength and durability, they can pose significant risks if not handled properly. Adhering to proper handling techniques, conducting regular maintenance, and following thorough inspection protocols are vital steps in ensuring the longevity of chains and the safety of personnel involved in their operation.

This article explores the most effective methods for safe handling, outlines maintenance strategies that can extend the lifespan of chains, and highlights essential inspection practices to prevent accidents and equipment failure.

The Importance of Proper Handling

Chains are designed to endure substantial loads, but incorrect handling can compromise their structural integrity and lead to severe accidents. Understanding how to handle them correctly is the first step toward maintaining a safe working environment.

When moving chains, it is crucial to avoid dragging them across rough surfaces, as this can cause abrasions and weaken individual links. Sharp turns and twists during handling should also be avoided since they can introduce unnecessary stress points that may eventually lead to fractures or deformations. Additionally, operators should never subject chains to sudden jerks or shock loading. Sudden movements can significantly increase the force on the links, potentially exceeding their load capacity and causing unexpected breakages. Chains should always be lifted and lowered smoothly to distribute the load evenly.

Key Maintenance Practices for Longevity

Regular maintenance is fundamental to preserving the strength and functionality of chains over time. Chains that are neglected or improperly maintained are far more susceptible to premature wear and catastrophic failure. Chains often accumulate dirt, debris, and corrosive substances, especially in outdoor or industrial environments. Periodic cleaning using appropriate solvents and brushes can prevent build-ups that may lead to rust or interfere with movement. Lubrication is equally important. Proper lubrication reduces friction between links, minimizes wear, and protects against corrosion. Regular reapplication is necessary, especially in high-use or harsh conditions.

Detailed Inspection Procedures

Inspection is a critical component of chain safety. A comprehensive inspection routine can identify potential issues early and prevent dangerous failures during operations. Chains should be visually inspected before each use. Operators should look for obvious signs of damage, such as bent, cracked, or deformed links. Wear measurement is another essential aspect of inspection. Over time, chains naturally elongate due to stretching under load. Using precise measuring tools, operators should check whether the elongation exceeds allowable limits as specified by manufacturers. Excessive elongation reduces the load-carrying capacity and indicates that the chain may be approaching failure. Corrosion is a hidden hazard that can severely compromise the structural integrity of chains. Rust spots, pitting, and discoloration should not be overlooked. Chains showing significant corrosion should be retired or subjected to more detailed inspection by qualified professionals. In addition to the links themselves, attention must be given to accessories such as hooks, connectors, and shackles. These components are integral to the chain system and must also meet safety standards. Scheduled inspections by certified inspectors should be part of the maintenance plan, especially for chains used in critical or high-frequency lifting applications. Detailed inspection records should be maintained for each chain to track wear patterns and service history.

Common Causes of Chain Failure

Understanding why chains fail can help in both prevention and response. This can lead to instantaneous breakage or long-term fatigue. Improper angle of lifting is another frequent issue. Lifting chains at extreme angles creates uneven stress distribution, which can weaken certain links more rapidly than others. Environmental factors, such as exposure to chemicals, saltwater, or extreme temperatures, can accelerate corrosion and material degradation. Failing to account for these conditions during selection and use can drastically shorten the chain's lifespan. Poor maintenance, such as inadequate lubrication or neglecting regular cleaning, contributes to accelerated wear and frictional damage. Chains that are not periodically inspected may also fail without warning due to undetected cracks or fatigue.

Safety Guidelines for Chain Operations

To maximize safety and operational efficiency, a few universal guidelines should always be followed when working with chains. First, ensure that the load is evenly distributed across all links and that proper lifting angles are maintained. Second, chains should never be modified or repaired using makeshift methods. Only approved components and professional services should be used for adjustments or repairs. Third, proper training is essential. Operators should be familiar with load limits, lifting techniques, and emergency procedures in case of chain failure. Continuous safety education can significantly reduce human errors that lead to accidents. Lastly, signage indicating load limits, inspection schedules, and handling instructions should be displayed in work areas where chains are frequently used. These reminders help maintain a safety-first culture on site.

Conclusion

Chains, especially MS chain, are indispensable tools in lifting, securing, and material handling applications. However, their safe and effective use requires more than just strength; it demands proper handling, regular maintenance, and meticulous inspection.

By following best practices in each of these areas, operators can greatly extend the service life of MS chain while minimizing the risk of accidents and equipment failure. Ensuring that chains are used correctly and safely not only protects valuable assets but also safeguards the lives of those who rely on them every day. In high-risk environments, attention to detail and respect for safety procedures can make all the difference.

0 notes

Text

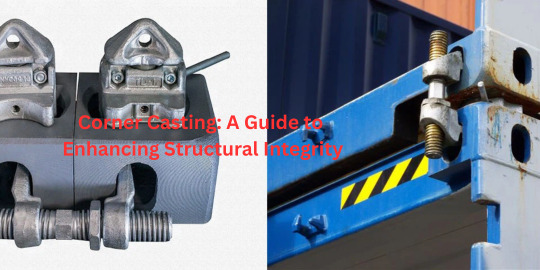

Among these vital elements are the specialized fittings used to reinforce corners and provide secure connections. These fittings are essential in industries ranging from manufacturing to logistics, contributing significantly to the structural integrity of metal frameworks and shipping containers.

Importance in Metal Fabrication

In metal fabrication, the assembly of frames, containers, and other structural elements requires precision and strength. The corner reinforcements used in this process serve multiple purposes. Primarily, they provide a secure fastening point that allows metal panels, beams, and other components to be joined at right angles, creating rigid frameworks that can withstand heavy loads and resist deformation. Metal fabrication often involves the production of customized enclosures, cabinets, and containers, where the corners are stress points vulnerable to bending or breaking. Reinforcement fittings designed for corner joints enhance load distribution and provide additional rigidity. This reduces the risk of failure under operational stress, making the fabricated product more reliable and durable over time.

Moreover, these components simplify the assembly process. By offering standardized, pre-formed attachment points, they allow fabricators to connect parts quickly and securely without the need for complex welding or bolting techniques. This increases production efficiency and reduces labour costs.

Applications in Shipping Containers

The logistics and shipping industries rely heavily on robust structural components to ensure the safe transport of goods across long distances. Containers used in shipping are exposed to harsh environmental conditions and mechanical stress from loading, unloading, and stacking. Reinforcement fittings at the corners of these containers are designed to meet stringent international standards, providing secure points for lifting, securing, and locking. These corner fittings enable containers to be stacked safely without risking collapse or shifting during transit. They also allow cranes and forklifts to engage securely when moving containers, facilitating smooth operations in ports and warehouses. The durability and design of these fittings are crucial for maintaining the structural integrity of the containers and protecting the cargo inside. Additionally, such fittings are engineered to withstand corrosion and wear, often made from high-strength steel with protective coatings. This ensures longevity even in marine environments where saltwater exposure is common.

Variations and Materials

The types of corner reinforcements used vary depending on the application. In metal fabrication, these fittings might be lightweight and designed for indoor use, often made from aluminium or mild steel. In shipping, the requirements are more demanding, with high-strength, weather-resistant steel being the norm. Some designs incorporate additional features such as locking mechanisms, twist locks, or integrated mounting points for accessories. These variations allow them to serve multiple functions beyond simple reinforcement, adapting to specialized needs in different industries. The choice of material and design also affects the ease of installation and maintenance. For instance, modular fittings with bolt-on features simplify repairs and replacements, reducing downtime in operational settings.

Enhancing Structural Safety and Performance

One of the main benefits of these corner reinforcements is the enhancement of overall structural safety. By distributing stress evenly along the edges and providing firm attachment points, they prevent deformation and failure that could otherwise compromise the entire structure or container. In metal fabrication, this means finished products that can endure heavy use, vibrations, and impacts without losing shape or functionality. In shipping, this translates to safer transport, reduced risk of accidents, and minimized damage to goods. Moreover, these fittings can contribute to compliance with industry standards and regulations. Many shipping containers, for example, must pass rigorous testing for load-bearing capacity and durability. High-quality corner fittings are a key factor in achieving these certifications.

Integration with Other Components

These fittings often work in conjunction with other hardware such as hinges, locks, and seals. In fabricated metal structures like cabinets or machinery enclosures, corner attachments provide mounting points for doors or panels, ensuring smooth operation and secure closure. In shipping, they integrate with twist locks and stacking cones that facilitate container interlocking during transport and storage. This integration is vital for operational efficiency and safety in logistics. The design of these fittings must therefore consider compatibility with other components to provide a seamless and effective assembly solution.

Maintenance and Inspection

Regular maintenance and inspection of corner reinforcements are essential, particularly in shipping, where exposure to harsh conditions can lead to wear and corrosion. Routine checks help identify damage early, preventing costly repairs or catastrophic failures. Maintenance may include cleaning, lubrication, repainting, or replacement of worn parts. In metal fabrication, inspection ensures that the structural integrity of fabricated products remains uncompromised during their service life. Employing quality fittings reduces the frequency and cost of maintenance, but vigilance remains necessary to ensure safety and performance.

Future Trends and Innovations

As industries evolve, so do the requirements for these corner components. Advances in materials science are leading to the development of lighter, stronger, and more corrosion-resistant alloys, improving durability without adding weight. Innovations in manufacturing techniques, such as 3D printing and precision machining, allow for more complex designs that can integrate multiple functions in a single fitting, reducing assembly time and improving performance. Sustainability is also becoming a focus, with manufacturers exploring eco-friendly coatings and recyclable materials to reduce environmental impact.

Conclusion

Specialized corner fittings, such as corner casting, are indispensable in both the metal fabrication and shipping industries. They provide essential structural reinforcement, ensuring durability, safety, and operational efficiency. Their ability to withstand heavy loads, resist harsh environments, and integrate with other hardware makes them a critical element in container construction and metal assembly.

As technology advances, components like corner casting continue to evolve, offering improved materials, innovative designs, and greater functionality. For manufacturers and logistics professionals, understanding the key applications and benefits of these fittings is vital for achieving reliable, high-quality results in their projects.

0 notes

Text

However, the modern era is ushering in a wave of innovation that is transforming how fighters perceive and use their uniforms. From reinforced stitching to moisture-wicking materials, the evolution of training gear is reflective of broader changes in athletic performance wear. The need for both durability and comfort is driving this transformation, ensuring that athletes can train harder, recover faster, and perform better.

Advanced Materials for Peak Performance

One of the most noticeable shifts in martial arts gear is the use of advanced textiles. Traditional cotton has served practitioners well for decades, but it has its limitations, particularly in terms of breathability and drying time. Modern alternatives utilize blends of polyester, elastane, and ripstop fabrics that offer the perfect mix of stretch, durability, and moisture control. These materials are often reinforced with antimicrobial properties, preventing odour buildup and extending the longevity of the apparel. Gi Chain has been at the forefront of integrating these cutting-edge materials into their designs, ensuring athletes benefit from the latest innovations.

This means less resistance during grappling and a more natural range of motion, both of which are critical in a high-stakes training environment. What was once a simple uniform has now become a carefully engineered piece of performance equipment, with Gi Chain leading the way in redefining standards for martial arts apparel.

Seamless Integration of Style and Function

Beyond functionality, there is also a growing emphasis on aesthetics. Fighters today want to feel confident and represent their individuality through their gear. Contemporary training apparel is now available in a wide range of colors, minimalist patterns, and sleek designs that still adhere to competition regulations. Branding and symbolism play a role, but the focus remains on allowing the athlete to feel empowered and focused during every session. Custom fits are another major development in this space. Options for tapered sleeves, tailored pants, and adjustable collars are now common, allowing practitioners to choose designs that align with their body type and personal preferences.

Sustainability and Ethical Manufacturing

With increasing awareness of environmental and social responsibility, martial arts gear manufacturers are taking steps to reduce their ecological footprint. Many are opting for sustainable production methods, using recycled materials or eco-friendly dyes in their products. Ethical labor practices and transparent sourcing are also becoming standard, as consumers demand more accountability from the brands they support. This shift toward sustainability does not mean compromising on quality. On the contrary, sustainable materials are often stronger and more adaptable than their conventional counterparts. From organic cotton to biodegradable packaging, these efforts demonstrate a commitment to both athletes and the planet.

Technology-Driven Innovation

Modern combat gear is no longer just about fabric and fit. The integration of technology is opening new doors in performance optimization. Smart textiles, which respond to temperature or sweat levels, are gradually being explored. Some experimental designs are even incorporating sensors that can track performance metrics like grip pressure, range of motion, or stress points during sparring. Although these features are still in early stages, they indicate a future where data and design come together to enhance training. By merging traditional martial arts philosophy with cutting-edge tech, this new generation of apparel empowers athletes to push boundaries and fine-tune their techniques with scientific precision.

Catering to Every Level of Practice

One of the strongest attributes of the latest training attire is its adaptability to various skill levels and disciplines. Whether someone is a novice attending their first class or a seasoned black belt preparing for competition, the right gear can make a noticeable difference. Entry-level designs focus on comfort and ease of use, while premium editions deliver high-performance features suited for elite athletes. Moreover, inclusive sizing and gender-specific cuts have made martial arts more accessible. Female practitioners, in particular, now benefit from designs that account for anatomical differences, providing better support and comfort than the unisex gear of the past. Youth-specific options have also become more widely available, encouraging participation from a younger generation.

The Community Behind the Gear

An often-overlooked element in the development of next-gen training apparel is the feedback loop created by the martial arts community itself. Brands and designers are increasingly collaborating with athletes, coaches, and even medical professionals to understand the real-world demands placed on their gear. This collaborative process has led to solutions that address pain points like collar burn, joint strain, or heat retention. Practitioners value authenticity, and gear that evolves based on their experience fosters a sense of trust and loyalty. When a product reflects the voice of the community, it becomes more than just clothing; it becomes a tool for growth, discipline, and personal achievement.

Conclusion

The transformation of martial arts apparel represents more than just a trend; it marks a shift in how athletes approach their craft. From advanced materials and tailored fits to sustainability and tech integration, every aspect of the uniform is being reimagined for the modern warrior. These innovations are empowering practitioners of all backgrounds and skill levels to train smarter, move freer, and perform at their best. Many turn to a trusted Gi Chain supplier in UAE to access the latest gear that combines tradition with innovation.

As the discipline itself continues to evolve, so too must the gear that supports it. Today’s fighter demands more than tradition; they require tools that meet the highest standards of performance, comfort, and purpose. The evolution of apparel is not just about looking good or feeling comfortable, it's about embracing the spirit of growth, resilience, and excellence that defines martial arts itself. That’s why choosing the right Gi Chain supplier in UAE can make all the difference in finding equipment that truly supports an athlete’s journey.

0 notes

Text

Their webbing slings are engineered for maximum strength and reliability, ensuring safe and efficient lifting operations, with a strong focus on customer satisfaction and support.

0 notes

Text

Corners, whether part of industrial frames, automotive housings, or architectural elements, are stress concentration points that require thoughtful reinforcement. To ensure that these critical zones can withstand pressure, shock, and long-term wear, specialised techniques are employed during the formative process.

Importance of Corner Strength

Corners are inherently vulnerable in any structural system. The convergence of surfaces, abrupt directional changes, and the presence of seams or joints mean that these areas are often the first to fail under duress. When poorly designed or fabricated, such junctions become the Achilles’ heel of a product. However, when reinforced using advanced forming methods, these critical points transform into the backbone of structural integrity.

Strengthening these regions isn’t just about adding more material. It involves engineering the flow of forces, distributing stress across the framework, and ensuring that internal grain structures align for maximum resistance. The result is a component that doesn’t just survive mechanical stress, it thrives under it.

Applications Across Industries

From aerospace and automotive to marine and construction, components featuring high-stress junctions are omnipresent. In vehicles, for example, these junctions are part of suspension mounts, engine brackets, and chassis assemblies—areas that demand unmatched strength and rigidity. In buildings, these intersections hold together support beams and foundational frameworks. What enables these sectors to maintain both form and function is the use of highly controlled manufacturing processes. These methods ensure that each unit can withstand torque, pressure, and vibrational impact without cracking or deforming.

Manufacturing Techniques That Enhance Durability

A precise method is used to shape molten or semi-solid materials into strong, unified parts. This process ensures seamless continuity across joints and corners, minimizing the risk of weak points. Unlike assembled parts that may be welded or bolted, this approach creates a singular form, eliminating the discontinuities often responsible for structural failure. Advanced tooling and temperature control during shaping allow for tight tolerances and excellent dimensional accuracy. Engineers can tailor designs to suit unique load paths, directional forces, and environmental demands. The result is not only strong but also reliable over long cycles of use. Moreover, integrating simulation tools into the design phase allows engineers to predict stress patterns before production. By understanding how force will interact with the geometry, the form can be optimized to redistribute strain and avoid fatigue.

Material Considerations for Maximum Effectiveness

The choice of base material significantly affects the success of any structural component. Aluminium alloys, for example, offer a blend of strength and lightness, making them ideal for aerospace and automotive applications. Steel provides excellent tensile strength, suitable for heavy-duty uses like construction and rail transport. Each material reacts differently to temperature and pressure.

Quality Control and Inspection

Creating robust structures demands rigorous testing. Non-destructive testing techniques like ultrasonic scanning, dye penetrant testing, and X-ray imaging allow engineers to detect internal voids, cracks, or inclusions that could compromise performance. Quality assurance doesn’t end with the initial part. Many industries mandate batch testing, lifecycle simulations, and real-world performance trials. Without multiple parts to join or weld, assembly becomes faster and more reliable. Fewer seams also mean fewer points of corrosion, reducing maintenance and prolonging operational life. Another advantage is weight reduction. Instead of overcompensating with thick joints or heavy fasteners, engineers can create optimized geometries that deliver strength exactly where it’s needed.

Environmental and Economic Impact

Efficient material use and reduced waste are crucial benefits of this technique. Since parts are formed to near-net shape, there is minimal need for additional machining or trimming. This not only saves time and resources but also lowers the carbon footprint of production. Energy savings also come from reduced processing steps. A single formation phase replaces multiple stages of cutting, joining, and finishing. Over large production runs, these efficiencies translate into significant economic advantages.

Conclusion

Creating strong, resilient frameworks starts with a focus on the most vulnerable areas, junctions, and transitions where forces converge. By using advanced shaping techniques that form these critical points as part of a unified whole, manufacturers can achieve superior performance, longer lifespan, and greater reliability across applications. Whether in the body of a vehicle, the spine of a building, or the core of an industrial machine, these approaches provide the backbone for enduring strength and efficiency. In environments where precision and consistency are non-negotiable, methods like corner casting reduce the margin of error while optimizing both time and cost.

The shift toward automation and digital integration further enhances accuracy, enabling real-time monitoring and adaptive control during production. Corner casting, in particular, benefits from these advancements, allowing for consistent quality and repeatability in high-stress zones. As technology continues to evolve, the ability to reinforce these pivotal areas will only become more refined, pushing the boundaries of what’s possible in modern design and setting new standards for safety, performance, and innovation across industries.

0 notes

Text

High-quality cargo hooks made for safe and effective load handling are available from Starhive Company. Professionals from a variety of industries rely on our cargo hooks because they are dependable and long-lasting and because they exceed strict safety regulations. For trusted cargo handling solutions, rely on Starhive.

0 notes

Text

Discover high-quality manila rope for all your needs. Durable, versatile, and perfect for crafts, décor, and marine use. Shop now for great prices.

0 notes

Text

Twist locks are a type of fastening device that is used to secure shipping containers together. They are typically made of steel and have a twist-to-lock mechanism. Twist locks are very strong and durable, and they are able to withstand the rigours of shipping. Starhive is a leading manufacturer of twist locks.

0 notes

Text

A specialised casting technique has emerged as a trusted solution, particularly for reinforcing high-stress areas like structural corners. This article explores how this process supports various industries—from construction to logistics—by improving strength, ensuring consistency, and enhancing performance while aligning with sustainability and cost-efficiency goals.

Strength at the Core of Structural Design

In structural engineering and heavy manufacturing, the integrity of joint areas plays a pivotal role in determining overall durability. These connection points are regularly exposed to mechanical pressure, vibrations, and environmental elements. Strengthening these areas ensures the long-term performance of equipment, buildings, or containers. Corner Casting is widely used in such applications, as it provides a reinforced solution specifically designed to handle concentrated stress. By incorporating Corner Casting in high-load zones, manufacturers can deliver structures with a stronger core, especially where failure is least tolerated.

Why Moulded Reinforcement Makes a Difference

Precision casting enables manufacturers to create solid, seamless parts that outperform traditionally welded or fabricated joints. The absence of seams reduces the risk of stress fractures, and the uniform density of the material provides excellent load-bearing capacity. These reinforcements offer peace of mind in critical applications such as building supports, lifting frames, or marine platforms, where absolute reliability is essential.

Selecting the right material is crucial. Cast steel remains a popular choice due to its strength, resistance to deformation, and ability to withstand harsh elements. For industries that demand peak mechanical performance, such as marine construction, oil rigs, or shipping containers, steel provides a trusted foundation. In addition, its compatibility with post-processing techniques like welding, painting, and machining makes it a versatile option.

Meeting Industrial Standards and Safety

The transportation and construction industries are governed by strict global standards. Shipping containers, for instance, must safely endure stacking, lifting, and shifting in unpredictable conditions. Their support structures are often produced using cast components that conform to these standards, ensuring durability during loading and unloading. In construction, these parts serve as dependable links between beams and panels, particularly in multistory frameworks.

Shaping Performance Through Design Precision

Modern design tools allow engineers to simulate real-world stress before production even begins. Using CAD software, manufacturers can predict the performance of a component under pressure, adjusting mould dimensions to improve strength or reduce weight. The result is a balance of structural integrity and efficient resource use, giving companies a competitive edge in performance and cost management.

Long-Term Durability in Harsh Conditions

Industrial environments are unforgiving. Components used in outdoor or high-pressure applications must endure continuous exposure to water, chemicals, UV light, and extreme temperatures. Precision-cast components offer enhanced resistance to these factors, maintaining shape and function for years. This makes them indispensable in projects where structural failure is not an option, such as coastal bridges, offshore platforms, or power facilities.

Consistency and Quality You Can Count On

Mass production demands consistency. Each unit must meet the same specifications, especially in industries where parts are installed interchangeably. The casting process allows for reliable repetition without quality degradation, thanks to reusable moulds and strict controls. Advanced inspection techniques like X-ray imaging or ultrasonic testing verify structural integrity before distribution, ensuring every piece is ready for performance. One of the most appealing aspects of this manufacturing method is its long service life. By minimising wear and tear in high-stress areas, companies benefit from fewer maintenance interventions and less frequent part replacements. This not only enhances operational uptime but also contributes to reduced lifetime costs—a major benefit for industries operating under tight margins or continuous production cycles.

Sustainability in Modern Manufacturing

Environmental responsibility is a growing concern in heavy industry. Today’s foundries incorporate eco-conscious practices like recycling excess materials, using energy-efficient furnaces, and adopting closed-loop cooling systems. Because these components last longer and require fewer replacements, they help reduce industrial waste. The combination of durability and low environmental impact adds significant value to any sustainable engineering project. From construction to aerospace, this production technique supports a wide range of industries. It is vital in the logistics industry, where containers must maintain their integrity during global transport. It supports mining equipment subjected to constant movement and impact. It also plays a key role in architectural structures that combine aesthetic appeal with strength. This wide range of applications highlights the process’s adaptability and importance in modern manufacturing.

Conclusion As engineering evolves, so do the methods that define precision and durability. Casting processes designed for structural enhancement remain at the forefront of reliable component manufacturing. Their ability to withstand pressure, maintain shape, and deliver consistent results across countless applications has made them a cornerstone of modern production. In particular, Corner Casting continues to be a preferred solution in industries that prioritise safety, efficiency, and performance, helping build the strong, sustainable structures of tomorrow. The increasing demand for high-performance infrastructure has placed a spotlight on components that provide structural integrity without compromising on design. From shipping containers and trailers to architectural frameworks and machinery, the corners often bear the brunt of stress. By incorporating robust casting techniques at these pressure points, manufacturers enhance both safety and longevity. This focus not only reduces repair costs but also ensures that structures remain reliable over decades of use. As materials and methods continue to improve, the reliance on expertly cast parts, especially at crucial joints, will become even more pronounced in the global industrial landscape.

0 notes

Text

Starhive is a company that specializes in the manufacture of corner castings. They offer a wide range of corner castings for different types of shipping containers, as well as for other applications such as construction and mining equipment. Starhive corner castings are known for their high quality and durability.

0 notes

Text

Their versatility lies in their ability to provide strength, security, and resistance to environmental conditions. Among the many types of metal chains available, one particular kind recognized for its corrosion resistance and durability is widely used in both industrial and domestic applications. Understanding the various grades, coatings, and specifications associated with this chain is crucial for ensuring optimal performance and long-term reliability.

Grades and Their Significance

The grade of a chain refers to the tensile strength of the material used in its construction. Different grading systems are used across regions, but the general principle remains the same: the higher the grade, the stronger and more suitable the chain is for demanding tasks.

Low-grade variants are typically utilized for lighter-duty tasks such as hanging signs or creating barriers, where heavy loads and extreme conditions are not a concern. These are often made from mild steel and are more cost-effective but less robust. A GI Chain in this category may still provide basic corrosion resistance, but should not be relied upon for structural support or high-tension applications. Medium-grade chains are more versatile and are commonly used in agricultural and general industrial contexts. They offer a balanced combination of strength, flexibility, and affordability, making them a popular choice for general-purpose use. When properly coated, a GI Chain in the medium-grade range can perform reliably in outdoor settings, resisting rust while maintaining structural integrity under moderate loads.

The Role of Protective Coatings

In many environments, metal chains are exposed to moisture, chemicals, and other corrosive elements. To combat this, protective coatings are applied to extend their service life and maintain their mechanical properties.

One of the most common protective finishes is a zinc-based layer. This coating provides a barrier between the metal and its surroundings, slowing the rate of corrosion significantly. The thickness of the zinc layer can vary, and it is typically applied through either hot-dip galvanization or electroplating.

Link Dimensions and Design Considerations

Chains are constructed from interlocking links, and the dimensions of these links play a vital role in determining their load-bearing capabilities. Important specifications include the wire diameter, inside length, and inside width of each link.

Wire diameter, also referred to as thickness, directly impacts the strength of the chain. Thicker wires mean more material per link, which generally translates to higher load capacity. However, this also increases the weight and cost. The inside length and width affect how the chain behaves in motion, its flexibility, and how easily it can be used with hooks, pulleys, or other hardware. For instance, shorter links tend to make the chain stiffer, which is ideal for lifting or applications requiring limited elongation. Longer links, on the other hand, increase flexibility but may reduce overall strength and stability under certain loads.

Application-Based Selection

Choosing the right product requires careful consideration of the intended use. For construction sites, factors like load capacity, weather resistance, and ease of handling are key. Chains used in scaffolding or load securing must meet specific strength and fatigue resistance criteria.

In marine applications, the emphasis is placed on corrosion resistance and durability in saltwater environments. Chains in this setting are typically paired with hot-dip galvanization to withstand constant moisture and the abrasive nature of sand and salt. Agricultural uses may not require the same level of corrosion resistance but often demand high flexibility and impact strength to deal with rough handling and variable loads. Chains in this context are often left exposed to the elements, so a moderate protective coating combined with a mid-grade steel composition is common.

Maintenance and Inspection

Routine checks for rust, cracks, and deformities in the links should be part of any maintenance schedule. Any signs of wear or damage, particularly at link junctions, should be addressed immediately. In critical applications, it is often recommended to retire a chain after a certain number of operational hours, regardless of visible condition, to eliminate the risk of fatigue failure. Re-coating and re-galvanizing may be an option for high-value chains that are still structurally sound but have lost their protective layer. However, this depends on the material composition and initial manufacturing process. Lubrication is another aspect of maintenance often overlooked. A light application of oil can help reduce wear in moving applications and offer an added layer of protection against corrosion, especially in non-coated variants.

Conclusion

By selecting appropriately based on the environment and required performance, and by maintaining these tools properly over time, users can maximize value and reliability while minimizing risk and downtime. An MS Chain can offer excellent strength for general applications, but its specific properties must be considered when used for tasks involving high-stress or harsh environments. Furthermore, choosing the correct product isn't just about technical specifications, it’s about long-term investment in safety, efficiency, and sustainability. Mismatched materials or underestimated load capacities can lead to costly failures or even serious accidents. This makes it imperative for both professionals and DIY users to take time to evaluate each factor carefully. An MS Chain that is properly selected and maintained can provide dependable performance over time, offering peace of mind and reducing the likelihood of issues arising during operation.

0 notes

Text

GI Chain: Enhancing Strength and Versatility in Industrial Applications

Industrial operations demand robust and reliable solutions to tackle the challenges of load management, structural support, and secure fastening. Innovations in metal link technology have elevated the performance standards in diverse industries, from construction to shipping. The inclusion of high-quality materials and advanced manufacturing techniques ensures durability and adaptability. The role of specialized providers, such as a GI chain, demonstrates how global markets are addressing the demand for dependable solutions. This article delves into the significance of these chains, their applications, and the emerging trends in their development.

The Significance of Metal Link Systems in Modern Industries

Metal link systems form the backbone of many industrial applications. Their strength and versatility make them indispensable in areas such as construction, where they are used for scaffolding and load-bearing structures, and in shipping, where they secure cargo during transit. The ability to withstand heavy loads and resist environmental factors such as corrosion makes them a preferred choice in demanding environments.

These systems are not only about brute strength; they also reflect engineering precision. Each link is designed to distribute weight evenly, ensuring stability and reliability. The importance of high-quality link systems is underscored by their role in safety-critical applications, where even a minor failure could lead to significant consequences.

Advances in Manufacturing Techniques

The production of these chains has evolved significantly with advancements in technology. Automated manufacturing processes now allow for greater precision and consistency, reducing the likelihood of defects. Materials such as galvanized steel are commonly used to enhance durability and resistance to rust, ensuring that the chains perform well even in harsh conditions.

Heat treatment processes are another critical aspect of modern manufacturing. By subjecting the links to controlled heating and cooling cycles, manufacturers can enhance their tensile strength and ductility. This ensures that the chains can handle dynamic loads and resist wear over time.

Furthermore, innovations in coating technologies, such as zinc and polymer coatings, provide additional layers of protection against environmental factors. These coatings not only improve the lifespan of the chains but also reduce maintenance requirements, making them cost-effective in the long run.

Applications Across Industries

The versatility of these systems is evident in their wide range of applications. In construction, they are used for hoisting equipment and stabilizing temporary structures. The shipping industry relies on them for securing containers and anchoring vessels. Even in agricultural settings, they find use in machinery and fencing solutions.

Customizable designs further enhance their appeal. Industries with specific requirements can opt for tailored solutions, such as chains with specialized hooks or connectors. This adaptability ensures that the systems meet the unique demands of various sectors, enhancing their utility and value.

In oil and gas, metal link systems are crucial for lifting and anchoring heavy equipment, often under extreme environmental conditions. The ability of these chains to withstand harsh temperatures and corrosive environments highlights their importance in such specialized fields. Similarly, in marine industries, their resistance to rust and saltwater corrosion ensures safe and efficient operations.

The Role of Sustainability in Metal Link Systems

As industries strive to adopt more sustainable practices, the production and use of these systems are also undergoing a transformation. Recycling plays a significant role in reducing the environmental impact of manufacturing. Many manufacturers now utilize recycled steel, which not only conserves natural resources but also reduces energy consumption during production.

Design innovations aimed at extending the lifespan of these systems contribute to sustainability. By reducing the need for frequent replacements, industries can minimize waste and lower their operational costs. Additionally, the use of eco-friendly coatings and treatments aligns with global efforts to reduce industrial emissions and promote green practices.

Efforts to improve supply chain sustainability include sourcing raw materials responsibly and ensuring ethical labour practices in manufacturing facilities. The involvement of certified suppliers like a GI chain supplier in UAE ensures adherence to these standards while meeting the rising demand for environmentally conscious products.

Trends Shaping the Future of Metal Link Systems

The future of metal link systems lies in continued innovation and adaptation. Smart chains equipped with sensors for real-time monitoring are becoming a reality. These sensors can detect stress, wear, and environmental conditions, providing valuable data to operators and preventing potential failures.

Lightweight yet strong materials, such as advanced alloys and composite metals, are being explored to reduce the overall weight of these systems without compromising their strength. This is particularly important in industries like aerospace and automotive, where weight reduction is a key focus.

Another emerging trend is the integration of these systems with automation and robotics. In warehouses and manufacturing plants, automated equipment can utilize these chains for efficient material handling, enhancing productivity and safety.

The digital transformation of manufacturing processes also plays a pivotal role. Advanced simulation and modelling techniques allow for the optimization of chain designs before production begins, reducing material waste and improving performance metrics. This digital-first approach aligns with the broader trend of Industry 4.0, where connectivity and data-driven decision-making are at the forefront.

Importance of Specialized Suppliers

Suppliers play a critical role in the distribution and development of high-quality link systems. Regional providers, such as a GI chain, cater to the specific needs of their markets by offering products that meet local standards and environmental conditions. Their expertise ensures that industries receive reliable solutions tailored to their operational requirements.

Collaboration between manufacturers and suppliers drives innovation. By understanding customer needs and industry trends, suppliers contribute to the development of new products and technologies. For instance, partnerships aimed at creating corrosion-resistant chains for marine applications or high-strength options for heavy industries demonstrate the value of this synergy.

Conclusion

The evolution of metal link systems reflects the industrial sector's commitment to innovation and efficiency. Their ability to combine strength, durability, and adaptability ensures their continued relevance across various applications. Whether in construction, shipping, or agriculture, these systems play a critical role in ensuring operational success.

Providers like a GI chain supplier in UAE are instrumental in meeting the global demand for high-quality solutions. By delivering reliable products that adhere to stringent standards, they contribute to the growth and sustainability of industries worldwide. The presence underscores the importance of regional expertise in addressing the unique challenges of different markets.

As advancements in materials, manufacturing, and technology continue, the future of these systems looks promising. The integration of smart features, sustainable practices, and lightweight materials ensures that they remain at the forefront of industrial innovation. For businesses seeking robust and efficient solutions, these chains, supported by specialized suppliers, offer a pathway to enhanced performance and reliability. By focusing on quality, innovation, and sustainability, the industrial sector ensures that metal link systems not only meet current demands but also adapt to future challenges. These advancements, supported by trusted suppliers, reinforce their indispensable role in shaping the future of industries worldwide.

0 notes

Text

At Woosooq.com, we provide a selection of premium clinical towels designed to meet the rigorous demands of healthcare and clinical environments. Our clinical towels are ideal for hospitals, clinics, and other medical settings where hygiene, absorbency, and durability are paramount. Crafted from soft, high-absorbency materials, our clinical towels offer exceptional performance for a variety of uses, including patient care, cleaning, and procedure prep. Their strong construction ensures they can withstand heavy use while maintaining effectiveness, making them a reliable choice for medical professionals.

0 notes

Text

https://starhiveuae.com/product-category/lashing/corner-casting/

Starhive is a company that specializes in the manufacture of corner castings. They offer a wide range of corner castings for different types of shipping containers, as well as for other applications such as construction and mining equipment. Starhive corner castings are known for their high quality and durability.

0 notes

Text

https://starhiveuae.com/product-category/rigging/hooks/

High-quality cargo hooks made for safe and effective load handling are available from Starhive Company. Professionals from a variety of industries rely on our cargo hooks because they are dependable and long-lasting and because they exceed strict safety regulations. For trusted cargo handling solutions, rely on Starhive.

0 notes