Don't wanna be here? Send us removal request.

Text

Advanced Robot Motion Sensors and Joint Torque Sensors | AIDIN ROBOTICS

AIDIN ROBOTICS offers advanced robot motion sensors and joint torque sensors designed to enhance the precision, safety, and intelligence of robotic systems. These sensors are built using AIDIN’s proprietary capacitance sensing technology, making them highly accurate, compact, and reliable for modern automation needs.

Robot Motion Sensor: This robotic motion sensor can be mounted on articulated or collaborative robots to detect joint torque and sense collisions. In addition to industrial robots, it is also applicable to joints in various assistive medical devices commonly used in healthcare fields such as rehabilitation and gait support.

Key Features:

6-axis sensing: Includes 3-axis gyroscope, accelerometer, and magnetometer.

High sampling rate: Supports fast, accurate motion tracking.

Compact & lightweight: Easy to install on robot arms, end effectors, or mobile robots.

Multiple interfaces: Compatible with USB, UART, or CAN depending on model.

Built-in filters: Provides stable, real-time orientation data with minimal drift.

Benefits:

Enhances robot path tracking and control precision.

Enables real-time feedback for AI-based motion analysis.

Improves collision detection and force estimation.

Ideal for direct teaching, motion learning, or wearable robots.

Joint Torque Sensor: AIDIN's joint torque sensor measures torque directly at each robot joint. It's designed to monitor interaction forces between the robot and its environment or human operators.

Key Features:

Ultra-thin & compact: Can be embedded directly in joints without redesigning the structure.

Capacitance-based sensing: High accuracy and minimal drift, even under long-term load.

All-in-one design: No need for external amplifiers or signal processors.

Various torque ranges: Available for light, collaborative, or industrial robot joints.

IP-rated options: Suitable for rugged environments.

Benefits:

Enables precise torque control at each joint, crucial for delicate or adaptive movements.

Provides real-time feedback for force-limited collaborative robots (cobots).

Improves safety and compliance, reducing risk of overexertion or injury in HRI (human-robot interaction).

Ideal for applications like robot-assisted surgery, exoskeletons, rehabilitation robots, and precision manufacturing.

If you are looking for robot motion sensors and joint torque sensors, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: Advanced Robot Motion Sensors and Joint Torque Sensors

0 notes

Text

High-Precision Force Torque Sensors | AIDIN ROBOTICS

AIDIN ROBOTICS offers the force torque sensor, a high-precision sensor that improves the sensitivity and dexterity of robotic arms performing difficult industrial tasks. Compared to the onrobot force torque sensor, it has higher performance, sensitivity, and precision due to AIDIN ROBOTICS' fringe effect skills. In addition, by applying capacitance technology, it is offered at a more affordable and competitive price. This innovative 6-axis force-torque sensor monitors forces and torques in all three dimensions (Fx, Fy, Fz, Tx, Ty, and Tz), allowing robots to detect even the smallest touch or pressure while operating.

Applications of Force Torque Sensors in Various Fields

AIDIN ROBOTICS force torque sensors, capable of simultaneously measuring multi-axis forces and torques, support robots in performing these tasks efficiently. The company also produces Miniature force torque sensors that can be easily integrated into narrow spaces like robot hands, grippers, and VR devices, enabling finer operations.

The miniature 6-axis force/torque sensor can be used not only in robotics but also in various other fields, with healthcare being a prominent example. For instance, it can be applied to orthodontic devices, where it helps accurately measure corrective forces during the orthodontic process. This allows for more precise alignment of the teeth and contributes to improved treatment outcomes.

Once force torque sensors are integrated into collaborative robots, they can be applied to a wide range of manufacturing processes requiring precision, such as grinding, welding, screw assembly, and surface treatment. These sensors offer broad versatility and scalability. The type of sensors used in collaborative robots, as well as in various industrial robots, varies depending on the manufacturing process and product formation of each robot maker. As robot manufacturers apply different sensors based on factors like robot price and product purpose, the types of sensors integrated into robots will become an important factor in customers' decisions when selecting a robot.

This trend is expected to have a significant impact on everything from the precision of robot movements to human-robot collaboration. The advanced force torque sensors developed by companies like AIDIN ROBOTICS will accelerate the sophistication of robots in the market, offering customers more affordable options and ultimately speed up the widespread adoption of robots.

If you are looking for an onrobot force torque sensor and multi axis sensors, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: High-Precision Force Torque Sensors

0 notes

Text

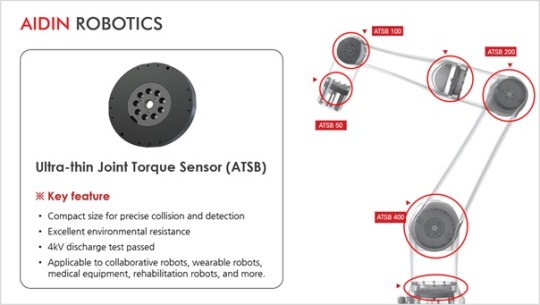

Ultra-thin Robot Joint Torque Sensor | AIDIN ROBOTICS

The AIDIN ROBOTICS ultra-thin joint torque sensor is designed to accurately measure the torque applied to robot joints. Its ultra-thin and compact design allows for seamless integration into robotic systems without adding significant bulk. This sensor enables precise collision detection and highly accurate torque control, making it ideal for advanced robotic applications that require both safety and performance. Its high sensitivity and reliability support smooth and responsive robotic motion, essential for collaborative and service robots.

Features of Ultra-thin Joint Torque Sensor:

Ultra-thin and Compact Design

The sensor is designed to be extremely thin, allowing easy integration into tight spaces within robotic joints without adding unnecessary bulk. This is especially valuable for compact or lightweight robots.

High Torque Measurement Accuracy

The sensor delivers precise torque readings, which are essential for applications requiring accurate force control, such as medical robots, collaborative robots (cobots), or high-precision assembly systems.

Real-time Data Output

The sensor provides torque data in real time, enabling immediate feedback for responsive control systems. This ensures smooth robot operation and fast reaction to environmental changes.

High Sensitivity and Resolution

Capable of detecting minute changes in force, the sensor supports delicate handling tasks, such as gripping fragile objects or adjusting pressure during contact.

Strong and Durable Construction

Built to withstand long operating hours and challenging industrial environments, ensuring long-term reliability and minimal maintenance.

Wide Compatibility

Can be used across different types of robots and actuators, making it a versatile component for a range of robotic applications.

Key Rolf of Joint torque sensor

Role of the Joint Torque Sensor

Torque sensors installed at each joint (motor) continuously measure the actual torque applied.

These readings are compared to the expected torque based on the robot's planned trajectory.

Abnormal Torque Detection

A collision causes an unexpected external force, resulting in a sudden spike or abnormal pattern in torque.

Example: If the robot arm hits a person’s arm, there will be a noticeable reactive torque.

Real-Time Detection and Response

The controller detects this anomaly in real time and immediately:

Stops the robot,

Slows it down, or

Moves it away (retreats),

If you are looking for ultra-thin joint torque sensors and robot motion sensors, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: Ultra-thin Robot Joint Torque Sensor

0 notes

Text

Onrobot Force Torque Sensor with High-Precision Control | AIDIN ROBOTICS

AIDIN ROBOTICS integrates advanced robotics solutions, and one of the key components they utilize is the force torque sensor. Compare to onrobot force torque sensor. This sensor is designed to provide precise control and feedback in robotic automation tasks, enhancing the capabilities of collaborative robots (cobots) across various industries by capacitance technology.

What is a Force Torque Sensor?

A force torque sensor is a device used in robotics to measure and control forces and torques applied in a three-dimensional space. In simple terms, force refers to a push or pull, while torque refers to a twisting force. These sensors play a critical role in enhancing the sensitivity and functionality of collaborative robots (cobots), especially in tasks requiring precision, compliance, or human-like responsiveness.

Force torque sensors are considered a key component in the sensor system of robotic hardware, alongside robotic arms, end effectors (also known as End of Arm Tools), controllers, and drive systems. Traditionally, torque sensors were used mainly in robot joints to allow movement in different directions. However, modern force/torque sensors go beyond that by enabling robots to detect both linear forces and rotational torques — capabilities that were previously out of reach.

Types of Force Torque Sensors:

6-Axis Force Torque Sensors (Fx, Fy, Fz, Tx, Ty, Tz): These measure forces in all three spatial directions (X, Y, Z) and torques around those axes. They offer full 3D force and torque detection, making them ideal for tasks like polishing, insertion, or precision assembly.

3-Axis Force Sensors (Fx, Fy, Fz): These measure forces in the three linear axes but do not detect torque. They are used where torque feedback is not required.

1-Axis Pressure Sensors: These detect force or pressure along a single direction only and are often used in simple contact detection applications.

Torque Sensors: These specifically measure rotational force (torque) around a single axis. They are commonly used in joints or motors to control rotation precisely.

Overall, force torque sensors allow robots to interact more naturally with their environment, improving safety, accuracy, and efficiency in industrial automation, research, and human-robot collaboration.

If you are looking for onrobot force torque sensor, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more:Onrobot Force Torque Sensor with High-Precision Control

0 notes

Text

High-precision Onrobot Force Torque Sensor | AIDIN ROBOTICS

AIDIN ROBOTICS' provides the force torque sensor, a high-precision sensor that enhances the sensitivity and dexterity of robotic arms for complex industrial tasks. Compared to onrobot force torque sensor, It shows high-performance, more sensitivity and precision based on fringe effect skills by AIDIN ROBOTICS. This advanced 6-axis force-torque sensor measures forces and torques along all three dimensions (Fx, Fy, Fz, Tx, Ty, Tz), allowing robots to detect even the slightest touch or pressure during operation.

Key Features of Force Torque Sensor

Compact 6-Axis Force/Torque Measurement: Measures force and torques along all 6 axes in a highly compact form, ideal for space-constrained applications.

All-in-One Integrated Design: Features fully integrated circuitry — no need for external amplifiers or separate measuring equipment, simplifying installation and operation.

High Durability and Impact Resistance: Built to withstand external shocks and harsh working conditions, ensuring long-term reliability.

Multi-Sensor Mounting Capability: Allows multiple sensors to be mounted and securely operated simultaneously for complex robotic applications.

Excellent Environmental Resistance: Robust against various environmental factors, making it suitable for demanding industrial settings.

Certified Safety and Performance: Passed 4kV electrostatic discharge test and holds international certifications including CE, KC, FCC, and RoHS, ensuring compliance with global safety and quality standards.

Application Areas

Assembly Automation: Enhances accuracy in inserting, fastening, and fitting parts together.

Polishing, Grinding, and Deburring: Maintains consistent contact force for surface finishing tasks.

Quality Inspection and Testing: Measures applied force precisely for material testing or component verification.

Medical and Laboratory Robotics: Handles sensitive samples and instruments with controlled, delicate force.

Collaborative Robotics (Cobots): Improves safety and dexterity for human-robot interaction by detecting contact forces.

If you are looking for onrobot force torque sensor, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: High-precision Onrobot Force Torque Sensor

0 notes

Text

Advanced Robot Force Control Systems with Force Torque Sensors | AIDIN ROBOTICS

AIDIN ROBOTICS specializes in advanced robot force control systems and robot torque sensors that enhance the precision, flexibility, and efficiency of industrial robots in a wide range of applications.

Robot Force Control: AIDIN ROBOTICS’ force control solutions enable robots to precisely sense and adjust the force applied during tasks such as assembly, polishing, deburring, surface finishing, and collaborative handling in many manufacturing sites. (Ex, Automotive, Home appliance, Electronics/Semiconductors, Medical, Aerospace, Shipbuilding and Construction / Interior)

Key Features Robot Force Control for Manufacturing automation

Precision: Achieve consistent quality with precise control up to ±0.1N, enabled by a 6 axis Force torque sensor

Flexibility: Customizable for diverse manufacturing environments

Efficiency: 16 hours daily capacity & 2x work speed boost

The Advantage of Robot Force Control

Self-developed 6 axis F/T Sensor & High-performance robot controller ensure ±0.1N precision

High productivity with 16 hours daily operation

Ensures uniform quality over manual labor

Robot performs control execution with no additional equipment

Intuitive interface for easy programming and fast development

This system composed of collaborative Robot, 6 axis F/T Sensor, Robot motion Controller, and other customizable tools tailored to fit the customer’s environment. Especially, this 6 axis F/T Sensor is based on fielding sensing technology, combined with capacitance measurement and AIDIN’s self-development skills. Therefore, it shows high-precision and high performance for data sampling.

Their force-torque sensors and controllers provide real-time feedback, allowing robots to perform delicate or complex operations with human-like sensitivity. Key benefits include improved process quality, minimized damage to workpieces, and adaptive control in dynamic environments.

Together, these technologies improve automation efficiency, increase safety in human-robot collaboration, and provide manufacturers with the flexibility needed to handle complex production challenges.

If you are looking for robot force control and force torque sensor, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more:Advanced Robot Force Control Systems and Robot Grippers

0 notes

Text

Precision Robotics with Advanced Force Control and High-Accuracy Sensing | AIDIN ROBOTICS

AIDIN ROBOTICS' robot force control technology offers advanced capabilities that enable robots to interact with their environment with high precision and adaptability. At the core of this system is high-precision force-torque sensing, which allows the robot to measure forces and torques across multiple axes with great accuracy. This real-time feedback enables the robot to adjust its movements instantly, ensuring consistent task execution even in dynamic or unpredictable environments.

One of the standout features of AIDIN's force control is its compliance control, allowing the robot to respond flexibly to external forces. This makes it ideal for delicate operations such as polishing, surface finishing, deburring, and precision assembly. The system also supports multi-axis control, which is essential for handling complex motions and interacting with uneven or curved surfaces. With a plug-and-play design, AIDIN's force control can be easily integrated into existing robotic systems, and its customizable software interface provides users with the flexibility to set force thresholds and behavior parameters to match specific task requirements.

The benefits of this technology are substantial. It significantly improves product quality by maintaining consistent contact pressure, which results in smoother finishes and fewer defects. By automating tasks that traditionally required manual labor, it enhances productivity and reduces operational costs. Safety is also improved, especially in collaborative environments, as the robot can detect and respond to unexpected contact. Moreover, the controlled application of force reduces wear and tear on tools and minimizes the risk of damage to delicate parts. Its ability to adapt to variations in part positioning or surface conditions makes it highly versatile for use in industries such as electronics, automotive, metalworking, and precision manufacturing. Overall, AIDIN ROBOTICS’ robot force control technology brings a new level of intelligence and efficiency to modern automation systems.

In summary, AIDIN ROBOTICS’ force control solution offers the following advantages:

* Differentiated technology: Self-developed 6 axis F/T Sensor & High performance robot controller ensure ±0.1N precision

* Integrated Solution: Robot performs control execution with no additional equipment

* Absolute performance: High productivity with 16 hours daily operation

* Easy control: Intuitive interface for easy programming and fast deployment

If you are looking for an industrial robotics automation, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: Precision Robotics with Advanced Force Control and High-Accuracy Sensing

0 notes

Text

Advanced Capacitive Sensing: Precision Force Measurement with Torque and Force Torque Sensors | AIDIN ROBOTICS

AIDIN ROBOTICS' innovative capacitance sensing technology enhances precision and stability through its advanced high-sensitivity detection mechanism. Designed to resist noise interference, this robust system ensures reliable data output, making it ideal for applications requiring accuracy, including those utilizing force torque sensors. Additionally, it demonstrates excellent adaptability to temperature fluctuations and environmental changes, maintaining consistent performance across varying conditions. By incorporating Fringe Effect technology, this approach overcomes the limitations of conventional sensing methods, delivering superior functionality and efficiency in diverse operational settings where precise force measurement is essential.

Advantages of AIDIN ROBOTICS’ Capacitance Sensor Technology Comparison: AIDIN ROBOTICS Capacitance Type Sensor vs. Strain Gauge-Type Sensor

High Sensitivity and Precision: Capacitive sensors detect subtle changes in capacitance, enabling accurate measurement of minute force and torque variations.

Durability and Long-Term Stability: Unlike strain gauges, which suffer from sensitivity degradation over time due to mechanical fatigue, capacitive sensors maintain stable performance.

Miniaturization Potential: The structurally simple nature of capacitive technology allows for ultra-compact designs, increasing design flexibility for robotic applications.

Cost-Effectiveness and Mass Production: The simplified structure enables sensor production without manual processes, facilitating mass production and enhancing cost-efficiency.

No Additional Equipment Required: While strain gauge sensors require amplifiers for high-precision data, capacitive sensors operate without the need for such equipment.

Why AIDIN ROBOTICS Sensors Are Ideal for Robotics Applications

Optimized for Multi-Axis Sensing: Capable of simultaneously detecting complex multi-axis forces and torques, making them essential for collaborative robots and precision manipulation tasks.

High Adaptability to Temperature Changes: Maintains stable performance in various work environments, even with fluctuating temperatures.

Compact and Lightweight Design: Enables easy integration into confined spaces such as robot joints, grippers, and wrists due to its ultra-small and lightweight structure.

Efficient Robot Integration: Operates without the need for external amplifiers, simplifying integration and saving installation space.

If you are looking for a torque sensor, you can find them at AIDIN ROBOTICS.

Click here if you are interested in AIDIN ROBOTICS products.

View more: Advanced Capacitive Sensing: Precision Force Measurement with Torque and Force Torque Sensors

0 notes

Text

Industrial Robot 6-axis Force Torque Sensor | AIDIN ROBOTICS

The 6-axis force torque sensor from AIDIN ROBOTICS is a high-precision solution for collaborative robots and industrial robots, designed to accurately measure forces and torques in all six degrees of freedom. This sensor is ideal for improving robotic accuracy and responsiveness, particularly in applications requiring precise control and feedback, such as assembly, grinding, and complex material handling.

Smart 6-axis Force Torque Sensor

The 6-axis force/torque sensor is an essential component in modern robotics, significantly enhancing wrist performance by detecting tool impacts, managing applied force, and accurately measuring weight. Designed to be attached to the wrist of a collaborative robot, this sensor uses an advanced electrostatic capacitance measurement method, enabling precise force control and collision detection, which are critical for tasks like object weight measurement, force regulation, and teaching applications.

Features of 6-Axis Force/Torque Sensor for Collaborative Robotics:

Next-Generation Measurement Technology: Utilizes a fringe effect-based capacitance measurement method for high-precision force and torque detection.

Integrated IMU: The sensor includes an Inertial Measurement Unit (IMU) to track and remember its position, adding another layer of spatial awareness.

Versatile Communication Options: Supports CAN, EtherCAT, and Ethernet communication protocols for seamless integration into various robotic systems.

Collaborative Robot Compatibility: Specifically designed for integration with collaborative robots, enhancing their performance and safety.

Exceptional Environmental Resistance: Built to withstand challenging environments, with excellent durability.

High-Voltage Protection: Successfully passed a 4kV discharge test, ensuring reliable operation under high electrostatic conditions.

If you are looking for a force torque sensor robot, you can find them at AIDIN Robotics.

Click here to if you are interested in AIDIN Robotics products.

View more: Industrial Robot 6-axis Force Torque Sensor

0 notes

Text

Leader of Global Robot Sensor Market | AIDIN ROBOTICS

The evolving robotic company AIDIN ROBOTICS Inc. has begun in robotics research carried out by Sungkyunkwan University's mechanical engineering department. Established on a foundation of innovation and technological excellence, AIDIN ROBOTICS is dedicated to realizing a future where people and robots seamlessly coexist and collaborate in a safe manner. At the core of AIDIN ROBOTICS’ mission is the development of advanced robot sensor technologies, building upon the extensive field sensing expertise the company has accumulated since 1995.

[Robot Sensor Market Analysis]

Global Market for 6-Axis Force/Torque Sensors for Robots

Out of the global robot sensor market worth 2.4 trillion KRW, the 6-axis force/torque sensor segment represents 25%, forming a market valued at approximately 600 billion KRW. It is projected to grow by 13% annually, reaching 1.105 trillion KRW by 2028.

Demand Forecast for 6-Axis Force/Torque Sensors Based on Industrial Processes

[1]

Based on the number of robots introduced into these processes, the global demand for 6-axis force/torque sensors in 2022 is estimated at around 90,000 units. With the global sensor market’s 13% CAGR, the worldwide demand is expected to grow to 165,000 units by 2026.

Forecast for 6-Axis Force Torque Sensor Demand in the Growing Collaborative Robot Market

While collaborative robots (cobots) are primarily being adopted by small and medium-sized manufacturers for cost-effective and safe operations with simple position control processes, future demand for competitive 6-axis force/torque sensors is expected to increase, as these sensors will enable force/torque-based operations without the need for expensive ATI sensors traditionally used in industrial robots.

As of 2020, in the domestic market, 10.3% of small and medium-sized manufacturers (3,060 out of 30,602 companies) expressed an intention to introduce robots. Of these, 34% (1,040 companies) are expected to adopt processes that require 6-axis force/torque sensors.

With the growth of the collaborative robot market, the number of companies requiring 6-axis force/torque sensors is projected to increase to 8,893 by 2026.

Expansion Strategy for EoAT+Solutions Utilizing 6-Axis Force/Torque Sensors

Expanding into solutions that integrate sensors with End-of-Arm Tooling (EoAT) is expected to generate sales for each process that uses 6-axis force/torque sensors. This would create a high value-added business, potentially 50 times more profitable than selling individual sensors alone.

In the future, most of the processes that have yet to be automated by robots involve tasks requiring skilled manual labor and the application of force. This suggests that the remaining automatable processes will largely rely on 6-axis force/torque sensors and EoAT solutions.

If you are looking for world's leading robot sensor technology company, you can find it on Aidin Robotics

Click here to contact AIDIN ROBOTICS.

View more: Leader of Global Robot Sensor Market

0 notes