Don't wanna be here? Send us removal request.

Text

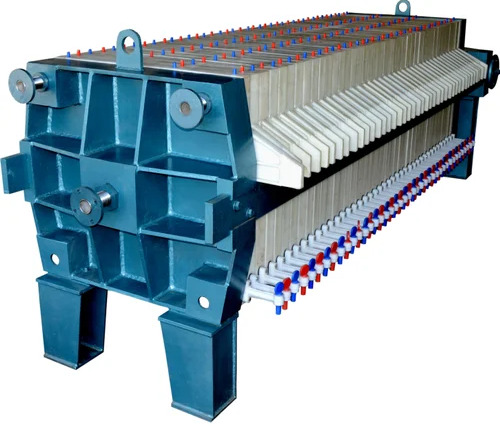

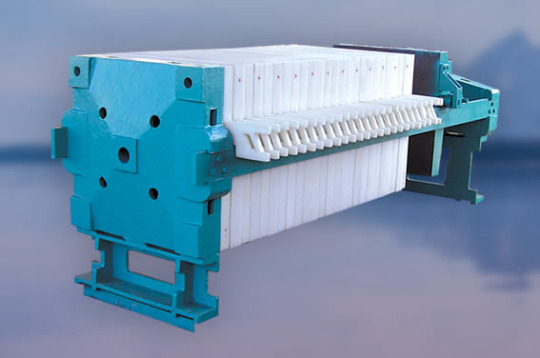

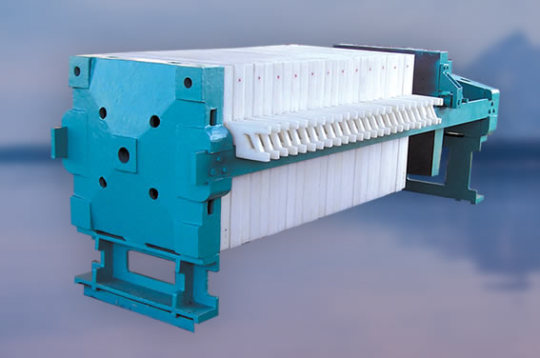

Best Membrane Plate Filter Press In India

Yotana is well known best membrane plate filter presses manufacturers in Ahmedabad, Gujarat. We provide top quality membrane plate filter presses to our local and global client. Our membrane filter presses offer exceptional dewatering and reduce filtration time by over 50%, based on the suspension. Explore our Filter Press Plates for superior filtration solutions.

0 notes

Text

Advantages of Auto Membrane Filter Presses from Professional Manufacturers

The use of Automatic Membrane Filter Presses in industrial applications has grown significantly in recent years, and for good reason. These types of filter presses offer a number of benefits over Conventional filter presses, making them a popular choice among filter press manufacturers.

One of the main benefits of automatic membrane filter presses is their ability to save time and labor. Unlike traditional filter presses, which require manual operation, automatic membrane filter presses can be operated remotely, allowing for continuous operation without the need for constant monitoring. This not only saves on labour costs, but it also increases the efficiency of the filtration process.

In addition to saving time and labour, automatic membrane filter presses also offer improved performance and higher solids retention rates. This is due to the use of membrane plates, which are made from polypropylene or polyethylene, as opposed to traditional filter cloths. Membrane plates are able to retain a higher percentage of solids, resulting in a more efficient filtration process and a higher quality end product.

Another benefit of automatic membrane filter presses is their ability to handle a wide range of applications, from waste water treatment to industrial processing. These filter presses are able to handle a wide range of materials, including liquids, slurries, and suspensions, making them a versatile option for a variety of industries.

When it comes to choosing a filter press manufacturer, it is important to choose a reputable company that offers a wide range of products and services. Leading filter press manufacturers will offer a variety of automatic membrane filter press options, as well as customization options to meet the specific needs of the customer. They will also offer technical support and after-sales service, including maintenance and repair services.

One of the key factors to consider when choosing a filter press manufacturer is their level of expertise and experience in the industry. A reputable filter press manufacturer will have a wealth of knowledge and experience in the design, engineering, and manufacturing of filter presses, as well as a deep understanding of the various applications for which their products are used.

In conclusion, automatic membrane filter presses offer a number of benefits over traditional filter presses, including improved performance, higher solids retention rates, and increased efficiency. When choosing a filter press manufacturer, it is important to choose a reputable company with a wide range of products and services, as well as a strong level of expertise and experience in the industry. With the help of a leading filter press manufacturer, you can be sure that your filtration needs will be met with the highest level of efficiency and quality.

In addition, automatic membrane filter presses are also known for their durability and long service life, making them a cost-effective solution for many industrial applications.

Established in 1972 in Ahmedabad, India, Yotana is a Professional manufacturer of filter presses. Yo-Tana Machine Tools Pvt. Ltd. is the leading manufacturer of high-quality membrane filter presses, Membrane Plate Filter Press, fully automatic filter presses, and PP filter presses in India.

0 notes

Text

Premium Quality Filter Press Manufacturers

Started in the year 1972 in Ahmedabad, Gujarat. We at "Yotana" are manufacturers of the best quality Filter Press. We are one of the most amazing Filter Press producers in India. A Filter Press is one of the most settled and trusted in pieces of dewatering equipment. It's used for wastewater treatment across an arrangement of organizations and applications.

A filter press manufacturer is a piece of hardware utilized in a fluid with strong partition. In particular, the filter press isolates the fluids and solids utilizing pressure filtration, wherein a slurry is siphoned into the channel press and is dewatered under tension. Fundamentally, each filter press is planned in light of the volume and kind of slurry that should be dewatered.

Yotana is a confided-in master in fluid with strong division and offers an extensive variety of filter press types and abilities to suit explicit application needs for inconvenience-free, efficient dewatering. These incorporate arrangements, for example, sidebar programmed, manual above, programmed double above the bar, treated steel clad, blast-resistant channel squeezes, vacuum channel presses, and hand channel presses.

Filter presses are a tension filtration technique and thusly, as the filter press feed siphon fabricates pressure, solids work inside the chambers until they are totally crammed with solids, shaping the cake. When the chambers are full, the cycle is finished and the channel cakes are fit to be delivered.

In numerous higher limit filter squeezes, quick activity programmed plate shifters are utilized, speeding process duration. Some filter presses are explicitly intended for completely programmed, 24-hour activity in a cruel climate, for example, mines or substance fabricating plants.

0 notes

Link

0 notes

Link

Filter presses are a pressurize filtration strategy and accordingly as the filter press feed siphon fabricates pressure, solids work inside the chambers up to they are stuffed with solids, shaping the cake.

0 notes

Link

Filter presses are a tensity filtration strategy. As the Filter press feed siphon fabricates constraint, the solids work inside the chambers until they are totally loaded with solids. This structures the cake. The Filter cakes discharge when the plates are completed, and the cycle is finished.

0 notes

Link

The functioning standard of filter presses is that slurry is bled into the machine with the end goal that solids are circulated uniformly during the filling cycle. Solids develop on the filter material, framing the filtrate exits the filter plates and leaves the filter plates through the area ports into the complex, yielding clean filtered water.

0 notes

Text

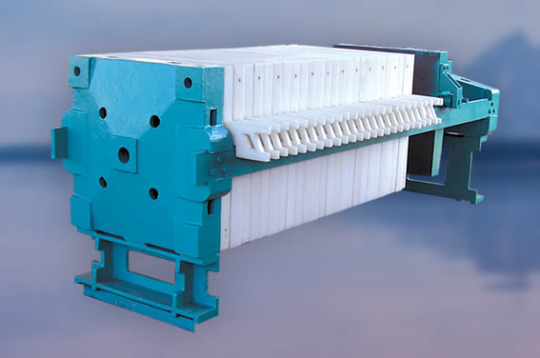

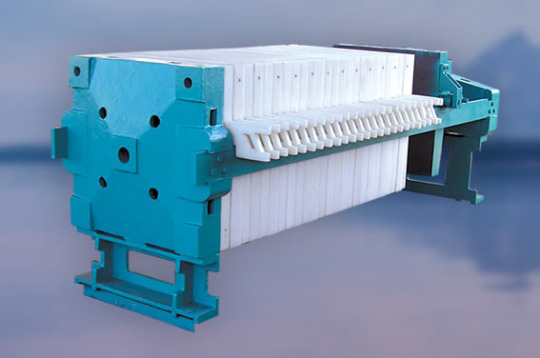

Plate and Frame Filter Press Manufacturers in India

Established in the year 1972, Yo-tana has been a well know filter press manufacturers in Ahmedabad, Gujarat. With years of experience, we deliver the best plate and frame filter press at “Yo-tana”. We have the best expert team of R&D with the latest manufacturing technology and applications. A filter press uses variety of environment processing for the final filter cake

This filter press applies pressure to the extracted solid and dissolves the particles and fluids with a frequent filtering cycle producing filter cake with water. We have kept the design traditional with modern facilities and processes. Our press machine operates with a hollow frame in the middle of every plate covered with filter cloth. The whole process of machine is semi-automatic with complete filtration.

Yo-tana provides plate and frame filter press for mineral handling with modern filters. The main part of this press is filter plates, frames, filter cloth, and chambers to meet the desired results.

Plate and Frame filter combined can hold the capacity of slurry and make the perfect cake with an effective and rapid process without any delay or tearing out the plates. This machine is compatible for any industry for rapid process and meet requirements.

The process is started in cycle format. The chambers are filled with the slurry through the inlet in all the plates and pressuring it to remove the excess water from it to make the perfect cake in every frame.

The plates make a cake with low moister and under the pressure of siphon, the particles are captured in filters chambers from the slurry. The outlet removes the water from the corners. Each plate produces the shaped cake for use in industry. The process is then run again for another cycle.

We offer effective and high-quality equipment for the press machine with a variety of applications and industry usage. We meet customer needs and try to fulfil the requirement with a unique industry unit.

1 note

·

View note

Text

Best Plate and Frame Filter Press Manufacturer in India

Yotana is well known filter Press Company in Ahmedabad, Gujarat established in the year 1972. We at "Yotana" are manufacturing of best quality Plate and Frame Filter Press. We are one of the best Filter Press Plates manufacturer in Ahmedabad India. A filter press utilizes further developed pressure to knock up the pace of filtration and production a last filter cake with a moderate water content.

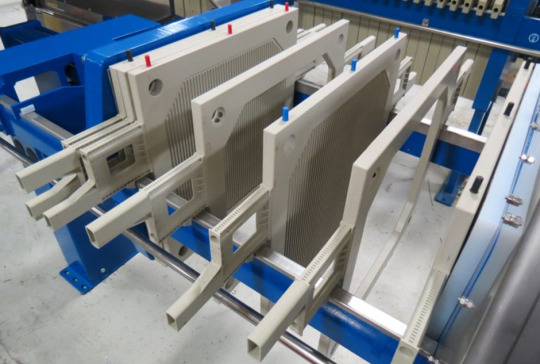

The Plate and Frame Press is the most principal plan and the most seasoned kind of Filter Press. The plate and frame configuration is to take care of a strong plate by a filter fabric and an empty in the middle of between each plate. The slurry is siphoned into at least one of the corner openings and it goes into each frame prior to filtering through the material.

The upside of this plan is that various thicknesses of frames can be utilized for an assortment of cake thicknesses. This permits adaptability in how much filtered solids that can be created per group. One hindrance is the way that taking care of the corner and coursing through a little opening into the frame can cause stopping leaving one frame full and another void.

Yotana Plate and Frame Filter Press is a verifiable term for current modern filter presses utilized in mineral handling. The principal part of plate and frame filter press is a bunch of filter chambers comprise by filter plates and filter frames in exchanging request. While working, the slurry will be moved by taking care of siphon from the taking care of opening on the push plate to all chambers, under the pressure of taking care of siphon, strong particles in the slurry will be caught into the filter chambers and structure into filter cakes gradually, fluid all through the filter garments and emerge from outlet openings.

A filter press is a piece of hardware intended for group process filtration expected to isolate solids and fluids utilizing pressure filtration driven by slurry feed siphons.

Filter presses comprise of two principal parts: the framework and the filter pack. A plate and frame filter press utilizes a filter pack that is comprised of substituting plates and frames. A frame, as recommended, is an emptied framework properly estimated to match a related plate. One of the Advantages of a Plate and frame filter press is the capacity to take care of a huge focus opening which effectively and rapidly fills the cavities without stopping up and harming plates in light of inconsistent pressure.

0 notes

Text

Best Fully Automatic Filter Press Manufacturers in India

Started in the year 1972 at Ahmedabad, Gujarat. We at "Yotana" are manufacturers of best quality fully automatic filter press. We are one of the best fully automatic filter press manufacturer in India. Right away, fully automatic filter presses contrast fundamentally from traditional filter presses.

0 notes

Text

Best Membrane Filter Presses Manufacturers in India

Yotana is well known membrane filter Presses Company in Ahmedabad, Gujarat established in the year 1972. We at "Yotana" are manufacturing of best quality filter press. We are one of the best solid liquid separation equipment manufacture in Ahmedabad India.

0 notes

Text

Best Pp Filter Press Manufacturers in India

Started in the year 1972 at Ahmedabad, Gujarat. We at "Yotana" are manufacturers of best quality Pp filter Press. We are one of the best Pp filter Press manufacturer in India. PP Filter Press Plates are utilized for fine filtration explicitly to isolate solids and liquids.

For more information about Pp filter press click this link: https://yotana.com/products/p-p-recess-chamber-plates

0 notes

Text

Best Plate and Frame Filter Press Manufacturers in India

Yotana is well known filter Press Company in Ahmedabad, Gujarat established in the year 1972. We at "Yotana" are manufacturing of best quality Plate and Frame Filter Press. We are one of the best Filter Press Plates manufacturer in Ahmedabad India.

For more information about plate and frame filter press click this link: https://yotana.com/product/conventional-filter-press

0 notes

Text

Filter Press Manufacturers | Fully Automatic Filter Press

Started in the year 1972 at Ahmedabad, Gujarat. We at "Yotana" are manufacturers of best quality fully automatic filter press . We are one of the best fully automatic filter press manufacturer in india. Right away, fully automatic filter presses contrast fundamentally from traditional filter presses. Fully automatic filter presses are explicitly intended for applications in which a ceaseless activity and quick process durations are fundamental and consequently pivotal.

Right away, fully automatic filter presses vary altogether from traditional filter presses. The essential engineering, the functioning standard and interaction innovation are indistinguishable. Fully automatic filter presses are explicitly intended for applications in which a persistent activity and quick process durations are fundamental and subsequently essential. MSE fully automatic filter presses give a serious level of computerization while giving continuous activity simultaneously.

Yotana semiautomatic frameworks, with the exception of the total activity, from the taking care of through the finish of the filtration cycle, is started through a solitary "start" press button in focal control board.

We make fully robotized progressed filter press manufacturers with plate moving and plate shaker for auto cake release alongside PLC based electrical control board and pneumatically worked control valves, stream sensor, and using pressurized water worked bomb entryway trickle plate.

The outcome is a high velocity filter press that permits expanded creation per unit area of filter. Consequently, these machines are utilized in applications with profoundly filterable items where high filtration speeds are required. These incorporate, for example mining concentrates and deposits.

0 notes

Text

Membrane Filter Presses | Solid Liquid Separation Equipment

Yotana is well known membrane filter presses company in Ahmedabad, Gujarat established in the year 1972. We at "Yotana" are manufacturing of best quality filter press. We are one of the best solid liquid separation equipment manufacture in Ahmedabad india. Membrane filter presses not just proposition the benefit of an incredibly serious level of dewatering, they additionally diminish the filtration process duration by in excess of 50% overall, contingent upon the suspension.

Membrane Filter Presses are utilized for additional dampness decrease in the cake. Our organization is a praised name offering amazing modern membrane filter press to many set up enterprises across India.

Membrane plates filter presses are utilized since quite a while in the compound, food and modern enterprises. These days this sort of filter presses is increasingly more utilized for any sort of materials (Dyes, Pigment, Pharmaceuticals, Edible Oil, quarries, metropolitan and modern slime of any sort)

The Yotana membrane press plate diminishes the long pressing cycle by bringing a fit medium into the focal point of the membrane crush plate. This permits the membranes to flex against the cake, compressing and pressing it.

The external sides of these plates are fixed with a plastic or elastic membrane. Membrane filter plates have a chamber beneath the seepage surface that might be swelled. Membrane Filter press is by and large utilized in blend pack arrangement of one sidekick plate (Recessed) and one Membrane plate. After an ordinary filtration process in the filter press (taking care of ordinarily at pressure: 7 to 10 bars), the membranes are swelled through pressurized water or compressed air along these lines crushing the cakes all around their surface.

The volume of the cake consequently diminishes and an extra volume of filtrate is extricated. The last filter cake is a consequence of just barely getting by the membrane. The high pressure PP membrane plate is the most recent and the most down to earth new sort filter plate.

0 notes

Text

Filter Press Plates

Yotana is well known filter press company in Ahmedabad, Gujarat established in the year 1972. We at "Yotana" are manufacturing of best quality Plate And Frame Filter Press . We are one of the best Filter Press Plates manufacturer in Ahmedabad india. A filter press utilizes further developed pressure to knock up the pace of filtration and production a last filter cake with a moderate water content.

A modern filter press plates manufacturer is an apparatus utilized in partition processes, explicitly to isolate solids and fluids. The machine stacks many filter components and permits the filter to be effortlessly opened to eliminate the filtered solids, and permits simple cleaning or substitution of the filter media.

A Yotana filter press is a piece of gear utilized in fluid/strong partition. In particular, the filter press isolates the fluids and solids utilizing pressure filtration, wherein a slurry is siphoned into the filter press and is dewatered under tension. Essentially, each filter press is planned in view of the volume and kind of slurry that should be dewatered. Micronics, Inc.

Filter presses are a pressure filtration strategy and thusly, as the filter press feed siphon assembles pressure, solids work inside the chambers until they are totally stuffed with solids, framing the cake. When the chambers are full, the cycle is finished and the filter cakes are fit to be delivered.

0 notes

Text

Top Common Filter Press Issues To Know About

Stop looking at the product prices only while you shortlist the plate and fqrame filter press exporters in the market. Only considering the cost of the equipment won't help you to make a wiser decision. Instead, you must look for the quality of the machinery, the company's background, etc. Along with that, you must also know about the common issues that frequently occur with such machinery.

Intrigued to know more? Let’s check out the common problems that might occur with the filter press and quick solutions:

Cake Stickiness

The first and pretty common problem is that the cake often tends to stick to the filter cloths. What happens next? Sticking to the filter cloth will only increase the time for discharging the filter cake. It can happen when you frequently wash the cloth due to the debris accumulation within it. Ensure to change the filter cloth of the frame filter press and plate periodically to smoothen the discharging process.

Poor Filtrate Quality

Did you know that poor-quality filtrate can cause non-compliance issues with your local water authorities? Yes, if the filtrate or the filter cake is poor in quality, you need to employ additional filtration methods.

Poor cakes consist of too much moisture that can cause the stickiness of the same to the cloths. It ultimately can increase the disposal expenses for the company. In addition, if the cake is any kind of product, it might require additional time for drying.

Build-Up Within The Feed Port

Another common problem with the filter press is the excess build-up of the filter cake within the feed port. It ultimately slows down the cake discharging process as each filter plate needs proper cleaning before shifting on to the next one. And in case it fails to do so, the entire filtration process might come to a halt.

Holes Within The Filter Cloths

Filter cloth will always remain vulnerable to most of the issues that commonly occur in your filter press. As it is responsible for conducting the entire filtration process, you need to be careful about changing the cloth frequently. Another common problem that occurs here is the occurrence of holes within the fabric. The holes can cause the sewage to become cloudy that can extend the duration of filtration.

Conclusion

If you need to eliminate these hassles, visit https://yotana.com/product/conventional-filter-press. The brand is a reputed name in the market for offering you excellent filter press machinery along with excellent after-sales services. In addition, you get incredible designs and hassle-free customisations as per your business requirements. To know more, call Yo-Tana today.

Yotana is well known filter press company in Ahmedabad, India established in the year 1972. We at "Yo-Tana Machine Tools Pvt. Ltd." are manufacturing of best quality Membrane Filter Presses, Plate And Frame Filter Press, Fully Automatic Filter Press and PP Filter Press in India.

1 note

·

View note