#3D Printing for Prototyping

Explore tagged Tumblr posts

Text

Revolutionize Your Prototypes with 3D Printing

Discover the power of 3D Printing for Prototyping at Metamorph. We collaborate closely to understand your project goals and select the ideal materials for your prototype. With cutting-edge additive manufacturing, our team delivers durable, functional prototypes to streamline your product development process.

Contact Us :- Phone:-+91 88840 52777 Email :[email protected] Website :-https://metamorph3dprint.com/prototyping/

0 notes

Text

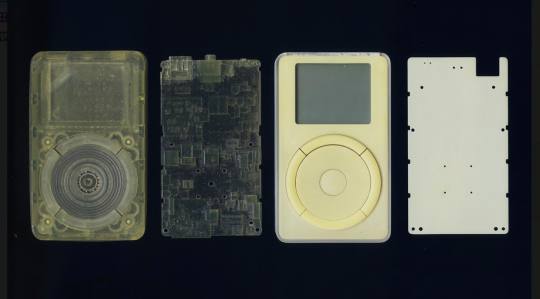

3D printed & machined prototypes of the first gen iPod

2K notes

·

View notes

Text

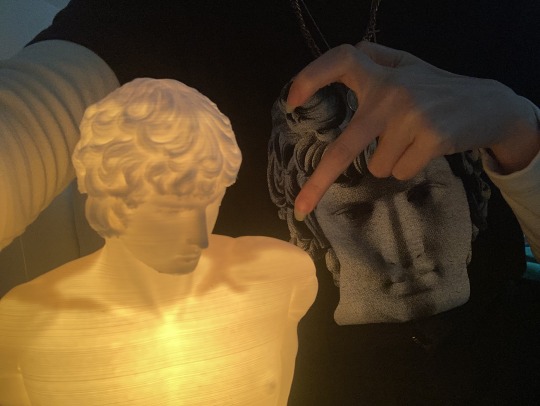

My star🥺🌟

The model I used <3 https://www.myminifactory.com/object/3d-print-antinous-ecouen-bust-26436. I modeled the lamp base myself

#just a prototype for now and i'll probably print a better version when I'm back at school!#antinous#ancient greece#ancient rome#my art#3d

40 notes

·

View notes

Text

The prototype stimboard

×/×/× ×/× ×/×/×

#text#autismposting#stim#agere#agere stim#stim toys#stim toy#the prototype#pastel rainbow stim#rainbow stim#pastel stim#sprinkles stim#cake stim#frosting stim#squishy stim#up close#irl hands tw#3d printed stim toys#3d printed stim#fast tw#eyestrain tw#cheesecake stim#taba squishy stim#cat paw stim#paw stim#soft stim#texture stim#tactile stim#heart stim#regretevator

23 notes

·

View notes

Text

3D Printed WIP Count Fabulous Stand Attachment!!

It's a little thick right now, and not super stable, but it does the job! I'm clueless when it comes to 3d modeling right now though. It's @kneesocksama on Cults3d for the base of the arm and then my brother and I worked together to make the platform Count stands on.

I think I'm gonna put a little more effort into developing this though. I think it's so silly that all of the monster pets have no real way to attach to the stands. I would love to do this is some shape or form with all of the pets that I have, but I'm not sure exactly what it would look like. Would Rockseena fly? Or is she like a chicken who can only fly short distances? Many such questions must be asked before I start working on these.

Anyways silly stuff aside, this is how she looks on my shelf for now and I think it's great!

#monster high#monster high g1#doll collection#fashion dolls#dolls#monster high dolls#3d printing#3D prototype#wip

12 notes

·

View notes

Text

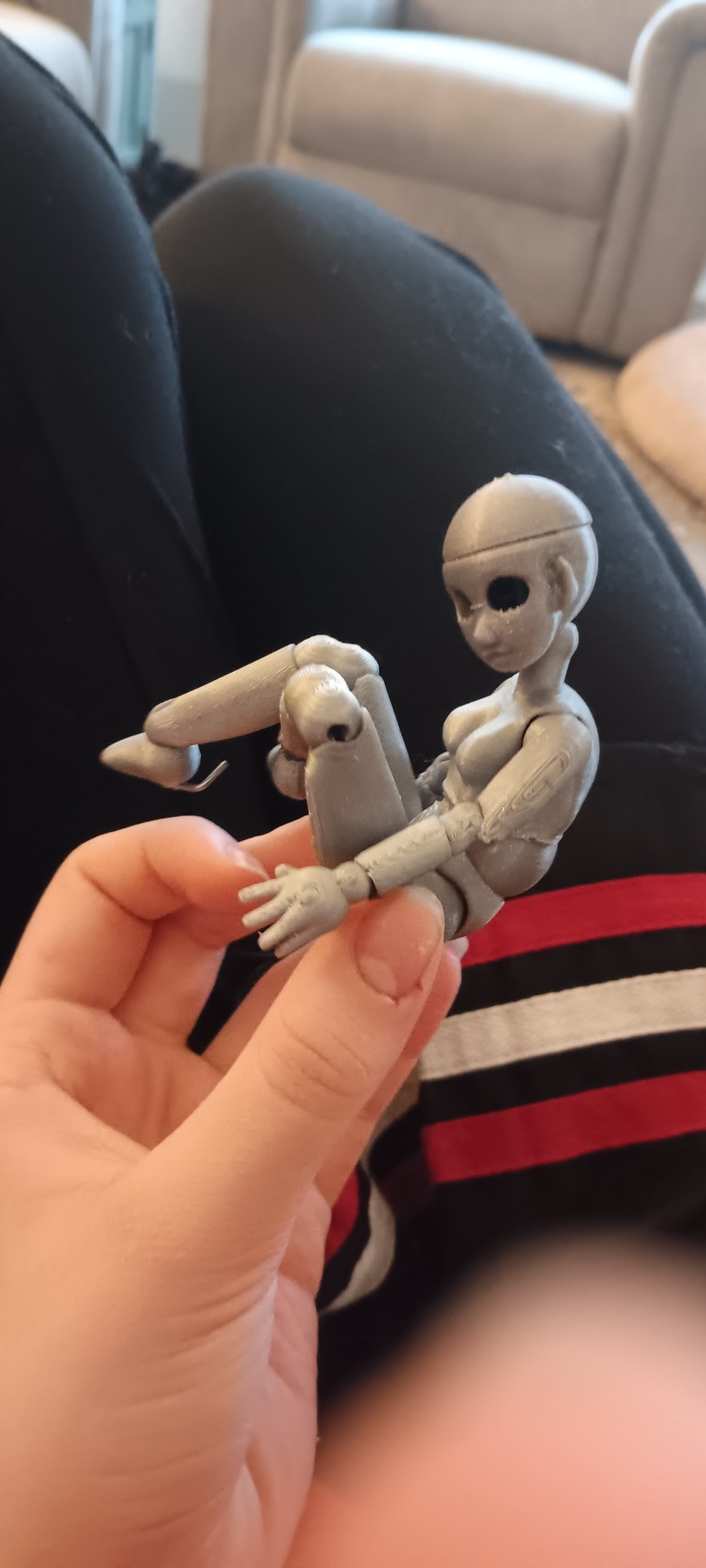

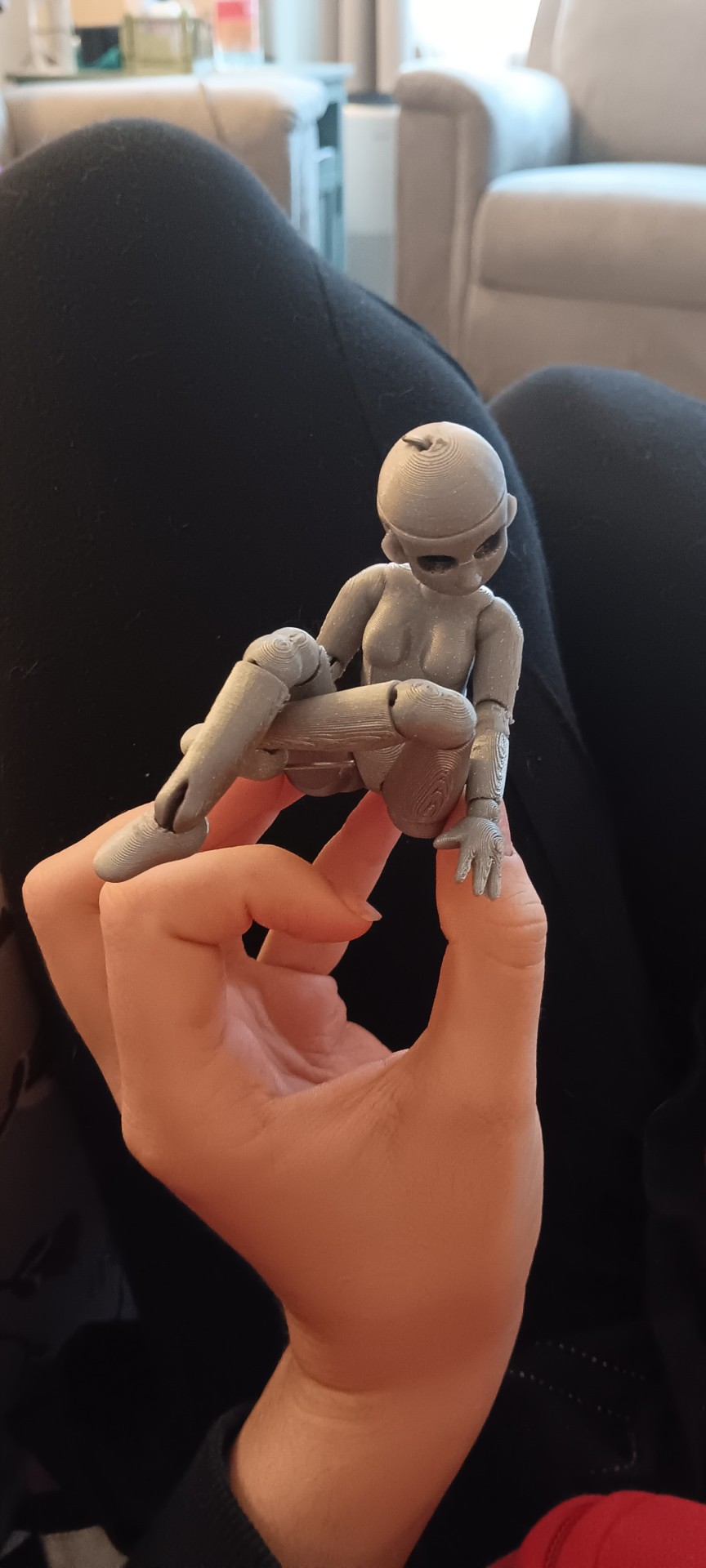

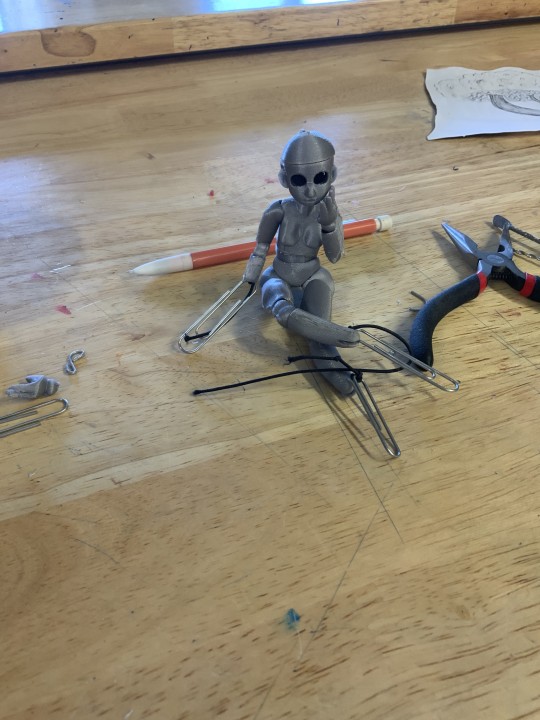

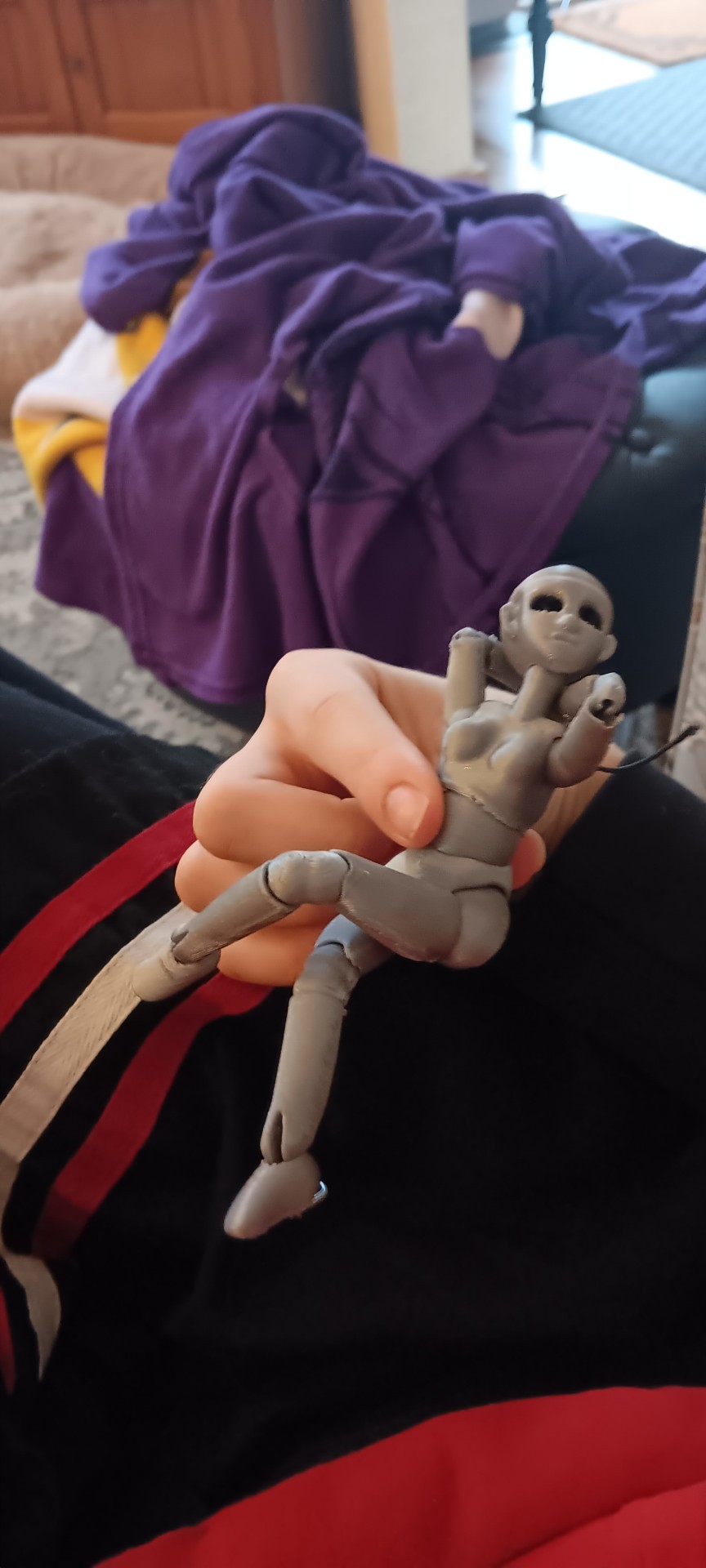

Things have been in the works

#i am sooo excited#also this was an accident but all the photos are angled so you cant tell her right hand is missing woops#the joint broke and then i lost it so she is currently 1 handed#this is just a prototype i'm hoping v2 can print soon >:3c#id in alt text#art#physical art#3d printing#dolls#my dolls#< hopefully ill make more and that can actually be a tag#bjd#bjd making#ball jointed doll#im so excited yall

15 notes

·

View notes

Text

I finally finished and printed my 4th iteration of the connector. It features now a thicker shell and some sort of infill grid that stablizes it more. I am quite happy with the result, very excited to built the 1:1 Model now!

#architecture#design#industrial design#3d print#3d druck#3d printing#connector#art exhibition#modular#modular architecture#prototype#prototyping

10 notes

·

View notes

Text

Let the prototyping beginnnnnn

#still have a while to go#but good start#3d printing#pokemon#pokémon#unown#Pokémon Unown#pokemon unown#prototype#WIP

3 notes

·

View notes

Text

Bahaha, so here's the other surprise package from my friend, Rae. It's a busted Namihu BJD Creatures Astarion she purchased from them during that charity drive for the dog that ended up dying anyway and HOOOBOY.

Apparently Rae hadn't even opened this package when it arrived since she was busy getting last minute stuff ready for Resin Rose so we have no idea how busted it was prior to her deciding to give it to me, but uh...dayum. Even his little dagger didn't make it in one piece (that I can glue back together though, most likely).

Honestly, even if it didn't arrived broken, this is still such a janky fucking doll. I cannot believe someone would charge people money for this garbage. I've been in the hobby for 15+ years and have owned and handled probably 80+ dolls from various makers and this is by far the worst body I've ever come across. This thing makes Resinsoul bodies seem like a dream in comparison. Absolutely unacceptable level of quality for the amount of cash Namihu charges. Genuinely embarrassing.

On top of the poor joint design, there are tons of cracks everywhere from the printing process. If this is the norm for 3D printed dolls, it's no wonder some faceup and modding artists don't accept commissions for them.

ALSO ALSO, learn how to properly wrap a fucking doll for shipping, Namihu. The taped up monstrosity I opened up was atrocious.

Counting my blessings I didn't bother commissioning Namihu for my CP2077 character's doll head, and it straight up was because the headback looked funky to me in what few pictures they have posted of it. It seemed like it'd have very limited head movement and I was absolutely correct. On top of that, because of how it was designed, it leaves scratches on the front of the neck lmao.

#namihu bjd creatures#bjd#legit bjd#3d printed bjd#ball jointed doll#my camspam#my doll: jankstarion#i am so pissed for my friend even if she never handled this doll bahaha#like...jeeeeesus chriiiiist#like bruh did the creator do absolutely no prototyping before posting this shit for sell?#pieces straight up don't even fit together properly

9 notes

·

View notes

Text

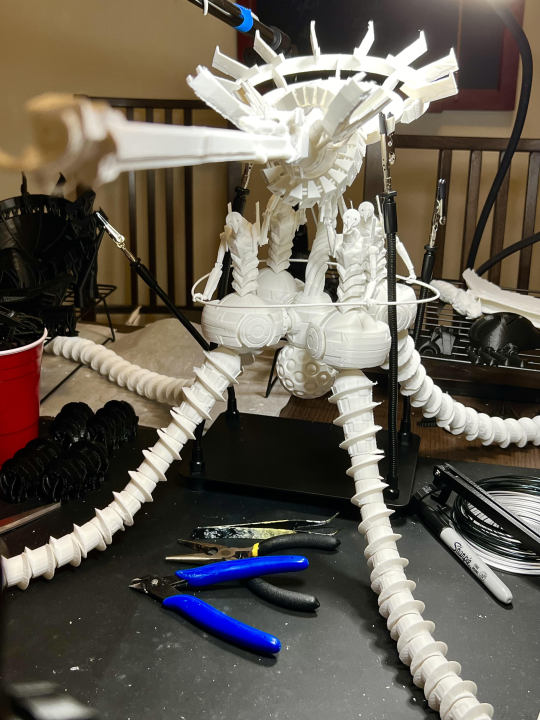

Finished with the prototype of Evangelion Mark.4444c. Managed to complete this figure in a couple of weeks with life happening, including travel to a wedding. Gonna do a final print and color later.

Also wanted to thank my friends for helping with the critiques and suggestions <3

#art#3d print#articulated#prototype#3d model#evangelion 3.0+1.0#evangelion#mark 4444c#mark#4444#4444c#c#eva#neon genesis evangelion#3d#3d modeling#3d figure#3d art#tentacle#tentacles#positron#cannon#positron cannon#figure

42 notes

·

View notes

Note

Mr. Radguy…”Kojima didn’t work on this so it doesn’t matter…” but what about the humble Metal Gear Acid 😔 it’s kinda neat…

….sorry for the ellipses I..I enjoy being dramatic……….

I mostly just meant like new major MGS games post-Kojima/Shinkawa that attempt to move the plot. Acid is great, it gave us the fantastic Solid Eye peripheral

#asks#I've got a soft spot for weird handheld spin-offs like GG's Dust Strikers and Judgment and MGS Acid lol#Never played either Acid game though I just know that they exist#I wonder how many Solid Eyes are still out there and usable lol since they were made of cardboard#Ohh I wonder if anyone has ever made a 3D print of one...#Quick google shows a bunch of the actual in-game tech but not the irl gizmo#That could be a fun project. I don't have a PSP though so I couldn't prototype it

4 notes

·

View notes

Text

🚀 Bring Your Ideas to Life with Professional 3D Printing | 3DPrintService.in🚀 Bring Your Ideas to Life with Professional 3D Printing | 3DPrintService.in

In the world of design and innovation, turning an idea into something real can be challenging. That’s where 3DPrintService.in comes in.

We specialize in high-quality 3D printing for individuals, creators, engineers, and startups across India. Whether you need a prototype, a functional part, or just a custom model, we’ve got the tools and experience to deliver—fast.

✅ Precision 3D Printing ✅ Affordable Pricing ✅ Multiple Materials & Finishes ✅ Quick Turnaround ✅ Ideal for Product Designers, Hobbyists, and Engineers

Just upload your design on our website and get an instant quote! 👉 https://3dprintservice.in

📩 Questions? We're always happy to help. DM us or contact via the website!

2 notes

·

View notes

Text

so i've been trying to make a comfortable controller for rivals of aether 2 and after thinking of so many stupid gimmicks THIS Fucking Thing was what came from the result of many hours of studying

i can assure you the ds is integral to The Construct

#nintendo ds#this is only the prototype. i ran out of superglue so i had to use my soldering iron to join the two 3d printed parts#the ds has a bluetooth cartridge in slot 2. i bought it from an australian store called insidegadgets#their stuff is really cool. they sell single-game flash cartridges

3 notes

·

View notes

Text

How Israeli Tech is Shaping the Future of Additive Manufacturing Worldwide

Overview of Israel’s Strategic Position in Additive Manufacturing

Israel has rapidly emerged as a global force in additive manufacturing (AM), fortified by a powerful high-tech ecosystem, robust government support, and a legacy of innovation in defense, aerospace, and medical technologies. With the Israel additive manufacturing market valued at USD 221.4 billion in 2024 and forecasted to exceed USD 280.3 billion by 2032, the nation is positioned to lead transformative advances in 3D printing technologies. The Israel additive manufacturing market compound annual growth rate (CAGR) of approximately 7% reflects both escalating domestic demand and global interest in Israeli AM innovation.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40589-israel-additive-manufacturing-market-research

Driving Forces of Growth in Israel's Additive Manufacturing Market

Innovation Across Key Industrial Verticals

Israel additive manufacturing market sector is evolving as a backbone for modernization in:

Aerospace and Defense: Lightweight components, complex geometries, and high-performance materials enable operational efficiency and reduced lead times.

Healthcare: Customized prosthetics, implants, bioprinting, and surgical models offer patient-centric care and improved clinical outcomes.

Automotive and Industrial Manufacturing: Rapid prototyping, tooling, and small-batch production optimize supply chains and cut production timelines.

These sectors benefit from the convergence of additive technologies with AI, machine learning, and advanced robotics, all core competencies of Israel's high-tech sector.

Rising Demand for Customization and Sustainability

The shift toward sustainable manufacturing and personalized solutions is fueling AM adoption. Israeli startups and research institutions are developing biocompatible, recyclable, and multi-material printing solutions that meet stringent regulatory and industry-specific standards.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40589-israel-additive-manufacturing-market-research

Technological Landscape of the Israeli Additive Manufacturing Ecosystem

Polymer-Based Additive Manufacturing

Valued at USD 306.31 million in 2024, this segment dominates due to its cost-effectiveness, versatility, and compatibility with lightweight, complex part production. With an expected CAGR of 17.3%, applications in consumer goods, automotive interiors, and medical devices continue to surge.

Metal-Based Additive Manufacturing

Growing at a robust 20.1% CAGR, metal AM is the cornerstone of defense and aerospace advancements. In 2024, it accounted for USD 180.86 million, projected to exceed USD 775.48 million by 2032. Israel’s focus on titanium, aluminum alloys, and nickel-based superalloys supports structural applications with high thermal and mechanical stability.

Hybrid Additive Manufacturing

By blending subtractive and additive processes, hybrid AM enhances surface finish and dimensional accuracy, critical in precision tooling, aerospace, and dental prosthetics. This segment is rapidly gaining traction due to its versatility and integration into smart manufacturing systems.

Segmental Breakdown of the Israel Additive Manufacturing Market

By Component

Hardware: Represents the largest share, valued at USD 1,137.28 million in 2024, supporting high-throughput production and industrial-scale fabrication.

Software: Fueled by AI-powered design, generative modeling, and process simulation, this segment is experiencing 19.9% CAGR, revolutionizing digital twin applications and real-time process monitoring.

Services: The on-demand printing ecosystem is expanding, empowering SMEs to access advanced AM capabilities with minimal capital expenditure.

By Deployment Model

In-House Manufacturing: With a Israel additive manufacturing market valuation of USD 317.09 million in 2024, large enterprises prefer internal AM operations for confidentiality and operational control.

Service-Based Models: Growing at 19.4% CAGR, third-party service bureaus are crucial in democratizing access to advanced AM technologies for startups and research institutions.

By Functionality

Prototyping: Dominates with USD 340.60 million in 2024, essential for R&D, iterative design, and proof-of-concept validation.

Production: The rising shift to end-use part manufacturing is catalyzing growth in this segment, valued at USD 197.73 million in 2024.

Tooling: Customized, high-durability tooling supports faster transitions from design to production across various industrial sectors.

By Printer Size

Small/Compact Printers: Most accessible and dominant segment, valued at USD 253.09 million in 2024, ideal for labs, healthcare, and educational institutions.

Medium and Large Printers: Increasingly adopted in industrial manufacturing, these enable batch production and larger component fabrication.

End-Use Industries Driving Adoption

Aerospace & Defense

USD 159.32 million in 2024, this sector prioritizes weight reduction, material performance, and supply chain agility. With Israel’s defense sector being R&D intensive, 3D printing significantly enhances manufacturing autonomy and mission-readiness.

Healthcare & Medical

USD 131.40 million in 2024, growing due to demand for patient-specific devices, bioprinted tissues, and anatomical models. With innovations in regenerative medicine, Israel is at the forefront of personalized healthcare.

Industrial & Automotive

Israel’s industrial ecosystem leverages AM for lightweighting, thermal management, and low-volume production, especially in EV components and robotics enclosures.

Strategic Movements and Competitive Intelligence

Leading Israel Additive Manufacturing Market Participants

Stratasys: A global pioneer, deeply rooted in Israel, with continuous development in multi-material, high-resolution systems.

XJet: Revolutionizing ceramic and metal printing with NanoParticle Jetting™ technology.

Nano Dimension: Innovator in multi-layer electronics and PCB printing, driving miniaturization and functional integration.

Recent Developments

XJet (June 2024): Launched new ceramic printers with applications in automotive and aerospace, enhancing resolution and mechanical strength.

Nano Dimension (Sept 2024): Acquired startups to advance multi-material electronics printing, expanding their capabilities in embedded sensor systems.

Challenges and Strategic Opportunities

Major Israel Additive Manufacturing Market Challenges

Capital Intensity: High upfront costs limit adoption, especially among SMEs.

Talent Gap: Scarcity of AM-trained professionals hampers rapid scaling.

Scaling Complexity: Transitioning from prototype to full production requires new QA methodologies and workflow optimization.

Strategic Israel Additive Manufacturing Market Opportunities

Workforce Development: Partnerships with universities and technical institutes to offer AM-centric curricula.

Material Innovation Hubs: Support from government and private sectors to develop high-strength composites, bioresorbable materials, and nanostructured alloys.

Sustainability Mandates: Incentives for closed-loop manufacturing systems, energy-efficient printers, and recyclable materials.

Future Outlook: Israel’s Role in Global Additive Manufacturing Leadership

Israel is poised to lead the next frontier of digital manufacturing, where data-driven fabrication, machine learning-enhanced design, and autonomous production lines define industry 4.0. With unmatched cross-sector collaboration between startups, research centers, and government agencies, the nation’s AM sector is evolving from rapid prototyping to full-fledged production infrastructure.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40589-israel-additive-manufacturing-market-research

Conclusion

Israel additive manufacturing market is entering a golden era, driven by its technological prowess, strategic policy initiatives, and vibrant innovation culture. As the global demand for agile, sustainable, and customized manufacturing solutions intensifies, Israel is uniquely equipped to lead the charge. Enterprises, investors, and policy makers must align to fully harness this momentum and establish Israel as a global additive manufacturing powerhouse.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Israel#Additive Manufacturing#3D Printing#Israeli Tech#Advanced Manufacturing#Industrial 3D Printing#Aerospace#Medical Devices#Defense Technology#Innovation#Startups#Tel Aviv#Prototyping#Manufacturing Industry#AM Materials#Digital Manufacturing#Smart Manufacturing#High-Tech Industry#Metal 3D Printing#Polymer Printing#R&D#Technology Trends#Engineering#Robotics#Supply Chain#Product Development

1 note

·

View note

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

Prototype for my mom's Christmas present printed today 🙌🏽

Definitely needs a lot of fixing 😭

8 notes

·

View notes