I am a software engineer working for the Satellite Servicing Capability Office and NASA's Goddard Space Flight Center, building space robots. Although many of the things I encounter during my day seem like just part of the job, it occurred to me that many might find them weird, interesting, or even cool.

Don't wanna be here? Send us removal request.

Text

OSAM1 spacecraft in the clean room with one of our space robot arms mounted on top. This is from September and is a public release photo from NASA.

4 notes

·

View notes

Text

I'm going to miss my hexapod.

1 note

·

View note

Text

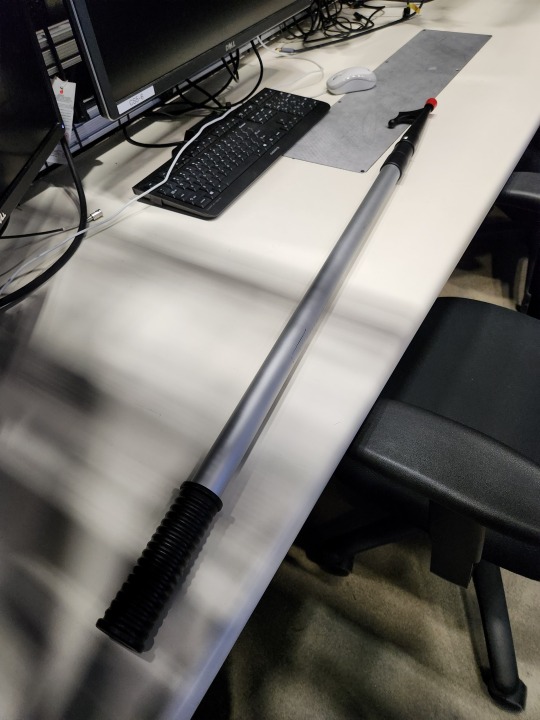

Precision force application device in use today

0 notes

Link

There’s a lot of nice shots of our robot lab here, oh yeah, and some very special visitors.

3 notes

·

View notes

Photo

I think I played this game once on an Atari 2600.

1 note

·

View note

Photo

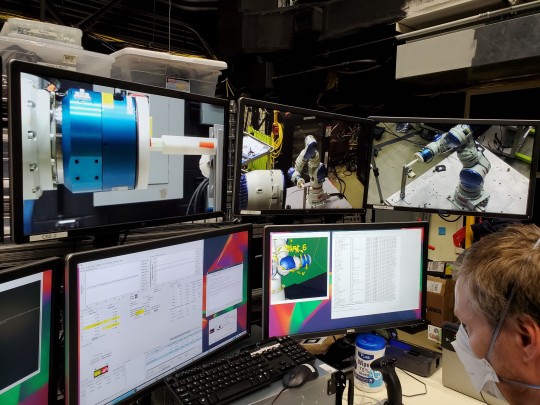

Vice President Harris stopped by the ROC on Friday during her NASA Goddard tour. The above picture is her controlling the OSAM-1 EDU Robot System (our space robot test version) using the joysticks at a robot console. You can read all about it here and there’s a lot more pictures here.

0 notes

Text

Today, we had a robot insert a tool into a slotted hole, then torque it without damaging it - all according to the operator's direction. I've been working with 3 really smart and capable robotics experts to teach a robot how to be gentle when it should and use force when needed.

0 notes

Photo

Poking robots again - A few weeks ago, we completed setup of our space simulation on the new, very large Hexapod robot. This photo was taken during some initial testing. A segment of the Marman ring on the mounted spacecraft model has sensors that can detect forces applied. The control software for the robot can simulate response to these forces, as if the spacecraft was floating in zero gravity.

0 notes

Text

So yeah, I work on this.

6 Fun Facts About Our New Hexapod Robot

Satellites are crucial to everyday life and cost hundreds of millions of dollars to manufacture and launch. Currently, they are simply decommissioned when they run out of fuel. There is a better way, and it centers on satellite servicing, which can make spaceflight more sustainable, affordable, and resilient. Our satellite servicing technologies will open up a new world where fleet managers can call on robotic mechanics to diagnose, maintain and extend the lifespan of their assets.

Our new and unique robot is designed to test robotic satellite servicing capabilities. Standing 10 feet tall and 16 feet wide, the six-legged “hexapod” robot helps engineers perfect technologies before they’re put to use in space.

Here are SIX interesting facts about the hexapod:

1. The hexapod has six degrees of freedom.

This essentially means the robot can move in six directions—three translational directions (forward and backward, up and down and left and right), and three rotational directions (roll, pitch and yaw). Because of its wide range of movement, the hexapod mimics the way a satellite moves in zero gravity.

2. It can move up to eight inches per second and can extend up to 13 feet (but usually doesn’t).

Like most space simulators, the hexapod typically moves slowly at about one inch per second. During tests, it remains positioned about nine feet off the floor to line up with and interact with a robotic servicing arm mounted to an arch nearby. However, the robot can move at speeds up to eight inches per second and extend/reach nearly 13 feet high!

3. The hexapod tests mission elements without humans.

The hexapod is crucial to testing for our Restore-L project, which will prove a combination of technologies needed to robotically refuel a satellite not originally designed to be refueled in space.

Perhaps the most difficult part of refueling a satellite in space is the autonomous rendezvous and grapple stage. A satellite in need of fuel might be moving 16,500 miles per hour in the darkness of space. A servicer satellite will need to match its speed and approach the client satellite, then grab it. This nail-biting stage needs to be done autonomously by the spacecraft’s systems (no humans controlling operations from the ground).

The hexapod helps us practice this never-before-attempted feat in space-like conditions. Eventually a suite of satellite servicing capabilities could be incorporated in other missions.

4. This type of robot is also used for flight and roller coaster simulators.

Because of the hexapod’s unparalleled* ability to handle a high load capacity and range of movement, while maintaining a high degree of precision and repeatability, a similar kind of robot is used for flight and roller coaster simulators.

*Pun intended: the hexapod is what is referred to as a parallel motion robot

5. The hexapod was designed and made in the U S of A.

The hexapod was designed and built by a small, New Hampshire-based company called Mikrolar. Mikrolar designs and produces custom robots that offer a wide range of motion and high degree of precision, for a wide variety of applications.

6. The robot lives at our Goddard Space Flight Center’s Robotic Operations Center.

The hexapod conducts crucial tests at our Goddard Space Flight Center’s Robotic Operations Center (ROC). The ROC is a 5,000-square-foot facility with 50 feet high ceilings. It acts as an incubator for satellite servicing technologies. Within its black curtain-lined walls, space systems, components and tasks are put to the test in simulated environments, refined and finally declared ready for action in orbit.

The hexapod is not alone in the ROC. Five other robots test satellite servicing capabilities. Engineers use these robots to practice robotic repairs on satellites rendezvousing with objects in space.

Watch the hexapod in action HERE.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

949 notes

·

View notes

Photo

Our full-size satellite model, mounted on top of the Hexapod robot, moving around in pre-determined trajectories, while our space servicing arm follows along, as a warm-up test leading to vision system testing. In space, the servicing arm will need to be able to track, reach out, and grab another spacecraft, without a human’s help. This test configuration will be able to simulate this, so we can prove it works before it packaged up and launched into orbit!

0 notes

Photo

A full-size model of a spacecraft was installed on our hexapod robot last week and is looking really good, even if it isn’t quite complete (More detail parts, a large model solar panel, and some instrumentation are yet to be added). The next is to setup and test our zero-gravity simulation software.

1 note

·

View note